Contact us today:

(847) 934-4500

tdaro@bernardandcompany.com

Contact us today:

(847) 934-4500

tdaro@bernardandcompany.com

Visit us at booth #239!

AERODEF 2014 – Siemens will present its SINUMERIK 840D sl numerical controller, the aerospace industry standard for CNC machine tool control, which features unmatched open architecture for the handling of the most complex cutting and forming operations. In addition, Siemens will demonstrate robotic control through its mxAutomation solution, where robotic functions are controlled on a second channel of the SINUMERIK CNC and transferred to the robot via the Siemens PLC. And as the only single-source supplier in the aerospace industry who can provide the entire CAD/CAM/ CNC process chain, it’s clear why Siemens is the first choice in aerospace part manufacturing.

For more information on Siemens SINUMERIK CNC, visit www.usa.siemens.com/cnc.

For specific product information and inquiries, call (800) 879-8079 ext. Marketing Communications or send an e-mail to: SiemensMTBUMarCom.industry@siemens.com.

Follow us on Facebook: www.facebook.com/SiemensCNC or Twitter: www.twitter.com/siemens_cnc_us.

—

Siemens Industry Sector is the world’s leading supplier of innovative and environmentally friendly products, solutions and services for industrial customers. With end-to-end automation technology and industrial software, solid vertical-market expertise, and technology-based services, the sector enhances its customers’ productivity, efficiency and flexibility. With a global workforce of more than 100,000 employees, the Industry Sector comprises the Industry Automation, Drive Technologies and Customer Services Divisions as well as the Metals Technologies Business Unit. For more information, visit http://www.usa.siemens.com/industry.

The Siemens Drive Technologies Division is the world’s leading supplier of products, systems, applications, solutions and services for the entire drive train, with electrical and mechanical components. Drive Technologies serves all vertical markets in the production and process industries as well as the infrastructure/energy segment. With its products and solutions, the division enables its customers to achieve productivity, energy efficiency and reliability. For more information, visit http://www.usa.siemens.com/drivetechnologies.

Continue reading

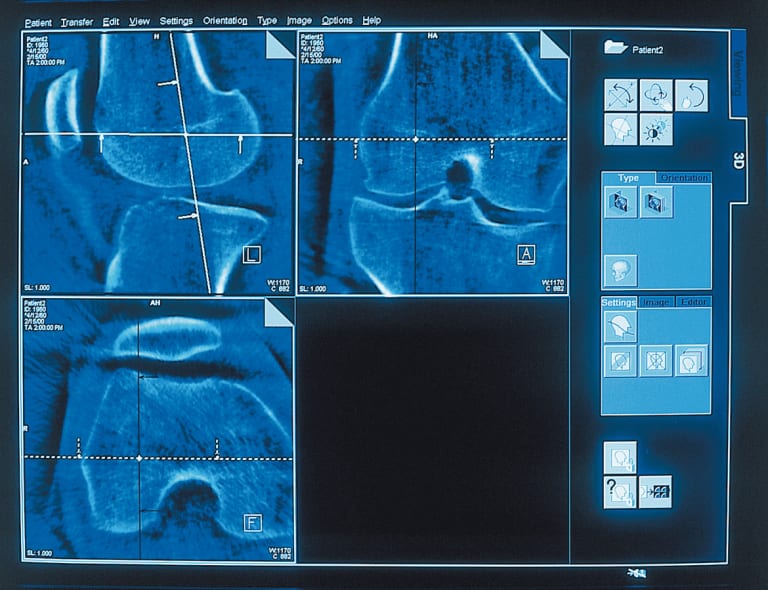

The process chain for a typical implant begins in the clinic, where the doctor uses CT scan imaging data to select an appropriate implant

Today’s machine shops, whether in the medical technology or tool and moldmaking sectors, can take advantage of an integrated Siemens CNC solution for everything from the design concept to the finished product.

The production of today’s medical implants involves an entire process chain, starting with the doctor and ending with the finished device. Doctors use the imaging data of a complex fracture, acquired with a computed tomography (CT) scan, to select an appropriate implant and then position it in the fracture area of the patient on the computer. Of course, this is only possible if the implant geometries are stored in a database, and the doctor has implants in stock or can access them immediately from a manufacturer.

Simulation of machining sequences

In plastic surgery, however, where implants specifically manufactured for each individual patient are needed, a different process is employed. Instead of pre-machined parts, implants are custom-made with the help of 3D imaging. In this case, the machine tools are controlled using the implant geometries. Calculated contours and shapes are acquired by the CT scan to produce implants that are literally a perfect fit. However, the feasibility of the planned production process can first be determined on a monitor using, for example, an NX graphic simulation from Siemens to avoid potential collisions or damage to the workpiece contours.

Technology package for milling

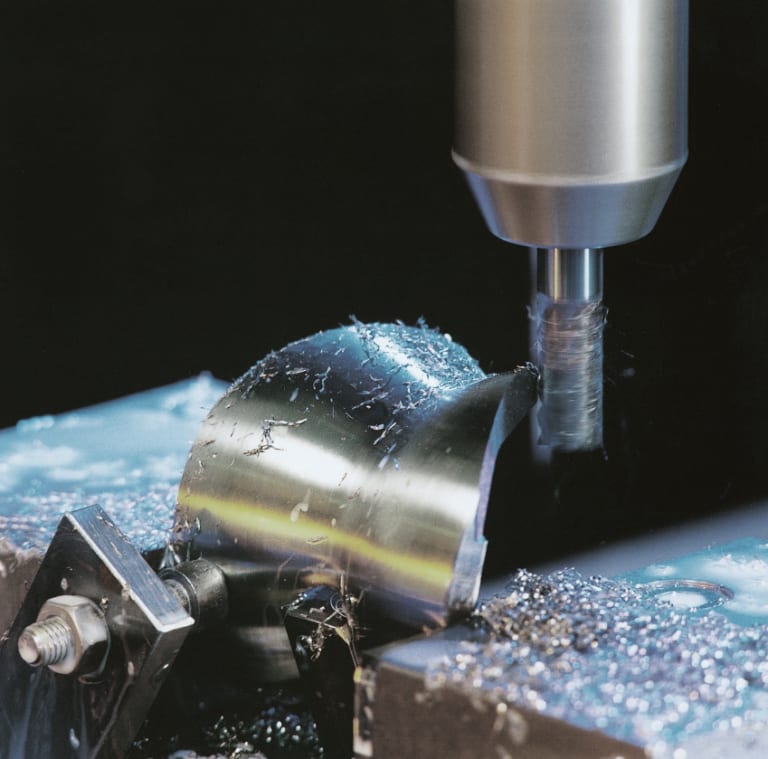

Implants for knee joints are precision machined with the High-Speed Cutting HSC process on a machine tool run by Siemens SINUMERIK 840D solution line CNC technology.

High-speed cutting (HSC) is a machining process with high material processing speeds. HSC machine tools achieve high spindle speeds, combined with feed rates that are much higher than those of conventional machine tools. Consequently, they require control systems and part programs that perform equally fast. The Siemens Sinumerik® 840D solution line CNC is specifically designed for the requirements of medical technology and this precision part HSC work. Integrated functions onboard the CNC assist users with set-up and programming, thus allowing faster and more precise production sequences.

Together, the Sinumerik CNC system and ShopMill® software from Siemens form a milling technology package that allows machine operators rapid access to the functions they need. Thanks to graphic function display and plain language input dialogs, cycles can be used quickly and effectively, after a brief training period. Even the smallest errors can be corrected during operation, using multi-axis kinematic analysis. The Siemens Safety Integrated® solution further provides protection for personnel and machinery. This software can be used to interlink emergency stop buttons and light barriers. In the event of an operating error, dangerous movements are immediately brought to a standstill and the power supply to the motor is quickly cut.

The use of measuring probes

The production of artificial knee joints on an HSC 20 linear milling center manufactured by DMG, for example, can be fully controlled and monitored by a Siemens Sinumerik CNC system. With its broad range of functions, this milling center is particularly well suited for use in the medical technology sector. It is equipped with linear drives on all axes and achieves acceleration rates over 2g. The machine can also generate a surface finish down to 0.2 micrometers Ra. The liquid-cooled machining spindle operates at speeds up to 42,000 rpm, thereby covering an extensive range of potential applications in the medical sector, where materials such as titanium, chromium-molybdenum, tantalum and niobium are typically milled.

In order to achieve maximum precision during implant production, while also maintaining a consistently high level of product quality, parametric measurements must taken continuously from both the machine and the workpiece. probes, for example, on HSC production machines measure tool dimensions in-process, detect broken tools and are used for the set-up and measurement of workpieces. In medical machine shops currently, the targeted use of such measuring probes can reduce set-up times by up to 90%, while substantially improving process control.

Cost-effective machining

Metal parts used in medical technology are often extremely complex. Therefore, choosing the right tooling can have a great impact on the quality of the finished products. After all, proper cutting tools ensure that the parts leaving the machining center are absolutely precise and require no further finishing work. Although the materials used for many medical and orthopedic parts are often quite difficult to machine, the tools must fulfill high performance requirements with respect to the precision and surface quality of these implants. Iscar, one supplier of such tools, offers a program for monitoring the use of precision tools on turning, drilling, milling and finishing jobs. They also help users assess the performance qualities of non-vibrating carbide milling cutters, which are well-suited for machining implant materials, plus they can offer information on more cost-effective and efficient machining processes.

For more information on Siemens SINUMERIK CNC, visit www.usa.siemens.com/cnc.

For specific product information and inquiries, call (800) 879-8079 ext. Marketing Communications or send an e-mail to: SiemensMTBUMarCom.industry@siemens.com.

Follow us on Facebook: www.facebook.com/SiemensCNC or Twitter: www.twitter.com/siemens_cnc_us.

—

Siemens Industry Sector is the world’s leading supplier of innovative and environmentally friendly products, solutions and services for industrial customers. With end-to-end automation technology and industrial software, solid vertical-market expertise, and technology-based services, the sector enhances its customers’ productivity, efficiency and flexibility. With a global workforce of more than 100,000 employees, the Industry Sector comprises the Industry Automation, Drive Technologies and Customer Services Divisions as well as the Metals Technologies Business Unit. For more information, visit http://www.usa.siemens.com/industry.

The Siemens Drive Technologies Division is the world’s leading supplier of products, systems, applications, solutions and services for the entire drive train, with electrical and mechanical components. Drive Technologies serves all vertical markets in the production and process industries as well as the infrastructure/energy segment. With its products and solutions, the division enables its customers to achieve productivity, energy efficiency and reliability. For more information, visit http://www.usa.siemens.com/drivetechnologies.

Continue readingCatalytic converter can production improved by 20 percent with roll former and laser welder. View the case study here and visit Siemens at Fabtech, Booth S-4686!

For additional product information and inquiries, call (800) 879-8079 ext. Marketing Communications or send an e-mail to: SiemensMTBUMarCom.industry@siemens.com.

Follow us on Facebook: www.facebook.com/SiemensCNC or Twitter: www.twitter.com/siemens_cnc_us.

—

Siemens Industry Sector is the world’s leading supplier of innovative and environmentally friendly products, solutions and services for industrial customers. With end-to-end automation technology and industrial software, solid vertical-market expertise, and technology-based services, the sector enhances its customers’ productivity, efficiency and flexibility. With a global workforce of more than 100,000 employees, the Industry Sector comprises the Industry Automation, Drive Technologies and Customer Services Divisions as well as the Metals Technologies Business Unit. For more information, visit http://www.usa.siemens.com/industry.

The Siemens Drive Technologies Division is the world’s leading supplier of products, systems, applications, solutions and services for the entire drive train, with electrical and mechanical components. Drive Technologies serves all vertical markets in the production and process industries as well as the infrastructure/energy segment. With its products and solutions, the division enables its customers to achieve productivity, energy efficiency and reliability. For more information, visit http://www.usa.siemens.com/drivetechnologies.

Continue readingService, support and training seal the deal for Janco Industries and Han Kwang. View the case study here.

For additional product information and inquiries, call (800) 879-8079 ext. Marketing Communications or send an e-mail to: SiemensMTBUMarCom.industry@siemens.com.

Follow us on Facebook: www.facebook.com/SiemensCNC or Twitter: www.twitter.com/siemens_cnc_us.

—

Siemens Industry Sector is the world’s leading supplier of innovative and environmentally friendly products, solutions and services for industrial customers. With end-to-end automation technology and industrial software, solid vertical-market expertise, and technology-based services, the sector enhances its customers’ productivity, efficiency and flexibility. With a global workforce of more than 100,000 employees, the Industry Sector comprises the Industry Automation, Drive Technologies and Customer Services Divisions as well as the Metals Technologies Business Unit. For more information, visit http://www.usa.siemens.com/industry.

The Siemens Drive Technologies Division is the world’s leading supplier of products, systems, applications, solutions and services for the entire drive train, with electrical and mechanical components. Drive Technologies serves all vertical markets in the production and process industries as well as the infrastructure/energy segment. With its products and solutions, the division enables its customers to achieve productivity, energy efficiency and reliability. For more information, visit http://www.usa.siemens.com/drivetechnologies.

Continue readingPress safety: ready-to-install Simotion Safety Unit provides certified control reliable solution for Windsor Match Plate & Tool Ltd. Click here to view the case study and visit Siemens at Fabtech, Booth S-4686!

For additional product information and inquiries, call (800) 879-8079 ext. Marketing Communications or send an e-mail to: SiemensMTBUMarCom.industry@siemens.com.

Follow us on Facebook: www.facebook.com/SiemensCNC or Twitter: www.twitter.com/siemens_cnc_us.

—

Siemens Industry Sector is the world’s leading supplier of innovative and environmentally friendly products, solutions and services for industrial customers. With end-to-end automation technology and industrial software, solid vertical-market expertise, and technology-based services, the sector enhances its customers’ productivity, efficiency and flexibility. With a global workforce of more than 100,000 employees, the Industry Sector comprises the Industry Automation, Drive Technologies and Customer Services Divisions as well as the Metals Technologies Business Unit. For more information, visit http://www.usa.siemens.com/industry.

The Siemens Drive Technologies Division is the world’s leading supplier of products, systems, applications, solutions and services for the entire drive train, with electrical and mechanical components. Drive Technologies serves all vertical markets in the production and process industries as well as the infrastructure/energy segment. With its products and solutions, the division enables its customers to achieve productivity, energy efficiency and reliability. For more information, visit http://www.usa.siemens.com/drivetechnologies.

Continue readingRajas Sukthankar is the Director of Sales for Motion Control at Siemens Industry, Inc. Click to view his article on Advanced CNC.

For additional product information and inquiries, call (800) 879-8079 ext. Marketing Communications or send an e-mail to: SiemensMTBUMarCom.industry@siemens.com.

Follow us on Facebook: www.facebook.com/SiemensCNC or Twitter: www.twitter.com/siemens_cnc_us.

—

Siemens Industry Sector is the world’s leading supplier of innovative and environmentally friendly products, solutions and services for industrial customers. With end-to-end automation technology and industrial software, solid vertical-market expertise, and technology-based services, the sector enhances its customers’ productivity, efficiency and flexibility. With a global workforce of more than 100,000 employees, the Industry Sector comprises the Industry Automation, Drive Technologies and Customer Services Divisions as well as the Metals Technologies Business Unit. For more information, visit http://www.usa.siemens.com/industry.

The Siemens Drive Technologies Division is the world’s leading supplier of products, systems, applications, solutions and services for the entire drive train, with electrical and mechanical components. Drive Technologies serves all vertical markets in the production and process industries as well as the infrastructure/energy segment. With its products and solutions, the division enables its customers to achieve productivity, energy efficiency and reliability. For more information, visit http://www.usa.siemens.com/drivetechnologies.

Continue readingOpen, flexible, powerful – Siemens Sinumerik 840D is the premium CNC for machine tools.

View the Sinumerik 840D sl Brochure and visit Siemens at Fabtech, Booth S-4686.

For additional product information and inquiries, call (800) 879-8079 ext. Marketing Communications or send an e-mail to: SiemensMTBUMarCom.industry@siemens.com.

Follow us on Facebook: www.facebook.com/SiemensCNC or Twitter: www.twitter.com/siemens_cnc_us.

—

Siemens Industry Sector is the world’s leading supplier of innovative and environmentally friendly products, solutions and services for industrial customers. With end-to-end automation technology and industrial software, solid vertical-market expertise, and technology-based services, the sector enhances its customers’ productivity, efficiency and flexibility. With a global workforce of more than 100,000 employees, the Industry Sector comprises the Industry Automation, Drive Technologies and Customer Services Divisions as well as the Metals Technologies Business Unit. For more information, visit http://www.usa.siemens.com/industry.

The Siemens Drive Technologies Division is the world’s leading supplier of products, systems, applications, solutions and services for the entire drive train, with electrical and mechanical components. Drive Technologies serves all vertical markets in the production and process industries as well as the infrastructure/energy segment. With its products and solutions, the division enables its customers to achieve productivity, energy efficiency and reliability. For more information, visit http://www.usa.siemens.com/drivetechnologies.

Continue readingBetter welding control helps R.H. Peterson produce a new line of grills achieve up to 30% improvement savings. View the case study here and visit Siemens at Fabtech, Booth S-4686.

For additional product information and inquiries, call (800) 879-8079 ext. Marketing Communications or send an e-mail to: SiemensMTBUMarCom.industry@siemens.com.

Follow us on Facebook: www.facebook.com/SiemensCNC or Twitter: www.twitter.com/siemens_cnc_us.

—

Siemens Industry Sector is the world’s leading supplier of innovative and environmentally friendly products, solutions and services for industrial customers. With end-to-end automation technology and industrial software, solid vertical-market expertise, and technology-based services, the sector enhances its customers’ productivity, efficiency and flexibility. With a global workforce of more than 100,000 employees, the Industry Sector comprises the Industry Automation, Drive Technologies and Customer Services Divisions as well as the Metals Technologies Business Unit. For more information, visit http://www.usa.siemens.com/industry.

The Siemens Drive Technologies Division is the world’s leading supplier of products, systems, applications, solutions and services for the entire drive train, with electrical and mechanical components. Drive Technologies serves all vertical markets in the production and process industries as well as the infrastructure/energy segment. With its products and solutions, the division enables its customers to achieve productivity, energy efficiency and reliability. For more information, visit http://www.usa.siemens.com/drivetechnologies.

Continue readingWhen implementing mechanical and hydraulic presses and handling equipment, for instance in the automotive industry, a predominantly modular design ensures the highest degree of flexibility and shortest engineering and installation times for customized systems. The Metal Forming Solution Package provides all of the functions required to automate press systems, therefore supporting press manufacturers when quickly implementing their specific press concepts.

View the Metal Forming Solution Package Brochure and visit Siemens at Fabtech, Booth S-4686!

Additional information can be found on the Siemens US metalforming website.

See below for customer reference videos:

For specific product information and inquiries, call (800) 879-8079 ext. Marketing Communications or send an e-mail to: SiemensMTBUMarCom.industry@siemens.com.

—

Siemens Industry Sector is the world’s leading supplier of innovative and environmentally friendly products, solutions and services for industrial customers. With end-to-end automation technology and industrial software, solid vertical-market expertise, and technology-based services, the sector enhances its customers’ productivity, efficiency and flexibility. With a global workforce of more than 100,000 employees, the Industry Sector comprises the Industry Automation, Drive Technologies and Customer Services Divisions as well as the Metals Technologies Business Unit. For more information, visit http://www.usa.siemens.com/industry.

The Siemens Drive Technologies Division is the world’s leading supplier of products, systems, applications, solutions and services for the entire drive train, with electrical and mechanical components. Drive Technologies serves all vertical markets in the production and process industries as well as the infrastructure/energy segment. With its products and solutions, the division enables its customers to achieve productivity, energy efficiency and reliability. For more information, visit http://www.usa.siemens.com/drivetechnologies.

Continue readingSee the MJC video HERE.

Custom machine tool builder in California contracts with research center at university in Glasgow, Scotland to design specialized equipment for forming new jet engine structures; machine completely controlled by Siemens CNC

AFRC facility performs fundamental and applied research on the forming and forging of metals, primarily for aerospace applications. A full battery of materials and performance testing is conducted at AFRC by a team of materials and process experts

MJC Engineering is a custom machine tool builder, specializing in metalforming machines for such applications as spinning, flow forming, wheel spinning and rotary forging. The company was recently contracted by the Advanced Forming Research Centre (AFRC) at the University of Strathclyde in Glasgow, Scotland for a very unique application, namely, a cold-forming rotary forge press that works the material between two synchronized rotary dies. The dies operate in angle from the parallel. Typically, the angle is fixed but, on this custom designed machine from MJC, the angle is fully programmable. This configuration allows compression in a concentrated area and provides a more efficient method for metal deformation, while producing superior mechanical properties in the finished section. Up to 90 percent material savings can be achieved by the use of this revolutionary metalforming technology, in comparison to conventional machining from a solid blank.

Operator loads workpiece during test run-up on machine; very hard aerospace materials such as Hastelloy and Inconel are typically processed

The aim of this new CNC technology, according to MJC company president Carl Lorentzen, is to make the aerospace engineers rethink how they design their products, so that a maximum material savings on exotic and costly metals can be realized.

Rotary forging can be defined as a two-die forging process that deforms only a small portion of the workpiece at a time, in a continuous manner. The reduced instantaneous area of tool and workpiece contact means lower forging forces are required to cause deformation in the material. Typical components for rotary forge operations are round or cylindrical hollow parts that deploy expensive or exotic alloys, require extreme material property targets or involve very complex geometries. At AFRC, the rotary forging machine provided by MJC is processing AerMet® 100, Inconel 718 and Allvac® 718Plus®, Ti-6Al-4V as well as the creep-resistant Ti6242 and some beta alloys.

New rotary forge press from MJC, built specially for the Advanced Forming Research Centre (AFRC) at the University of Strathclyde in Scotland. Two independent and synchronized rotary dies are fully programmable on the Siemens CNC to affect 0-45º pitch angles

Onboard the machine, the bottom and top spindles pivot from 0-45º, operated by AC vector motors and drives, plus an overall motion control CNC, all provided by longtime supplier to the builder, Siemens. The CNC is a Sinumerik 840D, which controls all the axis and spindle motion, hydro and servo positioning valves, plus the synchronization of up to four cylinders for the integrated motion of the rotary dies. In the processing of the workpiece, the control is monitoring all machine conditions, while maintaining the synchronized angles of the twin rotary dies.

Programmed motion sequences on the machine must be maintained with high precision to avoid improper deformation of the materials during the cold-forming process. In a manufacturing environment, where the high production output of parts is critical, this process must remain extremely well-regulated, documented and monitored. The CNC has the capability to upload all data in real time.

The unique operation of this MJC rotary forging press involves the application of pressure on a small portion of material at a time, reducing stress and saving up to 90% in material, compared to subtractive machining from a solid blank

Carl Lorentzen comments further on this MJC development, “Though the concept of the rotary die forge is certainly not new, the computer-controlled synchronized dual rotary dies on this machine offer a number of unique advantages in the cold-forming process of metals. The idea originated in a somewhat different form in the automotive market with the development of a front wheel hub hollow shaft. The cold-forming of metal around a bearing was combined with robot loading in production. The concept, combined with the Siemens CNC and its ability to control all the motion so precisely, made the development of this machine more practical for us.”

MJC is a custom machine tool builder, with equipment currently serving in the military, aerospace, general metalforming and automotive after-market segments of industry. The company is a member of PMA, NFTC and AMT.

The AFRC is jointly sponsored by the Scottish government, Scottish Enterprise and a variety of international aerospace manufacturers and engineering firms, including Boeing, Rolls Royce, TIMET, Aubert & Duval and Barnes Aerospace. It has operated as a world-class facility, supporting fundamental and applied research into the forming and forging of metals, since 2009. Having doubled in size recently, AFRC is expanding its market applications into the automotive, energy and marine markets. The center can currently heat, shape, finish, measure, test and analyze all types of metal materials and components in-house. The research done here comprises investigations into residual stress, die life, process characterization, materials characterization, heating and thermal processes, super-plastic forming, sheet forming and related technologies in automation, metallurgy and metrology.

The key challenge for AFRC, according to its website, is to take low maturity technology developed in a university environment and successfully deploy it into a manufacturing facility.

See the video of MJC @FabTech HERE.

For more information on this story, please contact:

MJC ENGINEERING & TECHNOLOGY, INC.

15701 Container Lane

Huntington Beach, CA 92649

Phone: 714-890-0618

Fax: 714-895-3561

Web: www.mjcengineering.com

Email: clorentzen@mjcengineering.com or carlson@mjcengineering.com

Attention: Carl Lorentzen, President or Per Carlson, VP

or

SIEMENS INDUSTRY, INC.

DRIVE TECHNOLOGIES

MOTION CONTROL

390 Kent Avenue

Elk Grove Village, IL 60007

Phone: 847-640-1595

Web: www.usa.siemens.com/cnc

Email: SiemensMTBUMarcom.industry@siemens.com

Attention: John Meyer, Manager of Marketing Communications

Follow us on Facebook: www.facebook.com/SiemensCNC or Twitter: www.twitter.com/siemens_cnc_us.

—

Siemens Industry Sector is the world’s leading supplier of innovative and environmentally friendly products, solutions and services for industrial customers. With end-to-end automation technology and industrial software, solid vertical-market expertise, and technology-based services, the sector enhances its customers’ productivity, efficiency and flexibility. With a global workforce of more than 100,000 employees, the Industry Sector comprises the Industry Automation, Drive Technologies and Customer Services Divisions as well as the Metals Technologies Business Unit.

The Siemens Drive Technologies Division is the world’s leading supplier of products, systems, applications, solutions and services for the entire drive train, with electrical and mechanical components. Drive Technologies serves all vertical markets in the production and process industries as well as the infrastructure/energy segment. With its products and solutions, the division enables its customers to achieve productivity, energy efficiency and reliability.