Contact us today:

(847) 934-4500

tdaro@bernardandcompany.com

Contact us today:

(847) 934-4500

tdaro@bernardandcompany.com

Did you miss Siemens at AeroDef 2014? Here’s what you missed!

At this year’s AERODEF conference in Long Beach, California, Siemens will demonstrate new CNC solutions and services for machine tool builders and end-users. Under the theme, “Productivity in motion,” the presentation will focus on turnkey solutions for the aerospace manufacturing industry.

For the aerospace market, the Sinumerik 840D sl offers the latest in CNC technology that increases machine tool performance and user productivity. The 840D sl is a universal and flexible CNC system based upon the innovative Sinamics S120 drive platform that can be used for up to 31 axes. It is a distributed, scalable, open and inter-connecting system offering a wide range of specialized functions for milling, drilling, turning, grinding, handling and robotics technologies. It offers users innovative features that increase productivity on the manufacturing floor, especially the challenging aerospace segments of high-speed and five-axis machining.

For the job shop, the Sinumerik 828D numerical control is the ideal CNC solution for mid-range machine tools. It is designed to address the needs of complex milling and turning machines in the job shop segment by combining CNC, PLC, operator panel and axis control for six CNC measurement circuits into a single, robust operator panel.

The 828D is capable of full graphical, high-level language command and supports ISO programming that is customary in the United States. Programming time can be further reduced for small-batch production with the use of the ShopMill and ShopTurn graphical workstep programming system, while high-level language programming can be used in conjunction with programGuide to significantly reduce programming times for large-scale serial production.

With the introduction of the Sinumerik 828D, extensive online help animations and a new type of input prompting system with moving picture sequences provide the basis for exceptional user convenience. USB, Compact Flash (CF) card and Ethernet ports enable high-speed data transfers onto storage media or integration of the control system into corporate networks.

SOLUTIONS FOR CNC TRAINING

Recently introduced to the American machine tool industry, and based upon the new Sinumerik Operate graphical user interface, SinuTrain is the ideal solution for control-identical CNC training.

With SinuTrain, actual NC programs are developed and simulated, to speed the program generation protocol. In this manner, machine tool operators not only learn the control language commands, but they also visualize part programs on a PC screen that are identical to the machine tool’s screen. As an additional benefit, programs generated through SinuTrain can then be used on actual machines.

Offered in several languages, SinuTrain is available for different needs and budgets including a trial version, a study version, a single-user license and an educational license.

For more information about advanced CNC solutions for the aerospace industry,

please visit: www.usa.siemens.com/aerodef-pr.

Download this article as a PDF: Siemens AeroDef14

Download the Siemens Aerospace Brochure: Siemens Aerospace

Download the SINUMERIK Integrate Run MyRobot Brochure: SINUMERIK Run MyRobot

For specific product information and inquiries, call (800) 879-8079 ext. Marketing Communications or send an e-mail to: SiemensMTBUMarCom.industry@siemens.com.

Follow us on Facebook: www.facebook.com/SiemensCNC or Twitter: www.twitter.com/siemens_cnc_us.

—

Siemens Industry Sector is the world’s leading supplier of innovative and environmentally friendly products, solutions and services for industrial customers. With end-to-end automation technology and industrial software, solid vertical-market expertise, and technology-based services, the sector enhances its customers’ productivity, efficiency and flexibility. With a global workforce of more than 100,000 employees, the Industry Sector comprises the Industry Automation, Drive Technologies and Customer Services Divisions as well as the Metals Technologies Business Unit. For more information, visit http://www.usa.siemens.com/industry.

The Siemens Drive Technologies Division is the world’s leading supplier of products, systems, applications, solutions and services for the entire drive train, with electrical and mechanical components. Drive Technologies serves all vertical markets in the production and process industries as well as the infrastructure/energy segment. With its products and solutions, the division enables its customers to achieve productivity, energy efficiency and reliability. For more information, visit http://www.usa.siemens.com/drivetechnologies.

Continue readingDid you miss Siemens at AeroDef 2014? Here’s what you missed!

Technology breakthroughs establish new flexibility and productivity paradigms for working with 2D data and massive assemblies. New functionality expands NX leadership in freeform shape design, PLM integration, and product development decision making.

AeroDef 2014 – The latest version of Siemens NX™ software (NX 9) includes new capabilities and technological breakthroughs that deliver enhanced product development flexibility and up to five times higher productivity across multiple industries. New tools like synchronous technology for 2D greatly facilitate 2D data editing. The introduction of fourth generation design (4GD) technology will enhance design productivity for massive assemblies.

And NX Realize Shape™ software delivers a new state-of-the-art freeform design toolset with unmatched product development integration. NX 9 also includes tighter PLM integration through Siemens’ Active Workspace environment, as well as multiple enhancements throughout the integrated CAD/CAM/CAE solution. The enhancements in NX 9 are aimed at creating value by addressing issues common to multiple industries such as automotive, aerospace, shipbuilding, consumer products, machinery and others.

“NX 9 represents a very significant step forward for Siemens, our customers, and for product development in general,” said Jim Rusk, senior vice president, Product Engineering Software, Siemens PLM Software. “With significant new breakthroughs such as synchronous technology for 2D, 4GD and NX Realize Shape, we are offering our customers unprecedented design flexibility while significantly increasing their product development productivity. And by leveraging our successful Active Workspace solution, we are enhancing the high definition user experience that helps our customers make smarter decisions that result in better products.”

While 3D modeling is the preferred method of product design throughout the world,

2D drawings and 2D product data – in a wide variety of digital formats – are still used in virtually every industry in some aspects of product development. Unfortunately, due to incompatible data structures and inconsistent CAD technology, working with these 2D files is typically tedious and time consuming. Synchronous technology for 2D eliminates these problems by adding intelligence to 2D data without the need for translation, enabling users to intuitively edit multi-CAD 2D files up to five times faster. This can be particularly useful for industries such as automotive, aerospace, machinery and others with large amounts of legacy 2D product data.

“Siemens’ synchronous technology for 2D is a Next Generation 2D tool that ad- dresses many of the downfalls of drafting and sketching,” said Chad Jackson, Principal Analyst for Lifecycle Insights, a leading PLM research and advisory firm. “It ‘understands’ the geometric relationships inherent in 2D drawings and applies user-controlled assumptions at the point of change to enable intelligent modifications. It also applies these assumptions locally instead of globally to ensure fast performance.”

The new NX Realize Shape offering in NX 9 provides a unique freeform design environment for producing products with highly stylized shapes or complex surfaces. It is the industry’s only solution that seamlessly integrates the most advanced, easy-to-use, flexible tools for performing freeform design, with a leading CAD/CAM/CAE software package. As a result, companies producing a wide variety of consumer products – as well as those in the aerospace, medical and marine industries – can shorten product development time by eliminating the multiple steps associated with using separate tools for freeform design and engineering development.

Hundreds of additional enhancements throughout NX 9 touch every aspect of CAD, CAM and CAE. The introduction of 4GD, a new design and data management paradigm that enables versatile and efficient methods for collaboration and design-in- context, accelerates the development of complex large-scale products containing millions of components. The embedding of Active Workspace 2.0, the innovative new interface to Siemens’ Teamcenter® software, enables NX 9 users to quickly find relevant information – parts, tasks, workflows, requirements and specifications – even from multiple external data sources.

New NX CAE tools improve thermal simulation of aircraft engines, reducing the time to setup complex boundary conditions by 75 percent. A new NX CAE parallel thermal solver provides improved performance on large-scale models delivering faster results. Enhancements in NX Nastran® software, the premier FEA solver for computational performance, accuracy, and scalability, enable noise, vibration and harshness (NVH) simulation times to be cut in half.

New capabilities in NX for manufacturing provide enhanced control for faster and more flexible CAM and CMM programming. For die/mold machining, the new cut region management capability provides graphical user interaction for more efficient programming, up to 40 percent faster for some complex parts, and precise control over machining strategies. The new multiple-part programming capability lets programmers reuse machining sequences across any number of similar parts in a setup. For example, a setup with six identical parts can be programmed up to four times faster. The new MRL Connect for NX, connects NX CAM directly to the Manufacturing Resource Library (MRL) in Teamcenter to give programmers easy access to a shared library of standard tools, fixtures, and templates. The CMM Inspection Programming capabilities have been expanded beyond solids to support sheet metal parts, delivering manufacturers in the aerospace and defense, high tech electronics, and automotive industries a highly automated inspection programming solution.

NX 9 is available immediately. For more detailed information on all the new functionality in NX 9, please visit www.siemens.com/plm/nx9.

Download this article as a PDF: NX 9

Download th

About Siemens PLM Software

Siemens PLM Software, a business unit of the Siemens Industry Automation Division, is a leading global provider of product lifecycle management (PLM) software and services with seven million licensed seats and more than 71,000 customers worldwide. Headquartered in Plano, Texas, Siemens PLM Software works collaboratively with companies, delivering open solutions to help them make smarter decisions that result in better products. For more information on Siemens PLM Software products and services, visit www.siemens.com/plm

For more information on Siemens SINUMERIK CNC, visit www.usa.siemens.com/cnc.

For specific product information and inquiries, call (800) 879-8079 ext. Marketing Communications or send an e-mail to: SiemensMTBUMarCom.industry@siemens.com.

Follow us on Facebook: www.facebook.com/SiemensCNC or Twitter: www.twitter.com/siemens_cnc_us.

—

Siemens Industry Sector is the world’s leading supplier of innovative and environmentally friendly products, solutions and services for industrial customers. With end-to-end automation technology and industrial software, solid vertical-market expertise, and technology-based services, the sector enhances its customers’ productivity, efficiency and flexibility. With a global workforce of more than 100,000 employees, the Industry Sector comprises the Industry Automation, Drive Technologies and Customer Services Divisions as well as the Metals Technologies Business Unit. For more information, visit http://www.usa.siemens.com/industry.

The Siemens Drive Technologies Division is the world’s leading supplier of products, systems, applications, solutions and services for the entire drive train, with electrical and mechanical components. Drive Technologies serves all vertical markets in the production and process industries as well as the infrastructure/energy segment. With its products and solutions, the division enables its customers to achieve productivity, energy efficiency and reliability. For more information, visit http://www.usa.siemens.com/drivetechnologies.

Continue readingDid you miss Siemens at AeroDef 2014? Here’s what you missed!

AeroDef 2014 – Siemens Industry Software announced today availability of a new version of their leading Operations Management System for Assembly and Complex Manufacturing.

Already an established benchmark in the market, the introduction of version 3.2 of this comprehensive suite consolidates Siemens at the forefront of production optimization software for the discrete manufacturing industry.

Whether you are looking to reduce the complexity of your IT landscape, increase the agility and flexibility of your manufacturing facilities, render your production processes transparent and measurable, shorten time-to-market, streamline the link between shop-floor and supply chain or adapt to new regulations, SIMATIC IT is the right choice for your business.

The biggest opportunity for manufacturers lies in their ability to Continuously Innovate in a Consumer-driven market on a Global basis. This requires that manufacturing facilities are seamlessly integrated into both the PLM and Supply Chain processes, and this is where SIMATIC IT is of unique interest, for only Siemens has a comprehensive portfolio of Industry Software seamlessly integrating PLM, MOM and Automation functionality.

SIMATIC IT ACM functionality includes:

SIMATIC IT ACM is part of the full Siemens Manufacturing Operations Management portfolio. The full range of SIMATIC IT products includes:

For more information about SIMATIC IT, please visit www.siemens.com/simaticit

Download this article as a PDF: SIMATIC IT ACM

Download the SIMATIC IT Assembly & Complex Manufacturing Brochure: SIM ATIC IT ACM

Download the SIMATIC IT Line Monitoring System Brochure: SIMATIC IT LMS

For inquiries, send an e-mail to: industrymanagement_simatic.it@siemens.com

Follow us on Twitter: www.twitter.com/simaticit

For more information on Siemens SINUMERIK CNC, visit www.usa.siemens.com/cnc.

For specific product information and inquiries, call (800) 879-8079 ext. Marketing Communications or send an e-mail to: SiemensMTBUMarCom.industry@siemens.com.

Follow us on Facebook: www.facebook.com/SiemensCNC or Twitter: www.twitter.com/siemens_cnc_us.

—

Siemens Industry Sector is the world’s leading supplier of innovative and environmentally friendly products, solutions and services for industrial customers. With end-to-end automation technology and industrial software, solid vertical-market expertise, and technology-based services, the sector enhances its customers’ productivity, efficiency and flexibility. With a global workforce of more than 100,000 employees, the Industry Sector comprises the Industry Automation, Drive Technologies and Customer Services Divisions as well as the Metals Technologies Business Unit. For more information, visit http://www.usa.siemens.com/industry.

The Siemens Drive Technologies Division is the world’s leading supplier of products, systems, applications, solutions and services for the entire drive train, with electrical and mechanical components. Drive Technologies serves all vertical markets in the production and process industries as well as the infrastructure/energy segment. With its products and solutions, the division enables its customers to achieve productivity, energy efficiency and reliability. For more information, visit http://www.usa.siemens.com/drivetechnologies.

Continue readingVisit us at booth #239!

AERODEF 2014 – Siemens will present its SINUMERIK 840D sl numerical controller, the aerospace industry standard for CNC machine tool control, which features unmatched open architecture for the handling of the most complex cutting and forming operations. In addition, Siemens will demonstrate robotic control through its mxAutomation solution, where robotic functions are controlled on a second channel of the SINUMERIK CNC and transferred to the robot via the Siemens PLC. And as the only single-source supplier in the aerospace industry who can provide the entire CAD/CAM/ CNC process chain, it’s clear why Siemens is the first choice in aerospace part manufacturing.

For more information on Siemens SINUMERIK CNC, visit www.usa.siemens.com/cnc.

For specific product information and inquiries, call (800) 879-8079 ext. Marketing Communications or send an e-mail to: SiemensMTBUMarCom.industry@siemens.com.

Follow us on Facebook: www.facebook.com/SiemensCNC or Twitter: www.twitter.com/siemens_cnc_us.

—

Siemens Industry Sector is the world’s leading supplier of innovative and environmentally friendly products, solutions and services for industrial customers. With end-to-end automation technology and industrial software, solid vertical-market expertise, and technology-based services, the sector enhances its customers’ productivity, efficiency and flexibility. With a global workforce of more than 100,000 employees, the Industry Sector comprises the Industry Automation, Drive Technologies and Customer Services Divisions as well as the Metals Technologies Business Unit. For more information, visit http://www.usa.siemens.com/industry.

The Siemens Drive Technologies Division is the world’s leading supplier of products, systems, applications, solutions and services for the entire drive train, with electrical and mechanical components. Drive Technologies serves all vertical markets in the production and process industries as well as the infrastructure/energy segment. With its products and solutions, the division enables its customers to achieve productivity, energy efficiency and reliability. For more information, visit http://www.usa.siemens.com/drivetechnologies.

Continue reading

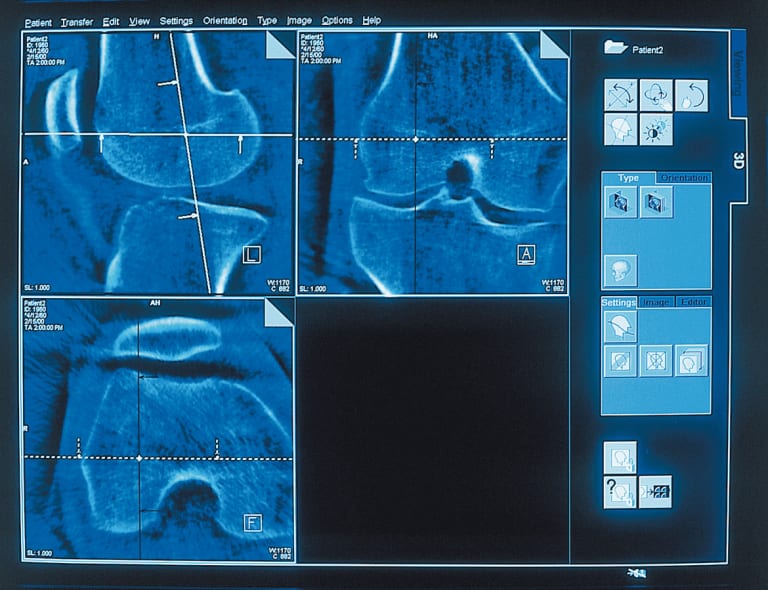

The process chain for a typical implant begins in the clinic, where the doctor uses CT scan imaging data to select an appropriate implant

Today’s machine shops, whether in the medical technology or tool and moldmaking sectors, can take advantage of an integrated Siemens CNC solution for everything from the design concept to the finished product.

The production of today’s medical implants involves an entire process chain, starting with the doctor and ending with the finished device. Doctors use the imaging data of a complex fracture, acquired with a computed tomography (CT) scan, to select an appropriate implant and then position it in the fracture area of the patient on the computer. Of course, this is only possible if the implant geometries are stored in a database, and the doctor has implants in stock or can access them immediately from a manufacturer.

Simulation of machining sequences

In plastic surgery, however, where implants specifically manufactured for each individual patient are needed, a different process is employed. Instead of pre-machined parts, implants are custom-made with the help of 3D imaging. In this case, the machine tools are controlled using the implant geometries. Calculated contours and shapes are acquired by the CT scan to produce implants that are literally a perfect fit. However, the feasibility of the planned production process can first be determined on a monitor using, for example, an NX graphic simulation from Siemens to avoid potential collisions or damage to the workpiece contours.

Technology package for milling

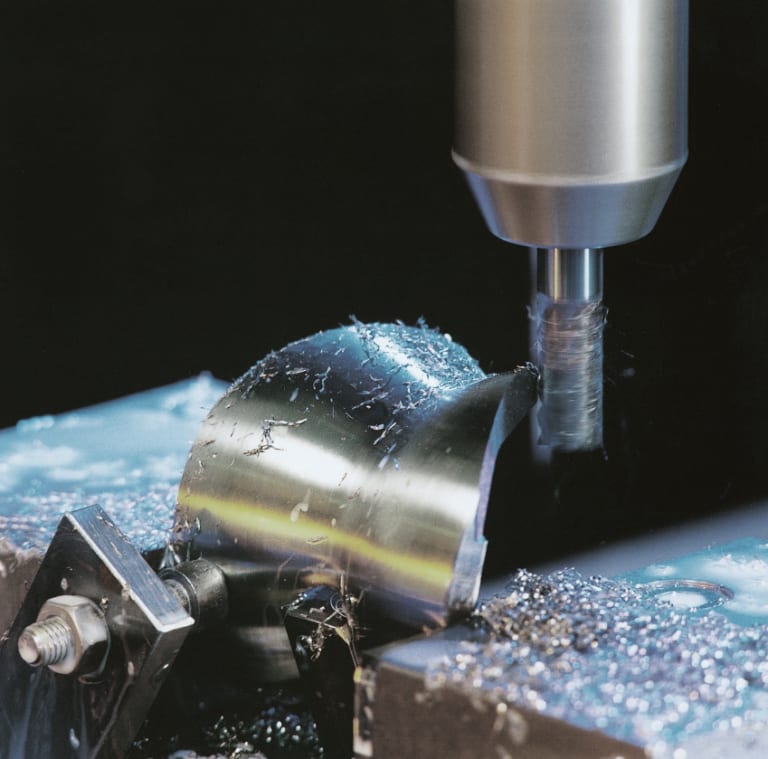

Implants for knee joints are precision machined with the High-Speed Cutting HSC process on a machine tool run by Siemens SINUMERIK 840D solution line CNC technology.

High-speed cutting (HSC) is a machining process with high material processing speeds. HSC machine tools achieve high spindle speeds, combined with feed rates that are much higher than those of conventional machine tools. Consequently, they require control systems and part programs that perform equally fast. The Siemens Sinumerik® 840D solution line CNC is specifically designed for the requirements of medical technology and this precision part HSC work. Integrated functions onboard the CNC assist users with set-up and programming, thus allowing faster and more precise production sequences.

Together, the Sinumerik CNC system and ShopMill® software from Siemens form a milling technology package that allows machine operators rapid access to the functions they need. Thanks to graphic function display and plain language input dialogs, cycles can be used quickly and effectively, after a brief training period. Even the smallest errors can be corrected during operation, using multi-axis kinematic analysis. The Siemens Safety Integrated® solution further provides protection for personnel and machinery. This software can be used to interlink emergency stop buttons and light barriers. In the event of an operating error, dangerous movements are immediately brought to a standstill and the power supply to the motor is quickly cut.

The use of measuring probes

The production of artificial knee joints on an HSC 20 linear milling center manufactured by DMG, for example, can be fully controlled and monitored by a Siemens Sinumerik CNC system. With its broad range of functions, this milling center is particularly well suited for use in the medical technology sector. It is equipped with linear drives on all axes and achieves acceleration rates over 2g. The machine can also generate a surface finish down to 0.2 micrometers Ra. The liquid-cooled machining spindle operates at speeds up to 42,000 rpm, thereby covering an extensive range of potential applications in the medical sector, where materials such as titanium, chromium-molybdenum, tantalum and niobium are typically milled.

In order to achieve maximum precision during implant production, while also maintaining a consistently high level of product quality, parametric measurements must taken continuously from both the machine and the workpiece. probes, for example, on HSC production machines measure tool dimensions in-process, detect broken tools and are used for the set-up and measurement of workpieces. In medical machine shops currently, the targeted use of such measuring probes can reduce set-up times by up to 90%, while substantially improving process control.

Cost-effective machining

Metal parts used in medical technology are often extremely complex. Therefore, choosing the right tooling can have a great impact on the quality of the finished products. After all, proper cutting tools ensure that the parts leaving the machining center are absolutely precise and require no further finishing work. Although the materials used for many medical and orthopedic parts are often quite difficult to machine, the tools must fulfill high performance requirements with respect to the precision and surface quality of these implants. Iscar, one supplier of such tools, offers a program for monitoring the use of precision tools on turning, drilling, milling and finishing jobs. They also help users assess the performance qualities of non-vibrating carbide milling cutters, which are well-suited for machining implant materials, plus they can offer information on more cost-effective and efficient machining processes.

For more information on Siemens SINUMERIK CNC, visit www.usa.siemens.com/cnc.

For specific product information and inquiries, call (800) 879-8079 ext. Marketing Communications or send an e-mail to: SiemensMTBUMarCom.industry@siemens.com.

Follow us on Facebook: www.facebook.com/SiemensCNC or Twitter: www.twitter.com/siemens_cnc_us.

—

Siemens Industry Sector is the world’s leading supplier of innovative and environmentally friendly products, solutions and services for industrial customers. With end-to-end automation technology and industrial software, solid vertical-market expertise, and technology-based services, the sector enhances its customers’ productivity, efficiency and flexibility. With a global workforce of more than 100,000 employees, the Industry Sector comprises the Industry Automation, Drive Technologies and Customer Services Divisions as well as the Metals Technologies Business Unit. For more information, visit http://www.usa.siemens.com/industry.

The Siemens Drive Technologies Division is the world’s leading supplier of products, systems, applications, solutions and services for the entire drive train, with electrical and mechanical components. Drive Technologies serves all vertical markets in the production and process industries as well as the infrastructure/energy segment. With its products and solutions, the division enables its customers to achieve productivity, energy efficiency and reliability. For more information, visit http://www.usa.siemens.com/drivetechnologies.

Continue readingIntegrated operation, programming, and diagnostics of KUKA robots via the Sinumerik Operate user interface from Siemens

Automation of machine tools will immediately become more flexible: with Sinumerik Integrate Run MyRobot, Siemens Drive Technologies Division and KUKA Roboter GmbH presented a solution for integrated operation, programming, and diagnostics of a KUKA robot in Sinumerik at EMO 2013. For example, in conjunction with the new “Run myRobot” technology, the CNC control Sinumerik 840D sl package can optimally enable KUKA robots to perform handling tasks on machine tools, in particular, loading and unloading of machining cells. Interaction, such as operation, tool retraction, teach-in, and diagnostics of robots, can be performed through just one operator panel with the Sinumerik 840D sl, thus increasing the efficiency and flexibility of the machine tools. Customer can order this technology package with immediate effect from Siemens.

As part of the dynamic automation solution, functions for handling are one hundred percent available at the Sinumerik Operate user interface. The execution of the machine tool and robot program can be tracked and controlled on screen on parallel channels. This gives the operator a quick overview of the current status of the machine tool and robot. The Sinumerik hand-held terminal HT8 and the user interface can be used to “teach” not only machine tool-related setup actions but, as part of the same operating philosophy, also the path points and functions of the robot.

Execution of the robot movements, provision of robot safety functions, and other robot-specific functions are still performed by the KUKA robot control KR C4. The Sinumerik 840D sl is connected to the KUKA control via a command interface.

With the mxAutomation function block library from KUKA, the motion sequence of the robot can be programmed completely in the Sinumerik control 840D sl. In this way, the robot program can be created completely without any knowledge of Step 7, the Siemens tool for PLC programming.

This press release and further press material are available at http://www.siemens.com/press/emo2013

For more information on this story, contact:

Siemens AG, Media Relations

Franz-Ferdinand Friese, phone: +49 911 895 7946

E-mail: franz.friese@siemens.com

KUKA Roboter GmbH, Corporate Communications

Wolfgang Meisen, phone.: +49 821 4533 1981

E-Mail: WolfgangMeisen@kuka-roboter.de

—

The Siemens Drive Technologies Division (Nuremberg, Germany) is the world’s leading supplier of products, systems, applications, solutions and services for the entire drive train, with electrical and mechanical components (Integrated Drive Systems). Drive Technologies serves all vertical markets in the production and process industries as well as the infrastructure/energy segment. With its products and solutions, the Division fulfills the key requirements of its customers for productivity, energy efficiency, and reliability. For more information, visit http://www.siemens.com/drivetechnologies

The KUKA Roboter GmbH, with its headquarters in Augsburg, is a member of the KUKA Aktiengesellschaft and ranks among the world’s leading suppliers of industrial robots. Core competencies are development, production and sale of industrial robots, controllers and software. The company is the market leader in Germany and Europe and the number three in the world. KUKA Roboter GmbH employs about 3180 people worldwide. In 2012, sales totaled 742,6 million Euro. 25 subsidiaries provide a presence in the major markets of Europe, America and Asia.

Continue readingTo guarantee perfect workmanship and the highest possible product quality, BMW uses five-axis machining centers equipped with Sinumerik 840D sl and a range of new user interfaces for machining operations in its Berlin motorcycle plant.

The horizontal design of the Grob five-axis G550 guarantees the highest levels of rigidity, which keeps axial deviations below 10 µm.

Thanks to previous positive experience with Siemens, the BMW manufacturing specialists in Berlin already employ technology from Europe’s market leader for 90 percent of their controllers. This allows both operators and tool setters the flexibility to work on almost all the machines in the plant. Other key requirements noted in the specification were adequate space for manufacturing all relevant components, the highest levels of precision and surface finish, compliance with pre-defined cycle times, and the ability to reuse all current tools and equipment.

The highest levels of precision on even the hardest material

Before committing to the new investment, the responsible BMW production engineer worked with a colleague from process engineering to investigate the effectiveness of the Grob machines in cylinder head production. Initially, it was the G550’s near-identical sibling, the G350, that was under consideration. As a first traditional single-workplace machine tool, it already met almost all the main criteria, but the space available inside was deemed too small to accommodate all the required processing tasks. However, the G550 satisfied this requirement as well. Among other factors, the horizontal design of this five-axis machine, which has both rotary axes in the work area, contributes significantly to its outstanding rigidity. As a result, axial deviation remains process-compliant at values under 10 µm. The level of precision that can be achieved is correspondingly high, even when processing extremely hard materials, as with valve seat inserts, for example.

The machine also produces a high-quality surface finish, with roughness (Rz) of up to 2 µm. Christian Heiß, applications engineer at Grob, explains a further benefit of the horizontal design: “Tool life can be increased by approximately 30 percent compared with that of vertical machining centers. And the problem of jammed slivers is almost completely eliminated because they are not able to fall onto the workpiece in the first place, but instead fall right through to the ground.”

One of the G550’s strengths is its compact size, at only 3800 mm x 6300 mm. However, despite its size, it still features an extremely long z-axis stroke of 1020 mm, meaning that tools up to 500 mm long can be retracted completely out of the work area and into the so-called spindle tunnel. The swivel-mounted shuttle table is another feature that helps deliver high levels of productivity. While one workpiece is being processed, the next can be clamped and set, thus minimizing costly downtime.

Programmed and set in no time at all

Employees find the new Sinumerik 840D sl CNC especially easy to operate because, in the production of BMW cylinder heads, only Siemens controllers are used. Despite this, the user interface presented on the Grob machines looks completely different from the others. Until now, operators and setters have been used to the DIN-based HMI Advanced user interface, but the new CNC on the G550 features the Sinumerik Operate animated graphical display. Siemens has integrated a new operation and programming structure, with practical functions such as copy and paste that are well known to users from their daily use of PCs. This allowed BMW employees to quickly adapt and master the new Sinumerik user interface in no time at all.

Thanks to its excellent usability and intuitive operation through various technology cycles, measurement cycles, and setting functionality, the new G550 machines can be set up for new batches much more quickly than before. As Heiß explains: “This means our customers are much faster than before. Previously, it might have taken several hours to set up the machine and the workpiece, now it can be done in just a few minutes.”

Highly trained employees and specialist suppliers help BMW motorcycles maintain their excellent reputation for reliability, quality, and safety.

Quick and reliable with remote maintenance

Along with the tools and equipment from the current machines, the German motorcycle manufacturer was able to reuse all its existing programs as well. It took a single employee only two days to upgrade these programs to be compatible with the latest software, which can be loaded onto the relevant machine as required either over the network or from a USB stick. The modern Windows Explorer-style program manager means that complex programs can be managed either on the CF (Compact Flash) card or directly on the CNC.

If problems arise while the machine is operational, BMW production engineer Taner Ögretmen and his colleagues use the network-based remote maintenance functionality provided by Grob. This has rarely been required so far – but when it has, it proved to be extremely smooth and efficient, stresses Ögretmen. Grob can also perform minor optimizations together with Siemens using the teleservice. This is usually done automatically and without any disruption to ongoing production. The Sinumerik-controlled Grob machines have met every expectation in full, which is why BMW has already ordered an additional four G550s.

Programming and operation using Sinumerik Operate

be clear and self-explanatory, so that even operators with no programming experience can learn the basics in no time at all. To write programs in programGUIDE, the operator will need some knowledge of G-code. The highlights here include new cycle support functionality and animated elements that can be used to represent the cycle graphically. Tooltip support is also provided.

For more information on this story:

SIEMENS INDUSTRY, INC.

MOTION CONTROL

MACHINE TOOL BUSINESS

390 Kent Avenue

Elk Grove Village, IL 60007

Phone: 847-640-1595

Fax: 847-437-0784

Web: www.usa.siemens.com/cnc

Email: SiemensMTBUMarCom.sea@siemens.com

Attention: John Meyer, Manager, Marketing Communications

Follow us on Facebook: www.facebook.com/SiemensCNC or Twitter: www.twitter.com/siemens_cnc_us.

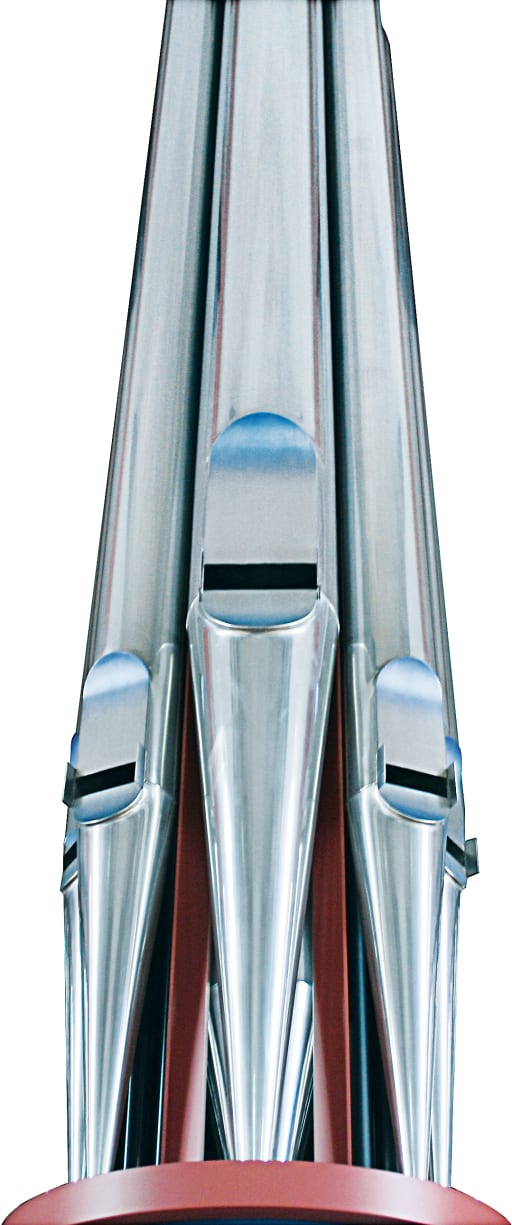

Continue readingThe art of organ building at the highest level with modern CNC techniques…

Laukhuff relies on five-axis milling center from Spinner with Sinumerik 840D sl for small-series production

At Laukhuff in Weikersheim, Germany, tradition and modernity merge together in a way that can not merely be seen, but also heard. The family-run company, with almost 200 years of history, is the international leader in organ building – as a supplier to the best-known organ builders and a provider of its own complete instrument developments. The company operates on a global level with 150 employees, considering itself an artistic crafting enterprise rather than an industrial company. Company CEO Hans-Erich Laukhuff emphasizes, “In our carpenter’s workshop and when manufacturing organ pipes, we are hardly able to use any machines because 90 percent of the work must be done by hand. When it comes to cutting, however, this is a different matter. Here, we can use modern milling and turning machines with innovative CNC equipment, so that we can keep productivity levels as high as possible.”

If required, these masters of organ building will supply everything from a single source. Laukhff further explains, “If requested, we will take on all the tasks involved in the design, the manufacture of individual parts and the installation onsite. We even make the bench seat and the key lights ourselves, as there are no usable, satisfying solutions in the market today.”

The high level of perfection shown by this organ builder is reflected in the optics, in the haptics (touch and feel) and naturally in the sound of the instruments. It also has a positive effect on their reliability. After all – quite unusual in these fast-moving times – it is typically not necessary to plan the replacement of a Laukhuff organ for more than 100 years. However, a few spare parts will still be required.

Despite the fact their high quality is globally recognized, this family-run company is still facing constant cost pressure. To achieve a high throughput in cutting applications, the company uses five CNC turning machines and three CNC milling machines – together with their latest acquisition, a five-axis CNC center (3+2) from Spinner’s U-series, with a state-of-the-industry Siemens Sinumerik 840D sl CNC onboard.

Impressive price-performance ratio

With the Sinumerik-controlled Spinner U5-620, Laukhuff uses new options for the more productive manufacturing of organ components, such as chimes

Company owner and CEO Hans-Erich Laukhuff and Production Manager Walter Rhein already had positive experiences with the CNC. However, since mid-2009, they have been relying on the Spinner machine tool factory in Sauerlach, Germany for the first time and using the U5. According to the production manager, this decision was based on the price-performance ratio and the small space required by the machine in contrast to comparable machines from other manufacturers. The U5-620 only needs 2000 x 2400 millimeters of surface area, but achieves travel distances of 620/520/460 millimeters in the X/Y/Z-axis direction.

The new Spinner machining center has high-quality individual components, including 32 tools as standard, a double arm for rapid tool changes and linear axes on roller bearing guides. Michael Schulz, Spinner sales representative at Hollenbach GmbH, confirmed, “This enables us to achieve rapid feed speeds of 48 meters per minute in all directions. Even in terms of accuracy and surface quality, our U-series sets a very high standard.”

In terms of the productivity and quality increases that can be achieved, as well, the organ builder expects the acquisition of the Spinner machine to be amortized within a relatively short period of time. Ultimately, an organ builder will often manage without time-consuming retooling, as Rhein noted, “In the cutting applications for our organ pipe tuners, we previously had to retool three times and needed around 13 minutes just for clamping – which doesn’t even take into account the downtime while retooling. The five axes mean that production is now possible in a single clamping, within about eight minutes per piece. All in all, we are at least twice as fast as a result.”

Graphically-animated user interface

Like many medium-sized contract manufacturers, this organ builder’s employees also program directly at the machine. CNC specialist Kurt Stüdlein is totally convinced about the Sinumerik 840D sl because, “…it is powerful, safe to operate, user-friendly and reliable. But the CNC user interface, tailored to shopfloor programming, also scores highly, being graphically-animated and logically-structured. ShopMill, the resident software suite, is great, particularly for beginners. Production Manager Rhein further explains, “Even a fitter who has only just finished his training, without any extensive programming experience, can work with it, after some brief instructions.”

CNC professional Stüdlein adds, “Even on complex components using the 3+2 axis machining, I can create lots of programming steps with ShopMill. If I reach the limits when entering certain contours, or if I am quicker with DIN, then I can switch from the graphic to the text-oriented DIN interface at the touch of a button.” For additional employee safety, the Safety Integrated software solution is also built into the control. This means that it is possible for the user to safely track his program’s production process in setup mode with the machine doors open.

Laukhuff is certain, based on the experience gained, that he has made the right decision with the Spinner-Siemens CNC combination. The technology and the continuously fast service from both companies have convinced him, “If there is a problem, we are helped very quickly – which is not always a given with other manufacturers in this particular industry.”

For more information on Siemens SINUMERIK CNC, visit www.usa.siemens.com/cnc.

For specific product information and inquiries, call (800) 879-8079 ext. Marketing Communications or send an e-mail to: SiemensMTBUMarCom.industry@siemens.com.

Follow us on Facebook: www.facebook.com/SiemensCNC or Twitter: www.twitter.com/siemens_cnc_us.

—

Siemens Industry Sector is the world’s leading supplier of innovative and environmentally friendly products, solutions and services for industrial customers. With end-to-end automation technology and industrial software, solid vertical-market expertise, and technology-based services, the sector enhances its customers’ productivity, efficiency and flexibility. With a global workforce of more than 100,000 employees, the Industry Sector comprises the Industry Automation, Drive Technologies and Customer Services Divisions as well as the Metals Technologies Business Unit.

The Siemens Drive Technologies Division is the world’s leading supplier of products, systems, applications, solutions and services for the entire drive train, with electrical and mechanical components. Drive Technologies serves all vertical markets in the production and process industries as well as the infrastructure/energy segment. With its products and solutions, the division enables its customers to achieve productivity, energy efficiency and reliability.

Continue readingTurning-milling centers with coordinated drive and CNC engineering achieve superior accuracy and repeatability

Hamuel CEO Dr. Markus Stanik (right) and his sales manager Jochen Schaede agree: “The Sinumerik 840D sl CNC complements perfectly the capabilities of our five-axis turning-milling centers in the HSTM Series. Because of this fact, we can usually convince leading turbine manufacturers from the aerospace and automotive industries about the dynamics, high-performance and precision of these machines.”

The complete machining of turbine blades requires striking a balance between powerful roughing and ultra-precise finishing, a task for which the modern five-axis turning-milling centers are ideal, when robust machine construction is combined with high-quality drive and control engineering. Experience is the solid basis on which the Hamuel Maschinenbau GmbH & Co. KG, Meeder, Germany, can offer a great deal: with 85 years of machine tool manufacturing, 35 years of CNC machining, 25 years of five-axis simultaneous machining and over 10 years in the construction of five-axis turning-milling centers. CEO Dr. Markus Stanik knows that experience by itself cannot be any yardstick for the quality of machine tools, noting, “It certainly helps us, together with the right partner companies, to design and build the machines so that our customers can be successful in the marketplace.” This machine builder and its many customers have developed correspondingly positive accomplishments together. Today, Hamuel stands on three standards:

The latter, as evidenced by Hamuel’s HSTM (high-speed turning-milling) series, has been marketed since 1999 and makes a decisive contribution to the sales and success of the company. Leading turbine manufacturers from the aerospace and power-generating industries have been particularly impressed by the dynamic response, capability and precision of these machines. Even the smallest faults are unacceptable on turbine blades

Form deviations are unacceptable for products such as turbine blades and blisks because even the smallest error would significantly reduce the efficiency of the power plant or aircraft turbine.

The HSTM that runs on the Sinumerik 840D sl CNC controllers is used mainly to manufacture turbine blades and blisks (turbine disks) deployed in stationary steam and gas turbines as well as in mobile turbines for aircraft jet engines and large turbochargers. These products always consist of high-strength materials, such as titanium or high-alloyed steels. Form deviations are taboo in such applications, because even the smallest error would significantly reduce the efficiency of the turbines. Correspondingly high and comprehensive are the requirements placed on the machine tools. Hamuel sales manager, Dipl.-Ing. Jochen Schaede, explains: “Our customers normally manufacture large turbine blades longer than approximately 1000 mm from forging blanks. In contrast, shorter workpieces are milled from a solid piece of material with a stock-removal ratio of approximately 80 percent. This makes it obvious that our machines must not only rough-cut very productively but also finish with high precision.” Whereas productivity takes precedence for rough-cutting, accuracy is more important for the subsequent finishing of the spatial free-form surfaces. “With regard to accuracy, our high-performance machining centers achieve a precision in the micrometer range coupled with excellent surface quality,” added Schaede.

Form deviations are unacceptable for products such as turbine blades and blisks because even the smallest error would significantly reduce the efficiency of the power plant or aircraft turbine.

Key to this capability is the combination of compact machine construction together with perfectly matched drive and control engineering. The basis is the robust machine design with a one-piece machine base – either as welded construction cast with special concrete or latterly directly as polymer-concrete made from a single piece of material. The careful distribution of the masses ensures the best dynamic rigidity. The experience of the developers at Hamuel paired with the knowledge of the Siemens mechatronic experts make such results possible, as Jochen Schaede confirmed: “Thanks to various simulation tools, the Siemens engineers could provide us with very exact data to which we could add or remove masses. It was certainly advantageous that we could procure all components required for the dynamics from Siemens starting with the spindle, including the axis drives, and ending with the CNC. This means we needed only a few iteration loops in order to obtain a perfect dynamic rigidity in the machines.” It is also important that all components are arranged so that the horizontally clamped turbine blades and blisks can be machined optimally. This is also facilitated by the 45°-inclined orientation of the axes that ensures a favorable swarf removal further augmented by the permanent rinsing of the machine internal area. The accessibility has also been enhanced by this inclined axis orientation. Such designed and built HSTM machines equipped with precise direct drives from Siemens achieve a maximum positioning accuracy of 5 µm with traversal speeds exceeding 40 m/min in all linear axes. Indeed, the extremely fast rotary axes have a positioning accuracy of 3 µm. This allows the user to achieve maximum productivity, accuracy and surface finishes in the range of Ra = 0.8 µm, and so fully meet the industry requirements placed on the blade machining. CNC ensures optimized surface transitions at the inlet and outlet edges One of the biggest challenges for the turbine-blade manufacturing industry concerns the critical surface transitions (leading and trailing edges) of the turbine blades. To achieve a high quality, the milling paths described with curve interpolation points must have a constant machining speed. As a consequence, the leading and trailing edges demand extreme angular accelerations. The number of curve interpolation points to be described is correspondingly quite high.

The manufacturing of precise free-form surfaces for turbine blades demands the highest performance from the CNC. The excellent block-cycle times of the Sinumerik 840D sl and its look-ahead function improved as part of the new “Advanced Surface” motion control, which play a significant role here.

The controller now faces the challenge to reliably process the generated NC steps that are supported by the fast block cycle times and the look-ahead function of the CNC. “Hardly any other controller can supply the drive information for all five axes in the required short time as reliably as the Sinumerik 840D sl controller,” confirmed Jochen Schaede, who added, “The new Advanced Surface motion control that includes among other things an optimized look-ahead function is also excellent. And I would also like to mention the five-axis high-speed turning-milling of free-form surfaces requires a continuous spatial reorientation of the geometry vectors.” This leads to the use of the Traori (transformation orientation) principle in the Sinumerik 840D sl. Hamuel’s customers can therefore achieve reproducible results with the best-possible surface finish, exact contour accuracy and with the maximum possible machining speed.

Despite being a high-end controller that offers many modern features, the Sinumerik 840D sl CNC is easy-to-use.

In addition to the primary properties of precision, productivity and reliability, Hamuel also appreciates other properties of the Siemens drive and control engineering – an example: the DRIVE-CLiQ interface. When this digital connection is used, all appropriately equipped drive components are detected automatically. Only a cable for the connection is required to achieve this result. Equivalent circuit diagram data for the motors and the characteristic values of the installed encoder systems are all stored. This avoids the need for manual data input during the commissioning and so makes this task more reliable and much faster, according to Hamuel engineers. Sales manager Schaede is also impressed with the “know-how” protection onboard the control. With the help of innovative software, his customers can protect all their programs and their application know-how, using individual passwords and so largely prevent unauthorized access. According to Hamuel, the Teleservice offered by Siemens has proven to be an important advantage for its machine users who often operate globally. It allows not only software problems to be rectified but also updates to be installed fast and reliably without needing to be present onsite. Manufacturing operations save time and money and they always remain up-to-date with the latest software releases, via this service. Powerful motor spindle with Hirth gearing

Leading turbine manufacturers are particularly impressed by the dynamics and high-performance of the HSTM machines. The perfect interaction of the robust Hamuel machine construction and the high-quality Siemens drive and control engineering provide the basis for this satisfaction.

The capability of the turning-milling center also depends greatly on the 54-kW motor spindle made by Weiss Spindeltechnologie GmbH (a Siemens subsidiary). Equipped with a HSK A63 tool holder, it is able to provide the high torque required for roughing plus speeds as high as 16,000 rpm for finishing. This means an optimum cutting speed is always guaranteed. As a practical detail, the Hamuel engineers also emphasize the integrated Hirth gearing that makes it possible to clamp the spindle and relieve load on the bearings during the turning process. The machine sizes in the HSTM Series are oriented to the length of the workpieces to be produced in standard ranges from ≤ 500 mm (HSTM 300) to 1750 mm (HSTM 1500). On special request, Hamuel also builds larger machines. A project for machining blades as large as 2500 mm in length is currently running in the field. CEO Markus Stanik explains, “Thanks to our modular machine construction, we are able to satisfy special requests and build turning-milling centers in these dimensions.”

The manufacturing of precise free-form surfaces for turbine blades demands the highest performance from the CNC. The excellent block-cycle times of the Sinumerik 840D sl and its look-ahead function improved as part of the new “Advanced Surface” motion control, which play a significant role here.

New developments already in the introductory phase are also evolving at Hamuel. For example, in the near future, a special gas will be able to be used to cool the tool in the HSTM machines. A machine base made of mineral casting is also now offered. One of the first machines of this type has already been presented at EMO. “This material not only exhibits excellent properties with regard to vibration suppression but we have also been able to reduce somewhat our dependency on steel suppliers,” noted Markus Stanik. For the machine user, this makes itself apparent directly in improved surface quality and a significantly longer tool service life. CNC gantry milling machines of the HSM (high-speed milling) series In addition to the component production and the construction of the HSTM series, the company’s HMS Series machines are another mainstay for Hamuel. These simultaneous five-axis machining centers are designed for high-speed cutting (HSC). They feature not only the modern Siemens drive and CNC control engineering, but also the optimized milling-head systems and the high-performance high-speed spindles, providing this capability. HSM machines allow high-performance roughing and ultra-precise finishing. With regard to the size of the HSM machines, the manufacturer adapts the designs specifically based on the customer requirements. As a component producer, Hamuel also has its own machines in constant use at its factory.

For more information about Siemens CNC solutions for the machine tool industry, visit our website: www.usa.siemens.com/cnc.

For more information on the this story, contact:

SIEMENS INDUSTRY, INC.

DRIVE TECHNOLOGIES

MOTION CONTROL

MACHINE TOOL BUSINESS

390 Kent Avenue

Elk Grove Village, IL 60007

Phone: 847-640-1595

Fax: 847-437-0784

Web: www.usa.siemens.com/cnc

Email: SiemensMTBUMarCom.sea@siemens.com

Attention: John Meyer, Manager, Marketing Communication

Follow us on Facebook: www.facebook.com/SiemensCNC or Twitter: www.twitter.com/siemens_cnc_us.

—

Siemens Industry Sector is the world’s leading supplier of innovative and environmentally friendly products, solutions and services for industrial customers. With end-to-end automation technology and industrial software, solid vertical-market expertise, and technology-based services, the sector enhances its customers’ productivity, efficiency and flexibility. With a global workforce of more than 100,000 employees, the Industry Sector comprises the Industry Automation, Drive Technologies and Customer Services Divisions as well as the Metals Technologies Business Unit.

The Siemens Drive Technologies Division is the world’s leading supplier of products, systems, applications, solutions and services for the entire drive train, with electrical and mechanical components. Drive Technologies serves all vertical markets in the production and process industries as well as the infrastructure/energy segment. With its products and solutions, the division enables its customers to achieve productivity, energy efficiency and reliability.

About Hamuel Maschinenbau GmbH & Co. KG, Meeder, Germany

Hamuel was founded in 1927 and is now part of the Hamuel Reichenbacher company group. More than 2000 CNC machines from this enterprise group are currently in use globally for the machining of a wide range of materials. The focus of Hamuel Maschinenbau comprises three areas: the production of machine-tool components, CNC gantry milling machines (HSM) and five-axis CNC turning-milling centers (HSTM).

Continue readingHighlights include two-sided machining and servo drive technology

Recently, Northern Italian machine tool manufacturer Biglia introduced its multi-functional turning centers of the ‘Quattro’ series with the Sinumerik 840D sl CNC. The mechanical concept, together with the scalable control, provides users with the most diverse standard turning and milling operations. The result is increased flexibility and higher speeds for end users. That quality machine tools are built in Northern Italy is nothing new. And this fact is confirmed again by the “Quattro” series from the machine tool manufacturer Biglia. These machines are multifunctional turning centers that are valued throughout Europe for their high reliability and performance power. The machines are available in different versions from 11 to 15 CNC axes. They are also intended for different turning diameters (45, 52, 65, 71 and 80 mm).

Biglia has equipped its turning centers of the ‘Quattro’ series with the Sinumerik 840D sl CNC control. The individual machines have 11 to 15 NC axes.

The two opposing spindles form a special feature of the “Quattro” series. This allows the workpiece to be machined from two sides, which reduces the machining time. The second spindle can also be moved linearly in two directions (lengthwise and crosswise). This provides some leeway in the case of additional milling operations, but it can also be used for automatic workpiece unloading. Two turrets, mounted on the y-axis, ensure proper positioning of the necessary tools.

The turning centers from Biglia have two spindles and two independent tool turrets for simultaneous machining.

This innovative machining technology allows the creation of not only rotary but also prismatic workpieces – including polygons. Dealing with everything in one setup not only reduces cycle times, it also enhances accuracy. The machines are developed on the basis of a modular concept that ensures flexible application options – from the universal CNC lathe, to complete machining of complex workpieces with powered tools (c- and y-axis).

Getting it right, from the start

By offering the Siemens Sinumerik 840D sl CNC control, Biglia now wants to expand its previous options and its own market by combining its technologies with that of the Siemens control. “In this project, which is of personal significance to all of us who worked on it and of strategic significance for Biglia, we wanted to do everything perfect right from the start and to get the most out of it,” says Giovanni Delmondo, Business Development Manager for machine tools with Siemens Italy. The result is an all-round successful machine series with a highly modern control that already includes the innovative system expansions of recent months – including increased energy efficiency options offered by the control and drive systems from Siemens.

To illustrate this, Giovanni Delmondo points out that “the fans on the spindles are shut down automatically when they are not required, or certain services such as hydraulics, lubricant supply, or compressed air are deactivated during machine standstill times. This is handled via special screen forms on the control and is extremely simple, using the Run MyScreens function.”

Also notable is the standard energy efficiency solution from Siemens in the Sinamics S120 drives onboard this machine series. This includes automatic power factor correction or regenerative feedback of the energy generated in braking operations, a substantial factor in energy savings.

Performance and scalability

The centerpiece of the automation concept of these Biglia turning centers is the Sinumerik 840D sl control. This is a universal and flexible CNC system, implemented in the Sinamics S120 design (see Fig. 3). It is suitable for up to 31 NC axes. Whether you are turning, drilling, milling, grinding, laser-machining, nibbling or punching, the Sinumerik 840D sl is suitable for use in the most diverse machining technologies. The CNC control also has PLC (programmable logic controller) functionalities, so that a special PLC can be eliminated, if applicable.

This high-end control from Siemens is ideally suited to medium and complex tasks and production and can be adapted to the task, thanks to scalable hardware. The CNC is also characterized by openness, so the operator interface and also the software present few limits to specific job adaptability. This applies all the way to supplementing the NC core of the control; however, a special license is required for this adaptation.

On the Biglia turning centers, the control was equipped with the Sinumerik Operate user interface, making operation simple and intuitive. Three different methods of parts programming are possible: Classic ISO code programming, programming with the help of the integrated ProgramGuide with graphical support of the selected cycles, and the new two-channel ShopTurn with graphical 3D simulation. The user is led step-by-step through the cycles, whether for simple metal removal, drilling, thread cutting, pocket milling, groove milling or engraving. Complex programming cycles for complex contours are also possible. The “ProgramSync” function for automatic synchronization of the machining programs via two channels ensures a significant increase in machine productivity. The control is equipped with a 15″ monitor and integral keyboard.

The Quattro series from Biglia also uses the highly effective personnel and machine protection system provided by the Sinumerik control concept with the Sinumerik Safety Integrated package.

Biglia is also breaking new ground with servo drives. Thus, the new servo motor generation 1PH8 from Siemens is used for the main spindle motors in this series. The linear axes are further equipped with the new 1FK 7 G2 series of permanent-magnet synchronous motors. These motor types from Siemens enable onsite replacement of the encoders without having to dismantle the complete motor. This combination of machine and CNC control in the Quattro turning centers from Biglia provides users with greater flexibility.

For more information about Siemens CNC solutions for the machine tool industry, visit our website: www.usa.siemens.com/cnc.

For more information on the this story, contact:

SIEMENS INDUSTRY, INC.

DRIVE TECHNOLOGIES

MOTION CONTROL

MACHINE TOOL BUSINESS

390 Kent Avenue

Elk Grove Village, IL 60007

Phone: 847-640-1595

Fax: 847-437-0784

Web: www.usa.siemens.com/cnc

Email: SiemensMTBUMarCom.sea@siemens.com

Attention: John Meyer, Manager, Marketing Communication

Follow us on Facebook: www.facebook.com/SiemensSiemensCNC or Twitter: www.twitter.com/siemens_cnc_us.

—

Siemens Industry Sector is the world’s leading supplier of innovative and environmentally friendly products, solutions and services for industrial customers. With end-to-end automation technology and industrial software, solid vertical-market expertise, and technology-based services, the sector enhances its customers’ productivity, efficiency and flexibility. With a global workforce of more than 100,000 employees, the Industry Sector comprises the Industry Automation, Drive Technologies and Customer Services Divisions as well as the Metals Technologies Business Unit.

The Siemens Drive Technologies Division is the world’s leading supplier of products, systems, applications, solutions and services for the entire drive train, with electrical and mechanical components. Drive Technologies serves all vertical markets in the production and process industries as well as the infrastructure/energy segment. With its products and solutions, the division enables its customers to achieve productivity, energy efficiency and reliability.

Continue reading