Contact us today:

(847) 934-4500

tdaro@bernardandcompany.com

Contact us today:

(847) 934-4500

tdaro@bernardandcompany.com

Bernard & Company is proud to announce recent client acquisitions including Suhner Automation, Gehring Technologies GmbH, Chemcoaters, Gray Machinery and S & G Press & Machinery Sales, for which they will be providing full advertising, PR, social media, trade-show and online promotional activity.

Since 1926, Gehring L.P has been a globally operating machine tool company specializing in high performance honing technology.

Website | ThomasNet Profile | |

|

| 24800 Drake Rd. Farmington Hills, MI 48335 | (248) 427-3901

Founded in 2001, Chemcoaters‘ continuous, coil processing line is designed specifically for the most economical application of environmentally friendly waterborne coating sys-tems.

Website | |

|

|

|

| 700 Chase St. Gary, Indiana 46404 | (219) 977-1929

Established in 1966, Gray Machinery Company has over 40 years of experience buying and selling pre-owned machinery.

Website | | 77 E Palatine Rd. Prospect Heights, IL 60070-1811 | (800) 292-1493

Founded in 2000, S & G Press & Machinery Sales operates worldwide, buying and selling used stamping and manufacturing equipment; specializing in metal stamping presses, feed lines and various types of automation, fabricating and tool room equipment.

Website | |

| 16660 East 13 Mile Rd. Roseville, MI 48066 | (586) 563-5000

Since 1914, SUHNER Automation has been providing economical, low-cost manufacturing solutions and machining units for drilling, milling and tapping operations.

Website | ThomasNet Profile | | 43 Anderson Rd. Rome, GA 30161 | (706) 235-8046

During this year’s [MC]2 2014 MTConnect: Connecting Manufacturing Conference, Siemens announced today the appointment of TechSolve (Cincinnati) as a Solution Partner to offer solutions to customers with Sinumerik CNCs who are interested in or have already implemented MTConnect into their factories. Through this development, Siemens proactively responds to the growing demand in the market for MTConnect solutions among the end-user and machine builder sectors. TechSolve was a Founding Sponsor of the Institute and is a major supplier of MTConnect Adapters, translation products as well as support software and services that enable shops and production departments alike to more efficiently gather and analyze machine tool performance data, using the open-source communication standard of MTConnect.

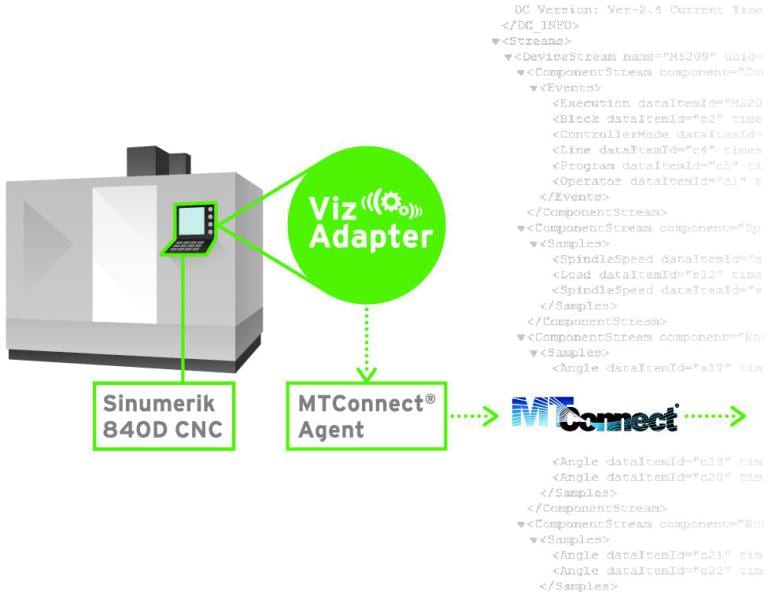

This schematic illustrates the typical scenario for a machine tool control modification at an end-user, where the Siemens CNC is modified with TechSolve Adapter software, allowing machine data to be sent through an agent in MTConnect compatible language. This facilitates a significantly greater degree of information gathering and analysis by the customer, across the open-source standard of MTConnect for greater interoperability between devices and software applications. Machine builders can also make such modifications to their controls, to suit customer needs or respond to market conditions.

In a typical machine tool end-user scenario, TechSolve applies its Adapter software to an existing machine’s CNC, such as the Siemens Sinumerik 840D, which enables data transfer through an MTConnect Agent. For older controls and legacy devices that do not have native communication output, TechSolve can also supply additional hardware and communication software to facilitate this process. The data can then be stored locally or cloud-based for further access and evaluation in an overall equipment effectiveness (OEE) strategy.

Likewise, TechSolve provides Adapter software to machine tool builders for integration into their control schemes to suit particular applications or customer-mandated specifications for MTConnect compatibility.

Ryan Legg, product manager, Sinumerik CNC, Siemens Industry, Inc., explains, “In the U.S. market especially, we are seeing growing demand for MTConnect. This appointment of TechSolve as a Solution Partner to support requests for MTConnect represents our company’s commitment to bring practical solutions to our customers through an experienced and reliable source of both products and services. When MTConnect is written into the specification on any job, we now have an ideal resource to complement our capabilities.”

Noting the open architecture of the Siemens CNC allows easy integration of the TechSolve solutions; Legg further explained the cross-platform advantages of this new relationship. “TechSolve has written their MTConnect Adapter for the Sinumerik CNC

in a way which allows complete flexibility regardless if the system architecture of the Sinumerik employs a PCU or if it is running in an embedded architecture without a PCU. Ultimately, this allows for more customers to take advantage of this offering.”

Ron Pieper, manager, VizProducts™ Group at TechSolve, observes, “To be affiliated with Siemens is a compliment to both of our products and services as well as our engineering talents. We believe this relationship will be mutually beneficial, as it will further promote the acceptance of MTConnect in the machine tool market, plus being a Solution Partner to Siemens will open new doors for our company.”

Pieper further comments on the market need for these solutions. “When all the data from the shop or factory floor is available as it occurs, the customer learns the reality of their situation, then can make confident steps to improve their game, so to speak.

They see where the inefficiencies are, where and why the downtime is occurring and how they might improve or streamline production. All of these factors are crucial in today’s competitive machining market.”

More information on the above-mentioned solutions will be available at the upcoming MTConnect Conference in Orlando, April 8-10, 2014, organized by the MTConnect Institute.

For more information about this announcement, please visit: www.usa.siemens.com/techsolve-pr.

For specific product information and inquiries, call (800) 879-8079 ext. Marketing Communications or send an e-mail to: SiemensMTBUMarCom.industry@siemens.com.

Follow us on Facebook: www.facebook.com/SiemensCNC or Twitter: www.twitter.com/siemens_cnc_us.

—

Siemens Industry Sector is the world’s leading supplier of innovative and environmentally friendly products, solutions and services for industrial customers. With end-to-end automation technology and industrial software, solid vertical-market expertise, and technology-based services, the sector enhances its customers’ productivity, efficiency and flexibility. With a global workforce of more than 100,000 employees, the Industry Sector comprises the Industry Automation, Drive Technologies and Customer Services Divisions as well as the Metals Technologies Business Unit. For more information, visit http://www.usa.siemens.com/industry.

The Siemens Drive Technologies Division is the world’s leading supplier of products, systems, applications, solutions and services for the entire drive train, with electrical and mechanical components. Drive Technologies serves all vertical markets in the production and process industries as well as the infrastructure/energy segment. With its products and solutions, the division enables its customers to achieve productivity, energy efficiency and reliability. For more information, visit http://www.usa.siemens.com/drivetechnologies.

TechSolve is a consulting firm that has helped organizations of all sizes leverage process improvement, machining expertise and innovation to enhance their competitive edge across ever-changing markets. We understand engineering and manufacturing, so we developed an array of machine monitoring software under the umbrella of VizProductsTM.

Our custom-tailored machine-monitoring and data-gathering solutions enable shops and production departments alike to more efficiently gather and analyze machine tool performance data, TechSolve can help manufacturers eliminate extraneous costs, increase productivity, and maximize profits. For more information please visit www.techsolve.org.

No. 910 is a 1000ºF, gas-fired, high-temperature walk-in oven from Grieve, currently used for heat cleaning large valve bodies at the customer’s facility. Workspace dimensions of this oven measure 60” W x 120” D x 78” H. 880,000 BTU are installed in a modulating natural gas burner to heat the oven chamber, while a 12,500 CFM, 10 HP recirculating blower provides combination airflow to the workload.

This Grieve oven features 8” thick insulated walls made from 2” of 1900ºF block and 6” of 10 lb/cf density rockwool; top-mounted heat chamber; 16 ga aluminized steel oven interior, 16 ga stainless steel heat chamber interior and 16 ga aluminized steel exterior. Inner and outer door gaskets are provided, with the inner gasket sealing directly against the door plug and the outer gasket sealing directly against the face of the oven. The 6” insulated oven floor features truck wheel guide tracks and Grieve also furnished the customer an 8000 lb capacity flatbed loading truck with this walk-in oven.

All safety equipment required by IRI, FM and NFPA Standard 86 for gas-heated equipment are provided on the oven, including a 1500 CFM, 2 HP powered forced exhauster.

Controls on No. 910 include a digital programming temperature controller.

For more information, please contact:

THE GRIEVE CORPORATION

500 Hart Road

Round Lake, IL 60073-2898

Phone: (847) 546-8225

Fax: (847) 546-9210

Web: www.grievecorp.com

Email: sales@grievecorp.com

Attention: Frank Calabrese, VP

Ann Arbor, Michigan – GMTA (German Machine Tools of America) represents various top-quality German metalworking machine builders, including Wera Profilator, Pittler, Praewema and WMZ. These machines are sold to the North American market by GMTA primarily for gear and spline production, as well as other power transmission applications. The company’s target markets include automotive, off-highway, energy and other heavy equipment manufacturing. Machines are provided for gear honing, gear grinding, the patented Scudding® process for gearmaking, polygon milling, turning, gear tooth pointing and multi-task machining operations. This newsletter is provided to our friends in the media to keep you and your readers updated on News of Note at GMTA.

In the news…

– GMTA proudly announces the addition of Stefan Kloos as Product Manager. Stefan will handle the Pittler vertical turning lathes and WMZ centerdrive lathes. He will be based in Ann Arbor, Michigan, North American Headquarters for GMTA.

– German Language and International Careers (LIC) students from Eastern Michigan University visited GMTA on March 12, 2014. Students were given a tour of GMTA facilities and a presentation in German by GMTA President, Walter Friedrich. As EMU Department of World Languages Professor Margrit Zinggeler Ph.D. pointed out, “Eastern Michigan was one of the first universities to combine foreign language with a practical business component. The EMU major in language and international careers (LIC) is designed to integrate the study of modern foreign languages and cultures with preparation for an international business career. The major objective of the program is to provide students with the skills, knowledge and understanding needed to function in a foreign environment and in professional dealings with people and clients who speak a foreign language. It is a very useful course of study in today’s global economy, especially with so many foreign companies setting up shop in the U.S.” After the presentation and questions, students were invited to a typical German “Brotzeit” (evening meal of German bread and coldcuts) and, of course, ample quantities of German beer Reissdorf Koelsch! GMTA is proud to support young people in the community and help provide them with (German) language opportunities in a business environment.

Students from Eastern Michigan University’s Language and International Careers (LIC) program visited GMTA for a detailed explanation in German from the company president, Walter Friedrich, right. Leading the group was Professor Margrit Zinggeler, Ph.D., third from the right

– A definitive explanation on the trademarked Profilator Scudding® process for advanced gearmaking is now available from GMTA. Please contact Scott Knoy below for details.

– GMTA supports the Judson Center, a charity that serves the needs of individuals with life challenges such as autism. Every year, the Center tries to provide the youngsters served with a life-changing event. This year, the Center is providing 150 bicycles. GMTA is part of a group of companies supplying the bikes, along with GM Warren Transmission and local radio station, 95.5 WYCD Detroit Country. Claudia Hambleton coordinated the effort for GMTA.

For more information on this announcement, please contact:

GMTA (GERMAN MACHINE TOOLS OF AMERICA)

4630 Freedom Drive

Ann Arbor, MI 48108

Phone: 734-973-7800

Fax: 734-973-3053

Web: www.gmtamerica.com

Email: scott@gmtamerica.com

Attention: Scott Knoy

Connect with GMTA online:

See Rattunde in Hall 6, Stand E-40 at Tube Fair in Dusseldorf, April 7-11, 2014!

Major German supplier of finished length tube and solid bar processing equipment offers dual tube cutting and finishing in one setup; produces up to 5000 pieces per hour with up to 40% energy savings

Rattunde ACS + CFMtwin machine for simultaneous dual tube processing; can produce up to 5000 parts per hour

Rattunde Corporation, a German-based manufacturer of finished length tube and solid bar production, today announces the introduction of the ACS® + CFMtwin machine, the newest member in the company’s family of tube production systems. Equipped with a specially-designed twin machining head that fits onto the standard head, this new machine can cut two tube or bar sections simultaneously, then machines both ends of both workpieces, also simultaneously. This new Rattunde machine can produce up to 5000 finished pieces per hour. The option also exists for single tube or bar production on the same machine.

The ACS® + CFMtwin machine, when in twin mode, can process two workpieces of 10mm to 41.5mm OD each into finished lengths from 10mm to 1500mm. Example: 21mm OD x 3.5mm wall x 45mm length cut from a 6.5 meter mill length of stock material, based on carbon steel. When the twin head is removed, the standard machining head can process a single workpiece up to 105mm OD.

In addition to the twin workpiece processing, this new Rattunde machine offers the OEM or production house all the capabilities found on Rattunde’s ACS® family of tube and bar production systems, including secondary brush deburring, end machining (chamfering and facing), inspection, washing, drying and robotic packaging. The entire machine and all auxiliary workstations are motion-controlled by CNC from a single operator station for maximum efficiency. The ACS® + CFMtwin is built on the same platform as the existing and popular Rattunde ACS® + CFM and ACS + CFMcurve systems.

Even when processing in twin mode, the setup time for a new job can be under 15 minutes, according to Rattunde engineering. Other standard features on this new Rattunde machine include data management on all workpiece parameters (approx. 10,000 workpieces), data logging of every part produced for full part traceability, material lead and end edge detection for minimized crop cut and tag end. All operating limits are set from the control panel, with continuous tool break monitoring for the saw blade and all cutting tools.

Each end of the two workpieces is simultaneously chamfered before automated transfer to the cleaning and final packaging stations

Alec Banish, director of business development at the company, states, “This new machine clearly gives us a decided advantage in the market for high-production requirements. Plus, with the standard machining head still in place on the machine, the ACS® + CFMtwin can be a highly flexible, adaptable production system for many types of manufacturing operations as well as a wide variety of end product producers.”

Because the machine offers essentially double the production in the same machine footprint, up to 40% energy savings have been documented on a 25mm OD x 3mm wall x 42mm long piece from a stock length of 6 meters in a typical batch count of 45,000.

For more information on this development, please contact:

RATTUNDE CORPORATION

4980 Kendrick Street SE

Grand Rapids, Michigan 49512

Phone: 616-940-3340

Fax: 616-940-2771

Web: www.rattunde-corp.com

Email: company@rattunde-corp.com

Attention: Richard Stadler or Alec Banish

Siemens brings a full complement of solutions and services with its value proposition to the North American conveyor sector of the material handling industry

Siemens is offering conveyor technology for material handling, to all builder, system integrator and end-users of both discrete and process manufacturing markets. An integrated drive system with Siemens motion control and drives products, along with communication protocols, is available. It spans the range of drives, motors, gear motors and automation technology, plus machine safety, power supply and circuit protection.

As a longtime supplier to the global conveyor and material handling industry, Siemens brings this offering to the North American market with the full support of its global network of engineering, sales, service and technical support.

Advantages for machine builders

Siemens brings a flexible and field-tested portfolio of products and software services to the builders of material handling equipment in all industries. Free design tools allow a more efficient process in customer design, configuration and product selection, plus communication and energy calculation.

When a large or multi-unit system is needed, the advantages of Siemens distributed control and common DC bus afford many with an economical solution to material handling. This translates to a lower installation and commissioning cost.

Through the OEM Partner Program, machine and equipment builders benefit from the global experience of Siemens. Machine conversion services, design tool-kits, global coordination for companies seeking more international business including full standards compliance, co-marketing opportunities and assistance in emerging markets are among the many services provided by the global team of Siemens.

Advantages for system integrators and end-users

Whether a greenfield project or brownfield expansion of an existing material handling machine or full production line, Siemens integrated drive systems bring a full portfolio of products and automation solutions to the task. In the field, fast commissioning is provided by a team of qualified personnel, resulting in quicker start-up and less downtime.

The preventive maintenance and remote diagnostics software combine to keep equipment running more productively. The recent expansion of our popular drives platform to include PROFINET, PROFIBUS, EtherNet / IP and AS-interface allow Siemens drives to communicate with other brands of existing products or new components on the customer’s line, resulting in cost savings and greater efficiencies.

Siemens can satisfy an array of typical material handling scenarios, as it supplies a full range of products and services to create the ideal solution for the customer.

Siemens products for material handling applications include:

Gear motors

Recently established in Greenville, S.C. to better serve the North American market, the Simogear gear motor facility assembles energy-efficient gear motor units commonly found in material handling. Simogear can be combined with Sinamics drives to suit a broad range of applications — from the low-speed uses (0.1–1000 rpm) to the most challenging, high-torque demands.

Siemens is in the forefront of the evolution from worm to helical bevel gear motor utilization in the material handling world, as this technology means less motor power is needed to produce the same output torque and speed. This translates to smaller units with higher efficiency and overall lower cost.

Drives

The complete family of Siemens Sinamics drives means a single source for a broad assortment of product solutions, globally recognized and capable of controlling virtually every application in material handling, from basic roller tracks to multi-axis, high-bay racking units, all with high-dynamic performance.

Central and decentralized drives are highlighted by the Sinamics V20, G120C and G120D. All are space-saving and offer a variety of communication, programming and control capabilities. In addition, the decentralized Sinamics G120D can be machine-mounted and is suitable for tough environments.

Controllers, I/O and Software

Simatic S7 PLCs offer both PAC and PLC reliability in their performance with modular and PC-based options.

Distributed I/O from Siemens is useful in all conveyor, sorting and assembly operations, plus is offered in space-saving compact or modular form factors.

Simatic software includes operator control and monitoring systems with a single software environment for every automation task. Totally Integrated Automation (TIA) means over 100,000 Siemens products share a core intelligence.

Additional products available in the Siemens suite include RFID code systems, industrial PC’s, various HMI options for panel mount and portable use, full wireless automation and motion control communications hardware, safety devices and power management switchgear, measuring and monitoring.

For more information, videos and to download the relevant brochure, please visit: www.usa.siemens.com/conveyor-pr

For specific product information and inquiries, call (800) 879-8079 ext. Marketing Communications or send an e-mail to: SiemensMTBUMarCom.industry@siemens.com.

Continue reading

Did you miss Siemens at AeroDef 2014? Here’s what you missed!

At this year’s AERODEF conference in Long Beach, California, Siemens will demonstrate new CNC solutions and services for machine tool builders and end-users. Under the theme, “Productivity in motion,” the presentation will focus on turnkey solutions for the aerospace manufacturing industry.

For the aerospace market, the Sinumerik 840D sl offers the latest in CNC technology that increases machine tool performance and user productivity. The 840D sl is a universal and flexible CNC system based upon the innovative Sinamics S120 drive platform that can be used for up to 31 axes. It is a distributed, scalable, open and inter-connecting system offering a wide range of specialized functions for milling, drilling, turning, grinding, handling and robotics technologies. It offers users innovative features that increase productivity on the manufacturing floor, especially the challenging aerospace segments of high-speed and five-axis machining.

For the job shop, the Sinumerik 828D numerical control is the ideal CNC solution for mid-range machine tools. It is designed to address the needs of complex milling and turning machines in the job shop segment by combining CNC, PLC, operator panel and axis control for six CNC measurement circuits into a single, robust operator panel.

The 828D is capable of full graphical, high-level language command and supports ISO programming that is customary in the United States. Programming time can be further reduced for small-batch production with the use of the ShopMill and ShopTurn graphical workstep programming system, while high-level language programming can be used in conjunction with programGuide to significantly reduce programming times for large-scale serial production.

With the introduction of the Sinumerik 828D, extensive online help animations and a new type of input prompting system with moving picture sequences provide the basis for exceptional user convenience. USB, Compact Flash (CF) card and Ethernet ports enable high-speed data transfers onto storage media or integration of the control system into corporate networks.

SOLUTIONS FOR CNC TRAINING

Recently introduced to the American machine tool industry, and based upon the new Sinumerik Operate graphical user interface, SinuTrain is the ideal solution for control-identical CNC training.

With SinuTrain, actual NC programs are developed and simulated, to speed the program generation protocol. In this manner, machine tool operators not only learn the control language commands, but they also visualize part programs on a PC screen that are identical to the machine tool’s screen. As an additional benefit, programs generated through SinuTrain can then be used on actual machines.

Offered in several languages, SinuTrain is available for different needs and budgets including a trial version, a study version, a single-user license and an educational license.

For more information about advanced CNC solutions for the aerospace industry,

please visit: www.usa.siemens.com/aerodef-pr.

Download this article as a PDF: Siemens AeroDef14

Download the Siemens Aerospace Brochure: Siemens Aerospace

Download the SINUMERIK Integrate Run MyRobot Brochure: SINUMERIK Run MyRobot

For specific product information and inquiries, call (800) 879-8079 ext. Marketing Communications or send an e-mail to: SiemensMTBUMarCom.industry@siemens.com.

Follow us on Facebook: www.facebook.com/SiemensCNC or Twitter: www.twitter.com/siemens_cnc_us.

—

Siemens Industry Sector is the world’s leading supplier of innovative and environmentally friendly products, solutions and services for industrial customers. With end-to-end automation technology and industrial software, solid vertical-market expertise, and technology-based services, the sector enhances its customers’ productivity, efficiency and flexibility. With a global workforce of more than 100,000 employees, the Industry Sector comprises the Industry Automation, Drive Technologies and Customer Services Divisions as well as the Metals Technologies Business Unit. For more information, visit http://www.usa.siemens.com/industry.

The Siemens Drive Technologies Division is the world’s leading supplier of products, systems, applications, solutions and services for the entire drive train, with electrical and mechanical components. Drive Technologies serves all vertical markets in the production and process industries as well as the infrastructure/energy segment. With its products and solutions, the division enables its customers to achieve productivity, energy efficiency and reliability. For more information, visit http://www.usa.siemens.com/drivetechnologies.

Continue readingDid you miss Siemens at AeroDef 2014? Here’s what you missed!

Technology breakthroughs establish new flexibility and productivity paradigms for working with 2D data and massive assemblies. New functionality expands NX leadership in freeform shape design, PLM integration, and product development decision making.

AeroDef 2014 – The latest version of Siemens NX™ software (NX 9) includes new capabilities and technological breakthroughs that deliver enhanced product development flexibility and up to five times higher productivity across multiple industries. New tools like synchronous technology for 2D greatly facilitate 2D data editing. The introduction of fourth generation design (4GD) technology will enhance design productivity for massive assemblies.

And NX Realize Shape™ software delivers a new state-of-the-art freeform design toolset with unmatched product development integration. NX 9 also includes tighter PLM integration through Siemens’ Active Workspace environment, as well as multiple enhancements throughout the integrated CAD/CAM/CAE solution. The enhancements in NX 9 are aimed at creating value by addressing issues common to multiple industries such as automotive, aerospace, shipbuilding, consumer products, machinery and others.

“NX 9 represents a very significant step forward for Siemens, our customers, and for product development in general,” said Jim Rusk, senior vice president, Product Engineering Software, Siemens PLM Software. “With significant new breakthroughs such as synchronous technology for 2D, 4GD and NX Realize Shape, we are offering our customers unprecedented design flexibility while significantly increasing their product development productivity. And by leveraging our successful Active Workspace solution, we are enhancing the high definition user experience that helps our customers make smarter decisions that result in better products.”

While 3D modeling is the preferred method of product design throughout the world,

2D drawings and 2D product data – in a wide variety of digital formats – are still used in virtually every industry in some aspects of product development. Unfortunately, due to incompatible data structures and inconsistent CAD technology, working with these 2D files is typically tedious and time consuming. Synchronous technology for 2D eliminates these problems by adding intelligence to 2D data without the need for translation, enabling users to intuitively edit multi-CAD 2D files up to five times faster. This can be particularly useful for industries such as automotive, aerospace, machinery and others with large amounts of legacy 2D product data.

“Siemens’ synchronous technology for 2D is a Next Generation 2D tool that ad- dresses many of the downfalls of drafting and sketching,” said Chad Jackson, Principal Analyst for Lifecycle Insights, a leading PLM research and advisory firm. “It ‘understands’ the geometric relationships inherent in 2D drawings and applies user-controlled assumptions at the point of change to enable intelligent modifications. It also applies these assumptions locally instead of globally to ensure fast performance.”

The new NX Realize Shape offering in NX 9 provides a unique freeform design environment for producing products with highly stylized shapes or complex surfaces. It is the industry’s only solution that seamlessly integrates the most advanced, easy-to-use, flexible tools for performing freeform design, with a leading CAD/CAM/CAE software package. As a result, companies producing a wide variety of consumer products – as well as those in the aerospace, medical and marine industries – can shorten product development time by eliminating the multiple steps associated with using separate tools for freeform design and engineering development.

Hundreds of additional enhancements throughout NX 9 touch every aspect of CAD, CAM and CAE. The introduction of 4GD, a new design and data management paradigm that enables versatile and efficient methods for collaboration and design-in- context, accelerates the development of complex large-scale products containing millions of components. The embedding of Active Workspace 2.0, the innovative new interface to Siemens’ Teamcenter® software, enables NX 9 users to quickly find relevant information – parts, tasks, workflows, requirements and specifications – even from multiple external data sources.

New NX CAE tools improve thermal simulation of aircraft engines, reducing the time to setup complex boundary conditions by 75 percent. A new NX CAE parallel thermal solver provides improved performance on large-scale models delivering faster results. Enhancements in NX Nastran® software, the premier FEA solver for computational performance, accuracy, and scalability, enable noise, vibration and harshness (NVH) simulation times to be cut in half.

New capabilities in NX for manufacturing provide enhanced control for faster and more flexible CAM and CMM programming. For die/mold machining, the new cut region management capability provides graphical user interaction for more efficient programming, up to 40 percent faster for some complex parts, and precise control over machining strategies. The new multiple-part programming capability lets programmers reuse machining sequences across any number of similar parts in a setup. For example, a setup with six identical parts can be programmed up to four times faster. The new MRL Connect for NX, connects NX CAM directly to the Manufacturing Resource Library (MRL) in Teamcenter to give programmers easy access to a shared library of standard tools, fixtures, and templates. The CMM Inspection Programming capabilities have been expanded beyond solids to support sheet metal parts, delivering manufacturers in the aerospace and defense, high tech electronics, and automotive industries a highly automated inspection programming solution.

NX 9 is available immediately. For more detailed information on all the new functionality in NX 9, please visit www.siemens.com/plm/nx9.

Download this article as a PDF: NX 9

Download th

About Siemens PLM Software

Siemens PLM Software, a business unit of the Siemens Industry Automation Division, is a leading global provider of product lifecycle management (PLM) software and services with seven million licensed seats and more than 71,000 customers worldwide. Headquartered in Plano, Texas, Siemens PLM Software works collaboratively with companies, delivering open solutions to help them make smarter decisions that result in better products. For more information on Siemens PLM Software products and services, visit www.siemens.com/plm

For more information on Siemens SINUMERIK CNC, visit www.usa.siemens.com/cnc.

For specific product information and inquiries, call (800) 879-8079 ext. Marketing Communications or send an e-mail to: SiemensMTBUMarCom.industry@siemens.com.

Follow us on Facebook: www.facebook.com/SiemensCNC or Twitter: www.twitter.com/siemens_cnc_us.

—

Siemens Industry Sector is the world’s leading supplier of innovative and environmentally friendly products, solutions and services for industrial customers. With end-to-end automation technology and industrial software, solid vertical-market expertise, and technology-based services, the sector enhances its customers’ productivity, efficiency and flexibility. With a global workforce of more than 100,000 employees, the Industry Sector comprises the Industry Automation, Drive Technologies and Customer Services Divisions as well as the Metals Technologies Business Unit. For more information, visit http://www.usa.siemens.com/industry.

The Siemens Drive Technologies Division is the world’s leading supplier of products, systems, applications, solutions and services for the entire drive train, with electrical and mechanical components. Drive Technologies serves all vertical markets in the production and process industries as well as the infrastructure/energy segment. With its products and solutions, the division enables its customers to achieve productivity, energy efficiency and reliability. For more information, visit http://www.usa.siemens.com/drivetechnologies.

Continue readingDid you miss Siemens at AeroDef 2014? Here’s what you missed!

AeroDef 2014 – Siemens Industry Software announced today availability of a new version of their leading Operations Management System for Assembly and Complex Manufacturing.

Already an established benchmark in the market, the introduction of version 3.2 of this comprehensive suite consolidates Siemens at the forefront of production optimization software for the discrete manufacturing industry.

Whether you are looking to reduce the complexity of your IT landscape, increase the agility and flexibility of your manufacturing facilities, render your production processes transparent and measurable, shorten time-to-market, streamline the link between shop-floor and supply chain or adapt to new regulations, SIMATIC IT is the right choice for your business.

The biggest opportunity for manufacturers lies in their ability to Continuously Innovate in a Consumer-driven market on a Global basis. This requires that manufacturing facilities are seamlessly integrated into both the PLM and Supply Chain processes, and this is where SIMATIC IT is of unique interest, for only Siemens has a comprehensive portfolio of Industry Software seamlessly integrating PLM, MOM and Automation functionality.

SIMATIC IT ACM functionality includes:

SIMATIC IT ACM is part of the full Siemens Manufacturing Operations Management portfolio. The full range of SIMATIC IT products includes:

For more information about SIMATIC IT, please visit www.siemens.com/simaticit

Download this article as a PDF: SIMATIC IT ACM

Download the SIMATIC IT Assembly & Complex Manufacturing Brochure: SIM ATIC IT ACM

Download the SIMATIC IT Line Monitoring System Brochure: SIMATIC IT LMS

For inquiries, send an e-mail to: industrymanagement_simatic.it@siemens.com

Follow us on Twitter: www.twitter.com/simaticit

For more information on Siemens SINUMERIK CNC, visit www.usa.siemens.com/cnc.

For specific product information and inquiries, call (800) 879-8079 ext. Marketing Communications or send an e-mail to: SiemensMTBUMarCom.industry@siemens.com.

Follow us on Facebook: www.facebook.com/SiemensCNC or Twitter: www.twitter.com/siemens_cnc_us.

—

Siemens Industry Sector is the world’s leading supplier of innovative and environmentally friendly products, solutions and services for industrial customers. With end-to-end automation technology and industrial software, solid vertical-market expertise, and technology-based services, the sector enhances its customers’ productivity, efficiency and flexibility. With a global workforce of more than 100,000 employees, the Industry Sector comprises the Industry Automation, Drive Technologies and Customer Services Divisions as well as the Metals Technologies Business Unit. For more information, visit http://www.usa.siemens.com/industry.

The Siemens Drive Technologies Division is the world’s leading supplier of products, systems, applications, solutions and services for the entire drive train, with electrical and mechanical components. Drive Technologies serves all vertical markets in the production and process industries as well as the infrastructure/energy segment. With its products and solutions, the division enables its customers to achieve productivity, energy efficiency and reliability. For more information, visit http://www.usa.siemens.com/drivetechnologies.

Continue readingMost standard products available from Chicago inventory

Heimatec, a world leader in live tools, angle heads and multi-spindle drill heads, today announces immediate availability of BMT (Base Mount Tooling) standard products from inventory at its Chicago-area headquarters for the North American market.

In addition to standard X and Z axis tools, styles such as adjustable tools, speed increasers and internal coolant tools with capabilities to 140 bar (2000 PSI) are now available in an assortment of standard BMT tooling types, including BMT 45, 55, 65 and 75.

All Heimatec BMT tooling is supplied with the company’s unique U-Tec® flexible machining system, which provides extremely high power transmission via polygonal drive. Integrated collet nut, with easy changeout, can convert the output to arbor (for face mills), Weldon or ER collet extensions. The U-Tec® system further allows the cutting tool to be in closer proximity to the bearing, which results in much higher rigidity. The cutting tools last longer and yield an improved finish, as a result of this Heimatec design feature.

All Heimatec BMT tooling is manufactured at the company’s home facility in Germany and is now carried in inventory in the Chicago-area facility, which serves the North American machine tool market.

Heimatec products are sold through authorized sales representatives and machine tool distributors in North America.

For further information and literature, or to arrange a demo of this product line, please contact:

Preben Hansen, President

HEIMATEC INC.

16 E. Piper Lane Suite 129

Prospect Heights, IL 60070

Phone: 847-749-0633

Fax: 847-749-2445

Email: info@heimatecinc.com

Website: www.heimatecinc.com