Contact us today:

(847) 934-4500

tdaro@bernardandcompany.com

Contact us today:

(847) 934-4500

tdaro@bernardandcompany.com

13-year-old student visits Forest City Gear to explore career options; meets many women already succeeding in “a man’s world”

Accompanied by her grandfather, Brian Cluff, vice president of Star-SU, a major gearmaking machinery and tooling supplier, Alexi Cluff toured Forest City Gear to see the manufacturing world and discuss the options there for young women. Alexi, though only 13, is currently enrolled in an advanced engineering class at Northern Illinois University, designed to encourage more young women to explore engineering and science as a career.

Roscoe, IL-Forest City Gear frequently opens its doors to visitors, usually from customer and prospect companies, as well as international trade associations, the media, vendors and occasionally competitors. Company owners Fred and Wendy Young have always believed this policy was beneficial to the visitors, who see some of the industry’s finest gearwork, produced and validated for quality on absolute state-of-the-technology, world-class equipment.

On March 30, 2011, however, another visitor came to tour Forest City Gear with a slightly different agenda. 13-year-old Alexi Cluff, accompanied by her grandfather Brian Cluff, vice president of Star-SU, a leading supplier of gearmaking machinery and tools, visited Forest City Gear to learn about manufacturing and especially to explore the options for women in manufacturing, an environment traditionally thought to be “a man’s world.”

Alexi is not your typical 13-year-old. She is currently enrolled in a program sponsored by a grant from the Motorola Foundation and conducted at the College of Engineering and Engineering Technology at Northern Illinois University. The program is a workshop in partnership with NIU-Enhanced Engineering Pathways, the Society of Women Engineers and the Girl Scouts of Northern Illinois. The stated objective of the program is to challenge and sharpen the skills of accelerated learning for 12- and 13-year-old girls selected by their local middle school science and math teachers. Currently, 48 girls work in small groups, assisted and taught by NIU women engineering professors and women engineers from various industries. These instructors mentor the girls on various engineering projects, from the building of simple electrical circuits to create sound, motion and light, to bridge building, chemical engineering and lean manufacturing simulation. The groups meet on Saturday mornings on the NIU Napervillie (IL) campus and also attend a summer camp, held each June.

Forest City Gear President Wendy Young conducts the tour through the plant, showing Alexi Cluff the many types of machines used to produce and validate quality on the company’s high-precision gearwork.

Often, the groups or individual students have tours arranged for them at local area manufacturing locations such as electronics and communications giant Motorola, where they can absorb “real world” experiences and especially meet women of all ages who have succeeded in the various disciplines required in a manufacturing environment. Since Alexi’s grandfather had a long working relationship with Forest City Gear, he reached out to Fred and Wendy Young to arrange a tour. The Young’s obliged, giving the young lady a complete tour of their factory and quality lab, plus arranging a roundtable discussion with a number of the women at the company, who perform all categories of activity for Forest City Gear. A world leader in precision gear manufacturing, Forest City Gear has an international reputation for “excellence without exception,” which happens to be the motto of the company.

Women from all departments of the company, including application engineering, human resources, gear grinding, gear deburring, gear hobbing, order processing, estimating, expediting, procurement, materials inspection, quality validation, machine set-up and company management were at the table. Alexi’s eyes and ears were wide open, as she listened attentively to every word.

Seated at the table for Forest City Gear, in addition to Wendy Young, president, were Kika Young, Geneva Parr, Mary McClellan, Krista King, Sharyl Stewart, Lori Lovett and Ingrid West. These women are involved in literally every aspect of the company. As Mary McClellan mentioned, “We touch the products at every step of the process, especially me (in gear deburring), because of my little fingers!” These women were unanimous in their advice to Alexi Cluff. “Always be willing to learn more, never be afraid to speak up with your ideas, bring all your skills to the job, every day, and don’t hesitate for ask for directions…something men never do!” They all had a good laugh.

Alexi said, “I’ve always been interested in making things and finding out how they work,” a sentiment her grandfather echoed. “I started making gears when I was 14 and it’s fascinated me, ever since.” If there’s anything to that old adage about the genes skipping a generation, perhaps the gear industry will have another Cluff in its future!

Forest City Gear CEO Fred Young explains some of the company’s gear successes to Alexi Cluff at the company’s display showcase.

At the end of the roundtable, Forest City Gear CEO Fred Young had some comments. He detailed the difference in the European education model, where there’s considerably more encouragement given to young women to explore any and every working option. In America, he noted, “Our greatest strength came from manufacturing, the basic ability to make things better and faster than anybody else. The value-added service of making something from raw materials is what builds a nation’s wealth and makes us more self-reliant. Letting go of manufacturing would be a big mistake. By learning and using the technology we develop, as well as what we can gather from other countries, we’ll make America a stronger nation and more successful, in the long run.”

Following the visit, her grandfather remarked to Forest City Gear President Wendy Young, “Alexi was excited and, on the way home, quite animated. The sharing time with your ladies impressed her immensely. She has been journaling her observations. She told us in the car on the way back home that the very first class she had at the NIU workshop for girls was a hands-on exercise in lean simulation and that what she saw at Forest City Gear, from the way the routing sheets, bar codes and processing were set up, that you obviously have implemented lean manufacturing practices! As she downloads, processes and articulates what she saw and observed, she has already started to ask me questions about gear geometry. Such sweet candy to this old grandpa!”

At this roundtable discussion, Alexi Cluff listened as women from every department of Forest City Gear spoke of their roles at the company and the many opportunities for women in the traditional “man’s world” of manufacturing. Many of these women are the lead or key individual in their respective departments at the company.

In reviewing the NIU program and the comments above, perhaps it’s possible Alexi Cluff actually IS your typical 13-year-old girl. They just need to be shown their options.

Forest City Gear was founded in 1955 by Stetler and Evelyn Young, parents of the current CEO, Fred Young, who runs the company with his wife, President Wendy Young. Forest City Gear is considered among the premier gearmakers in the worl

d, with successes ranging from the Mars Rover to the BMW/Oracle, winner of the America’s Cup.

Brian Cluff and his longtime colleague and partner, David Goodfellow, manage and operate Star SU LLC, located in Hoffman Estates, IL. The company sells various leading brands of gearmaking machinery, other machine tools and a proprietary line of cutting tools.

Here is a link to the news release about the program on the NIU-EEP website (www.niu.edu/eep): http://www.niu.edu/PubAffairs/RELEASES/2008/nov/scouts.shtml

For more information on this story, please contact: FOREST CITY GEAR CO., INC. 11715 Main Street Roscoe, IL 61073-0080 Phone: 815-623-2168 Fax: 815-623-6620 Web: www.forestcitygear.com Email: wyoung@forestcitygear.com Attention: Wendy Young, President

PR agency contact for Forest City Gear: Tim Daro Bernard & Company 847-934-4500 tdaro@bernardandcompany.com

Continue reading

International firm uses robotic ultrasonics and conventional machine tools to supply product, usually with 24-hour turnaround; achieving near 24-7 unattended operation with over 15 percent reduction in scrap material on very expensive substrates.

OpenHealth, one of the world’s leading providers of business and technical solutions to the dental healthcare industries, was formed by the owners of five major international dental lab groups — Aurum, Cordent, DTS, Race and ZMC — who combined to harness the strategic synergies of their respective lab and milling center services. The milling and technology business, under the brand name of Core3D Centres and operating six facilities, brings the OpenHealth group’s expertise and comprehensive service package to labs, dentists and educational institutions in 15 countries on three continents.

We interviewed Tim McKimson, Core3D’s Worldwide Director of Engineering, at OpenHealth’s Las Vegas-based Core3D facility, located near the prestigious Las Vegas Institute for Advanced Dental Studies (LVI), where restorative and cosmetic dental techniques are taught to practicing dentists and lab technicians, Here, Core3D provides a full range of CAD/CAM/CNC machining and finishing services to LVI and dental labs across the United States. Led by technical operators Mark Ferguson, Danny Palomares and Drew Hrubes, the Core3D team prepares CAD files developed from data typically gathered with an iTero oral scanning wand or from CAD files from scans of conventional dental impressions from the patient’s mouth, which are then digitally captured in a dental scanner from companies such as 3shape. CADENT and other software are typically used to image the impression and begin the process of creating the crown, bridge, abutment, coping, implant or even full denture restoration, as required by the individual lab. 3D CADENT files are G-coded at a remote location of the parent company for transfer to the CNC machine tools at the various Core3D facilities worldwide.

The next step is translation of the digital impression to a RenShape® mold, using conventional machine tools. In most cases, the required structures are designed simultaneously, then the mold with coping is introduced to the DMG Sauer ultrasonic dental machine for preparation of the final structures. This is where the most advanced substrates are processed, ranging from conventional, yet difficult to machine metals such as titanium and cobalt chrome, to the newest advanced materials, including glass ceramics, lithium disilicate and zirconia. These substrates are quite expensive, therefore extreme care is taken in their handling and processing to reduce scrap and conserve operating costs.

As McKimson explained, the decision to cut with ultrasonic technology was relatively easy, given the inherent wear conditions and high cost of conventional tooling. In the ultrasonic process, a combination of electrolysis and fluid lubrication act in concert to create an ionic attraction of particles, removing material in a highly predictable and accurate manner, without the mechanical stress implicit in conventional machining techniques. As a result, the surface of even the hardest materials can be machined with the necessary tactile smoothness required for dental implants.

The extremely hard materials being machined are produced with accuracies in the 2-4 micron range, owing to the combination of ultrasonic technology and the high precision of the Sinumerik CNC, according to McKimson, who notes the reliability of this accuracy has been a significant advantage in reducing scrap at Core3D.

In another area of the facility, conventional mills are used to make polyurethane models and Wieland Zeno 4820 and 4030 mini-milling machines are also utilized for the production of various crowns, wax/resin forms and models, veneers, inlays and implant abutments.

As evidence of the decidedly international nature of this emerging dental giant, all the zirconia and lithium disilicate materials are provided in the IPS e.max System from Ivoclar Vivadent, a company based in Liechtenstein. The company has branches in the United States and Canada, which supply the Core3D Centres in those countries. The templates and cutting tools are closely controlled and validated by the manufacturer to ensure that the preparation of these materials in dental applications is properly executed.

In commenting on the use of the DMG Sauer ultrasonic machines, McKimson notes that it was the machine builder who recommended the Siemens control. “They knew we were dental technicians and engineers, not machinists, by nature. The Siemens control has been extremely easy-to-use and our training time from the builder was minimal. Troubleshooting is mostly done by our operators, with only occasional assistance from Siemens.” Danny Palomares, one of the technical operators, agrees. “My training is in the dental lab world, not on machine tools. It was a great relief to have such a sophisticated control operate with relatively simple language commands and cycle adjustments.”

While there are substantial differences between the European and American dental labs in terms of the materials and assembly techniques used, and despite the fact that literally all projects are highly customized based on the individual needs of the patients and the preferences of the labs and those of the dentists performing the procedures, in the end, the typical project is being turned in 24 hours or less.

For Core 3d Centres, utilizing the best-in-class equipment is critical. In complement the quality machines here, a key part of the overall efficiency protocol in the Core3D network of companies, McKimson points out, is the “know-how” provided through their CAM-DO committee. This global technical committee conducts regular online meetings to discuss what’s working and what’s not in their various worldwide operations and then optimizes and standardizes the processes. He recalls one unanimous vote of approval was voiced on the performance of the DMG Sauer ultrasonic machines with Siemens controls. Core3D currently has nine such machines in their network, all used to process the most advanced materials.

® RenShape is a registered trademark of Huntsman Corporation.

For more information on this story, please contact:

Core3D Centres

Tim McKimson

Engineering Technology Director

5955-2 Wigwam Avenue

Las Vegas, NV 89139

Toll-Free: 1-888-750-9204

Phone: 702-750-9204

http://www.core3dcenters.com/

tmckimson@core3dcenters.com

OR

Siemens Industry, Inc.

John Meyer

Manager, Marketing Communications

390 Kent Avenue

Elk Grove Village, IL 60007

(800) 879-8079 ext. Marketing Communications

www.usa.siemens.com/cnc

SiemensMTBUMarCom.industry@siemens.com

Follow us on Facebook: www.facebook.com/SiemensCNC or Twitter: www.twitter.com/siemens_cnc_us.

—

Siemens Industry Sector is the world’s leading supplier of innovative and environmentally friendly products, solutions and services for industrial customers. With end-to-end automation technology and industrial software, solid vertical-market expertise, and technology-based services, the sector enhances its customers’ productivity, efficiency and flexibility. With a global workforce of more than 100,000 employees, the Industry Sector comprises the Industry Automation, Drive Technologies and Customer Services Divisions as well as the Metals Technologies Business Unit. For more information, visit http://www.usa.siemens.com/industry.

The Siemens Drive Technologies Division is the world’s leading supplier of products, systems, applications, solutions and services for the entire drive train, with electrical and mechanical components. Drive Technologies serves all vertical markets in the production and process industries as well as the infrastructure/energy segment. With its products and solutions, the division enables its customers to achieve productivity, energy efficiency and reliability. For more information, visit http://www.usa.siemens.com/drivetechnologies.

Continue reading

Hunter XL2024 matchplate molding system, just purchased by Travis Pattern & Foundry to boost their production. This is the fourth Hunter machine now in operation at Travis.

Spokane foundry, largest privately-owned aluminum caster west of the Mississippi, adds to its already impressive capacity with new matchplate molding system

Schaumburg, Illinois (USA)-Travis Pattern & Foundry Inc., a major producer of aluminum castings for the irrigation, power transmission substation and general-purpose fittings markets, as well as the originators of Li’l Mac sinker molds for the fishing industry, announces its purchase of a fourth Hunter matchplate molding system, the XL2024. According to Gene Johnson, project manager at Travis, “This new line will expand our already substantial casting capabilities for aluminum, as well as brass and cast iron work. We’re seeing an upturn in our business and purchased the machine in anticipation of increasing demand.” The machine is scheduled to be operational by the end of March, 2011.

The XL2024 is a fully automated matchplate molding system, using gravity-fill technology pioneered by Hunter. It produces sand molds up to 20” x 24” with shallow 6-1/2” cope and 5-1/2” drag (165mm/140mm) at 180 cycles per hour, using 400 lbs. (181kg) of sand. Variable squeeze surface pressure to 142 psi (10kg/cm2) can be achieved in production.

Travis Pattern, founded in 1922 and now a fourth-generation company, is the largest privately-owned aluminum caster (over 7,000,000 lbs./3,181,818kg annually) west of the Mississippi and boasts a network of affiliated companies through which their castings are marketed. The company also produces a variety of brass and cast iron products. Travis products are sold throughout North America.

Gene Johnson further described his company’s use of their Hunter molding systems. “We typically run jobs in the hundreds up to 1000 pieces. The fast pattern changeover and the flexibility of the Hunter system really speeds our production.” He estimated approximately 90% of the jobs run on the new Hunter machine will be aluminum, with the balance being brass.

For further information on this announcement, interested parties may contact: TRAVIS PATTERN & FOUNDRY INC. 1413 E. Hawthorne Road Spokane, WA 99218-3100 Phone: 509-466-3545 Fax: 509-467-6465 Web: www.travispattern.com Email: tpfgj@travispattern.com

Attention: Gene Johnson, Project Manager

Or

HUNTER AUTOMATED MACHINERY CORPORATION 2222 Hammond Drive Schaumburg, Illinois 60196-1094 USA Phone: +1 847 397 5136 Email: kpurdy@hunterauto.com Web: www.hunterauto.com Attention: Kevin Purdy, Vice President

Editor Note: Please direct all publication-generated inquiries to Kevin Purdy at Hunter. Thanks!

Agency contact for Hunter: Tim Daro Bernard & Company Palatine, Illinois (Chicago) USA +1 847 934 4500 tdaro@bernardandcompany.com www.bernardandcompany.com

Travis Pattern produces a variety of aluminum, bronze and cast iron products at its 220,000 sq. ft. complex in the Spokane, Washington area. Sand casting, permanent mold and no bake operations are conducted here, as well as machining, heat treating and galvanizing.

Continue readingMajor Indian caster anticipates dramatic improvement in surface quality and production rates from new Italian grinding/fettling center

Mr. N. Krishna Samaraj, managing director for Magna, stated it was the company’s expectation that this machining system, scheduled for start-up after July, 2011, will result in significant improvements in the surface quality and production rates at the company. Magna is a vertically integrated foundry, as it performs various machining, surface treatment and heat treating operations, in addition to its full foundry capabilities for various products sold to the valve, refrigeration, rail, hydraulics, automotive, wind turbine and other industries worldwide.

Magna runs a fully automated sand prep and mold line, as well, using equipment from its longtime supplier, Hunter Automated Machinery, who represents Maus in various world market areas. Magna currently runs a Hunter HMP20E Automatic Molding Machine (1994) and an HLH 20 Type II mold handling system (2007).

The sale of this Maus grinding/fettling machine was finalized between Mr. N. Krishna Samaraj for Magna and Mr. Ashwin Katke of Carraro, the parent company of Maus, with offices in India.

For further information on this announcement, interested parties may contact:

MAGNA ELECTRO CASTINGS LIMITED 43, Balasundaram Road Coimbatore – 641 -018 Tamilnadu, India Phone: +91 4322 2240109 Email: magnacast@vsnl.com Web: www.magnacast.com Attention: Mr. N. Krishna Samaraj, Managing Director

Or

MAUS SpA Via Caltana, 28 35011 Campodarsego Padova, Italy Phone: +39 0499299311 Sandra Selwan, Marketing Manager Sandra_Selwan@maus.it www.maus.it

Or

HUNTER AUTOMATED MACHINERY CORPORATION 2222 Hammond Drive Schaumburg, Illinois 60196-1094 USA Phone: +1 847 397 5136 Email: kpurdy@hunterauto.com Web: www.hunterauto.com Attention: Kevin Purdy, Vice President

Editor Note: Please direct all publication-generated inquiries to Kevin Purdy at Hunter. Thanks!

Agency contact for Hunter: Tim Daro Bernard & Company Palatine, Illinois (Chicago) USA +1 847 934 4500 tdaro@bernardandcompany.com

GM realizes “weeks to hours” reduction in line change and transmission build dynamics at Toledo Powertrain, resulting from Flexible Assembly Configuration System (FACS) and Siemens control/communication

A tried and true euphemism nowadays, “thinking outside of the box” usually refers to a pattern of thought or action that results in rapid innovation, enhanced relationships being developed from established concepts as well as new ones, plus a genuine willingness to forego past practices in favor of a better way. Enter the GF6 six-speed, front wheel transmission line at General Motors Powertrain on Alexis Road in Toledo, Ohio.

Here, a new front wheel drive transmission line for smaller, more fuel efficient vehicles such as the popular Chevy Malibu and new Chevy Cruze is currently ramping up to its initial goal of 2200 units per day. Nothing new about such an event, until a closer look reveals the method used to program this line, implement changeover, stage the workpiece flow, perform all machining, secondary operations and assemble the finished transmissions.

Greg Nazareth, GM controls engineer, demonstrates the reconfiguration procedure on the FACS server, part of the overall Flexible Assembly Configuration System, provided by Elite Engineering of Rochester Hills, Michigan.

During the development of this line, several years ago, GM engineering contacted its longtime controls suppliers to investigate ways of significantly reducing the workflow through the line, as well as enable faster changeover, reduce reprogramming and prevent the curse of all automated manufacturing lines, situations where one out-of-spec machine caused complete shutdown. Another key driver in the development of the GF6 line was the need to minimize maintenance time by installing PLCs, drives and component pallet recognition devices outside the conventional cabinetry found on traditional assembly lines. In addition, controllers were distributed throughout the system, which allowed for removal of typical zone controllers and, in turn, substantially increased system flexibility.

Following considerable investigation into the process for the new line, the major obstacle remained changeover and the need for a more flexible yet highly automated system of transmission builds. In consultation with the controls provider on the existing six-speed, rear wheel drive line, Siemens Automotive Center of Competence (Troy, Michigan), as well as third party software package provider, Elite Engineering (Rochester Hills, Michigan), a deterministic study was undertaken and the result was the line now in production. Siemens provided the PLC, CNC, HMI, RFID and its high-level Ethernet protocol, Profinet, to run on the GM network. Overlaying this hardware and communications topology, Elite Engineering delivered its Flexible Assembly Configuration System (FACS), complemented by Siemens to create its SIFACS solution, wherein all the control elements for every assembly operation and test stations would be fully integrated. SIFACS largely focuses on the integration of the core PLC software blocks and functionalities of the individual stations with the RFID tags on each of the workpiece pallets, according Jim Remski, manager of powertrain activities for Siemens.

Siemens CNC and HMI technology combine with its Profinet high-level Ethernet communications and RFID pallet tags to execute the machining, assembly and testing at this transmission plant, currently targeting an output of 2200 units/day.

AN INTEGRATED APPROACH

Within any flexible automated assembly system, the keyword is flexible. All hardware and related software must be designed with a deterministic functionality that is both valuable to the customer’s build strategy and cost-competitive, as well. Working with technical specialists in safety integrated systems and industrial communications alike was the key to the success of this project at GM Toledo. By creating a decentralized control network that was nonetheless in complete harmony with the overall workflow of the plant, GM and Siemens devised the optimum modular yet flexible architecture for the entire system. This totally integrated automation approach not only addressed multiple families of hardware involved, it also coordinates all code development, safety and communications functions into a seamless and interdependent yet highly flexible and adaptive control scheme.

This integration is nowhere more visible than in the modular and open controller and I/O rack assemblies located throughout the facility. A Siemens Simatic® S7 CPU, the Siemens Safety Integrated drives platform and all I/O, including RF antennas for RFID tag reading are configured and reside here.

Diagnostics in the system are similarly integrated, according to Matthew Thornton and Jeremy Bryant, who consulted from Siemens. “We devised pre-made templates and blocks important to the powertrain build process, as our starting point,” commented Thornton, who further noted the importance of placing the critical performance data on all the HMI panels in the system for easy operator access. “With all motion and safety functions integrated into the drives, there was no need to build a separate troubleshooting architecture for what would be a more traditional safety network of relay cabinetry.”

Bryant continued, “Only a few components talk on the Profibus system, all other I/O and automation components communicate over Profinet.

Reinhold Niesing of the Siemens Automotive Center of Competence further explained the contact process between his group and the provider of the FACS. “They provided the configuration and monitoring system, while we (Siemens) provided the automation run time system. Both systems needed to run in sync to provide GM with configurable options, when changes in production or manufacturing enhancements were needed.”

Each RFID tag carries all the information needed to produce the part at each of the machining and assembly stations in the line.

The result of this collaboration, coordinated under the Siemens Transline solution, whereby all operational, visualization and diagnostic functions are streamlined in a consistent control scheme, was the Transline HMI Lite CE package. This package provides uniform user interface for operational and diagnostic functions on the vast majority of the various machine tools, transfer lines, robotics, assembly machines, sensing devices and vision systems throughout the entire facility. As Michael Grass, project manager for Siemens, explains, “The best part is that the package can be customized to meet specific user needs and preferences. It provides our SIFACS (see sidebar) system of configurable assembly automation very useful information, as the two systems complement each other quite well.” In the safety communications area, he also noted that GM is currently reviewing another Siemens option for open safety communications technology on distributed automation systems.

RFID GETS THINGS STARTED

As a workpiece proceeds through the line, having been delivered by an AGV in most cases, each pallet is equipped with an RFID tag. Reinhold Niesing, engineering manager on the project for Siemens, explains, “The key here is the data throughput in the system, as it directly impacts the cycle time or takt time (maximum allowable time to produce one finished part or product) of the line. The tags must be able to function in static mode, whereby the data on the part must be read before the process begins. Model number, serial number and build status information are all contained in the tag. The faster we read the information, the faster the process begins.” Niesing also detailed the dynamic mode of operation for this RFID system, in which the information at subsequent line stations must be read “on the fly” without any line stoppage, as is often seen in conventional packaging, shipping or other line applications for RFID. In this case, all data are read as the tag passes by the antenna.

Often, in less sophisticated applications, the signal can degrade over time and number of reads. Here, according to the Siemens technical specialists, two interface protocols are supported, namely, ISO 15693 (open standard) and a proprietary Siemens-developed standard, Simatic RF300. The latter uses a state-of-the-art chip paired with highly optimized communications to achieve the faster data read/write rates. Large amounts of data (64kB) are handled in faster cycle times, while the overall RFID solution is applied in a high-speed, non-stop environment. One of the key drivers in the system is the fact that each RFID tag has both EEPROM and FRAM. The 20-byte EEPROM is actually designed to be a one-time programmable memory chip (OTP), a security feature that was deemed most desirable by GM for this application. Meanwhile, the FRAM can be written and rewritten many times for optimum utilization of the hardware, over time.

Despite this level of sophistication in the RFID hardware, the system easily communicates over the existing Profinet, Profibus and other common protocols.

LOGIC BLOCKS ALL AROUND

The overall thrust of the line development, according to George Jewell, the GM engineer responsible for the implementation of the FACS online at the Toledo plant, was to have consistent, even identical logic blocks at every station. This would allow, as is seminal to the FACS architecture, immediate successive modifications to be made in the machine or assembly operations performed, throughout all stages of the line. When rebalancing was needed, when an upturn/downturn in current production was required or when an entirely new model came onto the line, the changeover needed to happen in hours, rather than in weeks, as was the industry norm.

By standardizing on the hardware, software and communication protocols used, engineering costs could be contained and, as a collateral but vital side effect, maintenance on the system could be made much more efficient with much of the system hardware exposed on the line, rather than enclosed in electrical cabinets, again the norm for the industry in the past. Flexible modules would allow more rapid reconfiguration, product changes and a genuine synergy with the ongoing GM commitment to continuous improvement in the line, as the new GF6 transmission ramped up to incremental target levels of production.

Jewell noted that Siemens responded to the challenges, “…with a plug-and-play technology approach, coupled with an understanding of the processes we utilize.”

From the utility perspective, he also noted that the run-time component in the system would function without the full configuration system being online, further complementing a decentralized architecture. Bob Raven, GM controls manager, further commented, “The Siemens commitment to provide this value added functionality geared towards flexibility within our manufacturing principles has substantially supported GM Powertrain’s efforts to standardize processes, controls and continuously improve.”

Currently, GM uses the FACS at various plants in Mexico, China, India, Thailand, Korea and the U.S. — and soon in Canada and Eastern Europe, for the production of transmissions, engines and even the generator on the new Chevy Volt. These products, it should be noted, can be manufactured, assembled and tested, all within the same flexible control architecture, while supporting standardized GM processes.

Rather than textbook product life cycle management, Jewell sees FACS as more of a production line life cycle management tool, as its inherent adaptability means common hardware can be made to do diverse tasks, at varying rates, with on-the-fly changeover, in far less time than previously possible.

TYPICAL STATION DYNAMICS

On one automated assembly station, Hanwha produces the various sub-assemblies of the transmission, as other lines produce the components that go into the sub-assemblies. Adding a station, as Greg Nazareth, GM controls engineer, explained, requires simply adding a PLC with the standard SIFACS logic, desired process devices and downloading an eFACS configuration. In contrast to the traditional zone control, this reconfiguration is not a building block concept; rather, the instructions being given impact the entire line. Nazareth worked with the full GM controls team, headed by Ron Goeckerman, to implement FACS with the host server.

By contrast, all manual workstations on this line have the same download received to a PLC, provided by Siemens in its Simatic lines. While not reliant on the server network in a deterministic mode, the manual stations nonetheless utilize the same software to execute quick tooling changes, machine sequence variations, line balancing and report tracking. Operators received training from both Siemens and Elite Engineering personnel for these tasks.

All part build histories, troubleshooting and machine debugging are recorded for further analysis.

CONTROLS CALL THE BALL AT EVERY STEP

Throughout the metalcutting process here, mostly in the gear and spline forming, hobbing, grinding and finishing, CNC technology is onboard dozens of machine tools. Most of the machines here are controlled by Sinumerik® 840D, the highest-level CNC offered by Siemens. The control not only processes the particular part dimensions in the cutting theater of the machine, it also coordinates all motion control and movements into and out of the machine. Working in tandem with the other hardware and communication network software in the line, for example, ring gears cut on a Wera Profilator machine are indexed from one station to the next, in timed sequences, to coordinate with predetermined production requirements. This operation occurs in a fully automated mode, requiring no operator intervention, except for maintenance and planned inspections.

Likewise, in the machining of valve bodies and transmission cases, each step of the process is controlled by the Siemens CNC to produce the required components in the proper sequence for subsequent assembly and testing operations. During those subsequent operations, other motion control devices and software solutions provided by Siemens execute, monitor and control the assembly process, through the SIFACS solution set. (See sidebar.)

PROFINET TALKS THE TALK

Through a decentralized and cabinet-less design, GM achieves highly integrated RFID control with easy access and true out-of-the-box solutions for the control architecture installed on this line. A Profinet solution provides GM with a high-performance, reliable network with minimum bandwidth impact or additional network load achieved at this plant, all with no special hardware required, a further cost savings for GM.

SAFETY FIRST — AND LAST

Safety features are numerous here, resulting in a complete failsafe system across all Siemens Simatic PLC, I/O devices and safety-integrated drives. All safety devices are networked over Profisafe protocol, a certified safety network, eliminating time-consuming and difficult to maintain traditional hardwired safety connections. All safe I/O, failsafe drives are part of the Siemens Totally Integrated Automation (TIA) protocol. Since it is fully integrated, this protocol provides comprehensive system diagnostics,

Rear wheel drive, six-speed line has been in full production, while the new line is producing front wheel drive, six-speed transmissions for vehicles such as the Chevy Malibu and new Cruze models.

which can help guide maintenance staff to exact fault location and mitigate downtime. Since the drives, starters and machine safety are integrated into the multi-functional machine mount I/O system, Simatic ET 200pro, the overall engineering complexity is reduced because of simplicity in panel design, wiring architecture and seamless integration to the project level hardware configuration, which is reduced due to the totally integrated automation design. For service requirements in the event of a fault, hot swapping of an I/O module is possible during operation, without switching off the entire station. There is nonetheless a very high degree of integral protection, to IP65/67 standards. The fact that an enclosure is not required also helped save on the total cost of the project for GM.

MAJOR INVESTMENT PAYING OFF

Between the two lines here, GM Toledo has invested $872 million on its six-speed, rear- and front-wheel drive transmission production at this 2 million square-foot facility, which currently employs 1400 employees, most members of UAW Local 14.

The highly fuel-efficient rear-wheel drive Hydra-matic 6L80 transmission is now joined by the GF6 front-wheel drive, six-speed

units being produced on this new line under the FACS control solution that supports flexible manufacturing while driving standard processes.

As George Jewell, the GM engineer who spearheaded the implementation of FACS, stated, “From our first installation in Ramos Arizpe (Mexico) to this Toledo plant, we’ve seen great results, with activities that took months reduced to weeks and what took weeks reduced to hours. There’s less ramp-up time, plus the changeover and line balancing upsides are already proving this was a beneficial investment.”

Please direct all inquiries generated by this story to:

John Meyer

Siemens Industry, Inc.

Marketing Communications

390 Kent Avenue

Elk Grove Village, IL 60007

Phone: 847-640-1595

Fax: 847-437-0784

Email: SiemensMTBUMarCom.sea@siemens.com

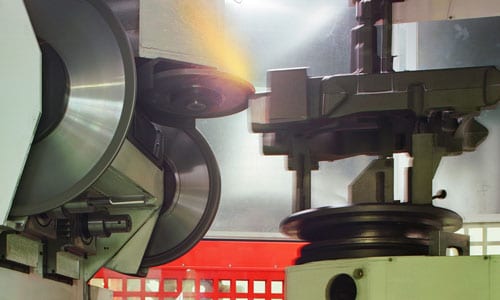

Wera Profilator gear profiler run by a Sinumerik 840D, the highest level CNC in the Siemens line, used for fully automated production of ring gears.

SIFACS — THE SIEMENS SOLUTION FOR THE FLEXIBLE ASSEMBLY CONFIGURATION SYSTEM (FACS)

Working in tandem with GM process specialists and Elite Engineering, the third party provider of the unique Flexible Assembly Configuration System (FAC

S) used at this GM Toledo transmission plant, Siemens personnel created SIFACS, a solution that integrates the host IT system at the facility with all hardware and software in the line.

SIFACS is quite literally the hub of the information management system for this line, as it coordinates all demand input from the GM server and FACS configuration stations, transmits it via the Profinet communications network in the plant to all the onboard PLC, HMI, motor starters, frequency converters, safety-integrated drives and other controls at the various machine tool, assembly and test stations.

Likewise, the feedback data from all RFID, smart sensors, RS-232 interfaces, hand scanners and other I/O devices are tracked and captured for detailed analysis by production management here.

In this way, not only is the system’s production output closely controlled, but also the line stations themselves can be reconfigured, using a unique Siemens micro memory card that allows easy component replacement, without a laptop. All PLC logic, hardware configuration and process data are embedded on the card, which is interfaced to three Ethernet and one Profibus ports for instant communications.

Critical for a continuous moving line such as those found here, the Siemens Simatic control systems are executing motion commands read from the RFID devices at 8000 bytes/sec, far in excess of the ISO 15693 standards for read and write performance.

SIFACS HMI screen extensions with Cognex Vision View further permit constant monitoring by both a team leader and a conveyor controller, eliminating a PC dedicated to a vision system.

All the smart devices on the line are also interfaced to the SIFACS solution, including fastening, leak test and pressing systems, plus barcode readers, barcode printers, robotic articulation and handling devices, vision systems and protocol gateways.

eFACS functionality is finally integrated into the SIFACS, as this feature of the Elite Engineering system provides connection establishment and monitoring, as well as configuration, process and status data exchanges, plus management of the model configuration data, all stored on the system.

On the most practical of levels, even the data structures feed to the Andon boards for in-plant display is integrated through the resident IT system via SIFACS.

Process Improvement Tools and Process Efficiency Tools, provided with the FACS, enable both process and production engineers to collect data and fine tune the system in real time, keeping build status and cycle time information always current. Line and station balancing can likewise be achieved on-the-fly, with complete process efficiency, operator loading, anticipated cycle time, even individual process operation time calculations being made, charted, displayed and rapidly analyzed by the team leader or station control personnel, in a hierarchy of need-to-know, need-to-act protocol.

The net effects of the Siemens SIFACS® system and the Elite eFACS are sustainable, highly flexible production scenarios, coupled with lower life cycle costs, as the controls and station hardware need not be re-invented for each new model, as well as lean manufacturing strategies, since the line can be constantly tuned without interruption. The flexibility, data analysis and transparent metrics of these systems further allow all employees to understand the current line performance in real time and to make suggestions for improvements that can be implemented almost immediately.

“It’s a win-win-win for all parties involved,” commented George Jewell of GM, whose team pioneered the development and application of these systems for his company’s various plants. Further advancements in FACS and SIFACS are currently being introduced at other GM facilities worldwide, according to Jewell.

For additional product information and inquiries:

SIEMENS INDUSTRY, INC.

DRIVE TECHNOLOGIES

MOTION CONTROL

MACHINE TOOL BUSINESS

390 Kent Avenue

Elk Grove Village, IL 60007

Phone: 847-640-1595

Fax: 847-437-0784

Web: Email: SiemensMTBUMarCom.sea@siemens.com

Attention: John Meyer, Manager, Marketing Communication

Follow us on Facebook: www.facebook.com/SiemensCNC or Twitter: www.twitter.com/siemens_cnc_us.

—

Siemens Industry Sector is the world’s leading supplier of innovative and environmentally friendly products, solutions and services for industrial customers. With end-to-end automation technology and industrial software, solid vertical-market expertise, and technology-based services, the sector enhances its customers’ productivity, efficiency and flexibility. With a global workforce of more than 100,000 employees, the Industry Sector comprises the Industry Automation, Drive Technologies and Customer Services Divisions as well as the Metals Technologies Business Unit. For more information, visit http://www.usa.siemens.com/industry.

The Siemens Drive Technologies Division is the world’s leading supplier of products, systems, applications, solutions and services for the entire drive train, with electrical and mechanical components. Drive Technologies serves all vertical markets in the production and process industries as well as the infrastructure/energy segment. With its products and solutions, the division enables its customers to achieve productivity, energy efficiency and reliability. For more information, visit http://www.usa.siemens.com/drivetechnologies.

Continue readingNo. 863 is an electrically-heated 1400°F(~760°C) box furnace from Grieve, currently used for preheating molds. 52 KW are installed in nickel chrome wire coils supported by a stainless steel frame. A

The unit has 7” thick insulated walls with stainless steel covers. The oven was specially built with inert atmosphere construction. This consists of a continuously welded outer shell, high temperature door gasket, sealed heater terminal boxes, inert atmosphere inlet and inert atmosphere outlet.

Controls onboard No. 863 include a motor-operated vertical lift door and a 4-point strip chart recorder.

For more information, please contact: THE GRIEVE CORPORATION, 500 Hart Road, Round Lake, Illinois 60073-2835 USA. Phone: (847) 546-8225. Fax: (847) 546-9210. Web:www.grievecorp.com. Email: sales@grievecorp.com. Attention: Frank Calabrese.

Continue readingNo. 983 is an electrically-heated 550°F(~287.78°C) bench oven from Grieve, currently used for curing medical instruments. 3KW are installed in Incoloy sheathed tubular heating elements.

The oven has 3” insulated walls, a Type 304, 2B finish stainless steel interior and a #4 brushed finish stainless steel exterior. Two 13” x 4” access slots are equipped with insulated covers on the rear wall of the oven. An 8” x 10” double-pane Pyrex window is used for viewing the oven chamber. An interior oven light is also provided.

Controls onboard No. 983 include recording and programming temperature controllers and a recirculating blower for this oven.

For more information, please contact: THE GRIEVE CORPORATION, 500 Hart

Road, Round Lake, Illinois 60073-2835 USA. Phone: (847) 546-8225. Fax: (847) 546-

9210. Web: www.grievecorp.com. Email: sales@grievecorp.com. Attention: Frank

Calabrese.

-0-

Photo enclosed

Significantly reduces inventory, changeover time for lathe and mill/turn users

See the U-Tec video HERE.

Heimatec, a world leader in live tools, angle heads and multi-spindle drill heads, today announced immediate availability of its newest development, recently unveiled at IMTS.

U-Tec® is the company’s patented flexible tool adapter system that allows a standard ER output live tool to accept various adapters for different applications. This allows users the ability to have quick changeover of tools on almost any lathe, using a single live tool, without having to commit to a quick-change system on the initial purchase. A facemill adapter, for example, can be quickly positioned into the standard holder, without the need for a completely new base being installed. This significantly reduces inventory costs as well as changeover time, for the busy shop.

The U-Tec® system, according to Heimatec Inc. President Preben Hansen, “…represents a real improvement in lathe and mill/turn tooling design. U-Tec® allows great user flexibility, while a polygonal drive system ensures extremely high power transmission stability and faster set-up with absolutely no loss in performance or accuracy, because the live tool base remains in position and only the adapter and collet get swapped.”

He went on to explain the unique collet nuts on the U-Tec® system have internal threading for rigid mounting and that this new tool adapter system enables the actual cutting tool to be brought into closer proximity to the bearing, thus further improving performance in use. This benefit results from the short and compact tool length design. Internal coolant up to 2000 psi(140 bar) is provided standard.

Every adapter in the U-Tec® system comes complete with any necessary clamping nuts and adapters are immediately available in face mill style, ER extensions, side lock, shrink fit, hydraulic and blank.

The U-Tec® system is available for all major turning machines on the market today. Heimatec currently manufactures over 10,000 live tool types.

For further information and literature on this new product, please contact:

Preben Hansen, President

HEIMATEC INC.

16 E. Piper Lane Suite 129

Prospect Heights, IL 60070

Phone: 847-749-0633

Fax: 847-749-2445

Email: info@heimatecinc.com

Website: www.heimatecinc.com

—

Heimatec is an international tooling manufacturer, based in Renchen, Germany. Its experienced staff is dedicated to providing customers the most innovative tooling technology possible. In 2010, the company opened Heimatec Inc. in Prospect Heights, IL, near Chicago, to serve its growing North American customer base with sales and service, plus an extensive inventory of products. Heimatec serves the auto, aero, medical, off-highway, rail, energy, woodworking, composites and other industries, as well as an ever-increasing number of machine tool OEM’s worldwide.

Continue readingNo. 898 is an electrically-heated 650°F(~343.3°C) universal oven from Grieve, currently used for heat depyrogenation. 12 KW are installed in Incoloy sheathed tubular heating elements. Workspace dimensions are 36” wide x 36” deep x 36” high. The unit has 6” insulated walls and a type 304, 2B finish stainless steel interior and an aluminized steel exterior.

A 600 CFM, 1/2-HP recirculating blower provides universal airflow to the oven. The oven is also equipped with positive latching door hardware, a solenoid operated door lock and an integral leg stand. Safety equipment is included for handling flammable solvents and the floor of the oven contains an explosion venting panel.

Controls onboard No. 898 include a digital indicating temperature controller, motor control push buttons and an on-off heat switch.

For more information, please contact: THE GRIEVE CORPORATION, 500 HartRoad, Round Lake, Illinois 60073-2835 USA. Phone: (847) 546-8225. Fax: (847) 546-9210. Web: www.grievecorp.com. Email: sales@grievecorp.com. Attention: Frank Calabrese.

Continue reading

At this manufacturing location, unlike a conventional parallel orientation assembly line, the frame and the axles move perpendicular to the work stations, on rail track-mounted dollies. Owing to the highly customized nature of the RV industry, it is frequently necessary for one-off assembly operations to be performed in sequence, as the content of a day’s quota. Plus, given the height of the units, these work platforms are invaluable assets to the production process at the company. In this case, work platforms were engineered and built to enable faster access from both sides of the unit.

With the work platform concept, the units can now be rolled from one station to the next, allowing the various build-ups to occur in sequence. As each step in the manufacturing process is completed, the entire work platform is raised. Because of the length of the platforms, (up to 30’) and the weight load bearing requirements (typically several hundred lbs. of materials and 1-2 workers per side), stability was a key issue.

One of the engineers at the integrator comments, “We’d seen the cylinder rod lock concept in a trade magazine article and contacted Advanced Machine & Engineering to discuss our needs. On each corner of the lifting system, the rod lock would need to attach to the platform and a separate rod installed for the Amlok.”

The Amlok® design, originated by AME, allows free movement of the cylinder during normal operation. When the lift system is stopped or when air pressure is lost, the locking mechanism secures the load in position until released by the return of air

The Amlok rod locks used in this application are the company’s fourth generation design and prevent the typical problems encountered with most large scale air movement systems, namely, over-travel, bouncing, drifting and reverse travel. The patented intensifier mechanism of the AME rod lock is spring-operated to lock and is released by normal 60-160psi air lines. These devices were deemed both cost-effective and functionally desirable for the work platform application at the RV builder.

On this project, AME supplied the rod locks, mounting brackets and all hardware, while the integrator supplied the controls, pressure valves and all pneumatic circuitry to match the plant’s existing air lines, which were substantial, given the number of air tools used in the manufacturing process here.

Following the installation, the RV builder commissioned an independent engineering firm to fully certify that the work platforms met all relevant codes. This certification has been received.

Worker satisfaction with the system and the platform stability has been found to be very high, as well.

For technical questions on this story or the Amlok devices, please contact Ken Davis (ken@ame.com) or Shane Hatfield (shane@ame.com), the AME engineers on the project.

—

Advanced Machine & Engineering Co., is a manufacturer located in Rockford, IL, serving the Machine Tool Industry with precision components and accessories, including spindle interface components, workholding devices, and, through our sister company, Hennig, machine enclosures, chip removal and filtration systems. The Fluid Power – Safety markets are served with cylinder rod locks and safety catcher devises; and the Production Saw market with our Amsaw carbide saw machines and Speedcut blade products. AME has manufacturing partners and customers around the world and across the U.S. To learn more, visit www.ame.com.

Hennig, Inc. design and produces custom machine protection and chip/coolant management products for state-of-the-art machine tools. Hennig products are designed to protect against corrosion, debris and common workplace contaminants. Manufacturing facilities located in the U.S., Germany, Brazil, India, Japan, China and South Korea. Repair centers are located in Machesney Park, IL; Chandler, OK; Livonia, MI; Blue Ash, OH; Mexico City, Mexico and Saltillo, Mexico. To learn more, visit www.hennigworldwide.com.

For more information, contact:

Tim Waterman

ADVANCED MACHINE & ENGINEERING CO.

2500 Latham St.

Rockford, IL 61103

Phone: 815-316-5277

Fax: 815-962-6483

E-mail: info@ame.com

Connect with AME online: