Contact us today:

(847) 934-4500

tdaro@bernardandcompany.com

Contact us today:

(847) 934-4500

tdaro@bernardandcompany.com

Low-cost kits allow easy-to-install, direct mounting of G120C Compact and G120 PM240-2 modular drive

Available in power ranges from ½ to 200 hp and voltages from 230V to 690V, the kits offer streamlined, compact design for use with all drive frame sizes of the corresponding Siemens drive units. Each kit provides best-in-class space-savings and direct access to the drive-mounted operator panel for simple commissioning, condition monitoring and even troubleshooting.

The new kits accommodate all G120C, PM240-2 and PM240P-2 power modules, control units and operator panels in the Sinamics drive family. Standardized designs permit efficient side-by-side mounting with minimal clearance, while multiple conduit knockout holes allow separate power, motor, I/O and network cabling.

Seven kits are currently available to fit all drive units from AA to F frame sizes.

Siemens offers seven sizes of NEMA 1/UL Type 1 wall-mounting kits for its popular G120C and PM240-2 modular drives. The kits feature space-savings plus multiple knockouts for separate power, motor, I/O and network cabling.

For specific product information, please visit: www.usa.siemens.com/sinamics-g120

Siemens Digital Factory (DF) offers a comprehensive portfolio of seamlessly integrated hardware, software and technology-based services in order to support manufacturing companies worldwide in enhancing the flexibility and efficiency of their manufacturing processes and reducing the time to market of their products.

Siemens Corporation is a U.S. subsidiary of Siemens AG, a global powerhouse focusing on the areas of electrification, automation and digitalization. One of the world’s largest producers of energy-efficient, resource-saving technologies, Siemens is a leading supplier of systems for power generation and transmission as well as medical diagnosis. With approximately 351,000 employees in 190 countries, Siemens reported worldwide revenue of $88.1 billion in fiscal 2016. Siemens in the USA reported revenue of $23.7 billion, including $5.4 billion in exports, and employs approximately 50,000 people throughout all 50 states and Puerto Rico.

Continue readingInformation-packed website features complete line of standard, machine brand specific and custom tooling

Heimatec, a market leader in live tooling for the North American machine tool industry, announced the rollout of its new website at www.heimatecinc.com.

The new site offers an in-depth look at the company’s extensive lines of standard and machine brand tooling, including the new Tecnicrafts line of collets and guide bushings, specifically designed for the Swiss machine tool market.

The site includes dozens of downloadable PDF catalogs, as well as an online tool search feature and videos of various live tool demonstrations. A “Contact” page offers customers the option to inquire directly from the site, and easy access to local manufacturer’s representative information. The site is easy-to-navigate and is mobile phone friendly.

Also included in the website is a dropdown section on custom designed tooling, which Heimatec offers in addition to its standard tooling and machine brand specific line. Tooling experts work directly with customers to design solutions to suit specific requirements for all CNC lathes, helping to solve the most challenging applications in multiple markets served by the company.

Heimatec tools offer the highest precision and most advanced technology available in the machine tool accessory market. The company is acknowledged as a world leader in live tools, angle heads and multi-spindle drill heads. With over 40,000 designs in its database, Heimatec offers the widest range of live tooling in the industry.

Heimatec North American distribution headquarters are located in Prospect Heights, Illinois (Chicagoland area) with world headquarters and all manufacturing based in Germany. A team of manufacturers’ representatives covers the North American market for Heimatec.

For more information please contact:

Preben Hansen, President

Heimatec Inc.

16 East Piper lane, Suite 129,

Prospects Heights, IL 60070

USA

Tel: 847-749-0633

www.heimatecinc.com

Product demonstrations and technical presentations from principals impress large crowds; 3D/CT scanners and NEW 3D printer line highlighted

Services on display at the Cincinnati open house included 3D scanning, reverse engineering, quality inspection, instant scan-to-CAD comparison and a full suite of PolyWorks software solutions. Equipment shown at the event included Aicon 3D systems, Breuckmann 3D scanners, Leica Geosystems, Romer and Hexagon brands of scanning devices and related hardware, all of which were available for hands-on use by event attendees. Company representatives from the various equipment lines, as well as Exact Metrology’s team of application engineering and testing specialists, were present for demonstrations and technical presentations, throughout the event.

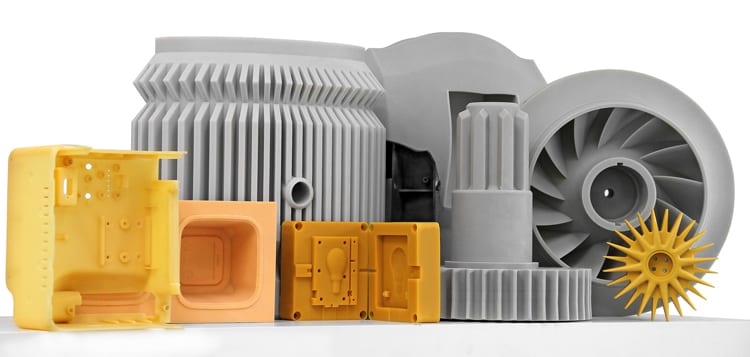

The EnvisionTEC line drew particular attention and Steve Young commented, “This new partner was a natural extension of our service work. We do 3D scanning and were using a 3D printer, so we had that light bulb moment and decided to connect with a 3D printer builder to expand our equipment offerings.” Exact represents EnvisionTEC throughout the Midwest. EnvisionTEC is a Detroit-based builder of various 3D printers for the medical, dental, jewelry and various industrial sectors, offering machines to produce parts up to 18” cube.

As Steve Young further noted commented, “We constantly seek to find the optimum combination of equipment and services to suit the applications and challenges presented by our customers. In some cases, it’s a matter of matching the right standard equipment to the job, while at other times we bring custom solutions and services to our customers, whether they buy, lease or rent equipment or use our services to achieve the desired results on their metrology projects.” Young credited his staff of metrology engineers, technicians and customer service personnel for their hard work, dedication and adaptability in seeking the correct solution to all customer challenges.

During the day, two big screen TV’s were raffled off to attendees, who also enjoyed a tasty pig roast luncheon.

Exact serves both industrial and commercial concerns, ranging from heavy equipment, automotive and appliance companies to nuclear test facilities and even museums, who routinely use metrology to examine artwork such as paintings and sculpture.

Cincinnati Photos:

Subsequently, on May 25, Exact held an open house at its Brookfield, Wisconsin (outside Milwaukee) location.

Attended by 70 companies in the area, the event was hosted by Exact Metrology co-president Dean Solberg in conjunction with Exact partners EnvisionTEC, Hexagon Metrology, PolyWorks, 3DSystems and ETI.

A variety of scanning equipment was demonstrated throughout two rooms in the facility. One highlight of the open house was the new Leica BLK360 Imaging Laser Scanner, a 360-degree scanner that allows high resolution scans for a full-dome in less than three minutes. Other devices showcased included the Hexagon Metrology Romer Absolute Arm, several Artec3D scanners, the Surphaser 100HSX, several Leica long range scanners and the ProCon CT scanner. While demonstration pieces were available to scan, attendees were able to bring in their own parts to show live 3D scanning on the screen.

Also present at the open house was Exact Metrology’s new 3D printer partner, EnvisionTEC, Inc. High-precision, high-detailed models illustrated the 3D printing capabilities of the Detroit-based manufacturer.

The Brookfield open house’s agenda consisted of four breakout sessions with experts in 3D metrology and scanning technology demonstrating their wealth of knowledge on the industry. The breakout sessions happened simultaneously during the day. During one presentation, Jason Reno of PolyWorks talked about what to expect in the industry for 2017. Another session was given by Dave Meyers, a Professor affiliated with Effective Training Inc. He instructed the audience on the use of GD&T Training (Geometric Dimensioning and Tolerancing). Greg George, Corey Mayeda and Mike Tsand from 3DSystems gave a discussion on 3DSystems Software: DesignX and Geomagic.

The guests enjoyed a full spread of delicious food for lunch and were given keepsakes such as mouse pads, pens, coffee mugs, and m&m’s, all with the Exact Metrology logo on them.

Wisconsin Photos:

Exact Metrology is an ISO 9001:2008 and AS9100 Certified Company and is also ITAR Registered.

Exact Metrology, with facilities in Cincinnati and Milwaukee and affiliated offices throughout the Midwest, is a comprehensive metrology services provider, offering customers 3D and CT scanning, reverse engineering, quality inspection, product development and 2D drawings. The company also provides turnkey metrology solutions, including equipment sales and lease/rental arrangements.

For more information on this event or to arrange a demonstration, please contact:

EXACT METROLOGY, INC.

Steve Young

11575 Goldcoast Drive

Cincinnati, OH 45249

Phone: 513-831-6620

www.exactmetrology.com

stevey@exactmetrology.com

Continue reading

New technologies in honing, coatings, coolants, 3D measurement and digital factory solutions were presented by panel of industry experts; attracted 80 attendees

June 7, 2017 – Gehring held its 2017 Honing Conference and Workshops event on May 10-11, 2017 at the Inn of St. John’s in Plymouth, Michigan. The conference and workshops brought together experts from the global industry to discuss and propose solutions to advanced manufacturing challenges in surface finish technology applications. A total of 80 attendees, most from the automotive primes and Tier One suppliers, were treated to two days of learning, networking and fun.

Cope concluded his remarks by noting that Gehring is now a “one-stop shop” for all elements of the honing process – machines, tools, gauging, automation, rework, abrasives, R&D – with global support for global production platforms.

Gehring’s Director of R&D, Michael Schaefer, commented, “Gehring was honored to host this first unique conference, dedicated to Advanced Honing and Surface Finish technology, in the USA and to provide a high level technical and networking platform for professionals in this field with the leading manufacturers in the automotive and other industry sectors.”

During the conference, these presentations and workshops were conducted by industry experts:

-Gehring L.P. and Gehring Technologies GmbH, Michael Schaefer and Dr. Wolfram Lohse, “Advanced Honing Technologies Presentations”

-Oerlikon Metco AG, Wohlen, Dr. Peter Ernst, “Surface Enhancement with Thermal Spray Coatings”

-NanoFocus, Dr. Christian M. Wichern, “3D Surface Measurement of Cylinder Bore and Liners – Advantages and Challenges”

-Quaker Chemical, Frank A. Robinson Jr., “Chemistry and Functions of Honing and Coolant Applications”

-Gehring Technologies GmbH, Marcell Wardin, “Form Honing Cylinder Bores – from Development to Mass Production”

-Gehring Technologies GmbH, Dr. Wolfram Lohse, “Digital Solutions at Gehring”

-Siemens Digital Factory, Dr. Stephan Ihmels, “Mindsphere Application in Large Scale Automotive Production Scenarios”

80 process and manufacturing engineering personnel responsible for surface finishing in automotive, hydraulics, aerospace & defense part applications, including plant managers, production managers and R&D specialists attended this Gehring conference.

The technical program was supplemented by networking events such as the pre-conference “Infinity “chartered dinner cruise with entertainment on the Detroit River and post conference golf, all of which were enjoyed by the attendees.

For more information on this event, please contact:

Rita Conroy-Martin

Director of Marketing

GEHRING L.P.

24800 Drake Road

Farmington Hill, MI 48335

734-926-7538

rconroy@gehringlp.com

www.gehring.de/en

This Grieve oven has 8” insulated walls and a 4” insulated floor. Additional features include an aluminized steel interior and exterior and safety equipment for handling flammable solvents, including explosion venting door hardware.

Controls on the No. 852 include a digital indicating temperature controller & manual reset excess temperature controller with separate contactors.

For more information, please contact: THE GRIEVE CORPORATION, 500 Hart Road, Round Lake, Illinois 60073-2835 USA. Phone: (847) 546-8225. Fax: (847) 546-9210. Web: www.grievecorp.com. Email: sales@grievecorp.com. Attention: Frank Calabrese.

Continue readingEffective immediately, Heimatec Inc., will be selling products from Tecnicrafts Industries, a manufacturer of collets and guide bushings for Swiss Type CNC Lathes.

Tecnicrafts is an ISO 9001:2015 Certified company, with its manufacturing plant in South India with state of the art machine tools and 115 technicians. Tecnicrafts collets and guide bushings are exclusively used for Swiss Turning applications on Citizen-Cincom, Tsugami, Star, Tornos, Hanwha, Traub, Hardinge, Manurhin-Kmx, Miyano, Nomura and other popular machine brands and are widely recognized and accepted by customers in Europe and Asia.

GUIDE BUSHINGS: Tecnicrafts Guide Bushings are generally offered in carbide lining having Super Finish bore with roughness value of less than 0.4 micron. These special guide bushings include U-Line, Extended Nose and Long Carbide Bores (Max Land) for special turning applications.

BAR FEEDER COLLETS: The Bar feeder collets are available for various bar feeders like Fedek, LNS, Ikura-seiki, Iemca, Citizen, FMB and other popular brands.

All Collets and Guide Bushings are offered in Standard and Ultra-Precision grades. The bore profile includes Round, Square, Hexagon, Rectangular and Profile bores as per customer drawings.

Heimatec Inc., with its expertise in precision tooling and having customer representatives throughout North America, is ready to meet the work holding tool needs for Swiss Turning applications with this new Tecnicrafts product line on its roster of quality tooling.

For more information please contact:

Preben Hansen, President

Heimatec Inc.

16 East Piper lane, Suite 129,

Prospects Heights, IL 60070

USA

Tel: 847-749-0633

www.heimatecinc.com

SUHNER presents new grinding, milling and polishing system

Intelligent technology for tool and mold making

In many technical fields, ultrafine grinding is one of the tasks that gives the product its final polish – in the truest sense of the word. This applies equally to both precision and the visual appeal.

One of the leading manufacturers of professional surface treatment tools and machines for over a hundred years, SUHNER now offers an innovative grinding, milling and polishing system, SUNmic 60.

The central element is an intelligent control unit with touch panel that can accept a range of micro motors and tool hand pieces depending on the application. The control part has modern features such as touch screen operation on a glass display, the option to save settings and a rotation speed regulator with tangible resistance.

Key settings are easily legible on a large digital display.

Micro motor system

The actual tools are driven by powerful micro motors whose 280 W place a lot of power in the user’s hand. The compact, brushless BL/DC motors provide an extraordinarily wide speed range of 1000–60,000 rpm and deliver a high torque. In practice, they can be compared with pneumatic technologies but do not need a compressed air supply, operate at lower energy levels and emit virtually zero noise, without exhaust air or oil mist emissions.

One further benefit is that they run virtually free of vibration. The high concentricity safeguards clean and reproducible results in all areas of operation. A special heavy-duty clamping system prevents the millers from shifting. Chuck diameters range from 2.35, 3.0 and 6.0 mm to 1/8 and 1/4 inch.

The new SUNmic 60 micro motor system can be connected to a 90–240 V source, and can therefore be used anywhere in the world. It offers a large number of combinations. The tools range from straight, angle and filing hand pieces to belt grinders. The control unit can be connected to two BL/DC motors and an AC motor.

Advantage: The new control unit is compatible with available micro motors. This is a true multi-purpose tool for many applications.

The new system can be used everywhere a precision finish is desired – for instance, grinding, milling, brushing and polishing in tool and mold making; in aircraft, engine and motor building; in engine tuning; and much more. SUHNER offers a range of matching machines, tools and abrasives that have been tailored specifically to each of these applications. Also an illustrated mold making tool catalog is available.

The new SUNmic 60 micro motor system has been designed for complex milling, grinding, brushing and polishing work in tool and mold making; in aircraft, engine and motor building; and similar applications.

Together with the brushless BL/DC motors, the hand pieces deliver the maximum in performance.

The high concentricity and low-vibration running can only benefit the final results.

The most important properties of SUNmic 60:

Knowhow on site

SUHNER provides demo services for field expertise. This offers interested parties expert advice, free of charge, from experienced field workers. The demo services vehicle carries all the usual tools, attachments and abrasives, plus the right end to end solution can be found directly onsite based on the actual workpieces.

For more information, please contact:

SUHNER Industrial Products, LLC

43 Anderson Road SW

P.O. Box 1234

Rome, GA 30161

Phone 706/235-8046

Fax 706/235-8045

info.usa@suhner.com

www.suhner-abrasive-expert.com

Attention: Aaron Beck, National Sales Manager, Abrasives & Power Tools

New Manual Motor Starter provides manual isolation, manual motor control and overcurrent protection in one unit.

The Ex9S32 Manual Motor Starter is designed to handle more amps and more accessories than previous models offered, while providing increased electrical and mechanical life. The Ex9S32 Manual Motor Starters are electro-mechanical devices that combine a number of functions in one unit, including disconnect for motor branch circuit, manual motor control, branch-circuit short circuit protection (magnetic protection), overload protection (thermal protection – Trip class 10) and switching (manual).

The Ex9S32 is available with up to 32A @600 Vac, UL 508 Type E self-protected combination motor controller (Type F coming soon) and built-in fault indication. The unit also offers a full-range of accessories including undervoltage release contacts, shunt release contacts, power connection adapters, extended rotary lockable handle, and waterproof enclosure.

NOARK Electric (North America), located in Pomona, CA, is a global electrical component and intelligent control system supplier. The company is establishing a representative and distribution network to serve its primary markets, which include the building trades and electric panel board builders in various industries. As a global supplier, NOARK currently operates four R&D centers, three distribution centers, 15 office locations and employs over 1,000 associates. Sales currently exceed $2 billion worldwide.

For more information on this product, consult your local sales representative found at www.na.noark-electric.com or email: nasales@noark-electric.com. Distributor inquiries invited.

Continue reading

This Grieve belt conveyor oven has a 48” long open belt loading zone and a 10’ long insulated heat zone with recirculated airflow. Features include a 30” wide, 1” x1” high carbon steel flat wire conveyor belt with 1/4-HP motor drive, variable from 1.4 to 27 inches per minute. Additional features include 4” insulated walls, aluminized steel interior and exterior and a manually operated vertical lift door at unload with viewing window. The oven also has a photo cell to automatically stop the belt when parts reach the unload position.

Controls on the No. 897 include a digital indicating temperature controller, manual reset excess temperature controller with separate contactors, recirculating blower airflow safety switch and SCR power controller.

For more information, please contact: THE GRIEVE CORPORATION, 500 Hart Road, Round Lake, Illinois 60073-2835 USA. Phone: (847) 546-8225. Fax: (847) 546-9210. Web: www.grievecorp.com. Email: sales@grievecorp.com. Attention: Frank Calabrese.

Continue reading

Leading supplier of 3D printers partners with longtime supplier of metrology equipment

Effective immediately, Exact Metrology is now the greater Midwest dealer for EnvisionTEC, a Detroit-based manufacturer of 3D printers and materials.

Exact Metrology offers a complete line of portable scanning and measurement technologies, as well as contract measurement for 2D and 3D laser scanning services, reverse engineering services, non-contact inspection, metrology services, 3D digitizing and training, long-range scanning plus its CT scanning services, usable by all types of manufacturing, packaging and product integrity concerns, as well as civil engineering, architects and municipal infrastructure developers.

For more information on this agreement, please contact:

Dean Solberg

Exact Metrology, Inc.

20515 Industry Avenue

Brookfield, WI 53045

Local: 262-533-0800

Toll Free: 866-722-2600

www.exactmetrology.com

deans@exactmetrology.com

Or

Steve Young

Exact Metrology, Inc.

11575 Goldcoast Drive

Cincinnati, OH 45249

Local: 513-831-6620

Toll Free: 866-722-2600

www.exactmetrology.com

stevey@exactmetrology.com

Exact Metrology is an ISO 9001:2008, AS9100 Certified and ITAR Registered Company.

Exact Metrology, with facilities in Cincinnati and Milwaukee and affiliated offices throughout the Midwest, is a comprehensive metrology services provider, offering customers 3D scanning, reverse engineering, quality inspection, product development and 2D drawings. The company also provides turnkey metrology solutions, including equipment sales and lease/rental arrangements.

Continue reading