Contact us today:

Author Archives: Bernard and Company

EXCEL ANNOUNCES TWO KEY APPOINTMENTS

Gear/Gearbox company names new manufacturing and marketing managers as growth continues

Excel Gear, Inc. of Roscoe, Illinois announces the appointment of Denis Bermingham as the manager of manufacturing engineering and special projects, plus William “Bill” Powers as the company’s marketing manager. Both appointments were made by company president N.K. “Chinn” Chinnusamy, who noted these hirings were made as the result of the company’s recent growth and anticipated expansion into new market segments.

Bermingham brings a strong engineering background in metalworking and machine tool building to his new position, as well as an extensive knowledge of metallurgy and heat treatment. He will oversee Excel’s manufacturing engineering and special projects, as well as continue the company’s ongoing implementation of lean manufacturing strategies. Denis brings 30 years of manufacturing and machine tool experience to Excel Gear. He worked the majority of his career at Ingersoll Milling Machine in Rockford, IL in the Manufacturing Engineering, Assembly, Engineering, and Prototyping departments. He has a degree in Industrial Technology and will be responsible for the various manufacturing functions at Excel.

He notes, “I joined Excel Gear to become part of the technical/manufacturing environment here. We can offer customers innovative solutions, with excellent quality and value. I’m very excited to be part of this team.”

Powers brings 30 years’ experience in the gear and machine tool business to Excel. Formerly an account manager, project manager and supervisor of customer training with Ingersoll, as well as other metalworking/automation systems firms, he has handled various sales, marketing and customer relations functions, giving him a well-rounded perspective on the dynamics of the industry. He has a degree in Business Administration and will oversee all the marketing and business development for Excel.

Bill observes, “Chinn has structured a first-class company at Excel, supplying engineering-based products, brought to market by a very highly-skilled and dedicated team. All customers receive the highest quality possible, backed by service and application assistance that’s second to none. It’s a great working environment and I look forward to the challenges of our changing markets.”

For more information on these appointments, please contact:

EXCEL GEAR, INC. 11865 Main Street, Roscoe, IL 61073. Phone: 815-623-3414 Fax: 815-623-3314 Web: www.excelgear.com Email: sales@excelgear.com N.K. Chinnusamy, President

ABOUT EXCEL GEAR

Excel Gear brings over 50 years of machine tool experience to the design, manufacturing and quality analysis of its various gear, gearbox, fluid bearing, spindle, CNC gimbal head, nutator and special equipment production. ANSYS software for FEA on stress, strain, deflection, as well as modal analysis, time and frequence domain, our Spindle Analysis Program, MATLAB/Simulink, AutoCAD/SolidWorks/CADAM and other programs are all utilized to effect the best solutions to customer requirements. Excel also builds two-axis CNC gimbal heads with 20,000RPM motorized spindle, 15,000RPM cartridge type spindle assemblies and CNC rotary tables for major machine tool companies. Our high-accuracy gear grinding equipment produces to AGMA 15 (DIN 2) tolerances for quality that meets or exceeds the increasing customer demands for high-speed and high power transmission with smooth, quiet operation. Recently, the company has entered the emerging wind turbine market to provide various gears and gearbox components.

PR agency: Tim Daro Bernard & Company tdaro@bernardandcompany.com 847-934-4500

Continue readingPneumatic Cylinder Rod Locks Hold Platform For Workers At RV Assembly Plant

At this manufacturing location, unlike a conventional parallel orientation assembly line, the frame and the axles move perpendicular to the work stations, on rail track-mounted dollies. Owing to the highly customized nature of the RV industry, it is frequently necessary for one-off assembly operations to be performed in sequence, as the content of a day’s quota. Plus, given the height of the units, these work platforms are invaluable assets to the production process at the company. In this case, work platforms were engineered and built to enable faster access from both sides of the unit.

With the work platform concept, the units can now be rolled from one station to the next, allowing the various build-ups to occur in sequence. As each step in the manufacturing process is completed, the entire work platform is raised. Because of the length of the platforms, (up to 30’) and the weight load bearing requirements (typically several hundred lbs. of materials and 1-2 workers per side), stability was a key issue.

One of the engineers at the integrator comments, “We’d seen the cylinder rod lock concept in a trade magazine article and contacted Advanced Machine & Engineering to discuss our needs. On each corner of the lifting system, the rod lock would need to attach to the platform and a separate rod installed for the Amlok.”

The Amlok® design, originated by AME, allows free movement of the cylinder during normal operation. When the lift system is stopped or when air pressure is lost, the locking mechanism secures the load in position until released by the return of air

The Amlok rod locks used in this application are the company’s fourth generation design and prevent the typical problems encountered with most large scale air movement systems, namely, over-travel, bouncing, drifting and reverse travel. The patented intensifier mechanism of the AME rod lock is spring-operated to lock and is released by normal 60-160psi air lines. These devices were deemed both cost-effective and functionally desirable for the work platform application at the RV builder.

On this project, AME supplied the rod locks, mounting brackets and all hardware, while the integrator supplied the controls, pressure valves and all pneumatic circuitry to match the plant’s existing air lines, which were substantial, given the number of air tools used in the manufacturing process here.

Following the installation, the RV builder commissioned an independent engineering firm to fully certify that the work platforms met all relevant codes. This certification has been received.

Worker satisfaction with the system and the platform stability has been found to be very high, as well.

For technical questions on this story or the Amlok devices, please contact Ken Davis (ken@ame.com) or Shane Hatfield (shane@ame.com), the AME engineers on the project.

—

Advanced Machine & Engineering Co., is a manufacturer located in Rockford, IL, serving the Machine Tool Industry with precision components and accessories, including spindle interface components, workholding devices, and, through our sister company, Hennig, machine enclosures, chip removal and filtration systems. The Fluid Power – Safety markets are served with cylinder rod locks and safety catcher devises; and the Production Saw market with our Amsaw carbide saw machines and Speedcut blade products. AME has manufacturing partners and customers around the world and across the U.S. To learn more, visit www.ame.com.

Hennig, Inc. design and produces custom machine protection and chip/coolant management products for state-of-the-art machine tools. Hennig products are designed to protect against corrosion, debris and common workplace contaminants. Manufacturing facilities located in the U.S., Germany, Brazil, India, Japan, China and South Korea. Repair centers are located in Machesney Park, IL; Chandler, OK; Livonia, MI; Blue Ash, OH; Mexico City, Mexico and Saltillo, Mexico. To learn more, visit www.hennigworldwide.com.

For more information, contact:

Tim Waterman

ADVANCED MACHINE & ENGINEERING CO.

2500 Latham St.

Rockford, IL 61103

Phone: 815-316-5277

Fax: 815-962-6483

E-mail: info@ame.com

Connect with AME online:

HAN-KWANG ADDS LARGEST LASER TO ITS LINE

Han-Kwang USA announces the introduction of its largest laser model, built to date. The FS8025 is a flying-optic CO2 laser cutting system with dual shuttle tables, each measuring 26’ long by 8’ wide. This laser system is immediately available for sale in the North American market.

Powered by either a 2.5KW, 4KW or 6KW Panasonic laser resonator, the FS8025 is the only laser in industry on which the cutting head can cover the entire 26’ x 8’ worktable area without repositioning the table in process, according to the manufacturer.

All other currently available laser machines must reposition the table to process such a large area, resulting in longer cycle times and severe limitations on the cutting of very long, continuous part surfaces. Also eliminated are the inherent inaccuracies that result from repositioning the table in process.

Other features on this new machine line from Han-Kwang include a Siemens 840D CNC, the builder’s unique Constant Beam Distance System (CBDS), automatic edge detection and sheet axis realignment, quick-piercing cross-jet system, multi-pulse piercing, high-speed cutting head and synchronized twin servo motors on the gantry with auto-focus control.

According to Robert Won, Han-Kwang vice president for North American operations, “Our company has developed this very large laser system, following years of research and testing. The first several units have already been produced and installed at customer sites in Taiwan and Korea. We are now in full production at our factories. Another FS8025 will be installed soon.”

Won also detailed other models of the large table laser systems in this new line from Han-Kwang, including FS8020, FS6025, FS4025 and FS4020. All models are currently in production.

Interested parties should contact the company or their local Han-Kwang dealer for details.

Full machine specifications may be found at http://hankwangus.com/fs8025.html

For more information or to arrange a visit to Han-Kwang, please contact:

HAN-KWANG USA INC. 1120 Garfield Street Lombard, IL 60148 Phone: 630-916-0200 Fax: 630-916-0300 Web: www.hankwangus.com Email: salesusa@hankwang.co.kr Attention: Robert Won, Eric Kim or Jane Lee

Agency contact: Tim Daro Bernard & Company tdaro@bernardandcompany.com 847-934-4500

Release: HAN-KWANG USA INC.

Date: May 1, 2010

Continue reading500°F Combination Airflow Walk-in Oven from Grieve

The unit has a 2” insulated floor with truck wheel guide tracks, an aluminized steel interior and exterior and an interior oven light. The roof has a 4” square access port and a 8” x 10” double pane Pyrex window that is adjacent to the access port.

Controls onboard No. 1015 include a digital indicating temperature controller, an adjustable, thermocouple actuated, manual reset excess temperature controller and 30-hour shut down timer.

For more information, please contact: THE GRIEVE CORPORATION, 500 Hart Road, Round Lake, Illinois 60073-2835 USA. Phone: (847) 546-8225. Fax: (847) 546-9210. Web: www.grievecorp.com. Email: sales@grievecorp.com. Attention: Frank Calabrese.

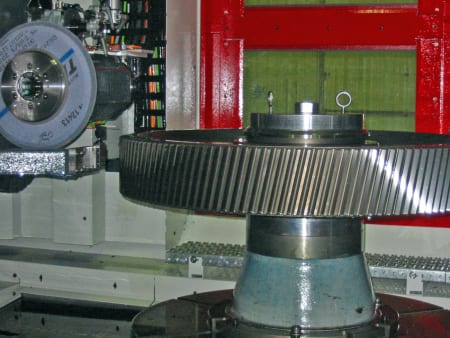

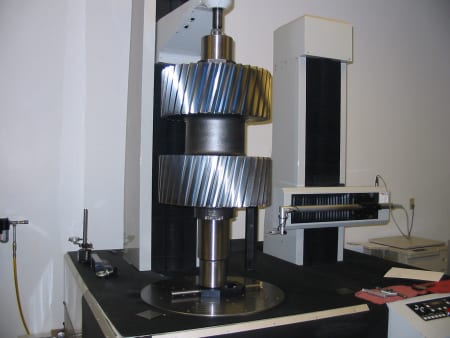

CONSIDERATIONS FOR GEARMAKING IN WIND TURBINE APPLICATIONS

Q & A with N.K. Chinnusamy, president of Excel Gear, Inc., Roscoe, IL

1. What are the challenges when machining gears for wind turbines?

Gears for wind turbine applications are typically large in diameter and have wide face widths, requiring very exacting material composition and heat treatment processing. The gear design must be optimized to insure low rolling resistance and long life, owing to the extreme costs of maintenance, down time, and repair of the gear box assemblies once they have been commissioned in the field. Every step in the manufacturing phase of these gears must be carefully processed, documented, and controlled to achieve the high quality, consistency, accuracy, and reliability that is demanded for operation in these environments.

The use of carburized steel for these gears is common and the associated heat treatments and stress relief operations have to be exacting to minimize part distortion and growth, as well as to achieve the proper metallurgical properties required. Oftentimes, a preheat treatment of the forging or bar stock is necessitated on these large gears to minimize part distortion. In addition, one of the seemingly small but critical techniques to minimize distortion on gears is the vertical insertion of the gear into the quench tank during the hardening phase.

Heat treatment can cause cracks as well, so careful processing with predetermination of stock allowance for grinding and final case depth must be considered. Inspection for cracks with magnetic particle inspection and for grinding burns utilizing nital etching is an important inspection tool.

Finally, off center crown grinding of the tooth geometry may be needed to properly distribute the load on the gear teeth.

2. What modifications, if any, are needed in the tooling or the machine tool, to make gears for this application?

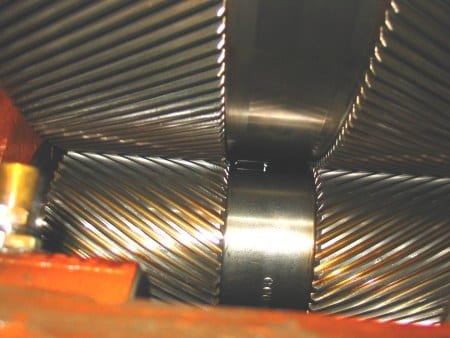

Helical gear grinding of large wind turbine gearbox components often requires off-center crowning to centerload the gear in operation.

Rigid, heavy-duty hobbing machines are needed for the coarse pitch gears, using roughing hobs or gear milling (gashing) cutters. Likewise, coarse pitch diamond dressing rolls and special grinding wheel abrasives are required for the large, high-accuracy gear grinders to produce efficient, accurate results and to prevent grinding burns and cracks.

The cutting fluids used must have the proper viscosity, the right amount of extreme pressure additives, and must be directed to the exact location of the work piece and cutting tool interface to maximize results. These fluids have to be routinely sampled and adjusted for optimum results.

3. Likewise, in building the gearbox, what special considerations must be taken into account?

Establishing the correct bearing clearances/preloads is critical to long life and proper gearbox operating temperature. Sophisticated measuring techniques with bearing inspection gages can only insure these results. The type and method of lubrication and proper sealing weighs heavily on the performance of a gearbox. The verification of gearbox performance through computerized analysis and testing is a crucial step to insuring long life.

4. What are some of the ancillary requirements in gear prep for wind turbines?

Special work holding and fixturing is an obvious consideration to bear the weight and to reduce the vibration and movement of the gear blank while hobbing or roughing. Careful and uniform torquing of the clamping fasteners during these operations prevents work piece movement and distortion of the gear blank during the roughing operation. The gear blank must have accurate mounting and indicating surfaces to control the pitch line runout to critical features (bearing journals, splines, etc.) and for minimal lead error.

5. Last thoughts?

The critical factor here, as with all similar power transmission applications, is that the gears are properly designed and manufactured. The other mechanical components that make up the assembly, along with the gearing, must be applied/designed so the overall system performance does not have any shortcomings that could affect the performance and life of the unit. Then if the sub-assembly/assembly is carried out with real precision and care, a favorable outcome is sure to follow.

Excel Gear, Inc. is a total service company, specializing in the design, manufacture and analysis of coaxial gearboxes, custom built gears, helical/bevel gearboxes, internal gears, spur gears, worm gears, gear-driven high-speed machine spindles, CNC gimbal heads and wind turbine gearbox components. The company performs full FEA and vibration analysis, plus complete metallurgical and heat treatment evaluation.

For more information on this interview, please contact:

EXCEL GEAR, INC. 11865 Main Street Roscoe, IL 61073 Phone: 815-623-3414 Fax: 815-623-3314 Web: www.excelgear.com Email: sales@excelgear.com N.K. Chinnusamy, President

Continue readingAME Billet Sawing System

- Highly compact, rigid design

- Hardened spindle gears ground for minimum backlash

- Special saw blade guide and dampening device for accurate cutting to stabilize the blade and prolong tool life

- Low maintenance design

- Dry operation – no coolant needed

- Saw blade changeover in less than 3 minutes

- Double and triple measurement strokes for extra length cuts

- Fast, dependable chip disposal

Also available are various chip conveyors, safety devices and machine enclosures offered by AME and its sister division, Hennig.

—

Advanced Machine & Engineering Co., is a manufacturer located in Rockford, IL, serving the Machine Tool Industry with precision components and accessories, including spindle interface components, workholding devices, and, through our sister company, Hennig, machine enclosures, chip removal and filtration systems. The Fluid Power – Safety markets are served with cylinder rod locks and safety catcher devises; and the Production Saw market with our Amsaw carbide saw machines and Speedcut blade products. AME has manufacturing partners and customers around the world and across the U.S. To learn more, visit www.ame.com.

Hennig, Inc. design and produces custom machine protection and chip/coolant management products for state-of-the-art machine tools. Hennig products are designed to protect against corrosion, debris and common workplace contaminants. Manufacturing facilities located in the U.S., Germany, Brazil, India, Japan, China and South Korea. Repair centers are located in Machesney Park, IL; Chandler, OK; Livonia, MI; Blue Ash, OH; Mexico City, Mexico and Saltillo, Mexico. To learn more, visit www.hennigworldwide.com.

For more information, contact:

Tim Waterman

ADVANCED MACHINE & ENGINEERING CO.

2500 Latham St.

Rockford, IL 61103

Phone: 815-316-5277

Fax: 815-962-6483

E-mail: info@ame.com

Connect with AME online:

Chris Koehn Appointed Business Unit Manager for Stotz Products at Advanced Machine & Engineering

Chris has over 20 years of sales and marketing experience in the machine tool industry. In his new position, he will focus on marketing the Stotz products, which include air and electronic gaging devices, to existing customers as well as development of new accounts. He will also be selling the complete product lines for Advanced Machine & Engineering and sister company, Hennig, Inc. Chris has worked in the air gaging industry for over 10 years and has been integral in the design and implementation of measuring systems from small table top devices to automated robotic manufacturing cells.

Stotz Feinmesstechnik GmbH has been a leader in gaging technology for almost 60 years. They design, manufacture and sell air-electronic gages and control devices. They are constantly striving to improve their designs and develop new products to solidify their position as a leader in new measuring technology. Numerous patents within the last few years have solidified their position as a trendsetter for new measuring technology and pneumatic measuring systems. Their diverse customer base covers many industries, including manufacturers and suppliers to the automotive, aerospace and medical industries.

Advanced Machine & Engineering Co., is a manufacturer located in Rockford, IL, serving the Machine Tool Industry with precision components and accessories, including spindle interface components, workholding devices, and, through our sister company, Hennig, machine enclosures, chip removal and filtration systems. The Fluid Power – Safety markets are served with cylinder rod locks and safety catcher devises; and the Production Saw market with our Amsaw carbide saw machines and Speedcut blade products. AME has manufacturing partners and customers around the world and across the U.S. To learn more, visit www.ame.com.

Hennig, Inc. design and produces custom machine protection and chip/coolant management products for state-of-the-art machine tools. Hennig products are designed to protect against corrosion, debris and common workplace contaminants. Manufacturing facilities located in the U.S., Germany, Brazil, India, Japan, China and South Korea. Repair centers are located in Machesney Park, IL; Chandler, OK; Livonia, MI; Blue Ash, OH; Mexico City, Mexico and Saltillo, Mexico. To learn more, visit www.hennigworldwide.com.

For more information, contact:

Tim Waterman

ADVANCED MACHINE & ENGINEERING CO.

2500 Latham St.

Rockford, IL 61103

Phone: 815-316-5277

Fax: 815-962-6483

E-mail: info@ame.com

Connect with AME online:

Stotz Air Gages and Measuring Systems Becomes Part of Advanced Machine & Engineering’s Family of Products

Stotz Feinmesstechnik GmbH has been a leader in gaging technology for almost 60 years. They design, manufacture and sell air-electronic gages and control devices. They are constantly striving to improve their designs and develop new products to solidify their position as a leader in new measuring technology. Numerous patents within the last few years have solidified their position as a trendsetter for new measuring technology and pneumatic measuring systems. Their diverse customer base covers many industries, including manufacturers and suppliers in the automotive, aerospace and medical industries. Stotz gages can be manufactured to measure I.D., O.D. out-of-round, straightness, parallelism, perpendicularity, flatness, taper, match grinding applications and many other geometric tolerances. Air gaging is a very easy-to-use method of measuring and requires no special training, plus it is non-contact technology, so it does not mark the parts. The measurements are extremely accurate and very fast. There are no mechanical moving parts; therefore, air gages have a very long life expectancy. The gages, coupled with the Stotz advanced line of air-electronic columns, make the integration into a user’s measuring system an easy transition. This is true for both simple table top systems as well as more complex robotic measuring cells with feedback to machine tools as well as integrating with an SPC program. Some common parts that are measured using air gages are fuel injection components, transmission components, hydraulic components, bearings, connecting rods, crankshafts, camshafts, valve seats, hip stems, surgical screws and many different tapers such as HSK, CAT, BT, KM, Morse and Jacobs, both the male and female portions.

Advanced Machine & Engineering Co., is a manufacturer located in Rockford, IL, serving the Machine Tool Industry with precision components and accessories, including spindle interface components, workholding devices, and, through our sister company, Hennig, machine enclosures, chip removal and filtration systems. The Fluid Power – Safety markets are served with cylinder rod locks and safety catcher devises; and the Production Saw market with our Amsaw carbide saw machines and Speedcut blade products. AME has manufacturing partners and customers around the world and across the U.S. To learn more, visit www.ame.com.

Hennig, Inc. design and produces custom machine protection and chip/coolant management products for state-of-the-art machine tools. Hennig products are designed to protect against corrosion, debris and common workplace contaminants. Manufacturing facilities located in the U.S., Germany, Brazil, India, Japan, China and South Korea. Repair centers are located in Machesney Park, IL; Chandler, OK; Livonia, MI; Blue Ash, OH; Mexico City, Mexico and Saltillo, Mexico. To learn more, visit www.hennigworldwide.com.

For more information, contact:

Tim Waterman

ADVANCED MACHINE & ENGINEERING CO.

2500 Latham St.

Rockford, IL 61103

Phone: 815-316-5277

Fax: 815-962-6483

E-mail: info@ame.com

Connect with AME online:

Forest City Gear’s green efforts

In addition to an aggressive recycling program, Forest City has implemented a number of other changes:

- Changing lights from T-12 to T-8, using 25, 28 and 32 watt lamps.

- Tinting windows with low-E film, to minimize heat and lower energy costs during the summer months.

- Replaced several heating/AC units with high energy efficiency units (Energy Star).

- Installed programmable thermostats throughout the building, and a large ceiling fan in the plant.

- Sun reflecting covers for skylights.

- Replacement of less efficient air compressors.

- Strategically planted shade and fruit trees, shrubs and plants, all around the building’s grounds.

- Turning off plant lighting during the lunch period, and as required in bathrooms, lunch room, conference room and warehouse.

- Adding sophisticated power factor optimization devices on factory motors.

“We’re really rethinking our rep/dealer/distributor force, in this internet age. What are your thoughts?”

Question:

“We’re really rethinking our rep/dealer/distributor force, in this internet age. What are your thoughts?”

Our President’s point-of-view…

Some companies, having actually received orders off their online rfq forms, have stumbled into thinking they no longer need those vital links (no pun at all, believe me) in their sales chain, namely, their reps, dealers, distributors or even their offshore agents. They tell us the age of the internet obviates the need for such personnel and the corresponding cost.

They are just plain wrong.

For numerous reasons, not the least of which are the local representation in a business community by someone who’s known to it AND the corresponding frequency of contact made, you all need these folks fronting your product message. For years, we’ve told our industrial clients that they’re not in the mail order or retail business. That’s as true today, even in the age of instant online purchases and even, I admit, in the age of one client who sold an $88,000 piece of equipment directly from their website to a company they’d never sold previously.

Your front line troops are exactly that, your first line of attack (or sometimes defense, when the internet rumors fly) in the market. Beyond sales contacts, they provide customer assistance in many, often unseen ways. We’ve worked for dozen of electrical clients over the years and there is no industry with a more multi-layered distribution channel to reach the various OEM, contractor and end user segments of that huge market. Quite naturally, the electrical market was one of the first ones we serve where clients began to think they could do quite nicely, eliminating a link in the sales chain. The smart ones have realized it’s not true, as each played and still plays a vital role in product delivery, but even more-so in product conditioning, product persuasion, product positioning and product promotion. Yes, just as their advertising, PR, direct/blast emailings, trade shows and other promotional tactics do, the reps, distributors and wholesalers in the territories each play a role in helping the overall marketing communication effort succeed.

Companies who overlook that fact are just dumb and will likely suffer the consequences of such short-sighted thinking.

The same applies to you capital equipment companies and even you contract manufacturers who might consider eliminating your reps or dealers. “Gee, Tim, we build a lot of custom stuff and our engineers can handle most everything online. We really wonder if those other guys are necessary.” The answer is a resounding YES. It’s a collateral consequence of the internet that MORE companies who once sold locally or regionally can now do business nationwide, even worldwide, owing to the online communication channel. However, along with this broader business base come all those “local” factors that must be taken into account. These might include local electrical codes, shipping restrictions, installation challenges and, on the international scene, currency and other cultural considerations. Having at least some regional representation can be very helpful in this process.

One longtime client of ours devotes an entire page of their catalog to extol the virtues of their reps, detailing the company’s philosophy for their use. Call me, I’ll share it with you, as I’ve handled the client personally for 35 years and wrote that page myself!

-TD

email Tim

Our Director of Social Media’s point-of-view…

The point of social media is to make you and/or your company MORE accessible, not less human. Social media should be used to help give your company and your products life and a personality.

Human connection; having a real person answer questions, solve problems and attend to clients or potential clients needs is still a necessary part of a thriving business.

One should not replace the other, they should work hand-in-hand to support each other.

-Wendy

email Wendy