Contact us today:

(847) 934-4500

tdaro@bernardandcompany.com

Contact us today:

(847) 934-4500

tdaro@bernardandcompany.com

Visit Siemens at Fabtech 2013, Booth S-4686

UPDATE! See the video of Siemens at FabTech HERE.

Broad-based CNC competence: Siemens will be demonstrating how productivity, flexibility and safety can be increased in CNC production with an array of smart additions to its Sinumerik portfolio

Industrial corporations are facing deep-rooted changes in the world of manufacturing. These changes are taking place alongside increasing integration of product development and production processes with the benefit of innovative software systems and high-performance software – a decisive step on the road toward a new industrial age in manufacturing. “Siemens has invested a lot of work in the integration of automation technology along the entire value chain over a period of many years, and is playing a cutting-edge role in shaping the future of production,” stated Robert Neuhauser, CEO of the Motion Control Systems Business Unit of the Siemens Drive Technologies Division, at a press conference held in the run-up to the EMO 2013. “In the Sinumerik environment in particular, and consequently in the field of CNC production in general, Siemens has been heavily involved for many years already in the area of simulation and the virtual machine, as well as the integration into factory IT systems. Our aim is to drive this process of integration forward to ensure that the field of machine tool construction is also prepared to embrace the next step in the industrial revolution,” continued Neuhauser.

With its Sinumerik family, Siemens offers an integral portfolio of CNC for everything from simple machine tools through standardized machine concepts to modular premium solutions, complete with “smart machine” solutions for the economical manufacture of high-end workpieces. It is working towards the consistent expansion of this CNC technology expertise. “In the future, production models will demand ever greater productivity, flexibility and efficiency, while at the same time expecting simplified machine operation and production sequences. As it continues to develop the Sinumerik CNC portfolio, Siemens is working to satisfy all these expectations,” said Joachim Zoll, Head of Machine Tool Systems Business Segment within the Motion Control Systems Business Unit. The innovations presented by Siemens at the Fabtech 2013 will consequently focus on smart function improvements, which will make for greater CNC operating convenience, increase precision at the workpiece and allow greater machining safety across every category of machine, from the compact to the high-end solution. A new function to protect against unwanted component collisions will be showcased by Siemens, for example, alongside improvements to its cohesive Sinumerik Operate user interface, including upgraded simulation options.

The Sinumerik CNC portfolio is additionally playing an increasingly important role in preparing the ground for the next step in the evolution of CNC production, also within the framework of the Siemens Integrated Drive System (IDS). With a view to optimizing the addition of value across the entire process chain through consistent integration, IDS is used to integrate all the components of the drive train consistently into the complete production process environment. This also applies to Sinumerik CNC system solutions.

For every Sinumerik application, ideally coordinated system components such as high-powered Sinamics drives and Simotics motors have always been used as the ideal complements. Alongside horizontal integration of the entire drive train, with Sinumerik Integrate for Production, Siemens is also allowing vertical integration within the control architecture of industrial manufacturing automation. As the example of a leading passenger car manufacturer illustrates, this type of vertical and horizontal integration within the production process can speed up the series start for a new vehicle by up to 50 percent.

Siemens is extending its preparations for the next step in manufacturing to offer the machine tool building industry an emerging series of integrated solutions. An integrated workpiece measurement system, with a measurement accuracy of 30 nanometers deployed in the world’s biggest precision optics machine, allows the production of telescopes capable of seeing up to 13 billion light years into space

The integration across the entire product life cycle can in turn be implemented using suitable Product Lifecyle Management (PLM) software solutions from Siemens. This concept is already being implemented by leading metals processing industries such as the automotive, aerospace and medical technology sectors. This entails the increasing execution of product development and production planning onscreen, before a single machine tool has even been installed. If a modular machine is developed on a virtual basis right from the outset so that it can be fully simulated, time savings up to 40 percent can be achieved. In running operation, productivity increases of 10 percent or more are also made possible by continued simulation and optimization. At this year’s Fabtech, Siemens will be showcasing the further development of its PLM software, which encompasses scalable solutions for component production and further improved IT integration from the workpiece model through to the machine tool. Siemens will also be revealing the next stage in productivity for NC programming with the further development of its already popular PLM software, NX CAM. Going forward, this software will include special industry-specific machining functions as well as access to a new Manufacturing Resource Library.

For more information on Siemens SINUMERIK CNC, visit www.usa.siemens.com/cnc.

For specific product information and inquiries, call (800) 879-8079 ext. Marketing Communications or send an e-mail to: SiemensMTBUMarCom.industry@siemens.com.

Follow us on Facebook: www.facebook.com/SiemensCNC or Twitter: www.twitter.com/siemens_cnc_us.

—

Siemens Industry Sector is the world’s leading supplier of innovative and environmentally friendly products, solutions and services for industrial customers. With end-to-end automation technology and industrial software, solid vertical-market expertise, and technology-based services, the sector enhances its customers’ productivity, efficiency and flexibility. With a global workforce of more than 100,000 employees, the Industry Sector comprises the Industry Automation, Drive Technologies and Customer Services Divisions as well as the Metals Technologies Business Unit. For more information, visit http://www.usa.siemens.com/industry.

The Siemens Drive Technologies Division is the world’s leading supplier of products, systems, applications, solutions and services for the entire drive train, with electrical and mechanical components. Drive Technologies serves all vertical markets in the production and process industries as well as the infrastructure/energy segment. With its products and solutions, the division enables its customers to achieve productivity, energy efficiency and reliability. For more information, visit http://www.usa.siemens.com/drivetechnologies.

Continue readingCauses, effects and control

This whitepaper covers definitions, harmonic generation, effects of harmonics and control of harmonics. It also addresses general awareness of power system harmonics, their causes, effects and methods to control them especially when these harmonics are related to variable frequency (or adjustable speed) drives.

—

For more information, please visit www.usa.siemens.com/motioncontrol

For specific product information and inquiries, call (800) 879-8079 ext. Marketing Communications or send an e-mail to: SiemensMTBUMarCom.industry@siemens.com.

—

Siemens Industry Sector is the world’s leading supplier of innovative and environmentally friendly products, solutions and services for industrial customers. With end-to-end automation technology and industrial software, solid vertical-market expertise, and technology-based services, the sector enhances its customers’ productivity, efficiency and flexibility. With a global workforce of more than 100,000 employees, the Industry Sector comprises the Industry Automation, Drive Technologies and Customer Services Divisions as well as the Metals Technologies Business Unit. For more information, visit http://www.usa.siemens.com/industry.

The Siemens Drive Technologies Division is the world’s leading supplier of products, systems, applications, solutions and services for the entire drive train, with electrical and mechanical components. Drive Technologies serves all vertical markets in the production and process industries as well as the infrastructure/energy segment. With its products and solutions, the division enables its customers to achieve productivity, energy efficiency and reliability. For more information, visit http://www.usa.siemens.com/drivetechnologies.

Continue readingSiemens and KUKA held a press conference at the EMO Hannover 2013. Manfred Gundel, CEO of the KUKA Roboter GmbH, and Dr. Robert Neuhauser, CEO of the Motion Control Systems (MC) Business Unit of the Siemens Drive Technologies Division, has informed about an enhanced cooperation.

· Joint solutions offered: integrated, operator-friendly loading of machine tools using robots

· Integration of robotics and CNC solutions for machining workpieces with robots

· Strengthening the fundamental idea of integrated production processes

· Development of new applications in lightweight construction

Siemens Drive Technologies Division and KUKA Roboter GmbH have announced comprehensive cooperation at EMO in Hanover. The central pillar of the cooperation is integration of KUKA robots and Siemens CNC solutions for loading machine tools. “With this joint approach, the two companies are strengthening the fundamental idea of integrated production and can, for example, develop new markets by close intermeshing of machine tool tasks and loading tasks,” says Manfred Gundel, CEO of KUKA Roboter GmbH. “The CNC control from Siemens and the robot controls from KUKA are ideal for integrating robot and CNC technology. With this cooperation, we are deepening our many years of cooperation and together advancing intelligent automation solutions as outlined by the Industrie 4.0 project for the benefit of both partners and to expand business,” says Dr. Robert Neuhauser, CEO of Business Unit Motion Control Systems at Siemens.

Highly flexible and fully automated production today demands complete integration of robots into the production flow and into the automation environment. In this area, in particular, applications for robots and machine tools are growing together steadily as a result of new requirements and technological progress. Given these developments, Siemens and KUKA are strengthening their cooperation in automation and industrial robots. The aim is to be better able to serve industries with high automation requirements in loading and machining. With the shared development, customers will have access to new products and solutions that are coordinated optimally over their entire life cycle, from design, to production simulation, to engineering and the production shop level. Moreover, in the long term, the two companies will be including aspects of robot automation in their activities as outlined in the Industrie 4.0 project.

With this close partnership, Siemens and KUKA can offer end customers integrated solutions with a high technological demand and level of maturity and position themselves still better on global markets. At the center of the joint development and the closely meshed marketing activities is seamless, operator-friendly integration of the robot for loading the machine tool. The companies will also develop scalable, integrated solutions for machining workpieces with robots, especially for lightweight construction. In this field, in particular, new materials such as composites require innovative machining concepts that the two companies will be intensively advancing as part of the cooperation.

KUKA will provide robot systems that make use of proven solutions in the field of CNC with Sinumerik from Siemens for integration with machine tools. The standard implementation of the concept includes loading by a KUKA robot, which is integrated in Sinumerik. A scaled offer is also planned ranging from a robot with additional CNC machining functionality to a robot as a pure CNC machining unit. Here, too, the aim is complete integration of the robot into the PLM processes.

At EMO 2011, both partners have already presented the integration of the robot into the Sinumerik user interface as an application, for programming, teach-in, and diagnostics. The next step will now be the connection to CNC tasks.

Click here to view the slide presentation from the press conference.

For more information on the story above, contact:

Siemens AG, Media Relations

Franz-Ferdinand Friese, phone: +49 911 895 7946

E-mail: franz.friese@siemens.com

KUKA Roboter GmbH, Corporate Communications

Wolfgang Meisen, phone.: +49 821 4533 1981

E-Mail: WolfgangMeisen@kuka-roboter.de

—

The Siemens Drive Technologies Division (Nuremberg, Germany) is the world’s leading supplier of products, systems, applications, solutions and services for the entire drive train, with electrical and mechanical components (Integrated Drive Systems). Drive Technologies serves all vertical markets in the production and process industries as well as the infrastructure/energy segment. With its products and solutions, the Division fulfills the key requirements of its customers for productivity, energy efficiency, and reliability. For more information, visit http://www.siemens.com/drivetechnologies

The KUKA Roboter GmbH, with its headquarters in Augsburg, is a member of the KUKA Aktiengesellschaft and ranks among the world’s leading suppliers of industrial robots. Core competencies are development, production and sale of industrial robots, controllers and software. The company is the market leader in Germany and Europe and the number three in the world. KUKA Roboter GmbH employs about 3180 people worldwide. In 2012, sales totaled 742,6 million Euro. 25 subsidiaries provide a presence in the major markets of Europe, America and Asia.

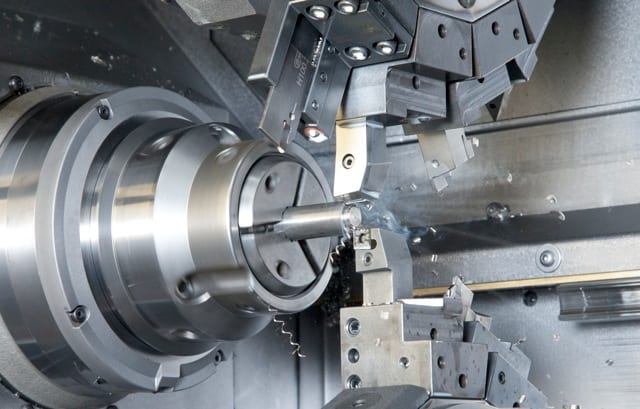

Continue readingTo guarantee perfect workmanship and the highest possible product quality, BMW uses five-axis machining centers equipped with Sinumerik 840D sl and a range of new user interfaces for machining operations in its Berlin motorcycle plant.

The horizontal design of the Grob five-axis G550 guarantees the highest levels of rigidity, which keeps axial deviations below 10 µm.

Thanks to previous positive experience with Siemens, the BMW manufacturing specialists in Berlin already employ technology from Europe’s market leader for 90 percent of their controllers. This allows both operators and tool setters the flexibility to work on almost all the machines in the plant. Other key requirements noted in the specification were adequate space for manufacturing all relevant components, the highest levels of precision and surface finish, compliance with pre-defined cycle times, and the ability to reuse all current tools and equipment.

The highest levels of precision on even the hardest material

Before committing to the new investment, the responsible BMW production engineer worked with a colleague from process engineering to investigate the effectiveness of the Grob machines in cylinder head production. Initially, it was the G550’s near-identical sibling, the G350, that was under consideration. As a first traditional single-workplace machine tool, it already met almost all the main criteria, but the space available inside was deemed too small to accommodate all the required processing tasks. However, the G550 satisfied this requirement as well. Among other factors, the horizontal design of this five-axis machine, which has both rotary axes in the work area, contributes significantly to its outstanding rigidity. As a result, axial deviation remains process-compliant at values under 10 µm. The level of precision that can be achieved is correspondingly high, even when processing extremely hard materials, as with valve seat inserts, for example.

The machine also produces a high-quality surface finish, with roughness (Rz) of up to 2 µm. Christian Heiß, applications engineer at Grob, explains a further benefit of the horizontal design: “Tool life can be increased by approximately 30 percent compared with that of vertical machining centers. And the problem of jammed slivers is almost completely eliminated because they are not able to fall onto the workpiece in the first place, but instead fall right through to the ground.”

One of the G550’s strengths is its compact size, at only 3800 mm x 6300 mm. However, despite its size, it still features an extremely long z-axis stroke of 1020 mm, meaning that tools up to 500 mm long can be retracted completely out of the work area and into the so-called spindle tunnel. The swivel-mounted shuttle table is another feature that helps deliver high levels of productivity. While one workpiece is being processed, the next can be clamped and set, thus minimizing costly downtime.

Programmed and set in no time at all

Employees find the new Sinumerik 840D sl CNC especially easy to operate because, in the production of BMW cylinder heads, only Siemens controllers are used. Despite this, the user interface presented on the Grob machines looks completely different from the others. Until now, operators and setters have been used to the DIN-based HMI Advanced user interface, but the new CNC on the G550 features the Sinumerik Operate animated graphical display. Siemens has integrated a new operation and programming structure, with practical functions such as copy and paste that are well known to users from their daily use of PCs. This allowed BMW employees to quickly adapt and master the new Sinumerik user interface in no time at all.

Thanks to its excellent usability and intuitive operation through various technology cycles, measurement cycles, and setting functionality, the new G550 machines can be set up for new batches much more quickly than before. As Heiß explains: “This means our customers are much faster than before. Previously, it might have taken several hours to set up the machine and the workpiece, now it can be done in just a few minutes.”

Highly trained employees and specialist suppliers help BMW motorcycles maintain their excellent reputation for reliability, quality, and safety.

Quick and reliable with remote maintenance

Along with the tools and equipment from the current machines, the German motorcycle manufacturer was able to reuse all its existing programs as well. It took a single employee only two days to upgrade these programs to be compatible with the latest software, which can be loaded onto the relevant machine as required either over the network or from a USB stick. The modern Windows Explorer-style program manager means that complex programs can be managed either on the CF (Compact Flash) card or directly on the CNC.

If problems arise while the machine is operational, BMW production engineer Taner Ögretmen and his colleagues use the network-based remote maintenance functionality provided by Grob. This has rarely been required so far – but when it has, it proved to be extremely smooth and efficient, stresses Ögretmen. Grob can also perform minor optimizations together with Siemens using the teleservice. This is usually done automatically and without any disruption to ongoing production. The Sinumerik-controlled Grob machines have met every expectation in full, which is why BMW has already ordered an additional four G550s.

Programming and operation using Sinumerik Operate

be clear and self-explanatory, so that even operators with no programming experience can learn the basics in no time at all. To write programs in programGUIDE, the operator will need some knowledge of G-code. The highlights here include new cycle support functionality and animated elements that can be used to represent the cycle graphically. Tooltip support is also provided.

For more information on this story:

SIEMENS INDUSTRY, INC.

MOTION CONTROL

MACHINE TOOL BUSINESS

390 Kent Avenue

Elk Grove Village, IL 60007

Phone: 847-640-1595

Fax: 847-437-0784

Web: www.usa.siemens.com/cnc

Email: SiemensMTBUMarCom.sea@siemens.com

Attention: John Meyer, Manager, Marketing Communications

Follow us on Facebook: www.facebook.com/SiemensCNC or Twitter: www.twitter.com/siemens_cnc_us.

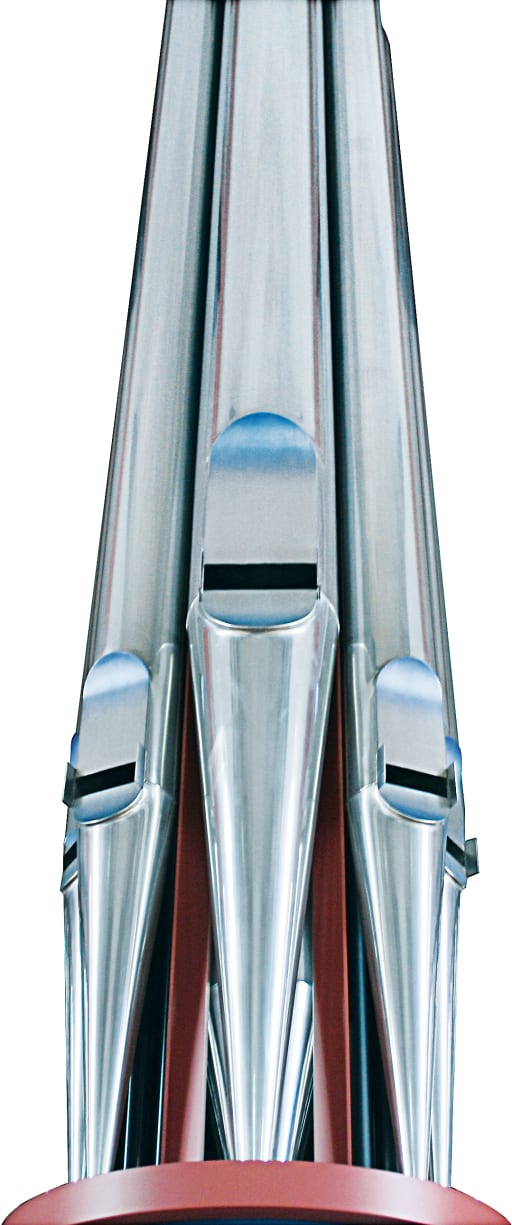

Continue readingThe art of organ building at the highest level with modern CNC techniques…

Laukhuff relies on five-axis milling center from Spinner with Sinumerik 840D sl for small-series production

At Laukhuff in Weikersheim, Germany, tradition and modernity merge together in a way that can not merely be seen, but also heard. The family-run company, with almost 200 years of history, is the international leader in organ building – as a supplier to the best-known organ builders and a provider of its own complete instrument developments. The company operates on a global level with 150 employees, considering itself an artistic crafting enterprise rather than an industrial company. Company CEO Hans-Erich Laukhuff emphasizes, “In our carpenter’s workshop and when manufacturing organ pipes, we are hardly able to use any machines because 90 percent of the work must be done by hand. When it comes to cutting, however, this is a different matter. Here, we can use modern milling and turning machines with innovative CNC equipment, so that we can keep productivity levels as high as possible.”

If required, these masters of organ building will supply everything from a single source. Laukhff further explains, “If requested, we will take on all the tasks involved in the design, the manufacture of individual parts and the installation onsite. We even make the bench seat and the key lights ourselves, as there are no usable, satisfying solutions in the market today.”

The high level of perfection shown by this organ builder is reflected in the optics, in the haptics (touch and feel) and naturally in the sound of the instruments. It also has a positive effect on their reliability. After all – quite unusual in these fast-moving times – it is typically not necessary to plan the replacement of a Laukhuff organ for more than 100 years. However, a few spare parts will still be required.

Despite the fact their high quality is globally recognized, this family-run company is still facing constant cost pressure. To achieve a high throughput in cutting applications, the company uses five CNC turning machines and three CNC milling machines – together with their latest acquisition, a five-axis CNC center (3+2) from Spinner’s U-series, with a state-of-the-industry Siemens Sinumerik 840D sl CNC onboard.

Impressive price-performance ratio

With the Sinumerik-controlled Spinner U5-620, Laukhuff uses new options for the more productive manufacturing of organ components, such as chimes

Company owner and CEO Hans-Erich Laukhuff and Production Manager Walter Rhein already had positive experiences with the CNC. However, since mid-2009, they have been relying on the Spinner machine tool factory in Sauerlach, Germany for the first time and using the U5. According to the production manager, this decision was based on the price-performance ratio and the small space required by the machine in contrast to comparable machines from other manufacturers. The U5-620 only needs 2000 x 2400 millimeters of surface area, but achieves travel distances of 620/520/460 millimeters in the X/Y/Z-axis direction.

The new Spinner machining center has high-quality individual components, including 32 tools as standard, a double arm for rapid tool changes and linear axes on roller bearing guides. Michael Schulz, Spinner sales representative at Hollenbach GmbH, confirmed, “This enables us to achieve rapid feed speeds of 48 meters per minute in all directions. Even in terms of accuracy and surface quality, our U-series sets a very high standard.”

In terms of the productivity and quality increases that can be achieved, as well, the organ builder expects the acquisition of the Spinner machine to be amortized within a relatively short period of time. Ultimately, an organ builder will often manage without time-consuming retooling, as Rhein noted, “In the cutting applications for our organ pipe tuners, we previously had to retool three times and needed around 13 minutes just for clamping – which doesn’t even take into account the downtime while retooling. The five axes mean that production is now possible in a single clamping, within about eight minutes per piece. All in all, we are at least twice as fast as a result.”

Graphically-animated user interface

Like many medium-sized contract manufacturers, this organ builder’s employees also program directly at the machine. CNC specialist Kurt Stüdlein is totally convinced about the Sinumerik 840D sl because, “…it is powerful, safe to operate, user-friendly and reliable. But the CNC user interface, tailored to shopfloor programming, also scores highly, being graphically-animated and logically-structured. ShopMill, the resident software suite, is great, particularly for beginners. Production Manager Rhein further explains, “Even a fitter who has only just finished his training, without any extensive programming experience, can work with it, after some brief instructions.”

CNC professional Stüdlein adds, “Even on complex components using the 3+2 axis machining, I can create lots of programming steps with ShopMill. If I reach the limits when entering certain contours, or if I am quicker with DIN, then I can switch from the graphic to the text-oriented DIN interface at the touch of a button.” For additional employee safety, the Safety Integrated software solution is also built into the control. This means that it is possible for the user to safely track his program’s production process in setup mode with the machine doors open.

Laukhuff is certain, based on the experience gained, that he has made the right decision with the Spinner-Siemens CNC combination. The technology and the continuously fast service from both companies have convinced him, “If there is a problem, we are helped very quickly – which is not always a given with other manufacturers in this particular industry.”

For more information on Siemens SINUMERIK CNC, visit www.usa.siemens.com/cnc.

For specific product information and inquiries, call (800) 879-8079 ext. Marketing Communications or send an e-mail to: SiemensMTBUMarCom.industry@siemens.com.

Follow us on Facebook: www.facebook.com/SiemensCNC or Twitter: www.twitter.com/siemens_cnc_us.

—

Siemens Industry Sector is the world’s leading supplier of innovative and environmentally friendly products, solutions and services for industrial customers. With end-to-end automation technology and industrial software, solid vertical-market expertise, and technology-based services, the sector enhances its customers’ productivity, efficiency and flexibility. With a global workforce of more than 100,000 employees, the Industry Sector comprises the Industry Automation, Drive Technologies and Customer Services Divisions as well as the Metals Technologies Business Unit.

The Siemens Drive Technologies Division is the world’s leading supplier of products, systems, applications, solutions and services for the entire drive train, with electrical and mechanical components. Drive Technologies serves all vertical markets in the production and process industries as well as the infrastructure/energy segment. With its products and solutions, the division enables its customers to achieve productivity, energy efficiency and reliability.

Continue readingPress Conference for the Americas — EMO Hannover / Hall 25, booth D33

Industrial corporations are facing deep-rooted changes in the world of manufacturing. These changes are taking place alongside increasing integration of product development and production processes with the benefit of innovative software systems and high-performance software — a decisive step on the road toward a new industrial age in manufacturing. “Siemens has invested a lot of work in the integration of automation technology along the entire value chain over a period of many years, and is playing a cutting-edge role in shaping the future of production,” stated Bernd Heuchemer, Vice-President, Global Marketing and Communications, Siemens AG, Drive Technologies Division, Motion Control Systems Business, at a press conference held in the run-up to the EMO 2013 recently. “In the Sinumerik environment in particular, and consequently in the field of CNC production in general, Siemens has been heavily involved for many years already in the area of simulation and the virtual machine, as well as the integration into factory IT systems. Our aim is to drive this process of integration forward to ensure that the field of machine tool construction is also prepared to embrace the next step in the industrial revolution,” continued Heuchemer.

With its Sinumerik family, Siemens offers an integral portfolio of CNC for everything from simple machine tools through standardized machine concepts to modular premium solutions, complete with “smart machine” solutions for the economical manufacture of high-end workpieces. It is working towards the consistent expansion of this CNC technology expertise. “In the future, production models will demand ever greater productivity, flexibility and efficiency, while at the same time expecting simplified machine operation and production sequences. As it continues to develop the Sinumerik CNC portfolio, Siemens is working to satisfy all these expectations,” said Rajas Sukthankar, General Manager, Siemens Industry, Inc., Machine Tool Systems Business. The innovations presented by Siemens at the EMO 2013 will consequently focus on smart function improvements, which will make for greater CNC operating convenience, increase precision at the workpiece and allow greater machining safety across every category of machine, from the compact to the high-end solution. A new function to protect against unwanted component collisions will be showcased by Siemens, for example, alongside improvements to its cohesive Sinumerik Operate user interface, including upgraded simulation options.

The Sinumerik CNC portfolio is additionally playing an increasingly important role in preparing the ground for the next step in the evolution of CNC production, also within the framework of the Siemens Integrated Drive System (IDS). With a view to optimizing the addition of value across the entire process chain through consistent integration, IDS is used to integrate all the components of the drive train consistently into the complete production process environment. This also applies to Sinumerik CNC system solutions.

For every Sinumerik application, ideally coordinated system components such as high-powered Sinamics drives and Simotics motors have always been used as the ideal complements. Alongside horizontal integration of the entire drive train, with Sinumerik Integrate for Production, Siemens is also allowing vertical integration within the control architecture of industrial manufacturing automation. As the example of a leading passenger car manufacturer illustrates, this type of vertical and horizontal integration within the production process can speed up the series start for a new vehicle by up to 50 percent.

The integration across the entire product life cycle can in turn be implemented using suitable Product Lifecyle Management (PLM) software solutions from Siemens. This concept is already being implemented by leading metals processing industries such as the automotive, aerospace and medical technology sectors. This entails the increasing execution of product development and production planning onscreen, before a single machine tool has even been installed. If a modular machine is developed on a virtual basis right from the outset so that it can be fully simulated, time savings up to 40 percent can be achieved. In running operation, productivity increases of 10 percent or more are also made possible by continued simulation and optimization. At this year’s EMO, Siemens will be showcasing the further development of its PLM software, which encompasses scalable solutions for component production and further improved IT integration from the workpiece model through to the machine tool. Siemens will also be revealing the next stage in productivity for NC programming with the further development of its already popular PLM software, NX CAM. Going forward, this software will include special industry-specific machining functions as well as access to a new Manufacturing Resource Library.

For more information on Siemens SINUMERIK CNC, visit www.usa.siemens.com/cnc.

For specific product information and inquiries, call (800) 879-8079 ext. Marketing Communications or send an e-mail to: SiemensMTBUMarCom.industry@siemens.com.

Follow us on Facebook: www.facebook.com/SiemensCNC

or Twitter: www.twitter.com/siemens_cnc_us

—

Siemens Industry Sector is the world’s leading supplier of innovative and environmentally friendly products, solutions and services for industrial customers. With end-to-end automation technology and industrial software, solid vertical-market expertise, and technology-based services, the sector enhances its customers’ productivity, efficiency and flexibility. With a global workforce of more than 100,000 employees, the Industry Sector comprises the Industry Automation, Drive Technologies and Customer Services Divisions as well as the Metals Technologies Business Unit. For more information, visit http://www.usa.siemens.com/industry.

The Siemens Drive Technologies Division is the world’s leading supplier of products, systems, applications, solutions and services for the entire drive train, with electrical and mechanical components. Drive Technologies serves all vertical markets in the production and process industries as well as the infrastructure/energy segment. With its products and solutions, the division enables its customers to achieve productivity, energy efficiency and reliability. For more information, visit http://www.usa.siemens.com/drivetechnologies.

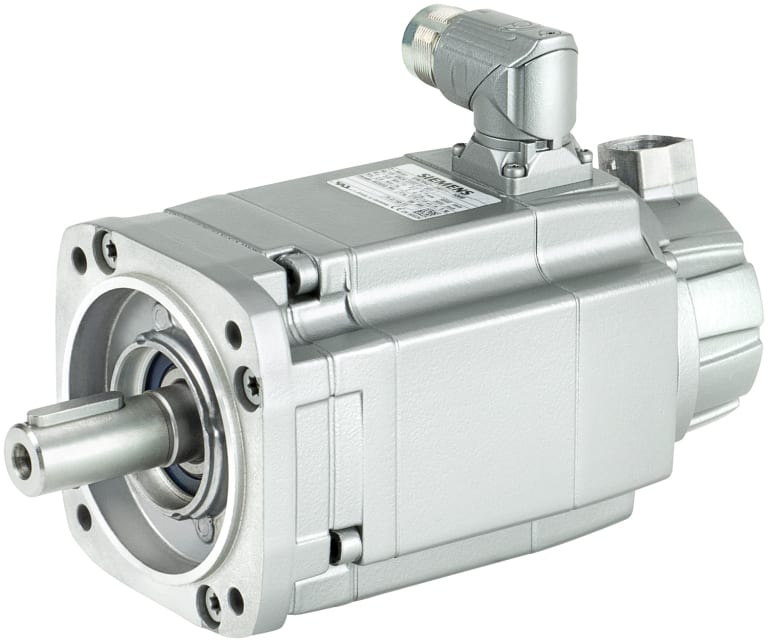

Siemens Industry, Inc. announces reduced lead times for its Generation II Simotics 1FK7 servomotors. Highly-configurable to suit a wide variety of applications, this new line features seven shaft heights, Quick-Connect power connector and high-accuracy 20- and 24-bit field replaceable encoders in 10 styles, all combined with a four-week lead time beginning July 1, 2013 — and ultimately reduced to three-weeks beginning January 1, 2014 on all models.

The Generation II servomotor offers three inertia versions — standard, high-dynamic for rapid acceleration jobs, and high-inertia for maximum smooth running. These motors are designed for operation without external cooling and the heat is dissipated through the motor surface. With 10 styles of field-replaceable encoders, the 1FK7 Generation II servomotors provide easy maintenance in the field, with reduced downtime and operating cost savings. Further, a 10 percent improvement in continuous (S-1) power is achieved since the encoders are mechanically and thermally decoupled from the motor. The mechanical decoupling also means the encoder is more resistant to vibration conditions on the machine. In addition, there is no need for battery back-up on the absolute encoders.

The full application of engineering assistance and service of the global Siemens network supports this new line of servomotors.

For more information on these new Siemens servomotors, please visit www.usa.siemens.com/simotics.

For product information and inquiries, call +1 800 879 8079 ext. Marketing Communications or e-mail SiemensMTBUMarCom.industry@siemens.com.

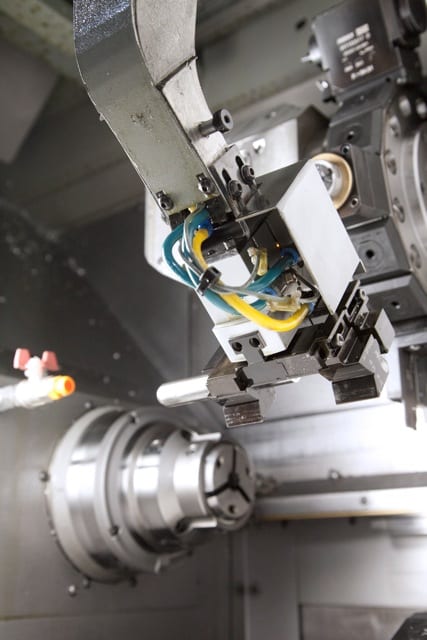

Continue readingWhen Task Force Tips, Inc. (TFT) decided to study the true costs of ultra-priced, high-speed machining, the company expected nominal gains on its machine-control investment; but when TFT began cutting the same precision parts in one-third of the time, it was, in the words of the company owner and president, Stewart McMillan, “a wake-up call.”

See the video on this story HERE.

Task Force Tips (TFT) is a manufacturer of highly engineered fire suppression tips, nozzles and other agent delivery equipment used by fire departments globally. For more than four decades, the company has always invested in premium machine tool brands associated with quality, performance and logically, higher price tags. Even so, it was the latter variable – the perceived barrier of price and cost – that prevented company owner and president, Stewart McMillan from ever considering more ultra-priced, high-speed machining options on the market.

“I hadn’t really looked at the economics when it came to an INDEX machine,” recalls McMillan. “And why? Because it always seemed like the INDEX brand was so prohibitively expensive. I never even thought its machines were within our league.”

That was prior to IMTS 2008, before TFT brought the company’s first INDEX machine into its 168,000 square foot facility in Valparaiso, Indiana, where TFT manufactures over 5,000 products across three shifts, seven days a week, all year around.

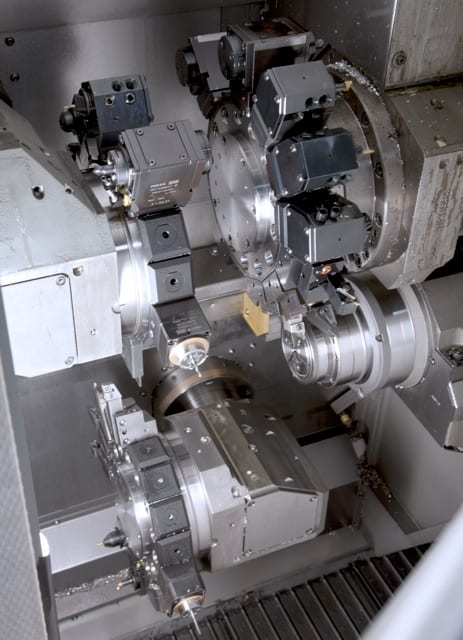

The Index C100’s “literal” coordinate system establishes actual reference points for programming the machine’s precise motion, rather than use arbitrary points in space.

“It was an INDEX C100 automatic production lathe, ultimately fitted with a Siemens 840D control package,” McMillan says. “We started making parts on it and our production times became typically 30%. I don’t mean a 30% reduction. I mean our run time for a part dropped to 30% of what it was before.”

As to why the company’s new machine made such an unprecedented productivity impact, McMillan points to both the high speed design of the machine and to the equally capable Siemens control package, which represented yet another paradigm shift for TFT.

Previous to the INDEX C100 purchase, TFT had scant experience with Siemens control packages. Much like the INDEX brand, Siemens five-axis controls were perceived as prohibitively sophisticated and just plain different. This lack of familiarity had been reason enough for TFT not to consider Siemens.

These were the company’s perceptions in 2008, before the INDEX C100 machine came into the plant, powered not by a Siemens control package, but by a more commonly accepted brand of CNC.

Upon learning that its new machine was underperforming for TFT, McMillan says INDEX swapped out the machine with an identical model, with one difference. This time, the INDEX C100 was powered by a Siemens motion control package, and TFT was able to set out in earnest to explore what price/cost lessons could be learned from its machine tool investment.

Zero to 5,000 RPM in one second

The INDEX C100 features automated remnant removal. The design has helped TFT increase revenues by eliminating the production delays caused by manual remnant stock removal cycles– typically not an option on lower priced machines.

McMillan recalls that an immediate revelation was seeing the difference a few thousand RPMs can make. The company began to run jobs at 5,000 to 6,000 RPM, ramping up from zero to 5,000 RPM in less than one second and ramping down just as fast. Several economic lessons soon emerged from this capability, as the sustained speed of the machine maximized motion in new time/cost saving ways.

“We never realized before just how much time we were losing waiting on the spindle to stabilize at a new commanded speed,” McMillan reports. “The turret indexing was also extremely fast, with the multiple tools overlapping to cut at the same time with incredibly fast accelerations.”

The INDEX C100 also leverages speed in new ways, as TFT discovered. The company can run more than 1,000 parts without having to change an offset. In addition, an automated remnant removal feature enables the machine to run continuously, by rapidly reloading bar stock without operator interaction.

“On the rest of our machines, we need to pick the remnant out and load a new bar into it,” McMillan explains. “That step should take just a few minutes. But the way things work, a machine can sit idle for six minutes before somebody realizes it, and then it takes five minutes to reload, and all that lost time adds up.”

Another speed-related discovery was the integration of rapid traverse rates, which have always been less than rapid in the company’s experience “A lot of machines advertise rapid traverse rates at maximum speed, but the fact is, unless you’re traveling 10 or 12 inches, traverse speeds have never reached maximum for us.”

Taking motion accuracy literally

As to how the machine eliminates slower traversing and other cost related functions, McMillan says the design of the INDEX C100 is unlike the design of conventional and yes, lower-priced machine bed coordinate systems.

“The INDEX doesn’t use the same coordinate system as other machines. It uses a set of parallelogram bars, a very unique system for rigidity,” McMillan explains. “The machine has a picture frame mount for its turret. The turret is not leveraged off a set of ways like most turrets. It’s close to where it’s sliding, so there’s not a big length over diameter ratio in terms of the tools of the turret hanging out from its support structure. This gives the machine a lot of rigidity for turning, and you can accelerate the axes so fast that you really do achieve faster traverse rates. The window on this machine is just a blur of motion.”

The coordinate system of the INDEX C100 uses a set of parallelogram bars for uniquely rigid motion that is fully exploited by the Siemens SINUMERIK 840D.

TFT’s lead programmer, Nate Price, sees additional efficiency advantages made possible by the INDEX machine’s unique coordinate system, whereby measurements and motion can be programmed based on actual numerical reference points and not on arbitrary points in space.

“On the INDEX, every machine space coordinate, every offset, every measurement that’s used to define how the machine operates has a legitimate explanation of why it is what it is and to where it relates,” Price explains. “This makes it much easier to automate these measurements; whereas, in the past we would measure manually, because these were arbitrary points. On the INDEX, they are defined, literal points. We know exactly what they relate to, so we can define them automatically before the program ever gets to the machine, before the set-up ever starts.”

(Click here to see: Normal Lathe Coordinates and Index C100 Coordinates)

Advanced cost control

According to Price, the Siemens 840D control interface brought a refined and intuitive approach to machine programming, setups and operation — an approach that was especially empowering to him as a programmer.

“I don’t know if anybody just doing set-ups would understand how much of a difference the Siemens control has made in the programming,” Price explains. “It has enabled me to more quickly and easily write the programs, write the post-processes, thus making the setup of special routines go much faster.”

In addition to easier programming and faster setups, Price says the machinists have found that the Siemens 840D enables them to more efficiently control and capitalize on the production potential of the INDEX machine.

“The control gives you ample shortcuts,” says Price. “There is a method of presenting messages to the operator that was not present in the other control. There is so much happening on the machine, it is really difficult to capture all that information on a single screen, but the control helps you keep track of what everything is doing. It’s really easy to get into more detail, without having to go through a lot of pages.”

As another example of CNC operational efficiency, Price points to the way the control manages error messages.

Another advantage brought about by the Siemens control was faster tool loading, made possible by faster and easier CNC programming.

“Tool loading was a big area of improvement,” Price says. “You essentially give the control a mini-program that tells it what tools you’re going to be putting in for this job that you’re setting up. The control will then present the stations on the turrets for you, tell you what tools to put in and what tools to take out. And it’s entirely guided. This has been a huge departure from what we traditionally had dealt with. It really accelerates set-up time.”

More profit per square foot

“I started to look at the numbers from a different perspective,” McMillan relates. “You have all these initial and ongoing costs to build a shop, to put in a floor, to put a roof over it, heat it, cool it, and all these costs can equate to so much per hour. Now you buy a machine that’s $600,000 versus a machine that’s $300,000 over 10 years. We run almost 24 hours a day, seven days a week, which helps our analysis. For us, it comes out to about an eight dollar per hour difference to buy the $600,000 machine. And for eight bucks more an hour, we’re getting triple the production out of that same square footage.”

Another way the company has measured its return on its investment in advanced machine-control manufacturing has been to witness the change in the people uplifted by the technology. Now, owner, programmer, machinists and others at TFT are enthusiastic about the possibilities of their more advanced, CNC-based manufacturing.

McMillan says that it will be such investments in machines and in people that will keep his company from selling itself short, having proven that with the right machine and the right motion control technology, anything is possible.

“We had a job that ran a couple of weeks ago,” McMillan recalls. “I received several e-mails before I even came to work that day. Different people were sending me e-mails that said in effect: Wait until you see what we’re doing with the INDEX today!”

See the video HERE!

For more information, contact:

Siemens Industry, Inc.

Motion Control Business — Machine Tools

390 Kent Avenue

Elk Grove Village, IL 60007

Tel: (847) 640-1595

Fax: (847) 437-0784

Web: www.usa.siemens.com/cnc

E-mail: SiemensMTBUMarCom.industry@siemens.com

Attention: John Meyer, Manger, Marketing Communications

Twitter: www.twitter.com/siemens_cnc_us

Facebook: www.facebook.com/SiemensCNC

A practical alternative to mechanical braking and non-regen drives systems in the converting, packaging, wireforming and printing industries

by William Gilbert, Industry Business Development Manager,

Converting and Cranes, Motion Control Solutions

The unwind brake operates much like the brake on a car, with disk, calipers and pads. The tension is linked to a position controller.

During the operation of any converting machine, whether for film, foil, wire, paper or board, plus most large printing presses, rolls of materials are handled by unwinds, often still driven by pneumatically operated braking systems. The traditional tension control system for an unwind stand is a simple mechanical brake. In principal, the unwind brake mechanically operates much like the braking system on your car, with a disk, caliper and pads, but is controlled by a tension sensor linked to a setpoint controller. As the roll unwinds, the tension is maintained by the brake for smooth passage of the material through the dies or rollers, resulting in better package alignment, less wrinkling, better print registration, even more consistent wire dimensioning and other production positives. These mechanical brake unwinds are effective in controlling the tension, but have inherent problems of heat and power loss, plus mechanical wear and constant maintenance needs, substantially impacting machine uptime.

The typical mechanical brake is pneumatically controlled and may utilize several sets of friction pads to control the web tension as the roll dimension decreases. Plus, a reasonable pressure range in many applications might be from 15-90psi or a 6:1 drop, a range significantly less than the core to full roll ratio for most jobs, an obvious inefficiency in operation.

To affect good tension control on the brake, these friction pad sets need to be manually changed in an out of the brake assembly, depending on the desired operating tension and the roll diameter changes involved. Often, the adjustments are several per roll during this manual changeover. Because the mechanical brake creates the unwind tension through friction, it generates substantial heat and often requires a separately powered fan for cooling to operate effectively. This friction also means the pads are subject to rapid wear, requiring frequent and time-consuming changes or maintenance checks.

For almost a decade now, this old technology has been gradually replaced, though usually in the lower power ranges, by newer precision technology, involving AC motors, drives and electronic loadcells. On converting lines today, a further leap forward is being made with the onset of active front end technology.

With such technology, the operating principle is as follows.

Since the unwind application is regenerative (regen) in nature, a driven unwind needs to return the energy that the mechanical the brake produced as heat back to the AC line. In the past, regen DC drives have been successfully applied as driven unwinds, but DC drive systems are no longer common and even during their prime were very costly. Early in the AC drive technology for these applications, the drives did not have the capability to regenerate the power back to the AC line and, when applied as unwind brakes, required regen resistors to dissipate the tension energy. This was wasteful and costly.

Today’s AC drive systems now have the technology to regenerate the energy back to the AC line just as the DC drive did, but with added benefits to the user and machine designer alike. Sending the tension energy back to the line means power that once was wasted can now be retained, instead of the system producing heat and worn parts. When the drive is equipped with active front end technology, it will return the previously wasted energy with near unity power factors, something not possible for any DC drive system.

Even an open loop AC drive motor combination offers a tension control range far beyond the limits of a pneumatic braking system. Synchronous AC motors can offer precision open loop torque control without a tension sensor, thereby saving further cost and inventory. Today’s highly accurate tension control systems can be designed with high resolution (sin/cos) feedback encoders on both the unwind motor and dancer position feedback. Additionally, in more advanced active front end designs, the regen capability of the drive can actually assist in the increase of stopping times and tension control regulation, owing to the four quadrant control, i.e., the motor can sink or supply current to the motor in both directions.

AC regen drive systems can also offer today’s machine designer software configurations with a wider range of control flexibility. They can be configured to operate in the most basic mode with no motor encoder or with tension feedback to system configurations, utilizing either dancer position sensors or loadcells. Alternatively, they can function as a programmable logic controller (PLC), controlling the machine functions on the unwind, while also connecting directly to a human-machine interface (HMI) panel. In most converting, packaging and printing applications, the dancer position sensor can be used to calculate the starting diameter of a roll, eliminating additional diameter sensors and the possibility of operator error in the roll diameter input. Further enhancements for unwind spindle motion such as jog for threading have also emerged for operator convenience through active front end technology.

Beyond the obvious cost savings of pad replacements on mechanical braking systems, AC motors are virtually maintenance free by comparison to DC motors, as AC motors have no brushes, do not require controller contactors to reverse direction of motor rotation or have commutators. Fewer moving parts invariably means less motor maintenance, for additional cost and time savings.

In the most advanced systems, common DC bus regulation, energy-monitoring devices for near unity power and, through the use of mechatronic services often provided by the manufacturers, “turn off” parameters in vector drives are possible. Mechatronic services can also be utilized for the proper tuning of these drives onsite or during machine build. For designers, such services further assist in the proper sizing of motors, based on the mechanical and electrical forces generated by machine operation or computerized simulation of it.

This combination of improved operation, reduced maintenance, motor power savings and conservation of nearly all energy within the system make AC regen drives with active front end technology a decided advantage for machine designers and end users of converting, packaging, printing, wireforming and other roll-fed machinery, where driven unwinds can be implemented.

For more information on regenerative drive motors and systems, please contact:

For product information and inquiries, call +1 800 879 8079 ext. Marketing Communications or e-mail SiemensMTBUMarCom.industry@siemens.com.

Continue readingDuring EASTEC 2013, Siemens will present its newest solution for the job shopfloor, the Sinumerik 808D, an attractively-priced CNC for entry-level milling and turning machines.

Over 50 years of Siemens CNC experience have been brought to the development of this control, which is specially designed for the highly competitive, high-volume 230V, three-phase and economy machine tool market. With up to three-axis plus spindle control capability in milling or turning applications, the 808D is offered as a package with Siemens Sinamics drives and Simotics motor solutions. The Sinumerik 808D will be immediately available for OEM machine tool builders and in-the-field retrofit installation by Siemens business partners worldwide.

Start with an IP 65 enclosure, easy-to-load USB port, mechanical, hot and soft keys for easy, intuitive operation, clamp-mounted front panel and a modular design that allows customizing by machine model or with out-of-the-box operation. Plus, the machine control panel is connected using plug-and-play technology using a simple USB interface. On a turning machine, the Sinumerik 808D provides high contour accuracy and maximum machine productivity on high-volume production runs. On a milling machine, likewise, the Sinumerik 808D offers machine builders of vertical machining centers all the benefits of the Siemens MDynamics velocity control for mold and die section work.

A 7.5-inch LCD color display with 640 x 480 resolution for easy reading, selectable function keyboard, rotary dials for speed and spindle override, LED tool number display, durable buffer battery and rear connection ports for USB, RS232 C, distributed and onboard I/O, setpoint to feed axes and spindle, spindle encoder, fast I/O, e.g., for probes and handwheel operation are all standard on the Sinumerik 808D.

With 80-bit nano floating point accuracy and intelligent jerk limitation for smoother path cutting and less mechanical stress on the machine structures, workpiece accuracy and repeatability are improved. Whether turning with a C-axis changeover or milling mold sections where path control is paramount, the Sinumerik 808D has been designed to significant heighten the performance level of basic machine tools.

With programGuide Basic, a wide range of pre-determined technology cycles are available, in addition to the standard G-code and coordinate transformation language. Standard ISO codes can also be intermixed with high-level Sinumerik CNC commands on the 808D. The onboard contour computer further allows complex programs to be created and modified at the CNC without the need for a CAD/CAM system.

For routine or even online help with maintenance or troubleshooting issues, a simple push of a button is the only requirement, as the complete library of system parameters is accessible onscreen.

Commissioning is made easier with a ready-to-run PLC program. Customizing the PLC is simpler, as well, with function and data blocks for program testing and debugging built-in. The Sinumerik 808D further allows easy connection to the PLC I/O of other machine devices, whether proximate or remote. The open architecture of Siemens CNC has not been sacrificed on the 808D, so customized HMI screens and menu trees are easily defined and created.

Finally, with Manual Machine Plus (MM+) function on this new CNC enables transition from conventional machining to CNC programming. A machine equipped with MM+ can be operated using handwheels but with all the benefits of CNC-assisted technology cycles.

The Sinumerik 808D is offered with full THREE-YEAR WARRANTY on parts and labor.

FOR END-USERS

In addition to the above features and benefits for the machine builder, shop operators and programmers alike will appreciate the Sinumerik 808D for its many end-user advantages, including simplified keyboard entry of all program values, named part programs in subfolders just like a PC, convenient shortcut keys to access tool offset lists or the Program Manager, intelligent jog features easily identified and graphically-supported, precise tool handling and tool wear data readily available onscreen and a powerful simulation routine. An operator can access all system information and obtain online help, whenever needed.

The multimedia training materials include on-screen tutorial video and full step-by-step procedures to go from the blueprint to the finished part. For offline training, a fully operable software machine control panel on a PC is available to end users.

For more information about Siemens CNC solutions for the machine tool industry, visit our website: www.usa.siemens.com/cnc.

For more information on the this story, contact:

SIEMENS INDUSTRY, INC.

DRIVE TECHNOLOGIES

MOTION CONTROL

MACHINE TOOL BUSINESS

390 Kent Avenue

Elk Grove Village, IL 60007

Phone: 847-640-1595

Fax: 847-437-0784

Web: www.usa.siemens.com/cnc

Email: SiemensMTBUMarCom.sea@siemens.com

Attention: John Meyer, Manager, Marketing Communication

Follow us on Facebook: www.facebook.com/SiemensCNC or Twitter: www.twitter.com/siemens_cnc_us.

—

Siemens Industry Sector is the world’s leading supplier of innovative and environmentally friendly products, solutions and services for industrial customers. With end-to-end automation technology and industrial software, solid vertical-market expertise, and technology-based services, the sector enhances its customers’ productivity, efficiency and flexibility. With a global workforce of more than 100,000 employees, the Industry Sector comprises the Industry Automation, Drive Technologies and Customer Services Divisions as well as the Metals Technologies Business Unit.

The Siemens Drive Technologies Division is the world’s leading supplier of products, systems, applications, solutions and services for the entire drive train, with electrical and mechanical components. Drive Technologies serves all vertical markets in the production and process industries as well as the infrastructure/energy segment. With its products and solutions, the division enables its customers to achieve productivity, energy efficiency and reliability.

Continue reading