Contact us today:

(847) 934-4500

tdaro@bernardandcompany.com

Contact us today:

(847) 934-4500

tdaro@bernardandcompany.com

Han-Kwang USA recently attended the Fabtech Mexico show, co-located with the Metalform and Weldmex shows. Over 8000 visitors per day were in attendance to see over 400 exhibitors and hundreds visited the Han-Kwang booth to watch the company’s plate laser, Model FS3015, in action. Onsite for this exhibition were Han-Kwang’s director of North American sales, Robert Won, as well as engineer Philip Kim and the company’s distributors in Mexico.

Mr. Won commented, “The Mexican market has been excellent for Han-Kwang. We’re assisted by a very strong distributor, who has an extensive sales and service network to cover the entire region with us. Our sales recently have been quite strong, because of the quality of our machines and the quality of our representation in Mexico. I believe this will continue to be a very good market for our plate and tube lasers into the future.”

The FS3015 is a 5’ x 10’ plate laser with shuttle tables, flying optic design, fast-axial flow type Panasonic resonator, S5 high-speed cutting head, twin servos for precise gantry motion and Siemens CNC, motors and drives to power and control the machine’s total operation. This plate laser is available in 2, 2.5, 4 and 6KW models to handle any type of plate cutting with speed and precision position accuracy to +/- 0.004” per 120” of travel. The machine also has automatic focus control with multi-pulse piercing technology, unique to Han-Kwang.

This machine was specifically chosen for display at the booth during Fabtech Mexico, because of its performance and value combination for the local market.

Han-Kwang enjoyed a very successful exhibition at Fabtech Mexico, held May 11-13

For more information or to arrange a visit to Han-Kwang for a demonstration, please contact:

HAN-KWANG USA INC. 1120 Garfield Street Lombard, IL 60148 Phone: 630-916-0200 Fax: 630-916-0300 Web: www.hankwangus.com Email: salesusa@hankwang.co.kr Attention: Robert Won, Eric Kim or Jane Lee

Agency contact: Tim Daro Bernard & Company tdaro@bernardandcompany.com 847-934-4500

Continue reading

Advanced Machine & Engineering Co. (AME) Rockford, IL announces their return to IMTS 2010. As in the past, they will have two booths to showcase their products and services.

Visit Booth W-2405 to learn about precision machine components, featuring:

Visit Booth E-5708, for additional AME products such as:

Our sister company, Hennig, Inc., will have their complete line of products in Booth E-5708 and W-2405.

Visit Booth N-7216 to learn about carbide sawing systems, featuring:

Advanced Machine & Engineering Co., is a manufacturer located in Rockford, IL, serving the Machine Tool Industry with precision components and accessories, including spindle interface components, workholding devices, and, through our sister company, Hennig, machine enclosures, chip removal and filtration systems. The Fluid Power – Safety markets are served with cylinder rod locks and safety catcher devises; and the Production Saw market with our Amsaw carbide saw machines and Speedcut blade products. AME has manufacturing partners and customers around the world and across the U.S. To learn more, visit www.ame.com.

Hennig, Inc. design and produces custom machine protection and chip/coolant management products for state-of-the-art machine tools. Hennig products are designed to protect against corrosion, debris and common workplace contaminants. Manufacturing facilities located in the U.S., Germany, Brazil, India, Japan, China and South Korea. Repair centers are located in Machesney Park, IL; Chandler, OK; Livonia, MI; Blue Ash, OH; Mexico City, Mexico and Saltillo, Mexico. To learn more, visit www.hennigworldwide.com.

For more information, contact:

Tim Waterman

ADVANCED MACHINE & ENGINEERING CO.

2500 Latham St.

Rockford, IL 61103

Phone: 815-316-5277

Fax: 815-962-6483

E-mail: info@ame.com

Connect with AME online:

The unit has 4” insulated walls, an aluminized steel exterior and Type 430, 2B finish stainless steel interior. The door is equipped with adjustable positive-latching door hardware and adjustable offset hinges. A 130 CFM blower pulls air through the air jacket on the inner oven for cooling and a solenoid automatically opens the outlet for purging.

On this Grieve inert atmosphere oven, the inner oven walls are sealed directly against a 1/2” thick silicone rubber door seal with an air jacket installed on the inner oven for cooling and a blower shaft seal and outlet with pressure relief also onboard. All the interior seams are welded gas-tight and all wall penetrations are equipped with compression fittings.

Controls onboard No. 967 include a digital programming temperature controller, manual reset excess temperature controller with separate contactors and a recirculating blower airflow safety switch. The critical pressure of the oven chamber is monitored with a pressure regulator, flow meter and pressure gauge.

For more information, please contact: THE GRIEVE CORPORATION, 500 Hart Road, Round Lake, Illinois 60073-2835 USA. Phone: (847) 546-8225. Fax: (847) 546-9210. Web: www.grievecorp.com. Email: sales@grievecorp.com. Attention: Frank Calabrese.

NEWS RELEASE: THE GRIEVE CORPORATION Agency contact: DATE: May 21, 2010 Tim Daro 847-934-4500

Continue readingHennig, Inc., Machesney Park, Ill., announces their return to IMTS 2010.

Visit Booth E-5708 to learn about Hennig’s machine protection products featuring:

Visit Booth W-2405, for additional Hennig products such as:

Other products include roll-up and flexible apron covers, wiper systems, and telescopic springs.

Our sister company, Advanced Machine & Engineering, will have their complete line of products in Booth E-5708 and W-2405.

Tim Waterman

Hennig Inc.

9900 N. Alpine Rd.

Machesney Park, IL 61115

(815) 316-5277

info@hennig.ame.com

www.hennigworldwide.com

—

Hennig, Inc. designs and produces custom machine protection and chip/coolant management products for state-of-the-art machine tools. Hennig products are designed to protect against corrosion, debris and common workplace contaminants. Manufacturing facilities located in the U.S., Germany, Brazil, India, Japan, China and South Korea. Repair centers are located in Machesney Park, IL; Chandler, OK; Livonia, MI; Blue Ash, OH; Mexico City, Mexico; and Saltillo, Mexico. To learn more, visit www.hennigworldwide.com.

Advanced Machine & Engineering Co., our sister company, is a manufacturer located in Rockford, IL, serving the Machine Tool Industry with precision components and accessories, including spindle interface components and workholding devices. The Fluid Power-Safety markets are served with cylinder rod locks and safety catcher devises; and the Production Saw market with our AmSaw carbide saw machines and Speedcut blade products. AME has manufacturing partners and customers around the world and across the U.S. To learn more, visit www.ame.com.

Continue readingAdvanced Machine & Engineering Co. (AME) Rockford, IL announces their participation in IMTS 2010.

Visit the pioneers of carbide sawing systems in North America at Booth N-7216, featuring: Amsaw high-speed production sawing machines for billets, tubes, rails and more Speedcut carbide saw blades.

Amsaw systems are specifically designed for faster cutting speeds, longer tool life and enhanced precision of carbide saw technology. Amsaw systems use carbide-or cermet-tipped blades to provide fast, accurate cutting for ferrous and non-ferrous materials, bars or billets, rails, profiles, pipes and tubes.

AME custom machine services include complete design and build services to go along with Amsaw sawing systems, blades and machine rebuilding services.

Speedcut sells and services saw blades with a variety of styles and tooth configurations. New carbide, cermet and thin-kerf blades are available along with complete in-house facilities for sharpening, re-tipping and repairing older blades. Virtually any size blade can be fully reconditioned, so it’s ready to cut ferrous and non-ferrous materials, bars or billets, rails profiles, pipes and tubes.

Speedcut can build and service blades as large as 80 inches in diameter, so whatever your application, you can make sure your blades are always sharp and ready for the rigors of high-speed, high-volume cutting.

See our other AME and Hennig group products in Booths E-5708 and W-2405.

Advanced Machine & Engineering Co., is a manufacturer located in Rockford, IL, serving the Machine Tool Industry with precision components and accessories, including spindle interface components, workholding devices, and, through our sister company, Hennig, machine enclosures, chip removal and filtration systems. The Fluid Power – Safety markets are served with cylinder rod locks and safety catcher devises; and the Production Saw market with our Amsaw carbide saw machines and Speedcut blade products. AME has manufacturing partners and customers around the world and across the U.S. To learn more, visit www.ame.com.

Hennig, Inc. design and produces custom machine protection and chip/coolant management products for state-of-the-art machine tools. Hennig products are designed to protect against corrosion, debris and common workplace contaminants. Manufacturing facilities located in the U.S., Germany, Brazil, India, Japan, China and South Korea. Repair centers are located in Machesney Park, IL; Chandler, OK; Livonia, MI; Blue Ash, OH; Mexico City, Mexico and Saltillo, Mexico. To learn more, visit www.hennigworldwide.com.

For more information, contact:

Tim Waterman

ADVANCED MACHINE & ENGINEERING CO.

2500 Latham St.

Rockford, IL 61103

Phone: 815-316-5277

Fax: 815-962-6483

E-mail: info@ame.com

Connect with AME online:

At this manufacturing location, unlike a conventional parallel orientation assembly line, the frame and the axles move perpendicular to the work stations, on rail track-mounted dollies. Owing to the highly customized nature of the RV industry, it is frequently necessary for one-off assembly operations to be performed in sequence, as the content of a day’s quota. Plus, given the height of the units, these work platforms are invaluable assets to the production process at the company. In this case, work platforms were engineered and built to enable faster access from both sides of the unit.

With the work platform concept, the units can now be rolled from one station to the next, allowing the various build-ups to occur in sequence. As each step in the manufacturing process is completed, the entire work platform is raised. Because of the length of the platforms, (up to 30’) and the weight load bearing requirements (typically several hundred lbs. of materials and 1-2 workers per side), stability was a key issue.

One of the engineers at the integrator comments, “We’d seen the cylinder rod lock concept in a trade magazine article and contacted Advanced Machine & Engineering to discuss our needs. On each corner of the lifting system, the rod lock would need to attach to the platform and a separate rod installed for the Amlok.”

The Amlok® design, originated by AME, allows free movement of the cylinder during normal operation. When the lift system is stopped or when air pressure is lost, the locking mechanism secures the load in position until released by the return of air

The Amlok rod locks used in this application are the company’s fourth generation design and prevent the typical problems encountered with most large scale air movement systems, namely, over-travel, bouncing, drifting and reverse travel. The patented intensifier mechanism of the AME rod lock is spring-operated to lock and is released by normal 60-160psi air lines. These devices were deemed both cost-effective and functionally desirable for the work platform application at the RV builder.

On this project, AME supplied the rod locks, mounting brackets and all hardware, while the integrator supplied the controls, pressure valves and all pneumatic circuitry to match the plant’s existing air lines, which were substantial, given the number of air tools used in the manufacturing process here.

Following the installation, the RV builder commissioned an independent engineering firm to fully certify that the work platforms met all relevant codes. This certification has been received.

Worker satisfaction with the system and the platform stability has been found to be very high, as well.

For technical questions on this story or the Amlok devices, please contact Ken Davis (ken@ame.com) or Shane Hatfield (shane@ame.com), the AME engineers on the project.

—

Advanced Machine & Engineering Co., is a manufacturer located in Rockford, IL, serving the Machine Tool Industry with precision components and accessories, including spindle interface components, workholding devices, and, through our sister company, Hennig, machine enclosures, chip removal and filtration systems. The Fluid Power – Safety markets are served with cylinder rod locks and safety catcher devises; and the Production Saw market with our Amsaw carbide saw machines and Speedcut blade products. AME has manufacturing partners and customers around the world and across the U.S. To learn more, visit www.ame.com.

Hennig, Inc. design and produces custom machine protection and chip/coolant management products for state-of-the-art machine tools. Hennig products are designed to protect against corrosion, debris and common workplace contaminants. Manufacturing facilities located in the U.S., Germany, Brazil, India, Japan, China and South Korea. Repair centers are located in Machesney Park, IL; Chandler, OK; Livonia, MI; Blue Ash, OH; Mexico City, Mexico and Saltillo, Mexico. To learn more, visit www.hennigworldwide.com.

For more information, contact:

Tim Waterman

ADVANCED MACHINE & ENGINEERING CO.

2500 Latham St.

Rockford, IL 61103

Phone: 815-316-5277

Fax: 815-962-6483

E-mail: info@ame.com

Connect with AME online:

The unit has a 2” insulated floor with truck wheel guide tracks, an aluminized steel interior and exterior and an interior oven light. The roof has a 4” square access port and a 8” x 10” double pane Pyrex window that is adjacent to the access port.

Controls onboard No. 1015 include a digital indicating temperature controller, an adjustable, thermocouple actuated, manual reset excess temperature controller and 30-hour shut down timer.

For more information, please contact: THE GRIEVE CORPORATION, 500 Hart Road, Round Lake, Illinois 60073-2835 USA. Phone: (847) 546-8225. Fax: (847) 546-9210. Web: www.grievecorp.com. Email: sales@grievecorp.com. Attention: Frank Calabrese.

The unit has 4” insulated walls, an aluminized steel exterior and Type 430 stainless steel interior. It is also equipped with an integral leg stand with casters and leveling pads.

Controls onboard No. 945 include a digital indicating temperature controller, manual reset excess temperature controller with separate contactors, recirculating blower airflow safety switch and SCR power controller.

For more information, please contact: THE GRIEVE CORPORATION, 500 Hart Road, Round Lake, Illinois 60073-2835 USA. Phone: (847) 546-8225. Fax: (847) 546-9210. Web: www.grievecorp.com. Email: sales@grievecorp.com. Attention: FrankCalabrese.

NEWS RELEASE: THE GRIEVE CORPORATION Agency contact: Tim Daro 847-934-4500

DATE: March 22, 2010

Continue reading

Automated loading and parts handling system complement state-of-the-industry laser and machine control technology

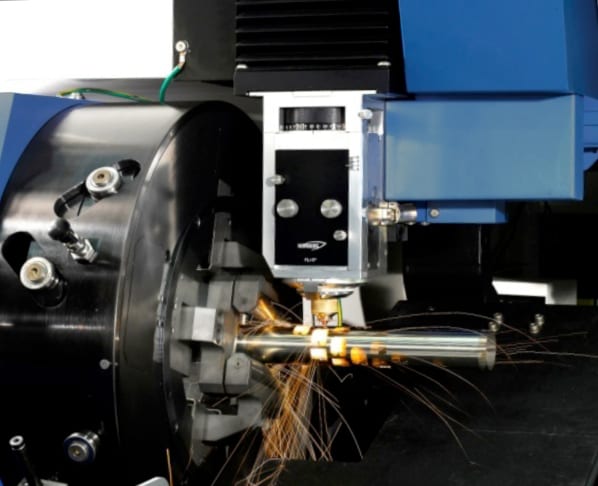

Han-Kwang USA announces immediate availability of its new Model TL 6015, a tube cutting laser system capable of handling 24’ long, 6.5” diameter workpieces up to 1/4” wall thickness in mild steel and 0.200” in stainless steel. Equipped with a powerful 2.5KW Panasonic laser and a versatile Siemens 840D CNC to control all functions of the machine, the TL 6015 can significantly increase the tube production in any department or shop, especially when used with Han-Kwang’s proprietary “Flex 3D” tube cutting software . The unit comprises an automatic bundle loading system with tube V-support, auto-centering rotary chucking system, laser cutting station and automatic parts removal station.

Maximum positioning speed on this new laser system is 4700 ipm for the X-

Han-Kwang S5 Cutting Head, featuring Auto Focus Control; adjusts focal length of cutting lens to automatically compensate for material variations and rapid changeover

axis and 120 rpm for the rotary A-axis. Max acceleration rate is 1G, while the laser beam is precisely controlled by the unique Han-Kwang Auto Focus Control (AFC). This AFC technology allows the machine to automatically adjust the focal length of the cutting lens to accommodate variations in the materials being processed or changes in material feed, which eliminates the downtime normally associated with manual adjustments.

A new generation of sensing board in the S5 laser cutting head on the TL 6015 translates into faster cutting speeds on round, square or rectangular shapes.

In a recent design modification, the entire loading section of the machine has been enclosed, as depicted in the attached illustration.

For more information or to arrange a demonstration, please contact:

HAN-KWANG USA INC. Phone: 630-916-0200 Web: www.hankwang.com

Agency contact: Tim Daro Bernard & Company tdaro@bernardandcompany.com www.bernardandcompany.com

Continue reading

We are very pleased to announce the promotion of Christian Schedler to the Product Manager position at this division.

In his new role, Christian will oversee P&L responsibility for the division, including its sales, application engineering, product management and project management functions.

Christian’s distinguished career has encompassed R&D, Engineering and Product Manufacturing. He has a broad assembly and service experience on machine tools and knows the market’s needs for productivity improvements. Prior to this promotion, he worked in service as a Global Service Rep for a German machine tool company and as a Designer of carbide saws at Advanced Machine & Engineering. Christian has the experience, energy and judgment necessary to lead the division to continued success, insuring its future growth objectives are achieved.

Advanced Machine & Engineering Co., is a manufacturer located in Rockford, IL, serving the Machine Tool Industry with precision components and accessories, including spindle interface components, workholding devices, and, through our sister company, Hennig, machine enclosures, chip removal and filtration systems. The Fluid Power – Safety markets are served with cylinder rod locks and safety catcher devises; and the Production Saw market with our Amsaw carbide saw machines and Speedcut blade products. AME has manufacturing partners and customers around the world and across the U.S. To learn more, visit www.ame.com.

Hennig, Inc. design and produces custom machine protection and chip/coolant management products for state-of-the-art machine tools. Hennig products are designed to protect against corrosion, debris and common workplace contaminants. Manufacturing facilities located in the U.S., Germany, Brazil, India, Japan, China and South Korea. Repair centers are located in Machesney Park, IL; Chandler, OK; Livonia, MI; Blue Ash, OH; Mexico City, Mexico and Saltillo, Mexico. To learn more, visit www.hennigworldwide.com.

For more information, contact:

Tim Waterman

ADVANCED MACHINE & ENGINEERING CO.

2500 Latham St.

Rockford, IL 61103

Phone: 815-316-5277

Fax: 815-962-6483

E-mail: info@ame.com

Connect with AME online: