Contact us today:

(847) 934-4500

tdaro@bernardandcompany.com

Contact us today:

(847) 934-4500

tdaro@bernardandcompany.com

It is very common for us to hear “My son (or daughter) set up our Facebook page (twitter account, blog etc) but nothing ever came of it.” You cannot have an “if you build it, they will come” mentality when it comes to social media.

Your online presence needs to be built, given life and then it needs to be nurtured so it stays alive and grows bigger and stronger.

Twitter or posting a blog once in a while. It’s not about someone who already has a full time job at your company spending a few minutes each week, “checking things out“. Here is the truth about social media: the beginning, the setting it up is actually the least time consuming and the easiest part. Why? because no one has found you yet and no one has started to communicate and interact with you yet. You are also not developing content, researching what’s being said and what are good, relevant things for you to be talking about. Getting content out into the world takes time. What are people interested in and talking about? How do you or your clients contribute to that conversation? This is not about selling products it is about participating in a conversation so you become the “go to” person for information and guidance in the world that your business is part of. I hear people say all the time, “what’s the big deal? I’ll just throw some things up on twitter once in a while and blog once in a while.” Sure, that is great if you want to use social media as an outlet for your daily ponderings… but if you want to get paying clients out of it, it’s a whole different ball-game.

Twitter or posting a blog once in a while. It’s not about someone who already has a full time job at your company spending a few minutes each week, “checking things out“. Here is the truth about social media: the beginning, the setting it up is actually the least time consuming and the easiest part. Why? because no one has found you yet and no one has started to communicate and interact with you yet. You are also not developing content, researching what’s being said and what are good, relevant things for you to be talking about. Getting content out into the world takes time. What are people interested in and talking about? How do you or your clients contribute to that conversation? This is not about selling products it is about participating in a conversation so you become the “go to” person for information and guidance in the world that your business is part of. I hear people say all the time, “what’s the big deal? I’ll just throw some things up on twitter once in a while and blog once in a while.” Sure, that is great if you want to use social media as an outlet for your daily ponderings… but if you want to get paying clients out of it, it’s a whole different ball-game. In the PR/ad world, we need to maintain this knowledge for our business to grow, but we also need to be a source and knowledge base for our clients so they can to look to us for expertise and guidance. How do we do this? We need to know about, speak about and write about anything and everything that is relevant to our world as well as theirs. We also need to know where our clients need to have a presence in order for social media to work for them. They look to us for knowledge and guidance and as their ad/PR agency; we better know what we are talking about.

In the PR/ad world, we need to maintain this knowledge for our business to grow, but we also need to be a source and knowledge base for our clients so they can to look to us for expertise and guidance. How do we do this? We need to know about, speak about and write about anything and everything that is relevant to our world as well as theirs. We also need to know where our clients need to have a presence in order for social media to work for them. They look to us for knowledge and guidance and as their ad/PR agency; we better know what we are talking about.

By definition, says Josh Johnson, vice-president, Continental Machine, Rockford, Illinois, his prototype and short-run production shop must constantly run lean. There can be no tolerating excessive programming, set-up or machining time of any kind, otherwise the shop loses and, in this economy, Johnson notes, that is simply unacceptable.

Continental Machine is a seven-person, 13,000 square-foot facility that houses a variety of CNC milling, turning, wire EDM, hole popping and grinding machines, as well as various sheetmetal and plastic injection molding machinery. Therefore, the shop is well positioned to produce a wide variety of metal and plastic prototypes used by its diverse customer base, which spans markets such as window hardware, bicycle components, automotive parts, chemical processing, medical devices and foodservice equipment. Materials processed here are just as wide-ranging, including aluminum, CRS, tool steels such as A2 and D2, zinc, brass, copper, bronze, titanium and a variety of engineered plastics such as glass-filled Delrin.

Recently, this job shop purchased a Fryer Easy Turn-21 CNC Combination Lathe, controlled by a Siemens SINUMERIK 840D sl numerical control. The two operators responsible for this machine upgrade at Continental had limited experience with CNC and none whatsoever with the Siemens protocol, as this was the first of its kind at the shop.

The Easy Turn-21 was particularly appealing to Josh Johnson, who comments, “The set-up is extremely easy. Teaching the tools, altering the lengths and diameters is kept very simple. After the initial learning curve, which took only a few days, the operators picked up on the conversational programming, right away. Also, one of the best features on the machine was that you could still turn the parts by using the electronic handwheel and just one function, such as hogging off material automatically or putting on a tapered thread.” He noted this feature was not only more comfortable for the operators, but it also allowed them to quickly and efficiently prove out part programs. Johnson commented that this would not have been possible on previous machines, owing to the flexibility of the control onboard the Fryer. The result has been a minimum 20% improvement in the overall cycle time on most part programs run at Continental. For this primarily prototype job shop, that fact translates into a substantial increase in the work product possible here.

Echoing this sentiment, Sue Ostrander, sales manager, Fryer Machine Systems, explained the process that led her company to select the SINUMERIK 840D sl numerical control for all its milling and turning machines, a move that was recently formalized by the company and announced to the trade.

“Since its inception 26 years ago, family-owned Fryer Machine Systems has based its operation on three core principles: build a quality product, price it fairly and provide quality service. This philosophy has allowed Fryer’s business to grow even in challenging times,” she said.

Fryer manufactures a diverse line of over 50 models of high-quality CNC machine tools in its 50,000 square-foot facility in Patterson, New York. Over the years, Fryer has become well-respected for its quality and innovation, throughout the job shop and production machining market segments.

“Moving to the Siemens 840D sl platform was the next step in Fryer’s ongoing commitment to provide our customers with the most innovative machine tools available in the market today,” Ostrander continued. “The Siemens solution allows machine tool end-users to achieve higher productivity through easy and intuitive features and step-by-step, on-screen programming. This enables them to dramatically reduce set-up, programming, and tooling times, while significantly increasing output.”

“The SINUMERIK 840D sl modular design allows us to take full advantage of the superior mechanical features in our machines,” continued Larry Fryer, president and CEO, Fryer Machine Systems. “Fryer has always been known for our easy conversational controls and the move to Siemens has allowed us to greatly enhance this feature,” Fryer noted. “The 840D sl menu-driven system combines an advanced geometry calculator that displays the part while the operator is programming it. Sophisticated solid model graphics allow the operator to verify the part program with more clarity than ever before,” he said.

Fryer further stated, “Siemens provides us with a highly flexible solution that is critical to our ability to meet the specific needs of each customer. Our enhanced capability to offer the same control for both turning and milling gives Fryer machines a unified platform that is very important to customers both in the short-term and for long range expansion. Coupled with Siemens quality and reliability, they are invaluable to us in competing in today’s aggressive marketplace.”

Johnson added this comment on the service and training received by his operators at Continental. “Siemens has been helpful and very thorough in their training and after-sale service. The ShopTurn program, being integral to the control, now enables us to accurately determine tool path, potential collisions, tool changes and real world run time. This makes our operators’ jobs much easier, with the added benefit of allowing us to estimate much more accurately than ever.” Johnson further noted the CNC has substantial hard drive space, thus allowing most programs to be stored directly on the machine, though the company does maintain a back-up system.

For more information on this story, please contact:

CONTINENTAL MACHINE CO.

Email: conmach@onecommail.com

FRYER MACHINE SYSTEMS, INC.

Web: www.fryermachine.com

SIEMENS MACHINE TOOL BUSINESS

John Meyer

Manager, Marketing Communications

Siemens Industry, Inc.

(847) 640-1595

www.usa.siemens.com/cnc

SiemensMTBUMarCom.industry@siemens.com

Follow us on Facebook: www.facebook.com/SiemensCNC or Twitter: www.twitter.com/siemens_cnc_us.

—

Siemens Industry Sector is the world’s leading supplier of innovative and environmentally friendly products, solutions and services for industrial customers. With end-to-end automation technology and industrial software, solid vertical-market expertise, and technology-based services, the sector enhances its customers’ productivity, efficiency and flexibility. With a global workforce of more than 100,000 employees, the Industry Sector comprises the Industry Automation, Drive Technologies and Customer Services Divisions as well as the Metals Technologies Business Unit. For more information, visit http://www.usa.siemens.com/industry.

The Siemens Drive Technologies Division is the world’s leading supplier of products, systems, applications, solutions and services for the entire drive train, with electrical and mechanical components. Drive Technologies serves all vertical markets in the production and process industries as well as the infrastructure/energy segment. With its products and solutions, the division enables its customers to achieve productivity, energy efficiency and reliability. For more information, visit http://www.usa.siemens.com/drivetechnologies.

Continue reading

Old customers and prospective new ones are being courted more often, both in print ads, direct mail (making a nice comeback as it’s now unique!) and online via blast email, regular newsletters and the inexpensive if rather impersonal vid conference.

The impact of such activity has had the collateral if unintended consequence of making our agency quite busy, this year. So thanks for that, clients!

Much more important is the fundamental tenet of marketing being applied here. They can’t buy from you if they don’t know you’re on the planet, to be blunt.

And, whether they’re currently buying or not, the ones who’ll stay in business are the targets of our messages for clients.

Having lived through four major recessions in business in my time, the theory has been proven true, time and again. Namely, companies who continue to maintain a presence in their market, by whatever means, come back faster and stronger than those who don’t. This is a fact and we have the evidence to prove it, for anyone interested.

TD

Hennig custom enclosures on generators provided through W.W. Williams to huge dairy products processing plant in Michigan.

Machesney Park, IL-On a recent installation at the Ovid, Michigan processing plant of the Michigan Milk Producers Association (MMPA), the standby power generation system supplier, W.W. Williams (WWW) of Dearborn, Michigan, required an increased level of sound and environmental protection on the three generating stations, in accordance with the specs received from their customer’s architectural firm. They turned to their enclosure suppliers for assistance, as the challenges were many. For the complete package, the project was awarded to Hennig. As WWW’s Brunswick, Ohio-based project manager on the job, Al LaManna, puts it, “We’d begun to see Hennig as our go-to guys on enclosures, owing to the continued satisfaction we’d experienced with their levels of quality, engineering and especially responsive service.”

The Ovid facility of MMPA processes over three million pounds of milk per day, specializing in the production of liquid dairy blends, dry powders and bulk butter. These dairy ingredients are offered in spray-dried, liquid, condensed and instantized forms. Fluid products are typically loaded for bulk tanker or 55-gallon drum delivery, while powders are packed in 50 lb. bags, 25 kg bags or one-ton totes. Butter is produced in 25 kg cubes. Such production processes place substantial load on the local utility company’s power generation system and also create ambient dust contaminant challenges for the plant’s equipment.

During the construction process on the three enclosures needed for the standby power generators, extra attention was given to the insulation, silencers and electrical controls for the unit, to ensure proper functioning, sound attenuation and minimized environmental impact. These enclosures and fuel tank assemblies further required additional features, as mandated by the Michigan Department of

Following the submission of the complete specification and winning the job, Hennig engineers Christian Grobe and Robin Moore, as well as sales rep Matt Sopchyk, led the team that produced the enclosures at the company’s manufacturing/fabricating facility in Rockford, Illinois. Al LaManna had occasion to visit the plant during the construction and was impressed by the efficiency of the vertical integration. Hennig performs all metal fabrication, finishing and the rigorous testing to UL standards in-house. “Even a midstream specification change by our customer was handled at Hennig with no upset in the production schedule,” notes LaManna.

As Territory Manager for the company, Todd James Rundhaug, observes, “We are constantly looking for quality component suppliers to

The UL142 approved steel fuel tanks are finished with a phosphoric pretreatment high-pressure wash and then a 2-step polyurethane process. Hennig enclosures are of a semi-monocoque design, meaning the structural integrity and inner strength are engineered and built into every panel and roof section. This allows for clean and functional design, without the need for separate framing or additional substrate supports of any kind. Also, the Hennig fuel tanks are engineered and built in a similar way, with full interior baffling and sub-structure integrity to support the genset without the need for surface mounted I-beams to support the genset or the need for an additional, costly raised floor above the tank top. The tank top is the floor within the genset.

To learn more about Hennig products & services, visit www.hennigworldwide.com or call contact:

Tim Waterman

Hennig Inc.

9900 N. Alpine Rd.

Machesney Park, IL 61115

(815) 316-5277

info@hennig.ame.com

www.hennigworldwide.com

—

Hennig, Inc., at www.hennigworldwide.com, has been designing and producing custom machine protection and chip/coolant management products for state-of-the-art machine tools for over 50 years. Hennig products are designed to protect against corrosion, debris and common workplace contaminants. Hennig has manufacturing facilities in the U.S., Germany, Czech Republic, France, Brazil, India, Japan, China and South Korea. Its North American repair centers are located in Machesney Park, Ill.; Chandler, Okla.; Livonia, Mich.; Blue Ash, Ohio; Mexico City, Mexico; and Saltillo, Mexico.

Continue reading

Founded in 1948 by Garman Kimmell, Kimray operates a 274,000 sq. ft. facility and employs over 400 people to serve its expanding customer base of oil and gas producing companies. Kimray machines iron, steel and aluminum, as well as thermoplastic materials, to build its comprehensive line of control valves, thermostats, energy-exchange glycol pumps, gas-operated pilots and other process control devices. Their products are used to control vessel and lead line temperatures, liquid level inside pressurized vessels, pressure drops and liquid/gas flow.

The company maintains a turnkey manufacturing facility, including dozens of lathes, grinders, turning, milling, sawing and bore finishing/honing machine tools, nearly all with CNC systems onboard. Originally, two machines were purchased, an Emco Maier EMCOTURN 420 MC PLUS and HYPERTURN 665 MC PLUS Lathes, each equipped with Siemens SINUMERIK 840D CNCs and SIMODRIVE 611D drive packages. As their productivity greatly increased, Kimray decided to purchase two more Emco Maier machines to keep up with increased demand for their products.

He further commented on the controls, “On a typical set-up, I like the sensitivity of the CNC. Being able to move the axis only a ten thousandth at a time to a hundred thousandth at a time comes in very handy for me. I also like the program test feature, especially on new programs. Each tool has its own geometry page and up to four offsets, making things much less complicated.”

Lastly, regarding the machine builder, this operator noted, “I received lots of good advice and training from the folks at Emco Maier, especially Doug Poling. He’s also assisted me a few times by phone, when needed.”

In determining the increase in overall machining efficiency at Kimray, VP of Operations David Hill commented, “Our commitment to run CNC machine tools has long been in place and the addition of the Emco Maier lathes with Siemens controls onboard are the latest steps in this process. We’ve literally had no problems with these machines, the CNC’s or the drives. When Kimray operators can keep running and producing parts in such a way, the impact on our overall efficiency is immediate and substantial.”

Mike Morris, Kimray’s Plant Engineer, added that “the control is strong and easy for the operators to use”. Over the years, the CNCs have been virtually bulletproof.”

From the builder’s perspective, Emco Maier shares Kimray’s appreciation for the performance of its CNC/drive package supplier.

“Our 420 machine enables simultaneous production of two parts without interruption or collision. The digital drives (Siemens SIMODRIVE 611D) produce dynamic performance in both the main spindle and X/Z axes,” commented the company’s Director of Sales Support Operations for Emco Maier USA. “Plus, programming is just the same as on any CNC lathe. Only one program is generated. The program for the second workpiece is simply transferred to the bottom system by means of a selector switch. No additional programming is necessary. As we like to say, twice as nice.”

The 665 Hyperturn machine enables true 4-axis machining plus full c-axis capability on both the main and counter spindles. The 665 uses some of the same programming features, plus the same digital drive system as the 420, but in a larger package.

For more information on this story, please contact any of the following individuals:

KIMRAY, INC.

Web: www.kimray.com Email: info@kimray.com

EMCO MAIER CORP.

Web: www.emcomaier-usa.com

SIEMENS MACHINE TOOL BUSINESS

John Meyer

Manager, Marketing Communications

Siemens Industry, Inc.

(847) 640-1595

www.usa.siemens.com/cnc

SiemensMTBUMarCom.industry@siemens.com

Follow us on Facebook: www.facebook.com/SiemensCNC or Twitter: www.twitter.com/siemens_cnc_us.

—

Siemens Industry Sector is the world’s leading supplier of innovative and environmentally friendly products, solutions and services for industrial customers. With end-to-end automation technology and industrial software, solid vertical-market expertise, and technology-based services, the sector enhances its customers’ productivity, efficiency and flexibility. With a global workforce of more than 100,000 employees, the Industry Sector comprises the Industry Automation, Drive Technologies and Customer Services Divisions as well as the Metals Technologies Business Unit. For more information, visit http://www.usa.siemens.com/industry.

The Siemens Drive Technologies Division is the world’s leading supplier of products, systems, applications, solutions and services for the entire drive train, with electrical and mechanical components. Drive Technologies serves all vertical markets in the production and process industries as well as the infrastructure/energy segment. With its products and solutions, the division enables its customers to achieve productivity, energy efficiency and reliability. For more information, visit http://www.usa.siemens.com/drivetechnologies.

Continue reading

We applaud this action, especially in this economy.

One client said to me, during a meeting where I was encouraging this tactic, “Tim, how can I take a very busy engineer or sales guy away from customers and quoting to play on the internet?”

After I calmed down, I explained to him that:

Seriously, since very little is new under the sun, this is just the new version of that longtime and revered guy at every company, the one people flocked to see at trade shows.

Two quick examples:

We had a client (sadly passed away) who invented polymer quenchants for commercial heat treating. This ancient industry used water and oil, mostly, as it had for literally centuries. People would come to the trade shows and actually wait in line to see the guy. Then, with almost papal severity, he would lean into them, listen to their quenching problem, ponder it for a moment and then put his finger in their chest and say, “OK, here’s what you do…”

We have a current client who runs what is arguably the finest gear company on the planet. He’s also a world-class fly fisherman. He stands in the aisles and goes “casting for customers,” as he says. When he arrives at a show or conference, you’d think Ghandi had walked into the room…with Mother Teresa on his arm! Talk about drawing a crowd. His theory evokes the old John Kennedy line that a rising tide lifts all boats. He actually shows customers, prospects AND his competitors his operation and his p&l. His company currently exports high-precision gears worldwide, including to China!

The internet guru at your company can be a powerful force for growth and a true agent of change for your business and the industry as a whole. Don’t overlook the possibilities or think that it’s just playtime! When a “social” network has a tangible business upside, that’s a game we’d all like to join!

TD

Bertsche iJet waterjet deburring system built for Linamar combines waterjet deburring with part cleaning for one inline system.

Canadian automotive part supplier realizes significant gains with Bertsche-designed multi-function system in its plant

With factory floor space at a premium and capital equipment funds scarce, Linamar, a Tier One Canadian automotive part supplier, turned to Bertsche Engineering recently for an all-in-one part deburring, final rinse and drying solution.

Typically, complex machined automotive parts with multiple intersecting holes require feature-specific part deburring to insure that parts are burr-free. After deburring, parts also need a final cleaning/washing to insure removal of microscopic particles that might adversely affect performance. They are then preserved with a rust or oxidation inhibitor and dried for shipment (transport) to be assembled. Usually, this involves separate pieces of equipment linked by conveyors or robots to transport parts to each machine.

To solve the problem of densely filled factory floor space, Bertsche Engineering developed a machine that handles all these processes in one machine, in one deburring cycle. The machine takes oil and chip contaminated parts, previously machined on CNC milling centers and mill/turn machines, then selectively deburrs critical features using high pressure water, blasting chips out of internal cavities, knocking off all feather-edge burrs and fan washing the outside of the part, using a CNC for full cycle control.

Close-up shows parts infeed and outfeed station, where considerable space savings were realized by the customer, Linamar, a major Canadian Tier One automotive parts supplier.

This process is accomplished by a series of rotating lance nozzles that probe small diameter internal holes in order to blast feather edge burrs clean at intersection points and wash chips out of dead-end passages. External features are then blasted with a series of direct nozzles that release up to 10,000 psi of water at the burr while tracing the part edges. The part is then washed with high-pressure rotating fan nozzles. Note: When required, additional mechanical wire and filament brush tooled deburring stations can be incorporated into the Bertsche system to mechanically remove burrs.

The same machine moves the deburred part to an agitated wash and rinse station, where the part is rinsed, cleaned and preserved with an aqueous rust inhibitor (providing up to 24-day protection) and is finally dried. The part is then ready for final assembly.

Close-up shows parts being indexed over high-pressure (10,000 psi) waterjet nozzles for full wash cycle and rust-inhibiting aqueous coating process

For more information on this application, please contact:

BERTSCHE ENGINEERING CORPORATION www.bertsche.com

PR agency contact: Tim Daro Bernard & Company www.bernardandcompany.com

Release: BERTSCHE ENGINEERING CORPORATION

Date: December 28, 2009

The unit is equipped with a roof-mounted heat-resisting alloy recirculating fan, powered by a 1-HP motor with V-belt drive, motor-operated vertical lift door, 100 lb. capacity alloy loading cart with cast alloy roller rails, 3-1/2” diameter cast alloy rollers and a roller rail loading table with 4” diameter cast iron rollers.

This Grieve furnace also features inert atmosphere construction, consisting of a continuously welded outer shell, high temperature door gasket, sealed heater terminal boxes, inert atmosphere inlet, inert atmosphere outlet and inert atmosphere flowmeter.

Controls onboard No. 954 include a digital programming temperature controller, manual reset excess temperature controller with separate contactors, plus a strip chart recorder.

For more information, please contact: THE GRIEVE CORPORATION, Web: www.grievecorp.com.

Agency contact: Tim Daro, Bernard & Company

NEWS RELEASE: THE GRIEVE CORPORATION

DATE: December 21, 2009

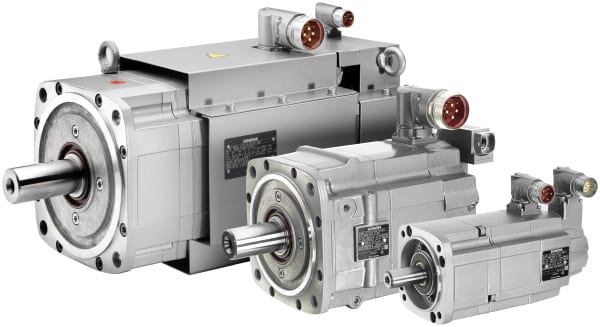

New Siemens 1FT7 servo motors, shown (l to r) in forced ventilation, water-cooled and air-cooled styles

Siemens introduces the 1FT7, a line of high-performance servo motors for such demanding motion control applications as machine tool CNC interpolation, production machine indexing control and more. Their use results in higher dynamic response, due to a 30% shorter design and 4x overload capacity versus 3x on the predecessor family of servos. Less downtime also results from the rigid vibration-insulated encoder mounting, which also enables the OEM or end user to exchange the encoder in the field in less than five minutes, without encoder alignment.

Design engineers have a choice in selecting this servo, as it is available in air-cooled, forced ventilation and water-cooled designs. The water-cooled design of the 1FT7 is provided with stainless steel piping in the stator.

Start-up and commissioning personnel will appreciate the Siemens electronic nameplate and digital encoder interface on this new servo, DRIVE CLiQ, as it simplifies start-up or replacement by not requiring all electronic data to be entered, as the DRIVE CLiQ cable recognizes all drive system components. With this feature, these motors become essentially plug-n-play devices. The drive recognizes the motor automatically and optimizes the parameterization accordingly. This digital encoder interface further allows users to route all their different encoder types along one signal cable.

High-resolution encoders, currently 22 bit, enable these servos to become highly precise motion control system components and these new high-dynamic 1FT7 motors also feature very low rotor inertia, thereby making them practical in applications where it was previously impossible to drive a servo. Such applications include sorters in the printing industry, which previously required mechanical cams but can now utilize electronic cams for better energy efficiency and less wear.

For a catalog or more information on these new servo motors, please contact:

SIEMENS INDUSTRY, INC.

GENERAL MOTION CONTROL

390 Kent Avenue

Elk Grove Village, IL 60007

Phone: 847-640-1595

Fax: 847-437-0784

Web: www.usa.siemens.com/motioncontrol

Email: SiemensMTBUMarCom.sea@siemens.com

Attention: John Meyer, Manager, Marketing Communications

Han-Kwang USA announces immediate availability of its new Model TL 6015, a tube cutting laser system capable of handling 24’ long, 6.5” diameter workpieces up to 1/4” wall thickness in mild steel and 0.200” in stainless steel. Equipped with a powerful 2.5KW Panasonic laser and a versatile Siemens 840D CNC to control all functions of the machine, the TL 6015 can significantly increase the tube production in any department or shop, especially when used with Han-Kwang’s proprietary “Flex 3D” tube cutting software . The unit comprises an automatic bundle loading system with tube V-support, auto-centering rotary chucking system, laser cutting station and automatic parts removal station.

Maximum positioning speed on this new laser system is 4700 ipm for the X-

axis and 120 rpm for the rotary A-axis. Max acceleration rate is 1G, while the laser beam is precisely controlled by the unique Han-Kwang Auto Focus Control (AFC). This AFC technology allows the machine to automatically adjust the focal length of the cutting lens to accommodate variations in the materials being processed or changes in material feed, which eliminates the downtime normally associated with manual adjustments.

A new generation of sensing board in the S5 laser cutting head on the TL 6015 translates into faster cutting speeds on round, square or rectangular shapes.

In a recent design modification, the entire loading section of the machine has been enclosed, as depicted in the attached illustration.

For more information or to arrange a demonstration, please contact:

HAN-KWANG USA INC. Phone: 630-916-0200 Web: www.hankwang.com

Agency contact: Tim Daro Bernard & Company tdaro@bernardandcompany.com www.bernardandcompany.com

Continue reading