Contact us today:

(847) 934-4500

tdaro@bernardandcompany.com

Contact us today:

(847) 934-4500

tdaro@bernardandcompany.com

Complete Unit for Cutting and Trimming Beef, Pork and Poultry

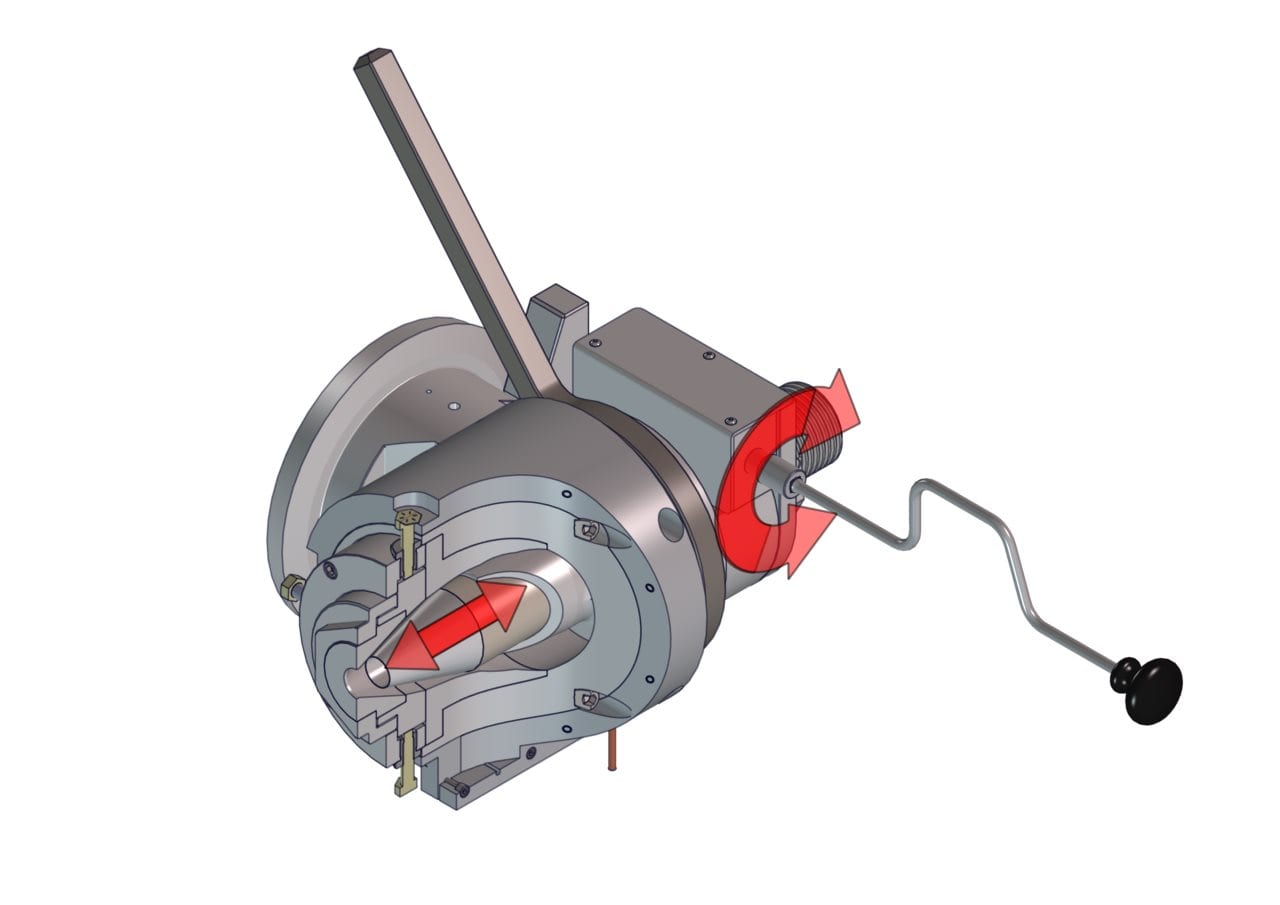

Photos show unit variations and the flex shafts that supply the rotary power transmission, when in use.

Rome, Georgia – Suhner Industrial Products, LLC introduces the TurboTrim – a complete unit for cutting and trimming beef, pork and poultry. The unit has multiple sized trimmers available for use in the different steps of the meat cutting process, helping to increase productivity, performance and product yield.

Features of the unit include high-quality, long-lasting stainless steel blades which require fewer sharpenings, a coated housing which runs smoothly and quietly with minimal vibration and a patented, adjustment free housing with fewer moving parts to save time. The TurboTrim has a hard plastic handle which is ergonomically designed for operator comfort and a lightweight handpiece to enhance operator performance and reduce fatigue.

TurboTrim knives are based on the principle of a rotating round knife, and manufactured with the highest Swiss quality and precision.

The TurboTrim has a stainless steel motor assembly featuring a slide out bracket which allows motor to be easily removed for cleanup without the use of tools. Downtime is reduced with a quick change assembly for flexible shaft replacement.

For more information, please contact:

SUHNER Industrial Products, LLC

43 Anderson Road SW

P.O. Box 1234

Rome, GA 30161

Phone 706/235-8046

Fax 706/235-8045

info.usa@suhner.com

www.suhner-abrasive-expert.com

Attention: Guido Broder, President

The oven travel comprises an 1-1/2’ long open belt loading zone, 20’ long insulated heat zone with recirculated airflow, 1’ long open zone, plus a 12’ long cooling zone and an 1-1/2’ long open unloading zone.

This Grieve belt conveyor oven features 4” insulated walls, aluminized steel exterior and stainless steel interior. Two 12” diameter tubeaxial fans, each driven by a ½ HP motor, push/pull air through cooling zone and a 12” wide, ½” x ½” high carbon steel flat wire conveyor belt with 1/3 HP motor drive, variable from 16 to 44 inches per minute, are also onboard the oven.

Controls on the No. 866 include a 10” diameter circular chart recording temperature controller and a manual reset excess temperature controller.

For more information, please contact:

THE GRIEVE CORPORATION

500 Hart Road

Round Lake, Illinois 60073-2835 USA

Phone: (847) 546-8225

Fax: (847) 546-9210.

Web: www.grievecorp.com.

Email: sales@grievecorp.com.

Attention: Frank Calabrese.

Rome, Georgia – Suhner introduces the Rotomax flexible shaft machine, a unique unit with interchangeable hand pieces that allow a user the freedom to perform a wide variety of machining operations with a single machine. The Suhner Rotomax functions as an angle grinder, straight grinder, drum polisher, belt sander, tube polisher or die grinder, simply by changing the hand piece. This new machine has myriad applications in industrial steel fabrication, polishing operations, sheetmetal assembly, food processing and foodservice equipment builds, appliance manufacturing, various stainless steel fabrications including medical and more.

The Suhner Rotomax offers users a range of power from 2.0-4.7HP and features electronically-controlled speeds ranging from 500-15,000 RPM in increments of 100 RPM at the touch of a button. The combination of an industrial grade motor and solid-state electronic control ensure constant speed and torque during any application. With no gearing, the Rotomax operates very quietly. Other features include soft start, integrated braking and an LED-displayed speed gauge.

The Rotomax is offered as a hanging model, for the user wishing to keep the power flex shaft above the work; on the basic stand, which can be mounted wherever the user desires; or on a specially-designed stable trolley (STM) for portability around the work shop or production line.

For more information, please contact:

SUHNER Industrial Products, LLC

43 Anderson Road SW

P.O. Box 1234

Rome, GA 30161

Phone 706/235-8046

Fax 706/235-8045

info.usa@suhner.com

www.suhner-abrasive-expert.com

Attention: Aaron Beck, National Sales Manager, Abrasives & Power Tools

GMTA Vice President Scott Knoy comments, “We welcome Dan to our team. His role will be a vital part of our ongoing efforts to be more customer-centric, as we expand our machine offerings, penetrate new markets and expand existing ones.”

Thomas will be responsible for the end-to-end coordination of the project flow at GMTA, from initial contact through commissioning of machines and systems onsite.

GMTA is a major supplier of machining centers, integrated laser-based work cells, fully-automated parts washing lines and related tooling, focusing primarily on gear, spline and other power transmission components.

See us at IMTS!

For more information, please contact:

GMTA (GERMAN MACHINE TOOLS OF AMERICA)

4630 Freedom Drive

Ann Arbor, MI 48108

Phone: 734-973-7800

Fax: 734-973-3053

Web: www.gmtamerica.com

Email: scott@gmtamerica.com

Attention: Scott Knoy, VP

Continue reading

Responding to growth in sales and expanded market opportunities, industry leader in rubber injection presses adds to staff

Bartlett, IL – REP Corporation announces the appointment of Derek Williams to the new position of National Sales Director, effective immediately. This move represents a return of Mr. Williams to the REP team, where he previously served as a Regional Sales Manager.

Commenting on the appointment, REP Corporation President Tim Graham observed,

“We welcome Derek back to REP. He brings us over 20 years in the rubber industry and his market knowledge is backed by very strong technical machine and material processing know-how. His new role at REP will bring us additional strength in project management and best practices. Current and future customers will benefit from Derek’s hands-on experience plus his knowledge of our company’s leading edge press technologies.”

For more information on this announcement, please contact:

REP Corporation, 8N740 Tameling Court, Bartlett, IL 60103-8146. Phone: 847-697-7210. Fax: 847-697-6829. Web: www.repinjection.com. Email: tgraham@repcorp.com. Attention: Tim Graham, President.

Provided by German Machine Tools of America (GMTA), Samag multi-spindle horizontal machining centers and deep hole drilling machines, used primarily for large block milling and deep hole drilling, now offered to the automotive powertrain, off-highway, moldmaking and other markets

Ann Arbor, Michigan – Now available from German Machine Tools of America (GMTA), a full line of Samag machining centers, including multi-spindle, horizontal machining centers, deep hole drilling machines and combination milling/drilling machines, is offered for the North American market.

Samag, based in Saalfeld, Germany, with offices worldwide, engineers and builds a variety of multi-spindle machines, including the MFZ Series for large workpieces, the smaller, modular WBM Series for up to six spindle deep drilling and the combination TFZ Series, which offers users the ability to bore and mill complex cubical workpieces on four sides with a single clamping. On the largest standard machine, large scale moldmaking is possible, with a maximum drilling depth of 2300mm (over 90”), 65mm (over 2-1/2”) bore and a 50-ton capacity work table.

The company also supplies complete turnkey operations, including robotic articulation, parts handlers and transfer mechanisms for high-production work such as connecting rods and complete machining of differential housings.

GMTA Vice President Scott Knoy comments, “This new partner dramatically expands our capability in the large block milling market. Plus, with deep drilling technology and the combination machine concepts, we will be able to offer significant advantages to our current and potential customer base. We’re excited to have the Samag name and reputation for quality machine tools added to our family.”

Videos of Samag machines in action may be seen on YouTube by visiting www.gmtamerica.com.

For more information, please contact:

GMTA (GERMAN MACHINE TOOLS OF AMERICA)

4630 Freedom Drive

Ann Arbor, MI 48108

Phone: 734-973-7800

Fax: 734-973-3053

Web: www.gmtamerica.com

Email: scott@gmtamerica.com

Attention: Scott Knoy, VP

New extrusion head from market leader features Mechanically Assisted Gum Space (MAGS) adjustment

Guill Series 500 crosshead with Mechanically Assisted Gum Space (MAGS) adjustment…specially designed for the flow characteristics of elastomeric compounds

Guill Tool introduces the NEW 500 Series crosshead with MAGS gum space adjustment. The 500 Series is designed specifically for the flow characteristics and unique processing challenges of elastomeric compounds. One of the key features engineered by Guill on this new crosshead design is the mechanically assisted gum space (MAGS) adjustment system. This new method of gum space adjustment allows the operator to make an effortless adjustment from a single point using a common socket wrench. No more need to struggle with multiple nuts and bolts in order to adjust gum space, which leads to faster adjustments. The visual indicator on the core tube allows the operator to see how far the gum space has been moved, making those adjustments much more accurate and repeatable.

The hardware-free and patented cam lock design of the NEW 500 Series from Guill means no time is wasted unbolting and re-securing fasteners for disassembly and re-assembly. Only half of a rotation of the cam nut is required to loosen and automatically extract the deflector from the head body, which is another time saver. Also, with no undercuts on the deflector, there are no material hang-ups when extracting the deflector, allowing for faster and easier cleaning and changeover.

The NEW 500 Series also features the latest Center-Stage concentricity adjustment system that significantly reduces pressure on the tooling, allowing easier and more precise concentricity adjustments without loosening the face bolts. Easy-Out inserts for the adjusting bolts also allow simple replacement of locked or damaged adjusting bolts, which further saves on repair and downtime.

Another innovative feature of this new rubber/silicone crosshead is a cast aluminum liquid-fed cooling sleeve that allows the user to switch out the cooling jacket in the event of a line obstruction, again reducing downtime compared to traditional integrated cooling systems.

The NEW 500 Series crosshead with MAGS gum space adjustment is a drop-in replacement on most existing NRM lines, however this crosshead design can also be adapted to fit any extruder design or line layout.

The addition of a newly designed flow inlet channel reduces the shear and heat that is generated as the materials are being processed. This leads to lower head pressures allowing the material to move through the head in a much more balanced and even flow.

All crossheads supplied by Guill are furnished with a tool kit for assembly and disassembly as well as a detailed operator’s instruction manual. The engineering team at Guill will gladly assist users in the implementation and operation of the NEW 500 series crosshead.

For a video of the NEW Guill 500 Series crosshead with MAGS gum space adjustment, please go to:

For more information, please contact:

Bill Conley, Sales Manager

Guill Tool & Engineering

10 Pike Street

West Warwick, RI 02893

USA

Phone: 401-828-7600

www.guill.com

sales@guill.com

Continue reading

New catalogs for Mori Seiki, TSUGAMI and Miyano machines offer standard tools from live tooling leader

Heimatec, a market leader in live tooling for the North American machine tool industry, has released a series of four new catalogs showcasing the company’s lines of machine brand specific tooling.

Already offering the most complete line of live tools available in the industry, with over 40,000 designs in its database, Heimatec machine brand specific tooling includes products for the following popular brands:

Heimatec sets the standard for the highest precision and most advanced technology in the machine tool accessory market. The company is acknowledged as a world leader in live tools, angle heads and multi-spindle drill heads.

In addition to its standard tooling and machine brand specific line, Heimatec also offers custom designed tooling. Heimatec tooling experts work directly with customers to design solutions to suit specific requirements for all CNC lathes, helping to solve the most challenging applications in multiple markets served by the company, ranging from orthopedic devices to oil & gas drilling equipment.

Heimatec North American distribution headquarters are located in Prospect Heights, Illinois (Chicago) with world headquarters plus all manufacturing based in Germany. A team of manufacturers’ representatives covers the North American market for Heimatec.

Visit Heimatec at IMTS 2016, Booth # W-2054 in Chicago.

For more information or to receive a PDF copy of the new dedicated tool catalogs, please contact:

Preben Hansen, President

Heimatec Inc.

16 East Piper Lane, Suite 129

Prospect Heights, IL 60070

847-749-0633

www.heimatecinc.com

phansen@heimatecinc.com

No. 868 is a 500°F (260°C), high-temperature special top-loading oven from Grieve, currently used for testing oil field downhole equipment at the customer’s facility. Workspace dimensions of this oven measure 185” W x 18” D x 24” H. The oven features 34.8 KW installed in Nichrome wire heating elements, while 4000 CFM total from two 2-HP recirculating blowers provide horizontal front to rear airflow.

This Grieve special top-loading oven features 4” insulated walls, aluminized steel interior and exterior, plus reinforced ¼” steel plate workspace floor designed to hold 3600 lbs. distributed load. The oven is supported on six swivel casters with swivel locks and brakes and has a motor-operated, rear-hinged door.

Controls on No. 868 include a digital indicating temperature controller, a manual reset excess temperature controller with separate contactors and a recirculating blower airflow safety switch.

For more information, please contact: THE GRIEVE CORPORATION, 500 Hart Road, Round Lake, Illinois 60073-2835 USA. Phone: (847) 546-8225. Fax: (847) 546-9210. Web: www.grievecorp.com. Email: sales@grievecorp.com. Attention: Frank Calabrese.

Continue readingMajor German supplier of finished length tube and solid bar processing equipment opens its doors in Monterrey/Apodaca to serve the Mexican market with sales, service, spare parts and engineering

Rattunde Corporation President Rick Stadler (front, left), Rattunde Mexico Director Javier Lopez (center, left), Director of Technical Services Renato Luna (center, right) and the team from Rattunde’s new facility celebrate the ribbon-cutting ceremony to open the company’s Mexican headquarters in Monterrey/Apodaca in the state of Nuevo Leon.Rattunde Corporation, the North American arm of a German-based manufacturer of finished length tube and solid bar production systems, has been operating from a single location in the Grand Rapids, Michigan area for over nine years. The company’s considerable success in the market resulted in the recent grand opening of a new facility in the Monterrey, Mexico area to serve its growing customer base in that country.

Rattunde Corporation President Richard Stadler and VP Alec Banish, joined by Rattunde Mexico Director Javier Lopez and his team, proudly opened the doors to the new facility in Monterrey/Apodaca on February 4, 2016.

This new 8,073 square-foot (750 square-meter) tech center houses the Mexican sales and service operations, application engineering and spare parts inventory. Future plans include a machine onsite in 2017 for demonstration and training. This decision to open a tech center in Mexico was reached, after an analysis of the current and anticipated business needs of the company in-country, according to Rick Stadler. “Our growth in America and in Mexico has been rapid, though not unexpected, due to the unique nature of our equipment and the reliability and performance characteristics of our machines. With a solid install base and growing demand for local service in Mexico, this move simply made a lot of sense to us.” Stadler further noted that solid growth of the company into diverse markets throughout North America made the new facility a logical choice. In addition, he said the new machine sales generated directly from Mexico-based management and procurement personnel also contributed to the decision.

This 8,073 square-foot (750 square-meter) facility will be a full tech center with application engineering, sales, service and spare parts inventory. Plans for a demo machine are in the works for 2017.

Concurrent with this new tech center, Rattunde has expanded its workforce in Mexico with technical service, sales and administrative personnel. As Stadler explains, “Whenever a machinery company grows quickly, there’s an ever-present need for more customer service and technical assistance personnel. Of course, new people must be found and trained.” Stadler went on to explain that rapid growth also means working smarter. Rather than waiting for a customer to reach out to Rattunde in a time of need, the company is proactively sending technicians to its customers and performing comprehensive machine inspections, identifying and correcting small issues before they become large ones.

For Mexico, two Rattunde service technicians are now in-country, one operating from the new tech center in Monterrey/Apodaca and another based in Guadalajara.

In the end, Stadler says, “This new facility solidifies our Mexican presence in the high-volume tube and solid bar production markets such as auto, appliance and aero, thus benefiting our current and future customers in many ways. We’re selling to a large number of companies in various markets, in-country, so it was a logical move for us to be here, in many ways.”

Other attendees at this grand opening included Rattunde personnel, sales representatives from the North American network, honored guests from the parent company in Germany, plus customers, prospective business partners and suppliers to the company.

For more information on this development, please contact:

RATTUNDE CORPORATION

5080 Beltway Drive SE

Caledonia, MI 49316

Phone: 616-940-3340

Fax: 616-940-2771

Web: www.rattunde-corp.com

Email: company@rattunde-corp.com

Attention: Richard Stadler or Alec Banish

OR

RATTUNDE MEXICO

Parque Industrial Kalos Encarnacion

Seccion 9 Edificio 1

#132 Ignacio Sepulveda

Apodaca, Neuvo Leon 66633

Phone: +52 81 10860406

Director: Javier Lopez

j.lopez@rattunde-corp.com