Contact us today:

(847) 934-4500

tdaro@bernardandcompany.com

Contact us today:

(847) 934-4500

tdaro@bernardandcompany.com

Effective immediately, Heimatec Inc., will be selling products from Tecnicrafts Industries, a manufacturer of collets and guide bushings for Swiss Type CNC Lathes.

Tecnicrafts is an ISO 9001:2015 Certified company, with its manufacturing plant in South India with state of the art machine tools and 115 technicians. Tecnicrafts collets and guide bushings are exclusively used for Swiss Turning applications on Citizen-Cincom, Tsugami, Star, Tornos, Hanwha, Traub, Hardinge, Manurhin-Kmx, Miyano, Nomura and other popular machine brands and are widely recognized and accepted by customers in Europe and Asia.

GUIDE BUSHINGS: Tecnicrafts Guide Bushings are generally offered in carbide lining having Super Finish bore with roughness value of less than 0.4 micron. These special guide bushings include U-Line, Extended Nose and Long Carbide Bores (Max Land) for special turning applications.

BAR FEEDER COLLETS: The Bar feeder collets are available for various bar feeders like Fedek, LNS, Ikura-seiki, Iemca, Citizen, FMB and other popular brands.

All Collets and Guide Bushings are offered in Standard and Ultra-Precision grades. The bore profile includes Round, Square, Hexagon, Rectangular and Profile bores as per customer drawings.

Heimatec Inc., with its expertise in precision tooling and having customer representatives throughout North America, is ready to meet the work holding tool needs for Swiss Turning applications with this new Tecnicrafts product line on its roster of quality tooling.

For more information please contact:

Preben Hansen, President

Heimatec Inc.

16 East Piper lane, Suite 129,

Prospects Heights, IL 60070

USA

Tel: 847-749-0633

www.heimatecinc.com

From time to time…

After 43 years in the agency business, always as a copywriter, I’ve seen many “evolutions” in the agency business. I started in a world of print, when direct mail was the sizzle product and bingo cards were the “proof of performance” metric…a word we never used, as we said yardstick. Funny. New ads and PR took 30-45 days to appear, now we have our PR online in 30 minutes or less.

Today, the emergence of the internet and social media have radically altered the face of industrial marcom, which remains a lap behind the consumer world, but not because our business lacks the talent or foresight to implement the changes in technology.

Rather, the fundamental driver in our business…and yours, as captains of industry…is one that hasn’t changed a bit, over time. It’s the fact that all 33 of our clients sell to only a small slice of the viewing public. We have several clients with less than 1000 prospects in all North America, including one who sells tiremaking machinery. Talk about a limited head count. At the opposite end, we have a client who sells every market you can name with a piece of discretionary capital equipment, as I call it. Requires a very different approach.

Continue readingSUHNER presents new grinding, milling and polishing system

Intelligent technology for tool and mold making

In many technical fields, ultrafine grinding is one of the tasks that gives the product its final polish – in the truest sense of the word. This applies equally to both precision and the visual appeal.

One of the leading manufacturers of professional surface treatment tools and machines for over a hundred years, SUHNER now offers an innovative grinding, milling and polishing system, SUNmic 60.

The central element is an intelligent control unit with touch panel that can accept a range of micro motors and tool hand pieces depending on the application. The control part has modern features such as touch screen operation on a glass display, the option to save settings and a rotation speed regulator with tangible resistance.

Key settings are easily legible on a large digital display.

Micro motor system

The actual tools are driven by powerful micro motors whose 280 W place a lot of power in the user’s hand. The compact, brushless BL/DC motors provide an extraordinarily wide speed range of 1000–60,000 rpm and deliver a high torque. In practice, they can be compared with pneumatic technologies but do not need a compressed air supply, operate at lower energy levels and emit virtually zero noise, without exhaust air or oil mist emissions.

One further benefit is that they run virtually free of vibration. The high concentricity safeguards clean and reproducible results in all areas of operation. A special heavy-duty clamping system prevents the millers from shifting. Chuck diameters range from 2.35, 3.0 and 6.0 mm to 1/8 and 1/4 inch.

The new SUNmic 60 micro motor system can be connected to a 90–240 V source, and can therefore be used anywhere in the world. It offers a large number of combinations. The tools range from straight, angle and filing hand pieces to belt grinders. The control unit can be connected to two BL/DC motors and an AC motor.

Advantage: The new control unit is compatible with available micro motors. This is a true multi-purpose tool for many applications.

The new system can be used everywhere a precision finish is desired – for instance, grinding, milling, brushing and polishing in tool and mold making; in aircraft, engine and motor building; in engine tuning; and much more. SUHNER offers a range of matching machines, tools and abrasives that have been tailored specifically to each of these applications. Also an illustrated mold making tool catalog is available.

The new SUNmic 60 micro motor system has been designed for complex milling, grinding, brushing and polishing work in tool and mold making; in aircraft, engine and motor building; and similar applications.

Together with the brushless BL/DC motors, the hand pieces deliver the maximum in performance.

The high concentricity and low-vibration running can only benefit the final results.

The most important properties of SUNmic 60:

Knowhow on site

SUHNER provides demo services for field expertise. This offers interested parties expert advice, free of charge, from experienced field workers. The demo services vehicle carries all the usual tools, attachments and abrasives, plus the right end to end solution can be found directly onsite based on the actual workpieces.

For more information, please contact:

SUHNER Industrial Products, LLC

43 Anderson Road SW

P.O. Box 1234

Rome, GA 30161

Phone 706/235-8046

Fax 706/235-8045

info.usa@suhner.com

www.suhner-abrasive-expert.com

Attention: Aaron Beck, National Sales Manager, Abrasives & Power Tools

New Manual Motor Starter provides manual isolation, manual motor control and overcurrent protection in one unit.

The Ex9S32 Manual Motor Starter is designed to handle more amps and more accessories than previous models offered, while providing increased electrical and mechanical life. The Ex9S32 Manual Motor Starters are electro-mechanical devices that combine a number of functions in one unit, including disconnect for motor branch circuit, manual motor control, branch-circuit short circuit protection (magnetic protection), overload protection (thermal protection – Trip class 10) and switching (manual).

The Ex9S32 is available with up to 32A @600 Vac, UL 508 Type E self-protected combination motor controller (Type F coming soon) and built-in fault indication. The unit also offers a full-range of accessories including undervoltage release contacts, shunt release contacts, power connection adapters, extended rotary lockable handle, and waterproof enclosure.

NOARK Electric (North America), located in Pomona, CA, is a global electrical component and intelligent control system supplier. The company is establishing a representative and distribution network to serve its primary markets, which include the building trades and electric panel board builders in various industries. As a global supplier, NOARK currently operates four R&D centers, three distribution centers, 15 office locations and employs over 1,000 associates. Sales currently exceed $2 billion worldwide.

For more information on this product, consult your local sales representative found at www.na.noark-electric.com or email: nasales@noark-electric.com. Distributor inquiries invited.

Continue reading

This Grieve belt conveyor oven has a 48” long open belt loading zone and a 10’ long insulated heat zone with recirculated airflow. Features include a 30” wide, 1” x1” high carbon steel flat wire conveyor belt with 1/4-HP motor drive, variable from 1.4 to 27 inches per minute. Additional features include 4” insulated walls, aluminized steel interior and exterior and a manually operated vertical lift door at unload with viewing window. The oven also has a photo cell to automatically stop the belt when parts reach the unload position.

Controls on the No. 897 include a digital indicating temperature controller, manual reset excess temperature controller with separate contactors, recirculating blower airflow safety switch and SCR power controller.

For more information, please contact: THE GRIEVE CORPORATION, 500 Hart Road, Round Lake, Illinois 60073-2835 USA. Phone: (847) 546-8225. Fax: (847) 546-9210. Web: www.grievecorp.com. Email: sales@grievecorp.com. Attention: Frank Calabrese.

Continue reading

Leading supplier of 3D printers partners with longtime supplier of metrology equipment

Effective immediately, Exact Metrology is now the greater Midwest dealer for EnvisionTEC, a Detroit-based manufacturer of 3D printers and materials.

Exact Metrology offers a complete line of portable scanning and measurement technologies, as well as contract measurement for 2D and 3D laser scanning services, reverse engineering services, non-contact inspection, metrology services, 3D digitizing and training, long-range scanning plus its CT scanning services, usable by all types of manufacturing, packaging and product integrity concerns, as well as civil engineering, architects and municipal infrastructure developers.

For more information on this agreement, please contact:

Dean Solberg

Exact Metrology, Inc.

20515 Industry Avenue

Brookfield, WI 53045

Local: 262-533-0800

Toll Free: 866-722-2600

www.exactmetrology.com

deans@exactmetrology.com

Or

Steve Young

Exact Metrology, Inc.

11575 Goldcoast Drive

Cincinnati, OH 45249

Local: 513-831-6620

Toll Free: 866-722-2600

www.exactmetrology.com

stevey@exactmetrology.com

Exact Metrology is an ISO 9001:2008, AS9100 Certified and ITAR Registered Company.

Exact Metrology, with facilities in Cincinnati and Milwaukee and affiliated offices throughout the Midwest, is a comprehensive metrology services provider, offering customers 3D scanning, reverse engineering, quality inspection, product development and 2D drawings. The company also provides turnkey metrology solutions, including equipment sales and lease/rental arrangements.

Continue reading

This Grieve walk-in oven has 6” insulated walls and an aluminized steel exterior with white epoxy paint. Type 304, 2B finish stainless steel interior with continuously backwelded seams and inert atmosphere construction are also onboard, including a pressure regulator, flow meter, pressure gauge, inner oven walls sealing directly against ½” thick silicone rubber door seal, blower shaft seal, positive latching door hardware, adjustable offset door hinges, outlet with pressure relief, interior seams welded gas-tight and all wall penetrations fitted with compression fittings. The oven has a 4” insulated floor with truck wheel guide tracks mounted on top of the floor.

Controls on the No. 1038 include a digital programming temperature controller plus a paperless event recorder.

For more information, please contact: THE GRIEVE CORPORATION, 500 Hart Road, Round Lake, Illinois 60073-2835 USA. Phone: (847) 546-8225. Fax: (847) 546-9210. Web: www.grievecorp.com. Email: sales@grievecorp.com. Attention: Frank Calabrese.

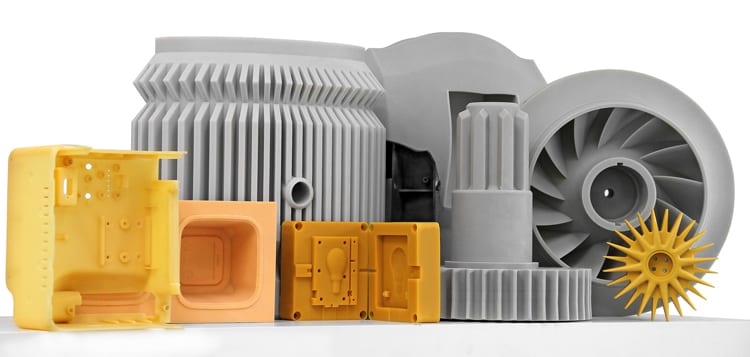

Continue readingInformation-packed site features full standard line of polyurethane products plus custom capabilities and unique calculation tools

New Kastalon website features hundreds of standard polyurethane rollers, pads and sleeves for industrial applications plus the company’s custom capabilities.

Kastalon, a longtime leader in polyurethane products, announces the rollout of its new website at www.kastalon.com. The new site offers a look at the company’s extensive lines of standard products, including rollers, pads, bumpers and sleeves for various uses in materials handling, metals producing and processing, as well as myriad other market applications.

Likewise, this new website details the custom material formulation and production capabilities of Kastalon, as the company has built a reputation for problem-solving solutions, since its inception in 1963.

Also included on the website are a number of engineering tools, which allow prospective customers an opportunity to detail their requirements for prompt quotation. Various materials performance calculation tools are provided on the site and these are among the most popular pages. Full company literature downloads are also offered.

Kastalon brings its decades of manufacturing experience and application engineering to each customer task, providing a high degree of material consistency and product performance to the global markets served by the company.

Inside Sales Manager Lyn Thorne comments, “We have worked for over two years to produce this site and believe it will be very useful to our current and prospective customers alike, as it provides a thorough presentation of our company’s successes and capabilities.”

For more information, please contact:

KASTALON, INC.

4100 W. 124th Place

Alsip, IL 60803

Phone: 708-389-2210

Fax: 708-389-0432

Web: www.kastalon.com

Email: sales@kastalon.com

Attention: Lyn Thorne

Announcing an exclusive Distribution Agreement to deliver the Intelligent SILO VLM product line to the North American Market

ICAM and SencorpWhite are proud to announce a new strategic partnership for the exclusive distribution of the SILO VLM product line in the United States and Canada.

Since 1947, SencorpWhite’s White brand automated storage and retrieval systems has been a recognized leader in the North American market. With ICAM’s unique product features, and White’s unmatched network of sales and field service engineers, this powerful partnership provides the North American market with the widest available range of VLM products and services.

Through this partnership, ICAM and White will enable North American companies to simplify day-to-day inventory storage and retrieval, optimize valuable floor space, and increase productivity. ICAM’s highly engineered, tailor-made VLMs are designed and manufactured to satisfy specific customer requirements, unlike standard, pre-configured solutions with limited choice of dimensions and configurations.

“This strategic partnership enables ICAM to bring the unique features of SILO VLMs to White’s extensive customer base in the North American market,” said Roberto Bianco, President and Chief Executive Officer, ICAM. “We are very pleased to partner with SencorpWhite. White is a respected brand throughout the industry, ideally positioning the company for rapid growth. With its technical sales and service capabilities, and multiple locations, SencorpWhite is able to provide customers with the highest level of service, which aligns with our own business philosophy”.

“ICAM and SencorpWhite share the same passion for innovation, quality, and value. This foundation provides a strong strategic and cultural fit for both businesses. We are pleased to partner with an established and innovative industry leader in Europe,” said Chris Lingamfelter, President of SencorpWhite’s White product line. “This strategic partnership leverages the strength of both ICAM and SencorpWhite to rapidly grow our existing footprint in North America, furthering our vision to offer uniquely configured, intelligent VLM solutions that provide value to our customers.”

About SencorpWhite

SencorpWhite, a Connell Limited Partnership portfolio company, is a leading provider of unique end-to-end solutions for the packaging and management of high-value inventory. The company’s products and services – which range from innovative thermoformers and other packaging technologies to automated storage and retrieval systems and inventory management software – cover the entire supply chain spectrum, from the point-of-manufacture through distribution and to the point-of-use. For more information, call (508) 771-9400 or visit http://sencorpwhite.com/.

About ICAM

For more than 50 years, ICAM has been designing and manufacturing automated-storage-and-retrieval (AS/RS) and filing systems for the European market. Today, ICAM is on the leading edge of Italian and European manufacturing, serving the industrial, retail, public administration and services markets. ICAM’s product range includes state-of-the-art automated vertical lift modules (VLMs); vertical carousels; mobile racking/shelving systems (di- vided into three distinct business lines: industrial, office and healthcare), and innovative, integrated inventory management software. ICAM is certified to ISO 9001 (certificate no. 191886); ISO 14001 (certificate no. 153853-2014 AE-ITA-ACCREDIA); and ISO 3834 (certificate no. IT246224), which assures product and procedure reliability and respect for the environment.

Continue reading

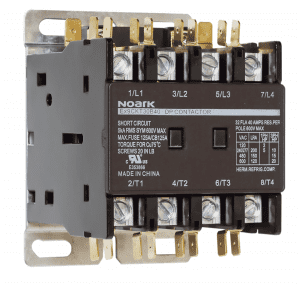

New Ex9CKT series designed for variety of HVACR applications; compliant to UL 508 and UL 60947-4-1 for air resistance heating

The Ex9CKT Series is UL 508 and UL 60947-4-1 Recognized and compliant to CSA C22.2, IEC/EN 60947, CE, RoHS and ARI-780 HVAC standards. It features a Double E magnet assembly for increased performance and reduced power consumption. The newly redesigned body has a high arc-resistant polyester base assembly, allowing for space savings, while the quick-connect spades speed install time. Users can select terminal options, screw or lug connection.

The Ex9CKT Series is designed for a variety of HVACR applications, including air conditioning, resistive heating, refrigeration equipment, motors, welding, pumps, power supplies, foodservice equipment, compressors and various business machines.

NOARK Electric (North America), located in Pomona, CA, is a global electrical component and intelligent control system supplier. The company is establishing a representative and distribution network to serve its primary markets, which include the building trades and electric panel board builders in various industries. As a global supplier, NOARK currently operates four R&D centers, three distribution centers, 15 office locations and employs over 1,000 associates. Sales currently exceed $2 billion worldwide.

For more information on this product, consult your local sales representative found at www.na.noark-electric.com or email: nasales@noark-electric.com.

Continue reading