Contact us today:

(847) 934-4500

tdaro@bernardandcompany.com

Contact us today:

(847) 934-4500

tdaro@bernardandcompany.com

By Amie Burke

We all know that social media can be the best thing to happen to your B2B communications and marketing. Social media is a great way to capture the attention of other businesses that may want to partner with you. You can also keep an eye on your competitors to see what they are up to. Social media can do a lot for your business that traditional forms of media just cannot do. But, how do you stay relevant & on top of the rapidly changing social media environment? Here are a few tips to remember:

Your business is really interesting.

Your business is interesting & there is a need for it. Otherwise, you wouldn’t be in business! So how do you capture the interesting ways your business gets things done? By showing a few peeks behind the curtain that most people do not get to see. This idea doesn’t have to be a grand production, it can be very small and unique. Of course, being cognizant of any privacy regulations for your company, you can still share something interesting about your company that your competitors do not have. What would that be?

Be genuine & authentic.

With the ever changing landscape of social media, it is more important than ever to show your business is run by humans. No one is perfect. Not every photo or video has to be perfect. Showing only a glossy exterior is now becoming something that is being ignored by younger generations as not being authentic. Yes, cool marketing shots are great, but they should not be the only thing that is shared on your business social media. Even a quick photo of workers having fun at a company cook-out from your phone speaks to your company’s authenticity.

For real, share it.

Sometimes we feel that other businesses or people don’t care about what we share. That’s not true. People take the time to follow your business page on various channels of social media. Now, it is your time to shine a light on what your business does to your audience. You already have an audience, or you are building one, you really want to be able to speak to them in a more relaxed way through social media. Don’t get hung up on feeling like no one will care about your post. They do care and they appreciate you sharing.

These tips are great starting points on how you treat your social media channels for your business. These tips will help you think more strategically for your social media posts as well. People are getting more critical of their own personal social media consumption. Customers are curating their own social media habits to fit the kind of media they would like to experience. Ensuring that your business profiles can serve your customers/audience, or potential partners, in a positive way, will help your business grow.

Continue reading

Guill Tool, a growing supplier of components to the global aerospace industry, today announced the production of a new Connector. The connector is made of Monel 400.

Dimensions on this product are 2.425” over flats x 2.625” outer diameter x 3.463” overall length, or (61.595mm over flats x 66.675mm outer diameter x 87.960mm overall length). This Guill connector was turned on a Doosan Puma turning center and finished on a Matsuura 1000 milling center.

Guill now offers its substantial machine shop capabilities as an independent service to customers in aerospace manufacturing. Products are made to customer specification.

For over 55 years, Guill Tool has offered high-quality, precision machined components for the defense and commercial industries. The company manufactures flanges, valves, fittings and various critical components for aircraft, weapons and nuclear submarines.

Guill offers its full capability of CAD/CAM design, plus EDM and 5-axis machining centers to the aerospace industry. Owing to its many years in the government and defense sectors, Guill also provides industry-standard cybersecurity and NDA confidentiality to its customers.

Guill has the following registrations and certifications: AS9100:2016 – Aerospace Manufacturing, ISO9001:2015 registered, JCP Certified – Government Contracting, ITAR Registered and NIST SP800-171Compliant Cyber-Security.

For more information, please contact:

Tom Baldock

Guill Tool & Engineering – Aerospace Division

10 Pike Street

West Warwick, RI 02893

USA

Office: 401-828-7600

www.guill.com/aerospace

QUICK® knurling and marking tools used in various industries including medical, aerospace, automotive and fitness

Platinum Tooling, the importer and master distributor of live tools, angle heads, marking tools, Swiss tools and multi-spindle tools manufactured by various global suppliers, is now the North American importer of the QUICK® knurling and marking tools from Hommel & Keller. The announcement was made by Platinum Tooling president, Preben Hansen, at headquarters in Prospect Heights, Illinois, near Chicago.

A longtime global leader in high-end knurling and marking tools, Hommel & Keller manufactures the QUICK® line with a combination of function and innovation. Quality, precision and stability are the key principals used to make QUICK® tools successful. Furthermore, the company prides itself on a rich history of providing customized solutions for its customers.

The QUICK® product spectrum offers innovative solutions for diverse knurling technology applications. For both form knurling and cut knurling, QUICK® fulfills the most stringent quality standards and masters difficult tasks. Knurling tools are available for use on a wide range of workpiece diameters, including small tools for Swiss type lathes from Ø 1.5 mm.

QUICK® marking tools make it possible to mark workpieces in seconds on a variety of surfaces and part geometries. Through single marking segments, the marking text can be individually customized. Tools are available in two diameters for interchangeable lettering, as well as custom logos.

These tools are used whenever absolute precision and first-rate surface quality are needed. Examples include medical and dental instruments, watches, fishing gear, windshield wiper shafts, barbells, screwdriver bits, fittings, connectors plus welding and cutting equipment.

To download the full catalog, click: https://platinumtooling.com/catalog/quick-catalog/

For further information, please contact:

Preben Hansen, President

PLATINUM TOOLING TECHNOLOGIES, INC.

16 E. Piper Lane

Suite 128

Prospect Heights, IL 60070

Phone: 847-749-0633

Fax: 847-749-2445

Email: phansen@platinumtooling.com

Platinum Tooling Technologies, Inc. in Prospect Heights, IL, near Chicago, serves its growing North American customer base with an extensive inventory of machine tool accessories. Its experienced staff is dedicated to providing the most innovative tooling and technology. Platinum Tooling Technologies, Inc. serves the auto, aero, medical, woodworking, composites and other industries, as well as an ever-increasing number of machine tool OEMs, through its network of manufacturers’ representatives. Platinum Tooling is the master importer of Heimatec, Henninger, Tecnicrafts, AMF Tooling and Hommel + Keller QUICK® for North America.

Continue reading

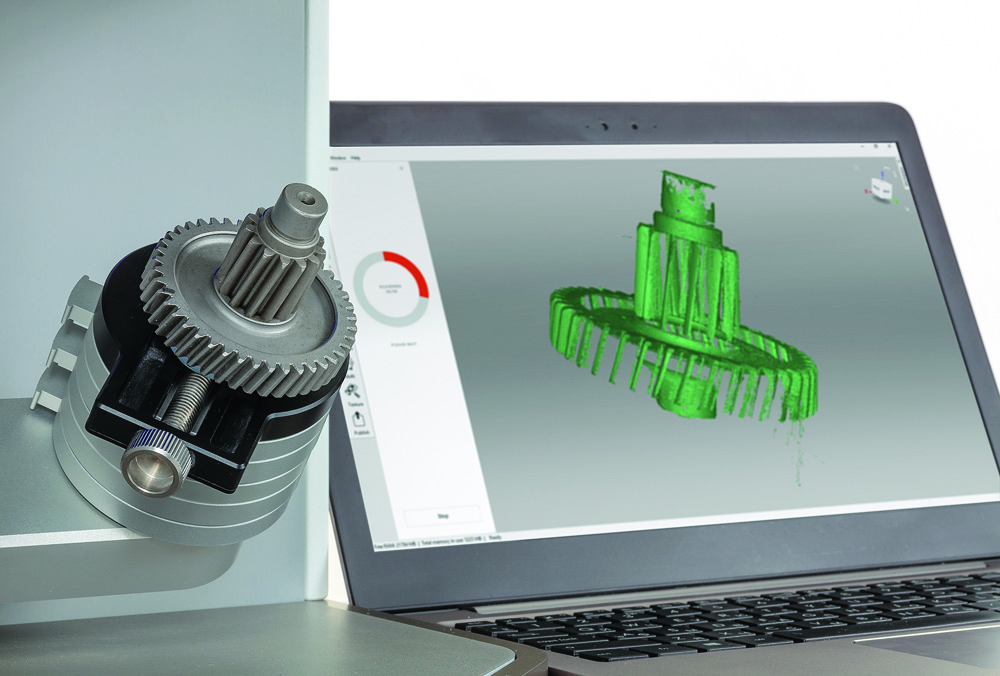

Exact Metrology: A Division of In-Place Machining Company and a comprehensive 3D metrology service provider and hardware sales company, attended this year’s CastExpo with a host of innovative solutions from Hexagon and Artec.

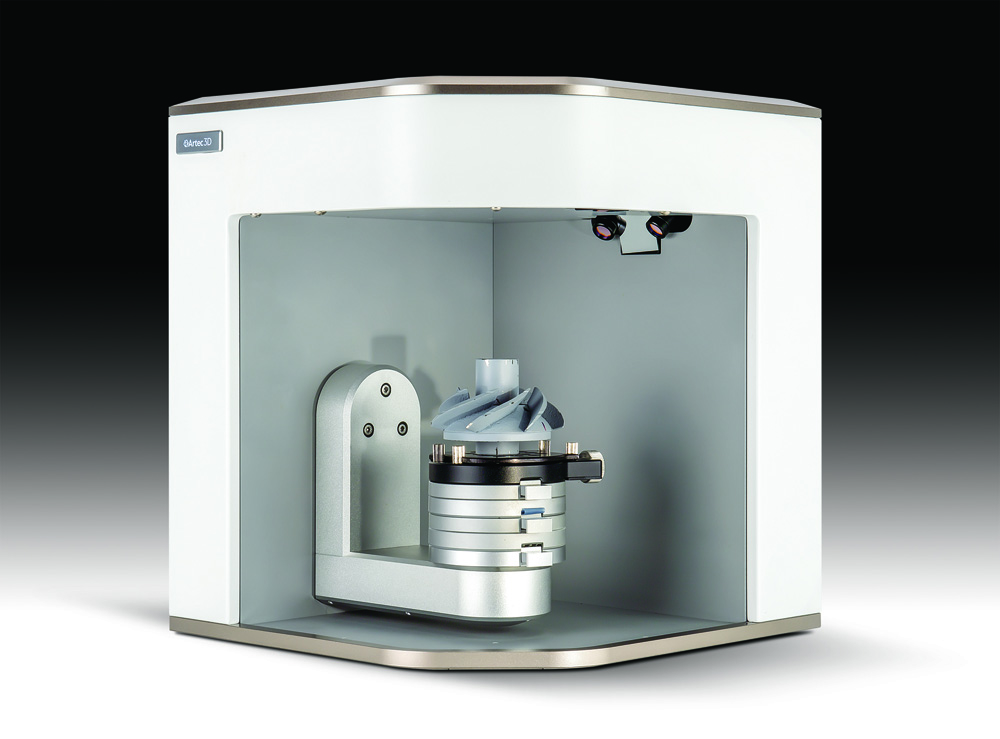

The event was held at the Greater Columbus Convention Center in Columbus, Ohio, from April 23rd to April 26th. Exact personnel at the booth included David Nichols, Applications Engineer, Darin Sherry, Regional Sales Manager and Chris Lafferty, Artec Sales. The team showcased the new IP54 Hexagon Absolute Arm, Artec Micro, and Artec Leo.

This Absolute Arm from Hexagon Metrology has an IP54 protection rating, a market first for portable measuring arms. It comes alongside an environment-related improvement that sees the system’s maximum operating temperature increased to 45°C. There are also improvements to the functionality of the Absolute Arm wrist display, now upgraded to a touchscreen, and the RDS software that drives it. With the CP-W Wireless Pack, also IP54 rated, every Absolute Arm boasts full-speed performance all of the time, even when high-speed scanning over a wireless connection.

Artec Micro’s professional ultra-high precision industrial desktop 3D scanner is designed to deliver industrial-quality scans in just one click. It includes up to 10 microns accuracy, producing metrology-grade scans suitable for quality control, while removing the need for targets on the scanned object. Furthermore, advanced twin color cameras and blue LED lights are synchronized with the scanner’s dual-axis rotation system to create a digital copy of your object with a minimum of frames captured. Artec Micro transforms intricate items into CAD/CAM data for design, modification, 3D printing and casting.

The 2022 Artec Leo features a new 3D scanning experience with a fresh new user interface and a screen that’s easier to use. Accuracy is guaranteed with a new calibration certificate and calibration kit. The new Auto Temperature Control enables the scanner to regulate its operation and keep its components at optimum operating temperature for capturing data at maximum accuracy. In addition, Leo has algorithms to automatically adjust the brightness level when scanning, providing true-to-life evenly lit color 3D models without the need for manual correction.

Commenting on the company’s involvement in metalcasting and their experience at CastExpo, Darin Sherry said, “Exact Metrology provides portable solutions for inspecting, measuring, and validating castings before a company begins their machining process. It was of incredible value to be a part of CastExpo as we were able to provide live demos of equipment that can be used as shop floor solutions, saving time with increased inspection time.”

In-Place Machining Company: On-Site Machining Solutions In-Place, Any Place in the World.

In-Place Machining Company, with facilities in Wisconsin, Washington, Virginia, Ohio, and Ontario, Canada, is the premier provider of high-precision engineered on-site machining, metrology, and large scale cutting & drilling services for a wide range of renewable energy, aerospace, industrial, and military customers throughout the world.

Exact Metrology: A Division of In-Place Machining Company, is ISO9001, AS9100 Certified as well as ITAR Registered.

Exact Metrology: A Division of In-Place Machining Company, with facilities in Cincinnati, Ohio, Moline, Illinois and Milwaukee, Wisconsin, plus affiliated offices throughout the country, is a comprehensive metrology services provider, offering customers 3D and CT scanning, reverse engineering, quality inspection, product development and 2D drawings. The company also provides turnkey metrology solutions, including equipment sales and lease/rental arrangements.

About Artec 3D

Artec 3D is an international company, headquartered in Luxembourg, with offices in the United States (Santa Clara, California), China (Shanghai) and Russia (Moscow). Artec 3D develops and produces innovative 3D solutions and products. Artec has a team of professional experts in the collection and processing of 3D surfaces as well as biometric facial recognition. Artec 3D’s products and services can be used in many industries, such as in engineering, medicine, media and design, entertainment, fashion, historic preservation, security technology and many more.

For more information, please contact:

Exact Metrology: A Division of In-Place Machining Company

Kelly Baldasare

11575 Goldcoast Drive

Cincinnati, OH 45249

Local: 513-831-6620

Toll Free: 866-722-2600

www.exactmetrology.com

kellyb@exactmetrology.com

As part of the digitalization group at Siemens and currently working with the machine tool systems business in Elk Grove Village, Illinois, near Chicago, Chunrong “Shelly” Shan is a digitalization software pre-sales engineer, primarily focused on the company’s advanced Industrial Edge technology. Edge brings machine tool users the ability to capture operational data from a machine or production line, feed it up to the cloud and analyze it in real time, in relation to a preset battery of monitored conditions. This technology, on a very practical level, enables the small job shop with a few CNC machines or a large production department with hundreds on the factory floor to maintain the highest levels of output coupled with consistent and constantly evolving manufacturing control, largely running through the algorithms in the machine’s control.

Shelly finds such work very stimulating. “In my current role at Siemens as pre-sales engineer, my primary task is to help our customers develop customized programs based upon our Edge technology platform to improve their manufacturing productivity.” She cites a recent example of her work, where she developed a software application for a top U.S. automotive manufacturer to capture the high-frequency data from the CNC on their many machine tools, then send that data to what Shelly calls the “data lake” for production optimization. Through the use of Edge devices on the various machines, such data are extracted from the machine controllers and fed to that data lake. Shelly notes it was a very big challenge, since the end user’s data lake uses a very specialized, proprietary protocol not supported by the standard Siemens solution. “That’s where it got interesting,” she muses.

Through a series of customized adaptations in the software, Shan was able to create a smooth interface between the data gathering and the host protocol, resulting in an optimal solution for the customer. One of the most significant challenges in Edge technology is something of a “too much of a good thing” scenario, as the power of Edge allows massive data sets to be gathered. The software needs to separate the data, prioritize it, compare it to preset levels or limits, then take the appropriate corrective action, all within milliseconds.

Shelly Shan brings an impressive skill set to the task, as she holds a Master’s degree in computer science from Penn State, as well as a Master’s degree in Mechanical Engineering from Beihang University in her home country of China. She first worked for Siemens in China for 11 years and now four years at the company’s U.S. machine tool headquarters in Chicago.

Shelly’s skills range from software development to AI, big data and cloud computing. She came to the U.S. when her family migrated.

In reflecting on her reasons for entering the engineering field, Shelly states, “I think it involves a combination of my personality and my technical interests. I feel most comfortable and engaged when I’m solving problems for a customer. That gives me a lot of strength and confidence, as well as joy in helping others.”

She makes mention of her mentor in China. “I had one colleague there who was simply good at everything! He could master technologies, problem-solve very quickly, and he was capable of numerous achievements simultaneously. His top skills were controller commissioning and debugging, as well as digitalization coding. I would say he definitely gave me a lot of help and guidance, as I worked to find the right directions in my career.”

Shelly enjoys her variety of tasks in customizing Edge application development and she seeks to do further software development for Siemens.

As a woman engineer, she notes there are both advantages and challenges. “Everyone tends to be very friendly to the often-lone woman in the room, which is nice,” Shan notes, also noting that it is sometimes difficult to talk to anybody about makeup or clothing styles. On the business side, she believes females tend to be more careful about details and can often communicate more easily with customers. The issue of work-life balance can also be a challenge. “Women often feel the need to take care of family as well as work, plus travel can be difficult, but I handle it. The company is also very supportive and flexible in helping me achieve my goals.”

From her performance and track record in the industry with a major corporation such as Siemens, Shan seems to handle it all quite well.

Asked where she sees herself in the coming years, Shelly observes, “I am sure I’ll still be working as an engineer and I’d like to make more contributions to the technology. I think the future for women in engineering is very bright and promising, as it will continue to drive the development of many technologies and improvements in our world.”

Continue reading

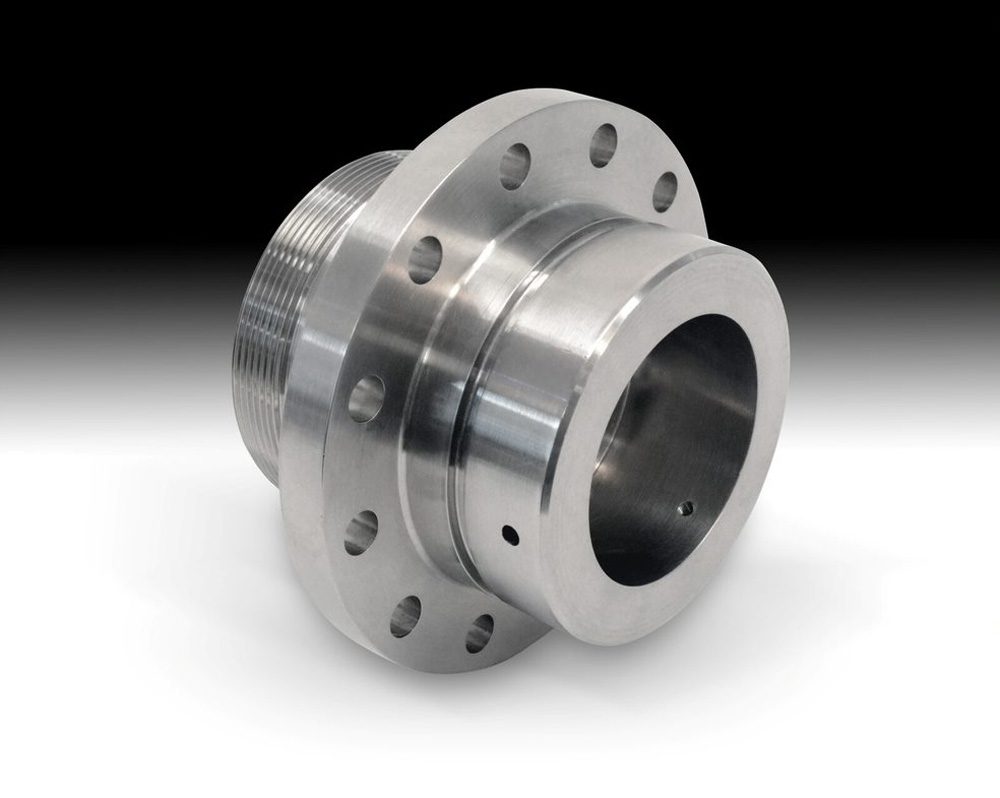

Guill Tool, a growing supplier of components to the global aerospace industry, today announced the production of a new Conduit Conductor. The conductor is made of Monel 400.

Dimensions on this product are 5.25” outer diameter x 3.625” overall length, or (133.35mm outer diameter x 92.075mm overall length). This Guill conduit conductor is turned on a CNC lathe and holes are drilled on a milling machine.

Guill now offers its substantial machine shop capabilities as an independent service to customers in aerospace manufacturing. Products are made to customer specification.

For over 55 years, Guill Tool has offered high-quality, precision machined components for the defense and commercial industries. The company manufactures flanges, valves, fittings and various critical components for aircraft, weapons and nuclear submarines.

Guill offers its full capability of CAD/CAM design, plus EDM and 5-axis machining centers to the aerospace industry. Owing to its many years in the government and defense sectors, Guill also provides industry-standard cybersecurity and NDA confidentiality to its customers.

Guill has the following registrations and certifications: AS9100:2016 – Aerospace Manufacturing, ISO9001:2015 registered, JCP Certified – Government Contracting, ITAR Registered and NIST SP800-171Compliant Cyber-Security.

For more information, please contact:

Tom Baldock

Guill Tool & Engineering – Aerospace Division

10 Pike Street

West Warwick, RI 02893

USA

Office: 401-828-7600

www.guill.com/aerospace

Located in Peterborough, England, Marlor Tooling has been designing and manufacturing cutting tools for more than 20 years. The cutting tool manufacturer specializes in delivering innovative solutions for the aerospace, automotive, energy, woodworking and general subcontract markets.

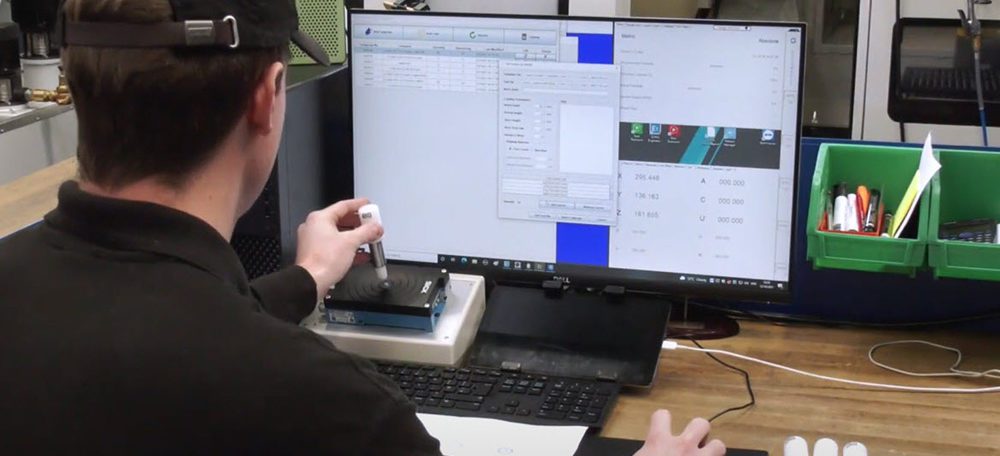

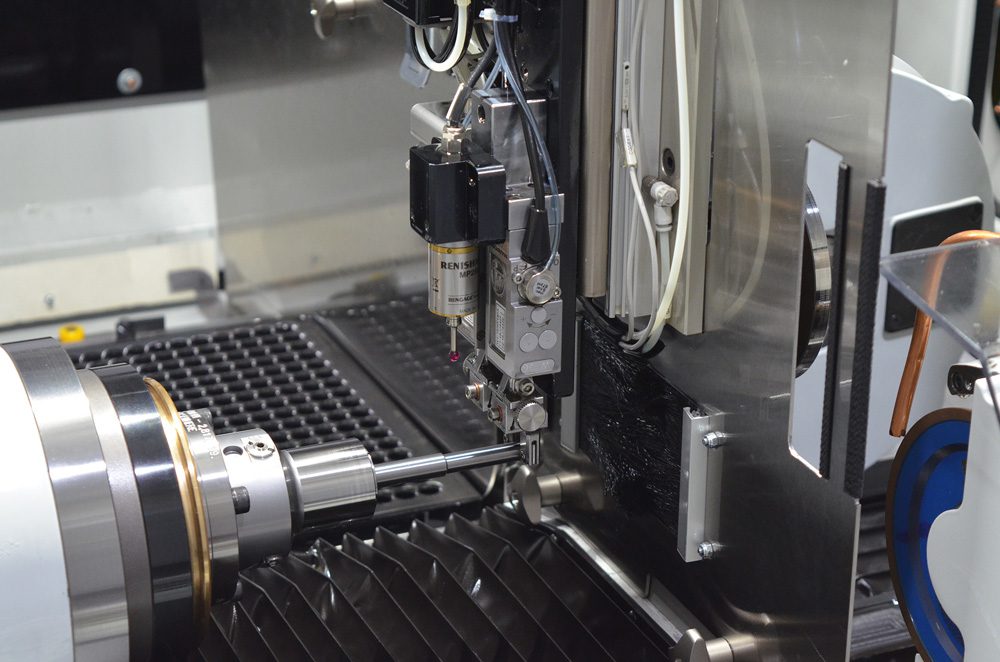

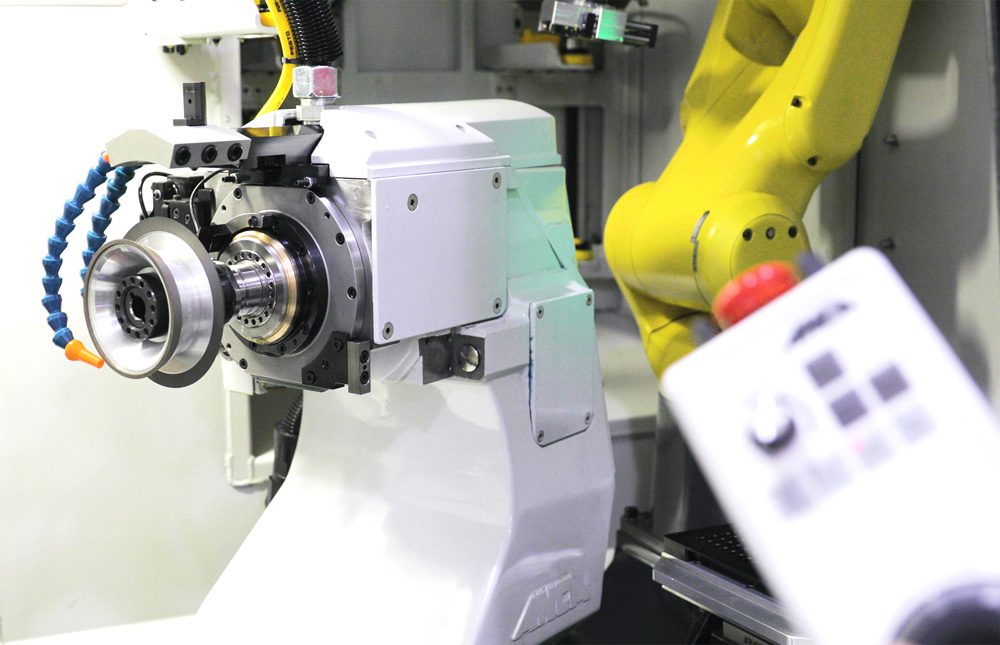

Discussing the business and the relationship with ANCA, Kevin Taylor from Marlor Tooling says: “Our business has grown with the technology. We aspire to have the best technology at all times and it has been an absolute pleasure working with the latest ANCA machine, the MX7 Linear. The quality of grind has always been there with the ANCA products, but this particular machine with the RFID technology has taken the loading of the machine to a different level. It’s an absolutely fabulous idea, chaotic loading is what it’s called and we have maximized the use of that. Things that we would consider being unable to load prior to the arrival of this machine, we now load. Whether it is a 1-off, 2-off, 3-off or a mixture of tools, it doesn’t mean anything to us now — everything can be automated. We are now trying to count our lead times in days and not weeks.”

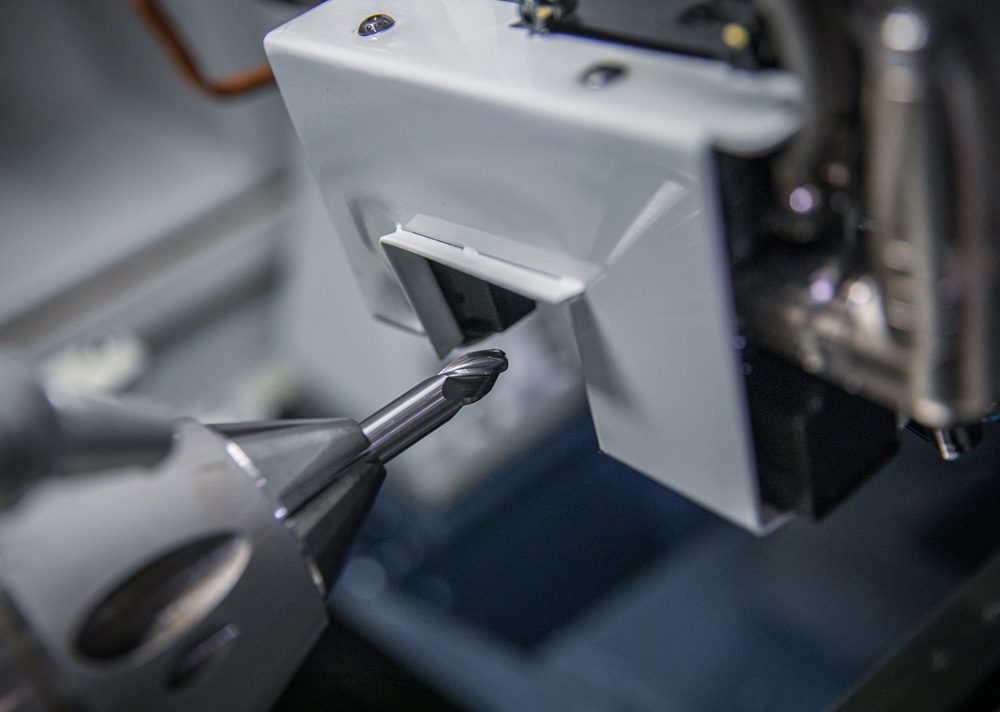

The ANCA MX7 Linear is a powerful, versatile CNC tool grinder designed for production grinding. It is built to meet the demands of high output, high precision manufacturing. The powerful 38 kW (51 HP) permanent magnet spindle provides high torque at lower RPM which is ideal for carbide grinding and a wide range of other applications. The MX7 Linear is a hard-working, high productivity system with unique features that enable it to handle varied batch sizes with minimum set-up time. The new cylindrical linear motor design increases reliability further and ensures a superior surface finish.

Commenting on the latest installation of the MX7 Linear with RoboMate loader which includes a FANUC LR Mate 200iD robot, Adrian Wright from ANCA says: “Marlor Tooling came to us after the FX7 machine was installed. They wanted a good all-around solution for chaotic regrinding, this means they can load tools from 3mm up to 16mm diameter and it doesn’t matter what the tool type is. We can also do small-batch manufacturing as well, once again it does not matter what the size of the diameter of the tool is for the loading sequence, as long as it is within the 3-16mm diameter range. The robot is programmed, and the program is done prior to the tools being loaded into the pallet. Then the machine does the rest — it changes the collets and it can measure in process with the LaserPlus System.”

The LaserPlus system provides accurate and repeatable measurement of tools inside the machine. The LaserPlus can automatically measure OD, run-out, EOT, ball nose and corner radius profile tools. Typically, the LaserPlus can achieve +/- 3 microns accuracy or better. An air blast unit ensures that coolant or contaminants are cleaned from the tool to ensure nothing hinders the measurement process.

The MX Linear range uses ANCA LinX Linear Motors for axis motion (X & Y axes). In conjunction with linear scales, a high level of machine precision and performance can be achieved, resulting in superior tool accuracy and surface finish. With LinX Linear Motors there is no loss of machine accuracy over time due to wear and it is not affected by temperature variations. The LinX Linear Motor has higher axis speed and acceleration leading to reduced cycle times. It achieves this while maintaining a smoother axis motion.

With two pallets in the machine, the ANCA MX 7 Linear can accommodate up to 200 tools. Referring to this, Adrian says: “it really doesn’t matter if the customer comes to Marlor today and requires five tools to be reground and turned around by tomorrow, the operator can change the five tools at the front of the pallet, or move them to the back of the pallet, if necessary, to ensure a fast turnaround of tools and the machine just carries on.”

“To go from a three-week lead time down to a 24-hour lead time is music to any business owner’s ears. We have the ultimate in flexibility here. When you combine this system with the LaserPlus or LaserUlta that can measure the tools in-process, you can intermingle the tools. So, it doesn’t matter if it is a re-grind tool or a newly manufactured tool, we can slot in any tooling and it is the solution for everything.”

Commenting upon the reliability of the ANCA automation system, Kevin Taylor continues: “It has been great, the system is very solid. We also do our programming offline, and that has its advantages too. We don’t have to stop the machine to do our programming, as the machine is automatically loading the next tool constantly. It’s not a machine you would have traditionally been running manually through the day and loading for automation overnight – it makes no sense. It is loaded all day and all night. The machine does not stop at all, where are some of our other machines are restricted in size, diameter and tool types – this machine does not have those restrictions.”

For further information, please contact:

Johanna Boland

Group PR and Communications Manager, ANCA

M: +61 407799779

Johanna.Boland@anca.com

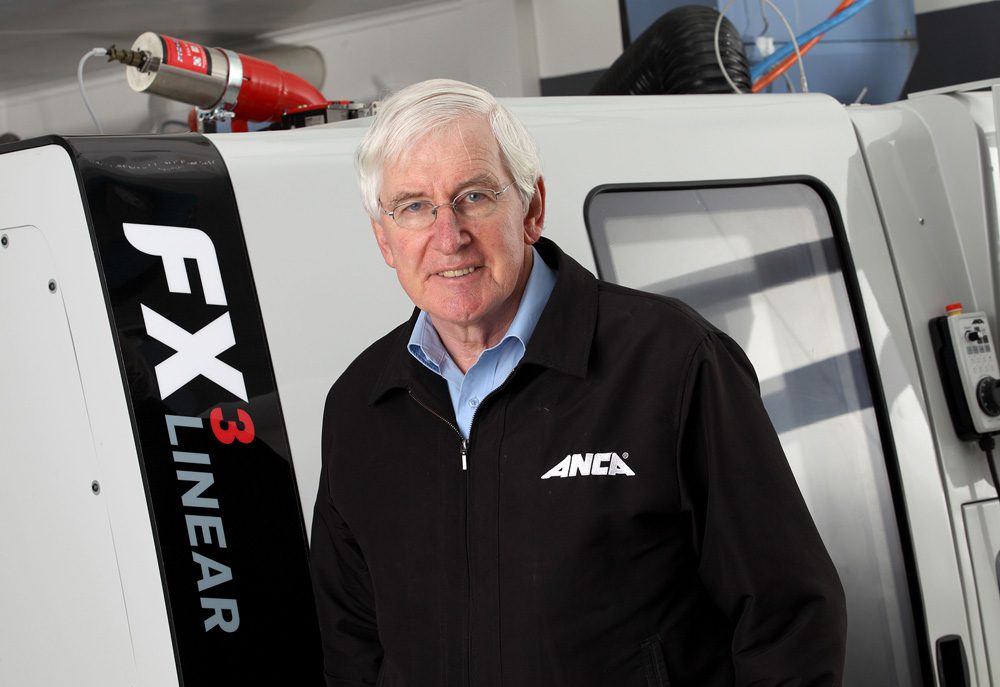

ANCA is a market leading manufacturer of CNC grinding machines. It was founded in 1974 in Melbourne, Australia where the company still has its global headquarters. ANCA has offices in the UK, Germany, China, Thailand, India, Japan, Brazil and the USA as well as a comprehensive network of representatives and agents worldwide.

ANCA CNC grinders are used for manufacturing precision cutting tools and components across a diverse range of competitive industries including cutting tool manufacture, automotive, aerospace, electronics and medical.

Continue reading

ANCA recently launched “The ANCA Academy,” a series of videos that cover a different technical topic each month. The third video in the series is called “Introduction to ANCA Software Applications,” and introduces the Academy’s new host, Hugh Ingham.

Biography

Hugh Ingham, ANCA

Hugh Ingham started at ANCA as an applications engineer in 2015, and for three years, was involved in testing and the development of new standard products, as well as grinding applications for custom solutions. In that time, he had multiple opportunities to travel to Thailand, Japan and South Korea gaining firsthand knowledge of customers’ experiences.

In 2018, Hugh was seconded for two years to ANCA Germany, functioning as both an applications and mechanical design engineer to deliver custom solutions to customers. This experience proved invaluable, as working directly with customers in Europe and seeing how they used ANCA’s products and how they could be improved – helps shape the way he approaches his job today. The scope and encouragement to explore new ideas, build new skills and develop as an engineer has driven Hugh’s passion for ensuring end-users get the most out of their technology.

In 2020, Hugh returned to Australia and since then has been continuing to develop custom solutions for a wide range of applications including medical, automotive, aerospace and more. Hugh is the host of ANCA Academy – a dedicated TV show for customers to learn more about ANCA’s products and solutions.

Continue reading

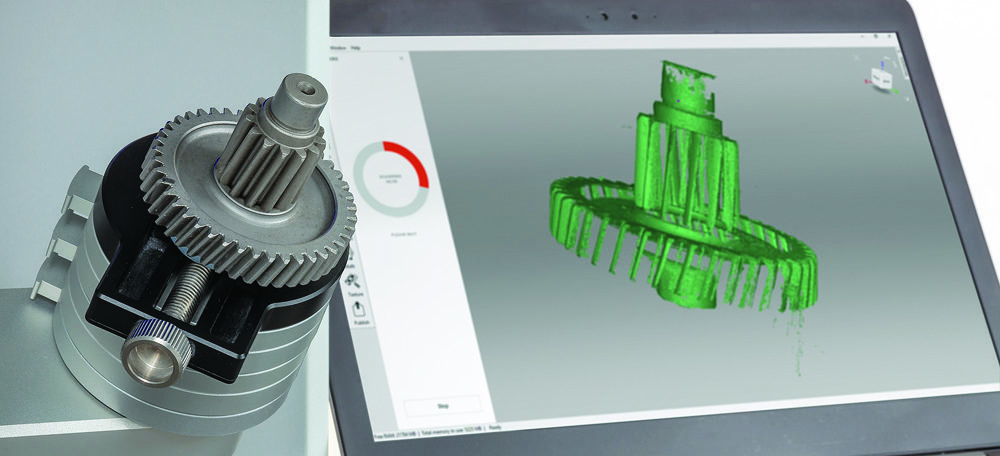

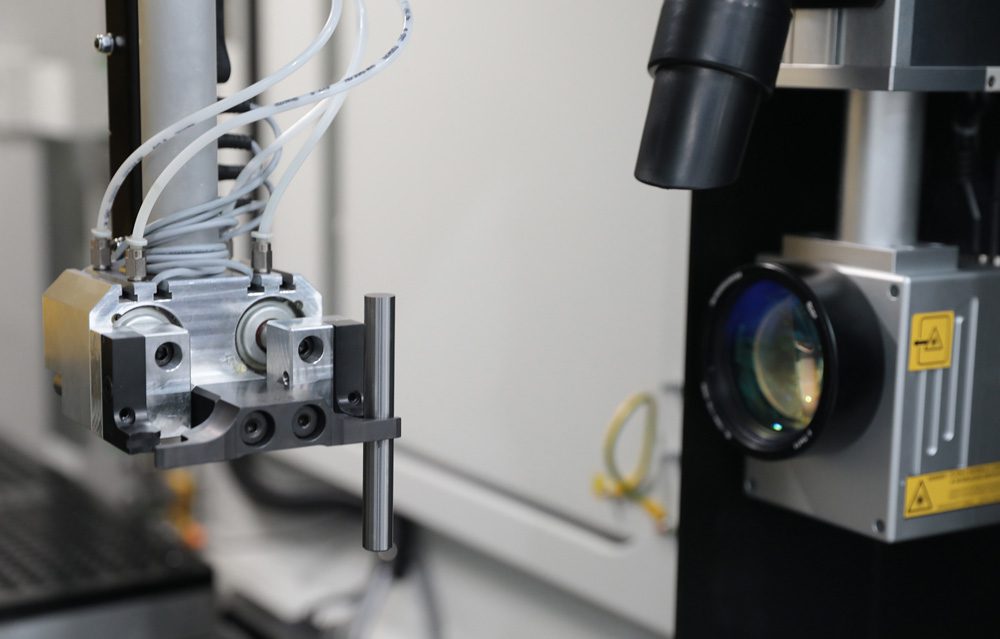

Exact Metrology: A Division of In-Place Machining Company and a comprehensive 3D metrology service provider and hardware sales company, now offers the newest version of its Artec Micro scanner. This new model distinguishes itself through its professional ultra-high precision industrial desktop 3D scanner, designed to deliver industrial-quality scans in just one click.

With a 2-year warranty, features of the Artec Micro include up to 10 microns accuracy and is perfect for quality testing and reverse engineering. It produces metrology-grade scans suitable for quality control, while removing the need for targets on the scanned object.

Artec Micro’s advanced twin color cameras and blue LED lights are synchronized with the scanner’s dual-axis rotation system to create a digital copy of your object with a minimum of frames captured. In addition, the Smart Scanning mode captures every surface of the object in the least amount of time, using an ideal number of frames. A minimum amount of training is required with Micro, as the scanner is user-friendly and ready to set up quickly. The scanner integrates with Artec Studio for real-time digital capture.

Delivering highly accurate scans, not only can Micro “see” well below the human visibility threshold of 40 microns, but its 3D measurements are among the best in today’s cutting edge scanners, making it a perfect choice for inspection and much more. Reverse engineering is completed with Artec Micro’s precise 3D measurement to digitally fit together legacy parts with those customers create, capturing even the smallest details that most scanners miss.

In minutes, Artec Micro transforms intricate items into CAD/CAM data for design, modification, 3D printing and casting. As a result, this saves hours of time in the design and production of complex pieces. The scanner also creates highly-detailed 3D models.

In-Place Machining Company: On-Site Machining Solutions In-Place, Any Place in the World.

In-Place Machining Company, with facilities in Wisconsin, Washington, Virginia, Ohio, and Ontario, Canada, is the premier provider of high-precision engineered on-site machining, metrology, and large scale cutting & drilling services for a wide range of renewable energy, aerospace, industrial, and military customers throughout the world.

Exact Metrology: A Division of In-Place Machining Company, is ISO9001, AS9100 Certified as well as ITAR Registered.

Exact Metrology: A Division of In-Place Machining Company, with facilities in Cincinnati, Ohio, Moline, Illinois and Milwaukee, Wisconsin, plus affiliated offices throughout the country, is a comprehensive metrology services provider, offering customers 3D and CT scanning, reverse engineering, quality inspection, product development and 2D drawings. The company also provides turnkey metrology solutions, including equipment sales and lease/rental arrangements.

About Artec 3D

Artec 3D is an international company, headquartered in Luxembourg, with offices in the United States (Santa Clara, California), China (Shanghai) and Russia (Moscow). Artec 3D develops and produces innovative 3D solutions and products. Artec has a team of professional experts in the collection and processing of 3D surfaces as well as biometric facial recognition. Artec 3D’s products and services can be used in many industries, such as in engineering, medicine, media and design, entertainment, fashion, historic preservation, security technology and many more.

To see the unboxing of the Artec Micro, click

For more information, please contact:

Exact Metrology: A Division of In-Place Machining Company

Kelly Baldasare

11575 Goldcoast Drive

Cincinnati, OH 45249

Local: 513-831-6620

Toll Free: 866-722-2600

www.exactmetrology.com

kellyb@exactmetrology.com

Transforming through innovation with ANCA’s AIMS: The future factory is efficient, automated and runs round the clock. It uses modular programs scripts, remote access, and cutting-edge machines to operate at maximum efficiency.

The world of CNC machining thrives on innovation. Grinding machines, cutting tools and software are constantly evolving to be more efficient, flexible, accurate and automated. ANCA chases customer requirements to identify the next challenge to solve — constantly iterating and refining its technology. Over its 40 plus years of operations, developments that were once considered cutting-edge are now business as usual — even at ANCA, we reflect on how revolutionary our early products felt.

Pat Boland, ANCA Co-Founder and Joint Managing Director, said: “We can recall a time when it was almost impossible to resharpen cutting tools on a CNC machine. That was until 1986, when ANCA launched our TG4, the first machine in the world to automate the measurement of tool geometry and regrinding through probing.”

“Or when we introduced the System 32 which, for the first time, applied advanced robotic software to tool grinding which enabled significant opportunities, for example, the soft axis or soft machine kinematics which simplified the grinding of cutting tools. We’ve come a long way, from probing for cutting tools, leading the competition in five-axis grinding or from simulating grinding processes before grinding with the CIM3D.”

“Designing the best technology requires a multi-pronged approach. We immerse ourselves in the market; are continually inventing; keep a keen eye on new developments and bring them into our applications. We seek out intelligent, talented people, and interact with customers daily to understand their specific needs. This is how we design and manufacture our market-leading solutions.”

At GrindingHub ANCA will showcase its technology range at a newly designed stand that enables customers to grow capacity, improve profit margins and gain efficiencies. Deciding what technology to invest in should be driven by business goals, working with existing objectives, processes, data and ideas.

LAUNCHING THE CPX IN-PROCESS OD MEASUREMENT SYSTEM

The CPX in-process OD measurement system is a quality control system that monitors and controls the OD of ground blanks within a batch production.

Batch grinding on a CPX with high material removal rates and to tight tolerances is a basic function of the machine, the OD measurement system takes it further by utilizing the Statistical Process Control (SPC) feature that comes standard with the OD measurement software. SPC is user defined, the tolerances along with the Cp and CpK values are constantly monitored, controlled, and reported to the user.

The OD measurement system is permanently mounted inside the machine and only called upon when required, based on the set tolerances and the frequency of measurement, an accurate in-process measurement and compensation is applied to maintain the blank OD to the nominal diameter.

The system is flexible with the ability to handle multiple diameters in one setup, making it perfect for complex blank geometries/shapes and longer batch runs.

AIMS

ANCA’s Integrated Manufacturing System (AIMS) is the future of optimized cutting tool production through streamlined manufacturing and connectivity. With ANCA and AIMS, customers can achieve continuous, unattended production that dramatically reduces non-productive machine time, with smart automation that connects sequential tool production processes and offers connectivity across the whole factory.

This is Industry 4.0 — factory-wide integration. The technology considers a factory as a single machine, rather than separating it into many different elements of design, blank preparation, grinding, laser marking, washing, packing and shipment. This is a powerful concept that brings together one ecosystem and builds it to be as efficient as possible. AIMS, being a modular solution, could be deployed in stages, allowing for easy, gradual and smooth transition from traditional to automated and integrated manufacturing.

An AIMS manufacturing cell will be displayed at GrindingHub, demonstrating a fully automatic process of tool manufacturing starting from the pallet with blanks and finishing with pallets with ground tools.

The GrindingHub demo consists of the following components:

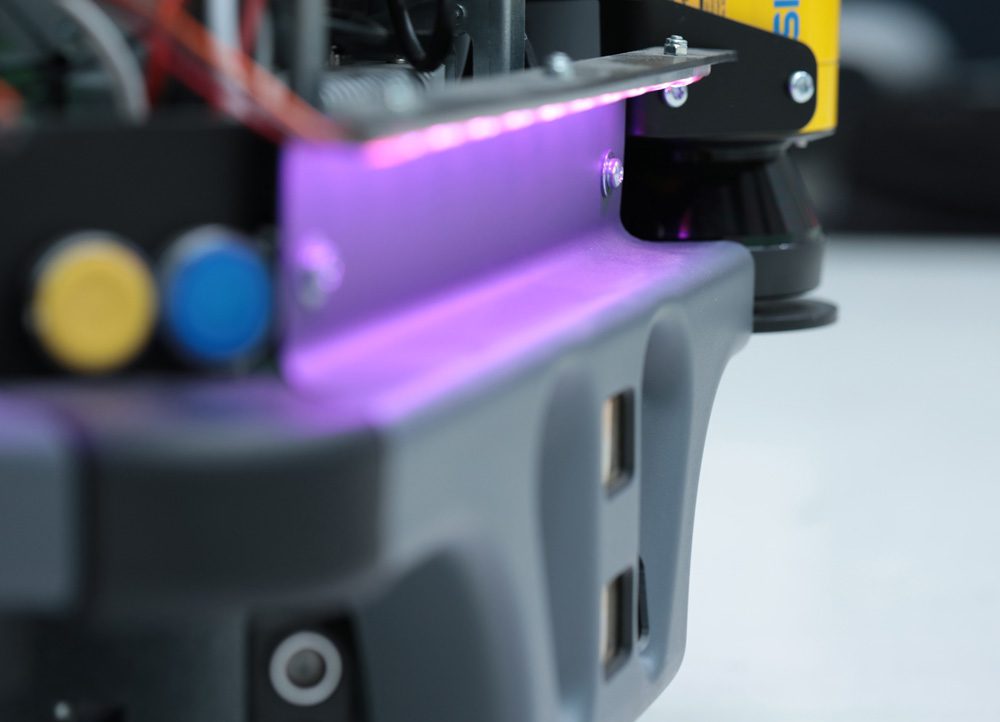

AUTOMARKX: ANCA’S AUTOMATIC LASER MARKING STATION

AutoMarkX is an automatic stand-alone laser marking station replacing manual and labor-intensive processes. It is AIMS Ready, which means it can be used as a standalone machine but could be easily integrated to your lights out, unmanned AIMS manufacturing cell with automatic pallet transfer using AutoFetch robot.

The AutoMarkX eliminates the need for manual laser marking which is a repetitive and labor-intensive job which could be automated and therefore saving you money. By avoiding manual handling, tool quality is protected by eliminating risk of chipping.

AutoMarkX accepts up to two full pallets of tools, which means you can mark a large batch of tools unmanned. Flexible marking means the message could be etched on a single side of the shank or on opposite sides of the shank as well as at the end of tool. The last option is particularly useful for applications where a unique tool identification code (e.g. Datamatrix) needs to be etched on the tool. Codes like Datamatrix are usually etched on the shank where they risk the exposure to excessive surface wear, rendering them unreadable. The end of tool is the best location to etch this type of code to overcome this issue.

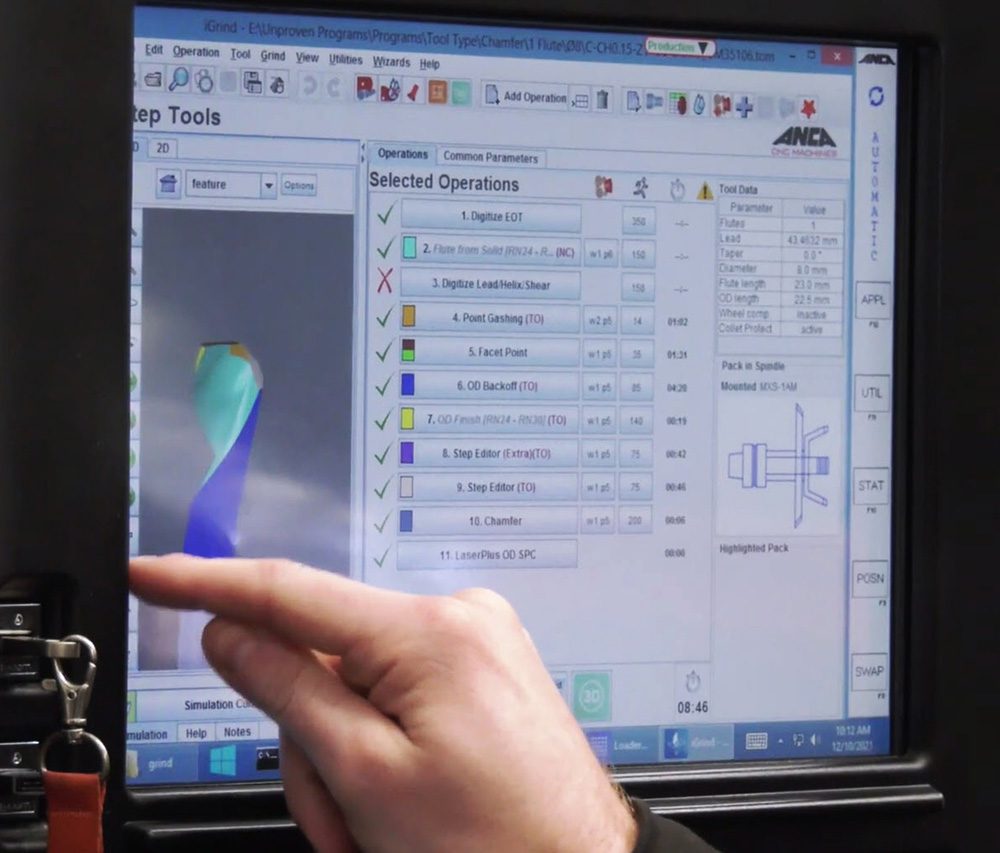

AUTOMATED SMALL BATCH AND REGRINDING SOLUTION AND INSERT GRINDING DEMONSTRATIONS

ANCA understands the requirement to continuously reduce cost within the production processes which is a particular challenge in smaller production batches of complex tools and in regrinding process. To address this challenge ANCA has developed a flexible solution utilizing RFID technology, our LaserUltra closed loop measurement and barcode reader interfaced into our iGrind and end-customer’s ERP system. This system will be demonstrated on the FX7 Linear platform. The demonstration will highlight how to set up a tool for regrind utilizing a barcode reader and QR code, how to easily make adjustments within our ANCA software, what inputs are possible in an ERP system, setting up the RFID to allow mixed diameter automation and the actual grinding process itself. The FX7 Linear machine will also be fitted with the Pop-Up Steady, AutoStick, Auto Wheel Qualification and iView.

The standalone MX7 Linear with RoboMate loader will be demonstrating ANCA’s solution for grinding and auto loading of indexable inserts. The machine and loader will be installed with workholding, grippers, pallets and interchange station specifically for the manufacture of special inserts. Accessories fitted on the machine include the 4-station Auto Stick, Auto Wheel Qualification and LaserUltra.

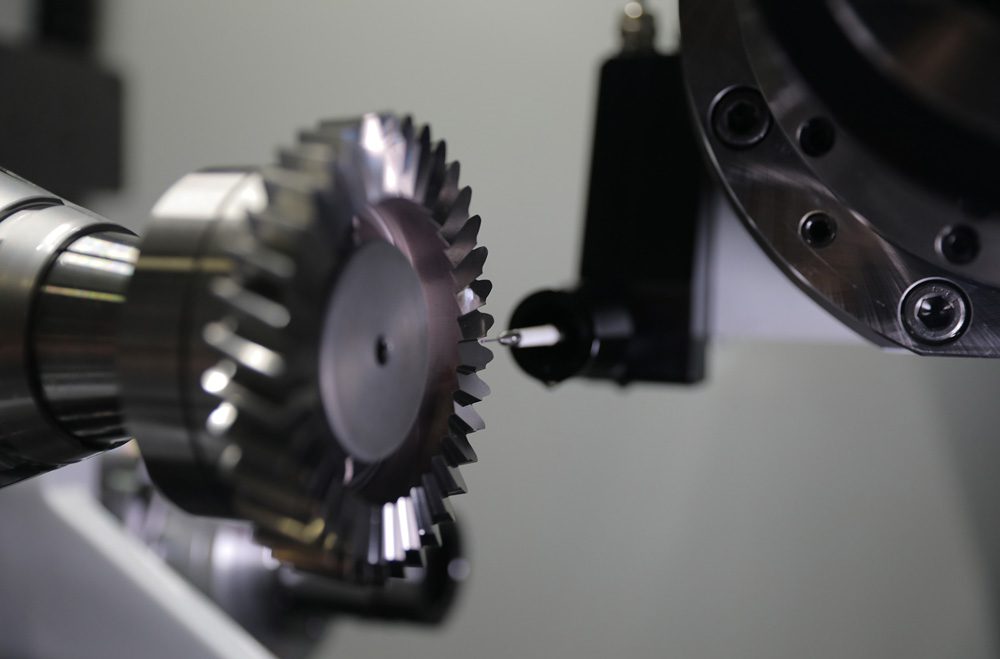

GCX LINEAR: GEAR UP FOR SKIVING

Driven by the automotive industry’s electrification and the general rise of e-mobility, the demand for skiving cutters has seen 30% year on year growth. The GCX Linear provides a complete solution for customers to tap into this rapidly developing market, including the ability to produce skiving cutters, shaper cutters and regrinding of hobs. It offers advanced stand-alone software to design and optimize the tool, neatly interfaced with the gear tool package inside ANCA’s renowned ToolRoom software. The machine is designed for accuracy with features including all axes with LinX linear motors and an enhanced headstock. GCX Linear also added a series of technologies: AEMS dressing, MTC on grinding spindle and dresser spindle, integrated gear tool measurement and direct compensation – setting the new standard for producing skiving tools that achieve the highest DIN AA quality class.

Due to the skiving tool’s novelty, many gear measurement machines still don’t have the correct mathematical model for evaluating the quality of the cutter. Leading the world in solving the quality control issue, ANCA developed the world-first integrated gear tool measurement system, which enables the grinding-measuring-compensation all done in the machine, as the only practical closed-loop solution.

At GrindingHub, the GCX Linear will demonstrate the skiving cutter production process assisted with the industry-first integrated gear tool measurement system.

NEW TOOLROOM RN35

Besides demonstrations on ANCA’s industry-leading ToolRoom and CIM3D software, visitors will have a special preview of the upcoming RN35 release.

ToolRoom RN35 focuses on productivity and cycle time improvements especially machine running costs. New process optimization features help to enable reduction in cycle time which in return provides better quality tools and wheel life. This includes automated reduction in air grinding time and gaps calculated based on tool simulation models. Some of the major enhancements include:

For further information, please contact:

Johanna Boland

Group Strategy and Communications Manager

Tel.: +61 407 799 779

E-Mail: Johanna.Boland@anca.com

ABOUT ANCA

ANCA is an advanced manufacturing company of CNC grinding machines, automation, motion control solutions and sheet metal fabrication. Founded in 1974 in Melbourne, where its global headquarters remain, it has grown to a thriving team with over 1000 talented people who work together to shape the future of technology.

As a global leader in its field, ANCA designs and manufactures highly complex and accurate machinery that requires lasers, automation and robotics to achieve accuracies in microns. It has offices in the UK, Germany, China, Thailand, India, Japan, Brazil and the USA and a comprehensive network of representatives worldwide. Its CNC grinders are used for manufacturing precision cutting tools and components across a diverse range of competitive industries including aerospace, medical cutting tools, automotive (including electric vehicles) and electronics.

ANCA partners with its customers to create bespoke solutions and invests almost 10% of annual turnover on research and development.

Joachim Jäckl

Marketing & Communications Manager

Tel.: 49 620 184 669 14

E-Mail: joachim.jaeckl@anca.com

About ANCA Europe

ANCA is a market leading manufacturer of CNC grinding machines. It was founded in 1974 in Melbourne, Australia where the company still has its global headquarters. ANCA Europe has its main technology centre in Weinheim, Germany and a smaller facility in Coventry, UK with expert teams covering service and sales, applications, customer training, operations, engineering, finance and administration. Regular customer demonstrations and events are conducted at the Weinheim technology centre. To offer customers a local experience ANCA has sales and service teams in Poland, France, Italy and Turkey as well as sales partners in Spain, Russia, Switzerland, Israel and other key European locations. See all our locations here: https://machines.anca.com/Contact

ANCA CNC grinders are used for manufacturing precision cutting tools and components across a diverse range of competitive industries including cutting tool manufacturers, power generation, woodworking, automotive, aerospace, electronics and medical.

Continue reading