Contact us today:

(847) 934-4500

tdaro@bernardandcompany.com

Contact us today:

(847) 934-4500

tdaro@bernardandcompany.com

by TJ Terrell, Business Development Manager,

Siemens Industry, Inc., Machine Tool Business

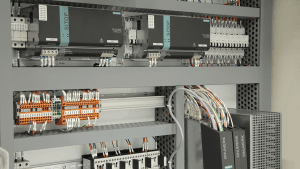

Given the multiple challenges associated with in-house panel building such as quality design, expertise, support and technology, outsourcing quickly becoming a viable option

A single source that can provide the design data, digitalization expertise, hardware, engineering, panel build and installation assistance, with factory warranty coverage, can yield myriad advantages for the builder.

Panel building on machine tools is no longer as simple as wiring a few components and calling it a day. Now, there are more deadlines, cost pressures, standards, new directives, plus an increasing pressure to innovate. Besides commonly encountered problems related to time, cost, compliance and quality, there is also an increased degree of automation in the pre-fabrication of cables and the automated production of sheet metal parts. In addition to the mechanical design and development of the automation concept, planning of the electrical power supply and distribution is the third engineering discipline involved in the production of a new machine. Electrical planning provides the framework for the automation engineer, as it involves specifying basics such as communication, topology and the control concept.

Increasingly, the daily work of electrical designers isn’t limited to planning activities. It now includes downloading, storing, processing and backing up data. These data management activities are an important part of the process, yet they occupy substantial time. To save time, machine tool companies need to create and implement a plan for handling data. If a machine tool builder has more than one electrical designer, it is worthwhile to relocate the product databases to a central server. Data only need to be maintained and imported once, then every user can access it. Since the engineering process is closely tied to other processes like procurement, storage, project-specific provisioning, assembly and inspection, it is useful to connect these processes electronically. All ECAD, or electrical drawing systems, are able to connect to typical Enterprise Resource Planning (ERP) systems. This makes it easier to calculate the price of a control panel. Prices are transferred from the ERP system to the product database of the ECAD solution.

Even though clients expect manufactured products to be high-quality, costs need to be kept to a minimum in order for companies to remain competitive. When machine tool builders think of cabinet costs, they typically think of costs originating from engineering, devices and materials, assembly and wiring. Engineering costs typically comprise 45% of the overall cost, devices and materials make up another 45% and assembly and wiring are the remaining 10%. However, there are also hidden costs like costs to order material, store it, the value of time from procurement, the time spent by engineering coordinating with suppliers or redesigning the cabinet and payment terms dictated when you order material.

Simplified designs are made possible by the expertise of custom panel builders, who bring experience in component clustering, footprint and enclosure space utilization to the task.

Increasing cost pressures stem from various sources. In general, the complexity of the documentation to be created is constantly increasing. End-users and machine builders want a high level of detail for better and more independent production. The communication portion of the integrated components is continuously increasing. A basic controller now has measuring and monitoring devices for tasks such as energy usage or machine condition monitoring. This makes planning more complex and time consuming. Demands on service personnel have also increased, as maintenance personnel must receive all necessary information for component replacement quickly and efficiently.

Although a favorable purchase price is desired, this doesn’t automatically lead to an economical control panel. The electrical planner works with a product log before it is purchased or integrated. Unfortunately, the burden placed by a component on electrical planning is often overlooked in the purchase decision. The manual creation of a complete dataset for a new project in the ECAD software often takes more than 2-½ hours. Therefore, the ability to use existing data is very important. Fortunately, ECAD systems often offer complete data packages that can be downloaded via data portals.

The use of tools for daily work is also changing. Only a few years ago, a “drawing” was the main way electrical plans were created. ECAD programs offered functions for easy and precise placement of circuit diagram placement and their interconnection. Then, the concept of object orientation was added to the software. A placed symbol is no longer simply a collection of drawn lines, but one of many views of a device that’s integrated into the control panel. With object orientation and automation functions in every ECAD software, users can take advantage of these benefits in their daily work. This “toolbox” concept has been popularized in various industries such as packaging, printing, converting and metal forming machinery. It allows slightly modified and next gen machine builds without the need to redo the entire electrical landscape. This evolution represents a significant potential savings for builders and integrators alike.

In-house projects often lead to delayed deadlines, wasted money and wasted effort. In fact, a significant number of machine tool builders often can’t afford building panels in-house. Occasionally, in-house cabinet building is done to keep a workforce employed. However, in today’s highly competitive business environment, the builder must evaluate whether or not overall cost could be lowered by reallocating resources? Often, this is not considered by machine builders, but could prove advantageous. Outsourcing to companies who specialize in electrical control and cabinet builds can establish milestones with contract manufacturers for timeline-based pricing, thus eliminating project management uncertainties and reducing time-to-market for the builder, beyond the time and materials costs.

Innovative projects or highly complex automation or robotic integration schemes often rely on multiple concepts to ensure they stand out in the market. Companies may lack the ability to have more staff working on developing projects. By working with another company, machine tool builders can use diverse teams of technologically advanced engineers to develop projects while eliminating the excess labor and engineering costs devoted to panel and cabinet builds.

As new software, automation technologies and tools continue to evolve, companies are placed in a competitively disadvantageous position. Tools and software programs can require a license or an expensive user fee. By outsourcing to a dedicated partner, machine builders can utilize the newest and most appropriate technologies for projects, in a cost-effective manner.

Problems with the equipment or the software can also lead to inactivity and unplanned expenses for a builder. An outsourced support staff monitors equipment efficiencies, diagnoses problems and repairs equipment in a more effective and economical manner.

Flexible set-up permits on-the-fly adaptation of control hardware, when design changes are required or subsequent iterations of a machine are produced.

By partnering with Siemens, for example, the process of panel building is streamlined and simplified. The company offers a unique product and system portfolio of CNC, PLC, drive, motor and other components in the control loop, backed by many years of expertise, data communications, software and tools. We further help the machine tool builder on the path to digitalization and also offers comprehensive support throughout each of the panel building stages including design, quoting, order, build and support. This achievement is often accomplished in tandem with a Solution Partner, authorized electrical distributor and job shop located in close proximity to the machine tool builder.

In the design stage, our company can assist with UL/EC standards and sizing optimization. Furthermore, the company offers component optimization, expert know-how and content-neutral devices. Additionally, the company can evaluate specification requirements and provide support regarding the application of standards and certifications, based upon the end-user’s market, physical location etc.

When quoting, Siemens and its partners can offer competitive pricing and fast response times to meet application-specific needs.

Ordering is likewise simplified, without complicated purchase orders and numerous line items, once the project details are set. One of the key reasons for outsourcing the cabinet build is to simplify the procurement process through time reduction. For a typical package, there may be more than 200 line items on the bill of material, each of which must be entered and tracked by someone in procurement. Outsourcing allows that procurement person to focus on obtaining better pricing instead of needless administrative work. In addition, there is no need to store pieces and parts for the panels in-house, as the partners maintain that carrying cost.

The building of the panel takes place in a UL-Certified production facility. There is a dedicated project manager onsite to handle engineering change notices (ECN) and communication. Our company and its partners provide quality control and assurance, along with clear scheduling and resource management. Continuity testing is performed, as well as automatic routing of the wiring and custom painting, per customer specification. All control panels feature a one-year warranty, pre- and post-purchase consultations, a communication log and a transparent ECN process.

There are several additional benefits when choosing Siemens to outsource panel and cabinet production. The company acts as the builder’s single source for all ordering, service, support and delivery, with comprehensive project management. Using a third-party to build a control panel greatly reduces the builder’s time-to-market. The total cost of ownership for the machine tool builder, which includes engineering, electrical and manufacturing engineering costs, is significantly lower when outsourcing, as well. In addition, our company has invested in a variety of panel shops to develop a “best practices” protocol for various machine categories.

Machine builders further receive competitive pricing by leveraging Siemens global agreements and enjoy extended payment terms, that is, terms at the completion of the project vs. when the order is placed.

Despite being implemented in the market presently for only one year, several machine tool companies are already realizing substantial savings with this new control panel initiative.

The company utilizes a global network of trusted partners with panel design and build expertise. These partners have years of experience and can optimize the overall design, cabinet heating and cooling, footprint, Siemens content, third-party content and more, thereby further enhancing the machine builder’s benefits.

For more information on this new approach to machine tool control panels, please contact:

TJ Terrell

Machine Tool-Business Development

Siemens Industry, Inc.

390 Kent Avenue

Elk Grove Village, IL 60007

770-653-9612

tyran.terrell_jr@siemens.com

250 aerospace supply company representatives enjoy hospitality, educational presentation and exclusive movie showing at Colossus de Laval in the Cosmodome

On Friday, October 12, approximately 250 suppliers to the bustling Montreal aerospace community gathered at the Colossus de Laval theater and entertainment complex for a premier showing of “First Man,” the new movie which traces the history of the first moon landing in 1969. The film focuses on the life of Neil Armstrong, the American astronaut who took that “one small step for man, one giant leap for mankind.”

This event was sponsored jointly by Maya HTT and Siemens PLM, partners in service to the aerospace industry in Montreal. Hosting the event was Ms. Rita Azrak, marketing director for Maya, who began the technical presentation portion of the day by musing that the actual “first foot” on the moon was Canadian, as the landing leg cones on the lunar excursion module Eagle were fabricated in Canada, a comment which aroused the crowd’s enthusiasm.

The three main speakers gave insights on their companies’ involvement in the industry and were quite optimistic for the future, as funding for renewed space exploration by both Canada and America is in the works with the respective countries’ governments. Before the first speaker, a recorded message was shown from the first Canadian astronaut, Marc Garneau, now Minister of Transport in Canada and a veteran of three flights on the Space Shuttle. He was followed by Mike Greenley, group president for MDA Corporation, a major aerospace supplier, George Rendell, senior director at Siemens and Marc Lafontaine, vice-president of Maya. All spoke of the longtime benefits derived in our daily lives from the space program, over the decades, as well as the next major project now under way, the Lunar Orbital Platform-Gateway, a lunar orbit space station which, according to NASA documents, will serve as a solar-powered communications hub, science lab, short-term habitation module and holding area for space rovers and other robots. They detailed some of the advancements and planned developments in artificial intelligence.

The program also included a variety of successes achieved with Siemens PLM products, especially NX CAD and NX CAM through the Teamcenter of product lifecycle management. Maya is the Siemens partner in Montreal and brings further value to these products and others in the Siemens suite as a Platinum Level VAR, serving a broad spectrum of industries, including aerospace, defense, automotive, marine and commercial building.

Many in the audience were quite moved by the touching story of Neil Armstrong and his Apollo journey to the moon and back.

For more information on this interesting event or the sponsoring companies, contact:

Ms. Rita Azrak, Marketing Director

Maya HTT Ltd

4999 Ste-Catherine Ouest, Suite 400

Montreal, Quebec QC H3Z 1T3

Canada

Phone: 514-369-5706, ext. 236

Rita.Azrak@mayahtt.com

www.mayahtt.com

Software solution combines maximum performance with minimal implementation time

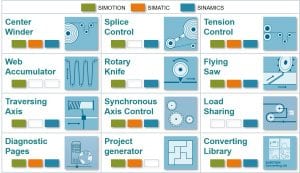

The toolbox enables machine builders to achieve considerably faster time to market by reducing the time required for engineering, programming, commissioning and documentation as much as 80%.

The Siemens Converting Toolbox has separate modules for each of the Siemens product categories typically found on converting machines, including SIMOTION motion controllers, SINAMICS drives and SIMATIC PLCs. SIMOTION is designed for high-performance motion control applications with centralized control in conjunction with the SINAMICS S120 drive system. SINAMICS is ideal for drive-based applications with process-related control implementation in the SINAMICS S120 drive system with graphical drag-and-drop programming. Lastly, the SIMATIC platform applies to centralized converting applications implemented in the PLC control to work in tandem with the SINAMICS S120 drive system.

Additional features of the Converting Toolbox include converting base applications such as: center winder, unwind flying splice control, sectional drive with tension/draw control, accumulator, rotary knife with print mark correction, flying saw, traversing control, synchronized multi axis drive control, load sharing, diagnostics Web pages, project generation tools and converting library process and logistic functions. These function blocks can literally be cut and pasted into a new design, with minimal programming time.

Other specialized application blocks are available upon request.

For more information, please contact:

William Gilbert, Converting Market Manager

Siemens Industry Inc.

5300 Triangle Parkway

Norcross, GA 30092-2538, USA

Tel: +1678 314-4222

William.gilbert@siemens.com

www.usa.siemens.com/converting

Siemens Digital Factory (DF) offers a comprehensive portfolio of seamlessly integrated hardware, software and technology-based services in order to support manufacturing companies worldwide in enhancing the flexibility and efficiency of their manufacturing processes and reducing the time to market of their products.

Siemens Corporation is a U.S. subsidiary of Siemens AG, a global powerhouse focusing on the areas of electrification, automation and digitalization. One of the world’s largest producers of energy-efficient, resource-saving technologies, Siemens is a leading supplier of systems for power generation and transmission as well as medical diagnosis. With approximately 351,000 employees in 190 countries, Siemens reported worldwide revenue of $88.1 billion in fiscal 2016. Siemens in the USA reported revenue of $23.7 billion, including $5.4 billion in exports, and employs approximately 50,000 people throughout all 50 states and Puerto Rico.

Continue reading

The Solution

Fortunately, recent advancements in digital technologies have fueled innovation in the field of crane control, and new solutions have been developed that are safer and smarter. One unique solution for modernizing cranes was designed to help operators by reducing load sway by a stunning 95%. This innovative solution, EXPERTOPERATOR™, was developed by PaR Systems (PaR) of Shoreview, Minnesota (www.par.com). PaR is a global manufacturer of advanced automation, robotic, and specialty material handling solutions. PaR supports global customers in automotive, aerospace, nuclear, life science, marine and other core industries.

EXPERTOPERATOR is currently installed on over 150 cranes worldwide – many of which are located in automotive, primary metal, and heavy equipment industry facilities. Users have indicated that EXPERTOPERATOR has allowed operators to control their crane loads with 95% less sway and 90% fewer “close calls” or collisions. Optional modules to the EXPERTOPERATOR platform provide robust zone control, sideload/snag prevention, and automatic load positioning.

How material handling customers are benefitting from EXPERTOPERATOR

Across 150 installations, EXPERTOPERATOR has improved personnel safety, reduced damages to equipment, increased efficiency, and reduced maintenance costs.

The evidence that EXPERTOPERATOR makes cranes easier to operate is further demonstrated by data captured through operator studies that measured the frequency of button pushes. While using the technology, operators pressed pendant buttons 60- 80% less than while conducting the same manipulation task without EXPERTOPERATOR. This metric demonstrates that fewer commands are needed to manipulate a swing-free load.

PaR Systems knew their success would depend on their ability to work with a partner who could provide critical hardware that is robust for industrial environments, quick to deploy, and highly configurable.

In material handling crane operations, wireless capability is a key operational factor. The Siemens Scalance W wireless solution offered PaR Systems a wireless component that was reliable and predictable. PaR had experience with non-Siemens wireless solutions in the past that were problematic, both functionally, and from a manufacturer support perspective. The Scalance W wireless solution can be configured to operate in a less congested frequency range (5 GHz), allowing for a more robust wireless signal. Since installing Siemens Scalance W wireless modules as part of their solutions, customers have experienced 100% uptime of their wireless communications. In addition to reliability, the Scalance Wireless Modules offered PaR exceptional customer and OEM technical support.

EXPERTOPERATOR is an advanced crane motion control system that is implemented entirely within the Siemens platform. The system uses equipment such as Simatic S7 PLCs, Simatic HMI Panels, and Scalance W Industrial Wireless Modules.

Time to market is also important to PaR Systems when delivering customer solutions. The Siemens Totally Integrated Automation (TIA) portal provided a platform to shorten engineering time through its simulation tools, programmer productivity tools, and additional diagnostics. PaR Systems benefitted from unique capabilities when programming the Simatic S7 PLCs and Simatic HMI Panel. They were able to dynamically change the cycle time of the main control loop during runtime, which is critical for optimizing the performance of their unique motion control. Debugging capabilities were enhanced because the tool monitors values and updates programs in real time for instantaneous feedback. Such tasks that are tedious and time consuming within other platforms happen automatically and dynamically when using the Siemens TIA solutions.

Material handling requires a fine balance between precision, efficiency, productivity, and most importantly, safety. As a result of the collaboration between PaR Systems and Siemens, new and experienced crane operators around the world can now confidently perform their tasks and contribute to enhanced plant safety and operational efficiency, while reducing equipment maintenance.

To learn more about how Siemens and PaR Systems can help digitalize operations, improve safety, and boost operational efficiency, visit https://www.siemens.com/global/en/home/products/automation.html or https://www.par.com/technologies/crane-controls/

Siemens Industry, Inc.

5300 Triangle Parkway

Norcross, GA 30092

For more information, please contact our Customer Support Center.

Phone: 1-800-241-4453

E-mail: info.us@siemens.com

usa.siemens.com

For specific information on this application, please contact:

Adam Shively

OEM Account Manager

Siemens Digital Factory

Phone: 952-221-3791

E-mail: adam.shively@siemens.com

Support: (800) 333-7421

The technical data presented in this document is based on an actual case or on as-designed parameters, and therefore should not be relied upon for any specific application and does not constitute a performance guarantee for any projects. Actual results are dependent on variable conditions. Accordingly, Siemens does not make representations, warranties, or assurances as to the accuracy, currency or completeness of the content contained herein. If requested, we will provide specific technical data or specifications with respect to any customer‘s particular applications. Our company is constantly involved in engineering and development. For that reason, we reserve the right to modify, at any time, the technology and product specifications contained herein.

About Siemens USA

Siemens Corporation is a U.S. subsidiary of Siemens AG, a global powerhouse focusing on the areas of electrification, automation and digitalization. One of the world’s largest producers of energy-efficient, resource-saving technologies, Siemens is a leading supplier of systems for power generation and transmission as well as medical diagnosis. With approximately 348,000 employees in more than 190 countries, Siemens reported worldwide revenue of $86.2 billion in fiscal 2015. Siemens in the USA reported revenue of $22.4 billion, including $5.5 billion in exports, and employs approximately 50,000 people throughout all 50 states and Puerto Rico.

Continue reading

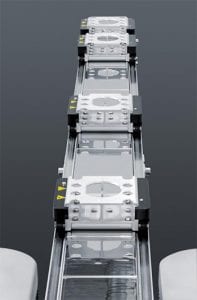

The MCS addresses the acute need for flexibility in modern manufacturing and production environments driven by increasingly complex product diversity, shorter product life cycles and growing levels of mass customization.

In this configurable transport system, the transport carriages, which are driven by linear motors, are flexibly moved to the individual units, e.g. filling, closing or labeling unit. The system moves freely and exactly synchronously to the process and can be integrated in the existing intralogistics – including seamless loading and unloading of the carriages. The other transport paths remain unchanged. The modular concept allows a quick conversion of the machine to different formats, other product types or seasonal requirements. The integrated concept allows control of the transport movements and Motion Control functionality as well as the coordination of additional machine module.

The MCS provides many benefits:

The MCS incorporates options for processing and packaging customers to achieve goals for advanced manufacturing. Some of these options are flexible electromechanical design for economic production down to batch sizes of one and decentralized sensors and intelligence incorporated within the work piece carriers and drives.

The modular servo controller and the motion controller also fully reflect the cyber-physical integration of Industrie 4.0 systems. The system provides OPC Unified Architecture (OPC-UA) messaging enabling open integration into Industrie 4.0 architectures and enterprise systems such as SAP.

Siemens offers a comprehensive portfolio of seamlessly integrated hardware, software and technology-based services in all aspects of packaging. Siemens supports the packaging industry on an industrial scale enhancing flexibility and efficiency processes and reducing the time to market.

Contact for product inquiries and information:

Mathias Radziwill

Phone: (800) 743-6367

Email: mathias.radziwill@siemens.com

Follow us on Twitter at: www.twitter.com/siemens_press

About Siemens USA

Siemens Corporation is a U.S. subsidiary of Siemens AG, a global powerhouse focusing on the areas of electrification, automation and digitalization. With approximately 348,000 employees in more than 190 countries, Siemens reported worldwide revenue of $86.2 billion in fiscal 2015. Siemens in the USA reported revenue of $22.4 billion, including $5.5 billion in exports, and employs approximately 50,000 people throughout all 50 states and Puerto Rico.

About Festo

Festo is a leading manufacturer of pneumatic and electromechanical systems, components, and controls for process and industrial automation. For more than 40 years, Festo Corporation has continuously elevated the state of manufacturing with innovations and optimized motion control solutions that deliver higher performing, more profitable automated manufacturing and processing equipment.

Siemens offers a new servo package consisting of drive, motor and controller for

a wide variety of motion control applications

“The Sinamics S210 focuses on highly-dynamic motor axis control, while the connected controller, for example the Simatic S7-1500 or S7-1500T with its extended motion control functionality, takes complete charge of positioning functions for the connected drive axes.”, says Craig Nelson, product manager for Sinamics S-series drives.

The Sinamics S210 is commissioned using an integrated web server. One-button tuning functionality allows automatic optimization of control parameters, taking into consideration the behavior of the connected mechanics by different dynamic levels.

Integrated safety functions include STO (Safe Torque Off) and SS1 (Safe Stop 1). Both can be actuated using Profisafe, STO additionally using a terminal. Additional functions are currently in the preparation stage. In conjunction with the rapid sampling and smart control algorithms of the Sinamics S210, a high-grade encoder system on the Simotics 1FK2 motor and the combination of low rotor inertia and high overload capability, allow the servomotors to achieve outstanding dynamic performance and precision.

Simotics 1FK2 motors are connected to the converters using a “One Cable Connection” (OCC), which includes the power conductors, encoder signal and brake — all grouped together in an exceptionally thin cable measuring just 9 millimeters in diameter. Its minimal cross-section makes the OCC cable thinner, lighter and more flexible than previous power cables, considerably simplifying the cabling process. This results in a single motor plug connector and connection at the converter is just as simple with user-friendly plugs with push-in terminals on the front.

To learn more about the Sinamics S210 servo system, please visit: usa.siemens.com/sinamics-s210

The new Sinamics S210 drive system with Simotics S-1FK2 servomotors and Simatic S7-1500 controllers offer users a highly-dynamic servo package with integrated safety functions and quick commissioning.

Siemens Digital Factory (DF) offers a comprehensive portfolio of seamlessly integrated hardware, software and technology-based services in order to support manufacturing companies worldwide in enhancing the flexibility and efficiency of their manufacturing processes and reducing the time to market of their products.

For specific product information and inquiries, send an e-mail to: mc.us@siemens.com

Siemens Corporation is a U.S. subsidiary of Siemens AG, a global powerhouse focusing on the areas of electrification, automation and digitalization. One of the world’s largest producers of energy-efficient, resource-saving technologies, Siemens is a leading supplier of systems for power generation and transmission as well as medical diagnosis. With approximately 351,000 employees in 190 countries, Siemens reported worldwide revenue of $88.1 billion in fiscal 2016. Siemens in the USA reported revenue of $23.7 billion, including $5.4 billion in exports, and employs approximately 50,000 people throughout all 50 states and Puerto Rico.

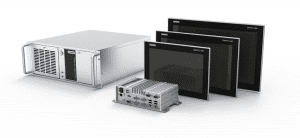

Siemens Factory Automation seeks to open market for its embedded and panel PC products in healthcare segment, including x-ray, analyzer, imaging and diagnostic equipment plus data acquisition to patient and hospital records; domestically sold product now assembled in Lebanon, Ohio

Commenting on the Lebanon, Ohio facility, Thorsten Julich noted the in-house development of Siemens IPC technology for this market segment will include both software and motherboard manufacturing. Complementing the PC product offerings, rugged handheld units with Windows 7 or 10 compatibility, will be offered for technician ease-of-use and connectivity to cloud-based systems.

Single- and multi-touch panel PCs will be offered in 7”-22” displays in the company’s Nanobox/Nanopanel and Microbox/Micropanel designs.

Julich concluded, “Because our IPC range has full interface capabilities with SCADA software plus the medical grade tablets offer full compatibility with networking solutions in the digital world, we believe the company is well positioned to enter this medical equipment market with a very substantial and sustainable suite of products and services.” He also mused the Lebanon, Ohio facility would give Siemens something of a “home field advantage” in the market.

To learn more about the event and products, please visit: usa.siemens.com/ipc or contact Siemens via email at info.ipc.us@siemens.com.

Siemens Digital Factory (DF) offers a comprehensive portfolio of seamlessly integrated hardware, software and technology-based services in order to support manufacturing companies worldwide in enhancing the flexibility and efficiency of their manufacturing processes and reducing the time to market of their products.

Siemens Corporation is a U.S. subsidiary of Siemens AG, a global powerhouse focusing on the areas of electrification, automation and digitalization. One of the world’s largest producers of energy-efficient, resource-saving technologies, Siemens is a leading supplier of systems for power generation and transmission as well as medical diagnosis. With approximately 351,000 employees in 190 countries, Siemens reported worldwide revenue of $88.1 billion in fiscal 2016. Siemens in the USA reported revenue of $23.7 billion, including $5.4 billion in exports, and employs approximately 50,000 people throughout all 50 states and Puerto Rico.

Continue reading

Siemens Factory Automation gathers its team, Solution Partners and End User community for four days of learning and fun

From February 19-22, 2018, at the Riverwalk Westin in San Antonio, Texas, approximately 130 people gathered for four days of product presentations, emerging technology discussions and a market trend outlook at the Siemens Factory Automation SCADA/IPC Days 2018. Members of the Siemens management, sales and support team joined their Solution Partners and a diverse assortment of end user companies from various market segments to review new product offerings in the IPC segment of the Siemens portfolio, plus a number of new platforms in the SCADA segment. The event was hosted by the product marketing teams for Factory Automation, based in Norcross, Georgia.

Following a welcome session on the first evening, a series of presentations were made on day two to the entire group by Siemens management and technical thought leaders, covering the digital factory strategy and the company’s forward-thinking move to Digitalization, the current theme for the Siemens marketing message across its entire industrial platform. Key speakers were Kevin Lewis, Russell Barnes, Thorsten Julich, Bernd Raithel, Michael Steigberger, Bernd Staufer and Tom Elswick. The primary message takeaway for the group was that Digitalization will hallmark the factory of the future and SCADA will be the “digital doorway for data” in that rapid evolutionary process, as it impacts all industries, both discrete and process.

There were also presentations on cloud computing and edge computing, the constituent elements of the Digitalization trend, comprising both hardware and software elements. This discussion led directly into the program’s introduction of various new thin client IPC product offerings and the latest version of SIMATIC WinCC SCADA systems.

In addition to the technical presentations and market overviews, a very interesting end user application was detailed by end user Derek Thoma of Hop Valley Brewing, a Miller/Coors company. Thoma spoke on the marked improvements in production and product quality tracking made possible by the advanced IPC and HMI provided by Siemens, in addition to the SCADA software for process monitoring and management.

During that evening, the entire group enjoyed a genuine Texas BBQ and a good time was had by all.

Presenters at the event (starting from left): 1-Russell Barnes, 2-Johann Strobl, 3-Bernd Staufer, 4-Kevin Lewis, 5-Michael Steigberger, 6-Thorsten Julich, 7-Bernd Raithel

Day three began with a review of new IPC products and emerging technologies on the horizon from Siemens, followed by more intense product and software breakout workshops, tagged the Wisdom Series by the event coordinators.

Finally, day four offered direct consultation from the Siemens product specialists gathered at the event, including the Solutions Partners, who represent the system integrator community at Siemens, as they bring the products, application engineering, installation and service, plus related data gathering and process control products to the process industries. In addition, those interested in becoming a WinCC Specialist were offered the opportunity to take their certification test during the event.

Guest instructors were present during the workshop sessions to discuss such topics as Automation for Networks, Using WinCC to Build a Toolbox, Batch Tracking Made Easier with WinCC Archives, Mindsphere and Cybersecurity, and the Industrial PC of tomorrow. Rapidly developing MindApps for performance optimization on all types of industrial manufacturing and process machines were also discussed in detail, as Siemens seeks to assist its customer base and machine builders alike to gather, process, analyze and apply relevant data. Such data allow better process control and KPI development, plus have positive uses for machine liability, insurance, warranty and even energy saving calculations.

To learn more about the event and products, please visit: usa.siemens.com/automation

Siemens Digital Factory (DF) offers a comprehensive portfolio of seamlessly integrated hardware, software and technology-based services in order to support manufacturing companies worldwide in enhancing the flexibility and efficiency of their manufacturing processes and reducing the time to market of their products.

Siemens Corporation is a U.S. subsidiary of Siemens AG, a global powerhouse focusing on the areas of electrification, automation and digitalization. One of the world’s largest producers of energy-efficient, resource-saving technologies, Siemens is a leading supplier of systems for power generation and transmission as well as medical diagnosis. With approximately 351,000 employees in 190 countries, Siemens reported worldwide revenue of $88.1 billion in fiscal 2016. Siemens in the USA reported revenue of $23.7 billion, including $5.4 billion in exports, and employs approximately 50,000 people throughout all 50 states and Puerto Rico.

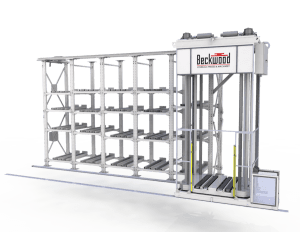

Continue readingMachine builder develops fully automated die handling system with 15,000-pound capacity to load and unload presses with staging tables for continuous production; die change time reduced from two hours to ten minutes

Beckwood twin hydraulic presses, each 1400-ton plus Quick Die Change (QDC) assembly with 15,000-pound load capacity and T-table staging devices for fully automated workflow.

Beckwood Corporation in Fenton, Missouri (St. Louis) is a leading manufacturer of custom hydraulic presses, automation systems and the Triform line of precision forming equipment. While their machinery serves a variety of industries and applications, they excel at developing robust aerospace forming technologies engineered for accuracy and repeatability. In detailing the sophistication of their machine designs for this challenging market segment, their website includes something of a company mantra, “It IS rocket science.”

One customer, a metalform fabricator and producer of various components for the commercial and military aircraft sectors, brought Beckwood their challenge. The company was seeking a turnkey package consisting of two 1400-ton hydraulic presses and two automated stamping die handling systems to load and unload the presses more efficiently than the conventional forklift and manual labor-intensive system this customer was currently utilizing. The presses and quick die change (QDC) workcells would be used to form a variety of parts in relatively low volumes, so the system to be designed needed a more automated die handling system. In addition, a 42”-diameter deep draw sheet hydroforming press with staging table was needed. Such a press would be the largest of its kind in the world, once produced.

Siemens motion control and HMI are used on the entire system, with Safety Integrated features, allowing operators to remain outside the work envelope, in full machine process and monitoring mode.

A critical part of the challenge involved the need for a QDC system with 15,000-pound capacity to feed each 1400-ton press. As Beckwood’s lead electrical engineer John Harte explains, “We conducted a thorough review with all our local die cart suppliers and all passed on the bid, citing too many obstacles on that large a load. So, as we often do, we decided to design, engineer and build the system ourselves.” The presses each had a footprint approximately 30’ square, and the QDC would need to service the presses with T-table staging devices, allowing the next die to be prepped and ready to insert upon completion of the previous run cycle.

With the degree of automation involved, Beckwood worked with the customer’s engineering staff to devise a workcell concept comprised of two 4-post presses, each with a QDC system including a cart, rack and T-table with 15,000-pound load capacity. Each press would be over 33’ in height and positioned in a 10’ deep pit.

As the customer was a longtime user of Siemens motion control and HMI, they specified this supplier for the project. Harte connected with Derek Eastep, his account manager for Siemens, and the product list for the project began to take shape. Various drives, PLCs, displays and motion controllers were specified. The latter was a critical component, as the motion controller was required to operate all press movements, as well as the motor starters, QDC integration, light curtains that protect the workcell and operators plus area scanners that maintain the integrated safety condition monitoring on the entire cell.

The system logic and data logging setup was to be done by the customer, who had considerable experience with Siemens controls, with the Beckwood team integrating the QDC and overall cell management.

The QDC operates in tandem with the two presses, using four 15HP motors to drive the lead screws on this massive die handling system. They are electrically geared through the onboard Siemens PLC to move the ram and shuttle. Additional motors and drives on the feed tables allow the next die to be positioned during press operation. When a press cycle is completed, the air bags on the feed tables lift the next die for positioning onto the QDC, then a shuttle inserts the die inside the press, with all motion controlled by the PLC. These T-tables and the QDC were designed, engineered, built and tested by Beckwood at their factory prior to shipment and installation at the customer’s facility. Both Beckwood and Siemens personnel were active in the commissioning of the entire system.

Press/QDC workcell currently utilized by a metalform fabricator in the commercial and military aircraft industries.

The PLC is a Siemens S7-1515—a robust controller that integrates function control, safety and condition display in a single module with Profinet protocol for bus communication. Through the TIA Portal and Step 7 software provided by Siemens, the end user can customize the operation of the devices remotely, integrating multiple part files and related safety commands in one controller. This “library” feature allows the end user, as they run a variety of parts during a shift, for example, to use one software package to program quickly and more efficiently. Likewise, the safety switches on the entire system are programmed through this secure and redundant safety back-up software through the TIA Portal.

All motor movements on the twin four-post presses are controlled with Siemens drive technology. In operation, the Beckwood presses with the QDC systems are expected to reduce die setup and changeover from approximately two hours to ten minutes.

As Derek Eastep from Siemens notes, “Because the end user was a longtime customer, we performed the application engineering with Beckwood and their customer, fully confident that the system would be set up and running in a relatively short time, as all parties had good familiarity with our protocols.” Harte adds, “We used the Selector, Sizer and Starter engineering tools from Siemens to spec and then commission the drives, which saved us a substantial amount of time. It made our lives a lot easier,” he muses.

The two 1400-ton presses in the workcells are Beckwood’s robust four-post frame style with replaceable, graphite-impregnated bronze bushings and solid chrome-plated posts to ensure precision ram guidance. Designed to form parts with challenging geometries in low-volume, high-mix production environments, the 42” Triform deep draw sheet hydroforming press will be the largest press of its kind in the world.

Josh Dixon, director of sales & marketing at Beckwood, says in the company video, “We hate the word ‘no’.” The success of this unique and first-of-kind press and QDC workcell, built by Beckwood with the help of its controls supplier Siemens, bears out that statement.

Due to the versatile nature of Beckwood’s “built to order” business model, their machines are engineered to serve a variety of industries. Beckwood’s extensive experience serving so many industries provides a unique vantage point that customers find incredibly valuable. They are often able to recommend process improvements that customers may have never known or considered, revolutionizing their manufacturing operations. Beyond metal forming, the company also manufactures presses used to form rubber, plastic, composites and other material substrates. The business started in 1976 and is today led by company president Jeff Debus.

For more information on this story, please contact:

BECKWOOD CORPORATION

889 Horan Drive

Fenton, MO 63026-2405

Phone: 636-343-4100

www.beckwoodpress.com

or

Siemens Digital Factory

5300 Triangle Pkwy

Norcross, GA 30092

(678) 427-8319

About Siemens USA

Siemens Corporation is a U.S. subsidiary of Siemens AG, a global powerhouse focusing on the areas of electrification, automation and digitalization. One of the world’s largest producers of energy-efficient, resource-saving technologies, Siemens is a leading supplier of systems for power generation and transmission as well as medical diagnosis. With approximately 348,000 employees in more than 190 countries, Siemens reported worldwide revenue of $86.2 billion in fiscal 2015. Siemens in the USA reported revenue of $22.4 billion, including $5.5 billion in exports, and employs approximately 50,000 people throughout all 50 states and Puerto Rico.

Continue readingUniversities and technical schools trying to keep up with advances in digital manufacturing often find themselves behind industry. However, I was privileged to visit one university, the University South Carolina, which will now be an important exception. Founded in 1801, USC is one of the oldest universities in the US with a history of creating the most innovative learning programs dating back to its first curriculum obtained from Oxford University. Today, USC is establishing a one of a kind Digital Factory Lab that combines technology and coolness to inspire and educate its students.

Ramy Harik is one of the professors at USC and he told me that these new resources will be put to good use. Already his students have been involved in working with composites, designing new ways of analyzing data for the helicopter AH-64 Apache airframe and developing insights into that aircraft’s mechanical operation for the Army. More innovations are sure to come. For instance, beginning this fall students will also be able to pursue a major in aerospace engineering.

In recent years, the state of South Carolina has become a magnet for sophisticated manufacturing particularly in aerospace, automotive and tire. As a result of working with these companies to deploy high-tech manufacturing and by supporting vocational learning in the state through USC’s College of Engineering and Computing and the McNAIR Center for Aerospace Innovation and Research, USC has grown into a major research university. Specifically, the McNAIR Center is aligned with two dozen educational and government partners, and a group of industry partners that include The Boeing Company, Fokker Aerostructures, KUKA Robotics, Ingersoll Machine Tools, Gulfstream and more.

To date, South Carolina’s business, education and state government partnerships have created jobs for more than 55,000 South Carolinians in the larger aerospace industry. As Raj Batra, President, Siemens Digital Factory Division, U.S., said, “Aerospace companies throughout South Carolina are heavily reliant on automation and digitalization as well as well-trained employees. Our partnership with the University of South Carolina will provide valuable experiential training with both software and hardware, providing the next generation workforce with the skills they need to be successful.”

Far from lagging, educators in South Carolina are working hard to stay out front. While I was at dinner, USC’s Hossein Haj-Hariri, Dean of the College of Engineering and Computing, told me “We are going to work very hard to make this the best investment that Siemens has ever made.” I am proud to be part of a company that will match that enthusiasm and make this a program known for enabling students to be competitive for jobs throughout the world.

Governor Henry McMaster, we are ready to help you build the workforce of tomorrow.

Siemens Industry, Inc.

Alisa Coffey

(678) 427-8319

alisa.coffey@siemens.com

About Siemens USA

Siemens Corporation is a U.S. subsidiary of Siemens AG, a global powerhouse focusing on the areas of electrification, automation and digitalization. One of the world’s largest producers of energy-efficient, resource-saving technologies, Siemens is a leading supplier of systems for power generation and transmission as well as medical diagnosis. With approximately 348,000 employees in more than 190 countries, Siemens reported worldwide revenue of $86.2 billion in fiscal 2015. Siemens in the USA reported revenue of $22.4 billion, including $5.5 billion in exports, and employs approximately 50,000 people throughout all 50 states and Puerto Rico.