Contact us today:

(847) 934-4500

tdaro@bernardandcompany.com

Contact us today:

(847) 934-4500

tdaro@bernardandcompany.com

Siemens announces immediate availability of two new compact quick disconnect switches used with the popular Sinamics G120D distributed drives. This new disconnect switch design mounts directly onto the input power connector of the drive and locks in place to provide a tight, reliable interface, in accordance with ISO 23570-3. Many applications exist in the decentralized distributed power environments, where control cabinets are being replaced with IP65 protected products.

Two versions of the new disconnect switches are now available. A 10-amp rated switch is offered for G120D drives up to 4 kW (5 hp) and features a daisy-chain Power-Y-junction box design to enable power wiring to additional G120D drives. A 25-amp rated version is offered for the heavier-duty 5.5 kW (7.5 hp) and 7.5 kW (10 hp) drive models. This larger unit features a standard Q4/2 pin configuration.

Through the introduction of these new disconnect switches, Siemens can now offer system integrators, OEMs and field maintenance personnel immediate availability to a drive and connector package for a number of applications, according to Robert Soré, product marketing manager, Sinamics general purpose drives at Siemens. “We’ve developed this product line in tandem with our solution partner Harting and we see it expanding our presence in the distributed, decentralized control markets, which include automotive, packaging, metals processing, food and beverage, as well as general conveyorized material handling.”

For more information about these new quick disconnect switches, please visit:

www.usa.siemens.com/sinamics-g120d

For specific product information and inquiries, call (800) 879-8079 ext. Marketing Communications or send an e-mail to: SiemensMTBUMarCom.industry@siemens.com.

No. 870 is a 500°F (260°C), inert atmosphere oven from Grieve, currently used for aging rubber parts at the customer’s facility. Workspace dimensions of this oven measure 36” W x 60” D x 36” H. 12 KW are installed in lncoloy sheathed tubular heating elements, while a 600 CFM, ½ HP recirculating blower provides universal airflow to the workload.

This Grieve inert atmosphere oven has 4” insulated walls, an aluminized steel exterior and Type 430 stainless steel interior. The oven features inert atmosphere construction, including a pressure regulator, flow meter, pressure gauge, inner oven walls sealing directly against ½” thick silicone rubber door seal, air jacket on the inner oven for cooling, blower shaft seal, positive latching door hardware, adjustable offset door hinges, outlet with pressure relief, interior seams welded gas-tight and all wall penetrations fitted with compression fittings. Also onboard is a 650 CFM blower with 2-position motorized dampers to pull air through the air jacket on the inner oven for cooling.

Controls on No. 870 include a recording and programming temperature controller.

THE GRIEVE CORPORATION

500 Hart Road

Round Lake, IL 60073-2898

Phone: (847) 546-8225

Fax: (847) 546-9210

Web: www.grievecorp.com

Email: sales@grievecorp.com

Attention: Frank Calabrese

Motor-integrated drive offers onboard safety features and communications

Simogear gear motors offer high torque density, low noise and high efficiency — and now with Sinamics G110M, it becomes easier for designers and system builders to integrate gear motors into a variety of control architectures. Plug connections for onboard I/O ensure fast installation, while optional power connectors deliver even more time savings. The system is delivered pre-configured and the drive offers simple yet comprehensive onboard diagnostic features. Options such as internal braking resistors and motor brakes — operational simultaneously — and integrated features such as “Quick Stop” and the limit switch function make this system ideal for conveyor applications.

For uses requiring safety technology, the Sinamics G110M offers integrated safety functions such as “Safe Torque Off” (STO), which can be activated via a fail-safe input or via Profisafe, without needing additional safety monitoring components.

Sinamics G110M features integral USS/Modbus RTU, Profibus and Profinet / EtherNet/IP communication profiles.

To watch a video of the Sinamics G110M for the material handling industry, please visit: https://www.youtube.com/watch?v=GgDxptBqpHg

For specific product information and inquiries, call (800) 879-8079 ext. Marketing Communications or send an e-mail to: mc.us@siemens.com

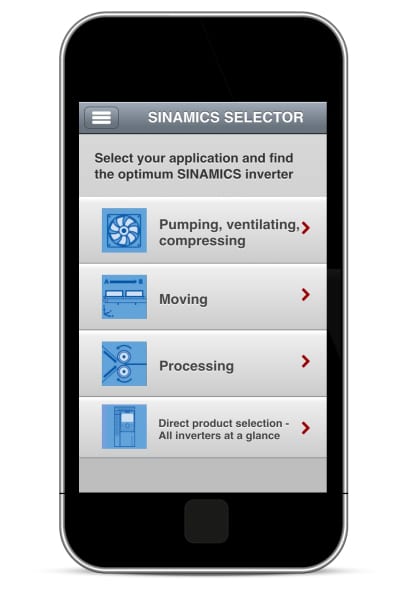

Drive selector app enjoys growing polarity

For some time, it has been apparent that mobile apps have been spreading more and more across the industrial environment and have become a popular medium among users. One special feature in this field is the variable frequency drive app for the easy selection of all necessary components from the respective corporate portfolio. The online selection is always up-to-date, available in many different language versions and saves the user time — laboriously poring over catalogs is now a thing of the past.

Due to the special requirements in some cases, selecting the right drive is not always straightforward and can often waste valuable time. After all, the fields of application and the requirements regarding operating behavior and costs are wide-ranging. Whether the drives are used to operate pumps, fans or compressors, or to drive conveyors, mixers or kneaders, it is important to find the appropriate drive for the required range of performance and voltage quickly and easily for each of these applications. And wherever possible, this must be done without the need for expert knowledge of drive technology.

The Sinamics Selector app helps you to select a suitable drive in just a few simple steps and also suggests alternative options.

Assembling components by smartphone

In order to simplify this sometimes complex process, Siemens, for example, has been offering its Sinamics Selector app free-of-charge. This is a solution that displays the entire collection of products from the portfolio of low-voltage frequency drives — Sinamics V20, G120C, G120 and G120P — on the most popular iOS and Android smartphones and can be used both online and offline. This offline capability is of particular importance in regions which do not have full cellphone coverage. Since Version 4.0, not only have brochures, product videos and application examples (Fig. 1) been available to users and electrical distributors, but also more language versions.

Everything up-to-date

Katharina Roehrlein, marketing manager for Sinamics drive systems at the Siemens Digital Factory division, explains additional innovations: “With the latest update, Version 5.0, we have adopted the second generation of the Sinamics G120 modular Frame Size D-E, as well as the Sinamics V20 Power Extension up to 30 kW, into the app. In addition, we have integrated more technical values such as resistance, peak performance and continuous power ratings into the logic of the app. And for good reason, because we want to make it as easy as possible for our customers to find the right drive in order to save valuable time.”

As a matter of principle, when assembling the appropriate components, the Sinamics Selector app offers not only a product-specific, but also an application-specific approach. In other words: either the user knows from the outset which frequency drive is required, or the app guides the user step-by-step to the right drive by asking for key parameters (Fig. 2). The information held by the Sinamics Selector app is kept up-to-date at all times by the central storage of data and continuous updates. Bob Hendrickson, applications engineer at Wesco, one of the largest distributors in the United States, regards this as an enormous advantage over conventional catalogs, especially when the app can save him a great deal of time in preparing a bid. “The Sinamics Selector app is very helpful as it lets me create a complete bill of materials for a customer offer very quickly. This option saves me a huge amount of time since I no longer have to create bills of materials by hand. The app also makes it easier for me to respond to queries arising from projects when I’m on the road and don’t have any catalogs or other documents to hand.”

Bid preparation made easy

After choosing the required type of frequency inverter, the rated output, device options and accessories can then be selected and adapted individually — if necessary, also with the support of the respective Siemens contact, whose details are also stored in the app. Once the components have been selected, the user has the option of either saving or emailing them. To make it easier for end-users to get in touch later, the headers and footers of the email can be adapted individually, for example, with personal contact information. The overview includes actual part numbers for all of the selected components. This can be used as information for the customer, but also as the basis for ordering specific components or preparing an offer at the local dealer/distributor. Kevin Young, application engineer at electrical distributor C&E Sales Inc., in the U.S., also confirms this: “I really like the Sinamics Selector app. I copy the result into my bill of materials, which enables me to immediately present a bid to my customer.” His colleague Jay Swank adds, “I use the application almost every day now.”

Over 15,000 downloads and counting…

Since the introduction of the first version, the Sinamics Selector app has been installed 17,000 times on mobile devices worldwide — and the number is still rising. Apart from Europe, China and the U.S., this trend is being led by key markets such as India, Brazil and Mexico. “It is particularly important in these countries to have a solution in the local language which also functions faultlessly offline. The email containing the results can be stored and then transmitted when sufficient network capacity is available again,” adds Ralf Weber from the Siemens Digital Factory division responsible for the app.

Think global, act local

Due to the great success of the app in all language versions offered thus far, Siemens is planning the integration of additional languages, as well as the continuous support and expansion of the product range covered. The main focus here is on Europe, particularly the eastern regions.

For more information about the Sinamics Selector app, visit:

www.usa.siemens.com/sinamics-selector-pr

Access – online and offline

Cost – Free-of-charge

Platforms – iOS, Android

Languages – English, German, French, Italian, Spanish, Portuguese, Chinese, Russian, Korean and Turkish

Quicklink to the Sinamics Selector app: http://ow.ly/WFRe5

For more information on this story, please contact:

SIEMENS INDUSTRY, INC.

DIGITAL FACTORY

MOTION CONTROL — GENERAL MOTION CONTROL

390 Kent Avenue

Elk Grove Village, IL 60007

Phone: 847-640-1595

Fax: 847-437-0784

Web: www.usa.siemens.com/motioncontrol

Email: mc.us@siemens.com

Attention: John Meyer, Manager, Marketing Communications

New Sinamics G120C FSAA — the “Tiny Drive” in frame size AA from Siemens Industry, Inc.

Siemens announced today immediate availability of its popular Sinamics G120C drive in AA size, which replaces the previous G120C frame size A in power ratings up to 2.2 kW

(3 hp), including communication variants for USS, PROFIBUS, PROFINET and EtherNet/IP. Offering high power density in a smaller footprint, the new “tiny drive” offers fully compatible replacement for the equivalent power ratings on the previous version.

On new control cabinet designs, the G120C FSAA has significant size advantages, up to 32% less overall volume, for the OEM or integrator, but requires no re-engineering, when migrating from the G120C FSA on current jobs. Overall dimensions on the smaller unit, designed for use with PROFIBUS and USS variants are only 173mm high x 73mm wide x 155mm deep (6.8” x 2.8” x 6.1”).

Other benefits of the new G120C FSAA include use with increased motor cable lengths,

up to 50m (165 ft) for shielded and 150m (495 ft) for unshielded, plus identical voltage ratings, current ratings, load cycles and compatibility with all standard Siemens options such as operator panels, input and output chokes, as well as external Class B EMC filters.

Sinamics G120C FSAA has smaller footprint, up to 32% less volume, but delivers comparable features to previous version of this Siemens drive.

The G120C FSAA offers UL open type, IP20 protection in the 0.55–2.2 kW (0.75–3 hp) range.

Through the introduction of this new tiny drive, Siemens can now offer machine builders another economical, space-saving and easy-to-operate standard AC drive with a wide range of functions, according to Robert Soré, product marketing manager for general purpose drives at Siemens. Typical applications for this product span a broad machine and equipment range, including smaller test stands, mixers, conveyors, fans, pumps, compressors and basic production machinery.

For more information about the Sinamics G120C drive platform, please visit: www.usa.siemens.com/sinamics-g120c-pr

For specific product information and inquiries, call (800) 879-8079 ext. Marketing Communications or send an e-mail to: mc.us@siemens.com

Continue readingNo. 958 is a 500° (260°C), electrically heated walk-in oven from Grieve, currently used for heat treating long fluorocarbon shapes supported by fixtures on wheels at the customer’s facility. Workspace dimensions of this oven measure 36” W x 300” D x 36” H. 60KW are installed in lncoloy sheathed tubular heating elements, while a 4200 CFM, 3-HP recirculating blower provides combination airflow to the workload.

This Grieve walk-in oven has 4” insulated walls and an aluminized steel interior and exterior. Features include an integral top mounted heat chamber, single door front and rear, 2” insulated floor with channel guide tracks and two (2) fixture supports with flanged wheels.

Controls on No. 958 include a digital programming and recording temperature controller, manual reset excess temperature controller with separate contactors plus recirculating blower airflow safety switch and SCR power controller.

For more information, please contact:

THE GRIEVE CORPORATION

500 Hart Road

Round Lake, IL 60073-2898

Phone: (847) 546-8225

Fax: (847) 546-9210

Web: www.grievecorp.com

Email: sales@grievecorp.com

Attention: Frank Calabrese, VP

Ann Arbor, Michigan – GMTA (German Machine Tools of America) represents various top-quality German and other metalworking machine builder companies, including Profilator GmbH, Praewema, K + G, Rasoma, FIMAT and BvL, as well as Arnold lasers and other equipment. These machines are sold to the North American market by GMTA, primarily for gear and spline production, as well as other power transmission and various metalworking applications. The company’s target markets include automotive, off-highway, energy and other heavy equipment manufacturing. Machines are provided for gear honing, gear grinding, the patented Scudding® and now the game-changing Hard Scudding® process for gearmaking, polygon milling, turning, gear tooth pointing and multi-task machining operations, as well as various laser operations or laser line integration. This newsletter is provided to our friends in the media to keep you and your readers updated on “News of Note” at GMTA.

In the news…

-General Motors has selected GMTA to partner on the CVT 250 project for gear hones.

-Ford Motor has selected GMTA as a supplier for Scudding® sun gears on its new transmission lines.

-Scudding and now the Hard Scudding process, in which hardened gears can be cut and finished on the same machine, using the company’s unique adaptive software, are fast gaining acceptance in the market. Already the leader in high-precision internal gear processing, the result of our unique Scudding® technology, which leaves skiving and other methods far behind, GMTA has taken another giant step forward in gear production with the development of Hard Scudding. The Scudding process provides excellent results on green or soft gears, while this new Hard Scudding advancement enables the re-machining of hardened gears on the same machine, with a tooth-to-tooth composite error and total composite error in the AGMA 11, DIN 6 range and a surface finish better than 1.5 Ra. This all happens due to the adaptive software developed by GMTA.

-A new series of operational videos on Arnold lasers in action is now viewable on the GMTA website, www.gmtamerica.com. The website is currently undergoing substantial upgrades, but remains visible to all.

-The new Mexican office of GMTA, located in Queretaro, is reporting brisk activity, owing to the substantial procurement authority in-country now. According to VP Scott Knoy, “This contrasts with bygone days, when the decision-making and purchasing were largely centered in America and specifically (here) in Detroit. It’s a whole new ballgame with the Mexican market today and we believe our new location (Queretaro) is well positioned to serve this dynamic manufacturing environment.” GMTA already has a substantial installed base of machines in Mexico with all their partner companies. At the new facility, machines are in place for demo and test run, plus the facility is fully staffed with application engineering, technical support, after-sale service and parts inventory.

-Sales continue to be brisk on the 9- and 10-speed transmission projects in the automotive market. Scott Knoy, GMTA VP, comments, “We’re seeing a lot of activity here in the States and especially in Mexico, so we know our timing was right with the opening of our new facility there.”

-GMTA attendance at Gear Expo in Detroit was highly productive, as we saw old friends and made many new ones! The demonstration of Hard Scudding was given and we met with all the top editors from the gear market media during the show. The Motor City is still the place to be for us gearheads!

-GMTA is now representing Rasoma machining centers, used primarily in the gear and spline markets, as well as FIMAT, an Italian builder of machining centers. These agreements cover full sales engagement for North America. Meanwhile, an agreement has been signed by GMTA to represent BvL parts washers exclusively in Mexico. The BvL line now means GMTA can be a single integrating source for machining, part cleaning and laser joining of power transmission products.

-Our Claudia Hambleton again braved the elements and brought a class of German language students from Saline, Michigan to Chicago for Christkindlmarket, as well as tours of the Museum of Science & Industry and the new Maggie Daley ice rink! A good time was had by all…and everyone made it back on the bus! She assures us all the gluwein consumed was strictly non-alcoholic!

-Our Christmas party was a good time to connect with our GMTA family and exchange presents. Some of the guys, who are themselves brilliant mechanical techs and machine tool engineers, tried to wrap their own presents and failed miserably, according to Claudia! “It takes a talent these guys clearly do not possess,” she mused.

For more information on any items in this announcement, please contact:

GMTA (GERMAN MACHINE TOOLS OF AMERICA)

4630 Freedom Drive

Ann Arbor, MI 48108

Phone: 734-973-7800

Fax: 734-973-3053

Web: www.gmtamerica.com

Email: scott@gmtamerica.com

Attention: Scott Knoy, VP

No. 899 is a 500°F (260°C), high temperature truck oven from Grieve, currently used for curing a coating on parts hanging from rods at the customer’s facility. Workspace dimensions of this oven measure 48” W x 36” D x 96” H. 24 kW are installed in Nichrome wire heating elements, while a 1000 CFM, 1-HP recirculating blower provides vertical upward airflow to the workload.

This Grieve truck oven is sectioned to fit in a 5’ W x 8’ D x 6’8” elevator. It has 4” insulated walls, aluminized steel exterior and Type 304 2B finish stainless steel interior.

Controls on the No. 899 include a 10” circular chart recorder, manual reset excess temperature controller with separate contactors, digital indicating temperature controller and a recirculating blower airflow safety switch.

For more information, please contact:

THE GRIEVE CORPORATION

500 Hart Road

Round Lake, IL 60073-2898

Phone: (847) 546-8225

Fax: (847) 546-9210

Web: www.grievecorp.com

Email: sales@grievecorp.com

Attention: Frank Calabrese, VP

REP offers a simple and economical solution to a problem that is familiar to manufacturers of pipe seals.

The stripping process…often the stumbling block of the moulding process

When performed manually, the stripping process is often very difficult and productivity is considerably impacted; when being performed automatically, the challenge is to do it quickly without any heat loss and without production stoppages, due to overlapping seals. The solutions generally implemented in the industry today, such as molding with two sets of rotating core bars, require a very large press opening stroke to perform the core bar rotation outside the press and/or front and rear stripping units that lead to considerable space requirements and very high capital costs.

A simple and efficient solution

REP has recently worked on several projects and today offers its customers a competitive and profitable turnkey solution for reduced size on the automatic stripping of EPDM pipe seals of any size. You can watch the stripping process on http://www.youtube.com/REPinternational.

The solution can be matched to any seal size. It is based on conveyor belts equipped with rotating belts, allowing for the individual stripping of the seals. The spacing between the bottom and top belts can be easily adjusted, thanks to a mechanical stopper system, thus making it possible to switch over from one seal type to another. The rotation speeds of the top and bottom belts can also be adjusted independently.

The belts are designed in compliance with a multi-layer technology, in order to ensure the reliability of the stripping process and the speed, while observing the quality of the stripped parts. In addition, the core bar in/out speeds on the kit (low/high speed, depending on the stroke limit) can be controlled. The kit is fully retractable for easy access to the cores on the rear side of the machine, allowing maintenance operations or more rapid production changes.

Project example for a pipe seal of a nominal diameter of 50 and 100mm

The equipment

The machine proposed is an injection molding machine REP V69Y50 with a clamping force of 400 tons, including a kit specially designed for automatic stripping, a vacuum system, hydraulic top and bottom ejectors and ancillary heating comprising heating elements inside the cores to hold the core temperature during the stripping process.

The tooling consists of a 112-cavity mould (2 cores) and a 2-nozzle cold runner block for the part of a nominal diameter of 110mm. For the part of a nominal diameter of 50mm, we use a 208-cavity mould (4 cores) and a 4-nozzle cold runner block.

The cycle

After the mould opens, the ejectors move out to lift the frame-supported cores. The cores move to the rear of the press (electrical movement) and simultaneously the rotation of the two belts allows for sequential stripping of the pipe seals.

The runners are automatically stripped and separated from the parts during the core bar translation. Metal guides are used to separate the runners as the core bars index on the kit.

The runners are recovered in a receptacle inside the cage, whereas the parts are recovered at the discharge end of the cage extension in a receptacle or using an automatic conveyor.

When the cores move inside press, a laser detection unit is activated to guarantee no seal adheres to the cores. If this is the case, an alarm signals for operator action at the end of the in-stroke of the cores.

The result

On this project, the customer’s profitability requirements have been met. The stripping time reached for both types of seals was approximately 40 seconds.

The entire system is competitively priced, with an excellent investment/payback ratio. This is a simple, rugged solution that is both reliable and easy to control during production.

For more information, please contact…

REP CORPORATION

8N470 Tameling Court

Bartlett, IL 60103

Phone: 847-697-7210

www.repinjection.com

Tim Graham, President

tgraham@repcorp.com

Standard and custom styles available for Hyundai, Miyano and Nakamura machine tools; offered for all tapers, including HSK and BT30; fixed and adjustable models; many in stock for immediate delivery

Heimatec live tooling is now available in stock for all the popular models in the Nakamura, Hyundai and Miyano lines.

Heimatec, a world leader in live tools and multi-spindle drill heads, today announces immediate availability of live tooling for all popular models in the Hyundai, Miyano and Nakamura turning center lines. According to Preben Hansen, Heimatec president, “We’re carrying a substantial inventory of live tools for our customers’ machines now and it represents a substantial financial and warehouse space commitment we’ve made to support them in the North American market.”

Hansen added that the company will be announcing its in-stock arrangement for many other lines of machine tools, moving forward, as the company commits a major investment to the market. Heimatec Inc. serves its North American customers with a full team of manufacturers’ rep firms, plus its Chicagoland facility offers stocking, repair, application engineering and service for the company’s line of live tools, multi-spindle tool, adapters, UTEC® right angle heads and other items offered.

Literature detailing all the Heimatec products now available in stock for Hyundai, Miyano and Nakamura machining centers is offered at the company’s website, www.heimatecinc.com. Interested parties may also contact the company directly with inquiries.

CAT 40, BT 40, BT 30, HSK 63A, CAT 50, BT 50, HSK 100A and many other taper styles are available, as well as custom modifications such at 18” extension shafts. Offset, Slim, Dual and Adjustable styles. Heimatec offers a full one-year warranty on all parts and labor.

For further information and brand-specific literature, or to arrange a demo on any Heimatec tools, please contact:

Preben Hansen, President

HEIMATEC INC.

16 E. Piper Lane

Suite 129

Prospect Heights, IL 60070

Phone: 847-749-0633

Fax: 847-749-2445

Email: phansen@heimatecinc.com

Heimatec is an international tooling manufacturer, based in Renchen, Germany. Its experienced staff is dedicated to providing customers the most innovative tooling technology possible. In 2010, the company opened Heimatec Inc. in Prospect Heights, IL, near Chicago, to serve its growing North American customer base with sales and service, plus an extensive inventory of products. Heimatec serves the auto, aero, medical, off-highway, rail, energy, woodworking, composites and other industries, as well as an ever-increasing number of machine tool OEM’s worldwide.

Continue reading