Contact us today:

Author Archives: Bernard & Company

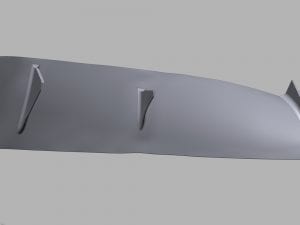

Exact Metrology Offers Tips on Airfoil Scanning Procedures

Market Leader in 3D and CT Scanning Details a Typical Airfoil Procedure

Exact Metrology, a leading supplier of 3D laser and CT scanning equipment and services details the steps to a successful airfoil evaluation.

The scan can occur at the customer’s facility or at Exact Metrology’s. In many cases, it is most cost effective for the digitizing or scanning to take place at the Exact facility. However, in certain instances, when turnaround time is of great importance or downtime of the scanned component is critical, the scanner is mobile and available for onsite operation.

The airfoils that are typically provided by customers will be received by Exact Metrology for full documentation with photos, measurements and any surface markings or serial numbers recorded prior to any high definition scanning.

Setup

The mobility of the Exact scanner allows a high degree of flexibility in performing onsite scans (Option A) at a customer facility or the more cost efficient in-house scan at the Exact facility (Option B).

Due to the reflective nature of the blades, a thin coating of Magnaflux spray is applied. The SKD-S2 spray is a second phase of the crack checking processes. Phase 1 is a die penetrant that will not be used typically. The spray meets the requirements for AMS 2664, ASTM E165 and is ASME approved. (Health – 1, Flammability – 4, Reactivity -0, No Specific Hazard). See MSDS 0166 for more information on the SKD-S2 product.

When scanning the blade, Exact uses a fixture device. Targets will also be used to constrain data during the alignment phase. Targets will be placed using magnets on either side of the air foil. The fixture itself will also act as an alignment constraint while holding the airfoil in place and allowing Exact technicians to capture maximum data on the part without moving or touching the part. A manual or automatic turntable may be used to allow enhanced scanning and registration access to the part.

Scanning

The part is positioned on the rotating table or on a stationary marble top and scanned from multiple perspectives. This procedure is repeated multiple times to provide complete coverage of the part. Known geometric objects, cubes and spheres are often placed in the scene for quality assurance and validation during the validation stage.

The scanner used on these projects is a Breuckmann Stereo 3D Scanning system. This device uses a unique halogen structured white light projection system with dual 6.6 mega-pixel cameras. The scanner is the highest resolution scanner available on the market and was specially built for Exact Metrology in Germany.

Registration

The registration process can be done with or without targets. Both registration methods have different techniques with similar results. Essentially, the targeting procedure uses an automated fitting of point clouds or scan worlds together, based upon three common positions on the part or scene. This process has been simplified with modern software technology. The software will then analyze every point with overlap and run a best fit algorithm over hundreds of iterations to find the tightest and best alignment. The result of this process will yield a fully registered and organized point cloud.

Validation

It is important to verify the automated method with targeting and adding known geometric shapes to the scan. All scans are documented with notes, computer logging and digital photos accompanying the recorded scan setup within the software. A CD copy of all digital data is recorded prior to returning the part or teardown.

MODELING PROCESS:

Once the data is gathered and the registration process is complete, the point cloud or data set can now be worked. The first step is to triangulate or mesh the points together. As part of this early process, points are “intelligently” removed from the network by algorithms in the software. Essentially, the points of redundancy and overlap are decimated and averaged. This mesh is further manipulated by reducing the triangles and points along flatter areas and retaining more triangles in areas of curvature and complexity. This poly mesh can now be exported as a complete *.STL file or similar format.

Surfacing

The process of fitting NURBs and geometry to the poly mesh or point cloud can be a time-consuming and arduous process. A surface is basically draped over the mesh and smoothed to be reflective of the actual part. Once this task is completed and a complete watertight object is created, the model is ready to be exported to nearly any format via various methods. The end file format is entirely up to the client and the limitations of existing conversion tools available today. A final 3D solid model can be provided as a “dumb solid” with no parametry or history tree as an imported object. The available formats include: Siemens NX, Pro/E Wildfire, AutoCAD, AutoCAD Inventor, SolidWorks, as well as generic formats such as IGES, STEP, ParaSolid (X_T) and others.

Parametric Modeling

The final deliverable is a parametric model. Unlike a solid model, the parametric model possesses relationships of all dimensions within the CAD. With these relationships, the CAD model can be manipulated and fine-tuned without disturbing the overall geometry of the part. For this workpiece, the specific parameters of each cross section within the model can be independently modified without disturbing neighboring cross sections. The end result is a Pro/Engineer CAD model with known geometry that is fully adjustable and possesses a design history.

For more information on this application, please contact:

Dean Solberg

Exact Metrology, Inc.

20515 Industry Avenue

Brookfield, WI 53045

Phone: 262-533-0800

Local: 866-722-2600

www.exactmetrology.com

deans@exactmetrology.com

Exact Metrology is an ISO 9001:2008 and AS9100 Certified Company.

Exact Metrology, with facilities in Cincinnati and Milwaukee and affiliated offices throughout the Midwest, is a comprehensive metrology services provider, offering customers 3D and CT scanning, reverse engineering, quality inspection, product development and 2D drawings. The company also provides turnkey metrology solutions, including equipment sales and lease/rental arrangements.

Exact Metrology offers a complete line of portable scanning and measurement technologies as well as contract measurement for 3D laser scanning services, reverse engineering services, non-contact inspection, metrology services, and 3D digitizing. The company’s newest equipment includes a CT Scanner, the first in America being used for metrology rather than medical testing. Exact sells and rents metrology equipment solutions, in addition to providing testing as a service and application software training.

Continue reading

Chemcoaters Names Mike Tieri VP of Sales & Marketing

Longtime veteran of steel industry to lead sales and marketing efforts for major coil coater and coatings manufacturer

Effective immediately, Mike Tieri, 59, has been named Vice President of Sales & Marketing at Chemcoaters, Inc., a leading coil coater as well as a manufacturer of proprietary coating chemistries at its sister company, Eco Green, both based in the heart of the American steel industry, Gary, Indiana. This appointment was announced by company president Bill Capizzano.

Mike joined Chemcoaters in 2013, following a long career in steel sales dating back to 1993 at Cresco Steel, then Viking Materials and Kloeckner Metals. Subsequently, Mike was a Sales Manager for Chicago Tube & Iron, Kloeckner and JDM Steel.

Prior to this promotion, Mike served as Director of Sales & Marketing for Chemcoaters and Eco Green, spearheading the efforts on both companies’ sales initiatives, key account management, sales strategy and new business development. He works closely with the company’s ad and PR agency on brand building and development of the messaging to the mills, service centers and OEMs in the industry. Recently, he developed a highly successful campaign for the Chemcoaters coil washing service, using a “Car Wash” theme he developed with the agency. Mike was also honored in 2016 by the Metal Service Center Institute for his innovative and clever social media campaigns.

Mike and wife Jill live in Tinley Park, Illinois, have five children and six grandchildren. They are members of Harvest Bible Chapel in Rolling Meadows, Illinois.

Based in Gary, Indiana, Chemcoaters, Inc. is a leading supplier of green coil coatings, as well as traditional prepaint and protective coil coatings such as dry film lubes and other RoHS-compliant coatings. Virtually no VOCs or HAPs are present in the process. The company’s patented InterCoat® ChemGuard 300 coating is formulated with trivalent chrome vs. hexavalent chrome, making it environmentally friendly in all building, architectural, transportation and consumer appliance applications. InterCoat® ChemGuard 300 coating has superior corrosion resistance, as well. Chemcoaters offers a presentation on their unique and proprietary patented coating that evidences this fact to all interested parties.

For more information, please contact:

Bill Capizzano, President

Chemcoaters, Inc.

700 Chase Street

Gary, IN 46404

Phone: 877-411-2905

Email: billc@chemcoaters.com

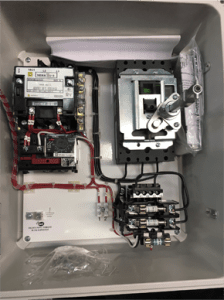

Sinamics DCM DC drive products warranty extended by TWO years

Effective immediately, Siemens announces the standard 12-month warranty on newly purchased Sinamics DCM DC drive products, including DC converters, base drives, enclosure cabinets and control modules, has been extended by two years, to a total of three years from date of manufacture.

This extended warranty, according to company sources, applies to new orders only and previously placed orders cannot be included in this offer. The extended warranty is exclusive of any other extended warranty program or initiative offered by Siemens or its sales distribution network.

The offer applies to all products in the DCM drive products line and no registration or application is required for compliance.

Siemens has extended the warranty on its Sinamics DCM DC drive products, including DC drives, base drives, enclosure cabinets and control modules, by two years, to a total of three years from date of manufacture, effective immediately.

Contact for journalists:

Siemens

John Meyer

(847) 640-1595

john.meyer@siemens.com

Siemens

Hollie Davis

(770) 751-4882

hollie.davis@siemens.com

For specific product information and inquiries, call (800) 879-8079 ext. Marketing Communications or send an e-mail to: mc.us@siemens.com. Or, go to the website for full details: www.usa.siemens.com/drives.

About Siemens USA

Siemens Corporation is a U.S. subsidiary of Siemens AG, a global powerhouse focusing on the areas of electrification, automation and digitalization. One of the world’s largest producers of energy-efficient, resource-saving technologies, Siemens is a leading supplier of systems for power generation and transmission as well as medical diagnosis. With approximately 348,000 employees in more than 190 countries, Siemens reported worldwide revenue of $86.2 billion in fiscal 2015. Siemens in the USA reported revenue of $22.4 billion, including $5.5 billion in exports, and employs approximately 50,000 people throughout all 50 states and Puerto Rico.

Guill Announces New 800 Series Hybrid Extrusion Tooling

Seeking to design the next generation multi-layer die to overcome these challenges, the engineers at Guill looked for a way to incorporate this technology into an updated version of the 800 Series. This led to the creation of the 800 Series Hybrid. The inherent benefits of the 800 Series are retained, including compact design, low residence time and a common deflector bore that eliminates tolerance stack up. The challenge was to create a hybrid design that incorporates the benefits of layer overlapping, while reducing unnecessary complexity and making the technology more cost-affordable for customers. This was achieved by overlapping layers in each semi-deflector, using a single cone. The highly efficient design of the 800 Series Hybrid reduces cost and size, as opposed to other methods of overlapping layers.

Essential benefits of the 800 Series Hybrid include eliminating weld lines in materials through patented overlapping technology, producing a more consistent finished product; reduced sensitivity to changes in viscosity; reduced sensitivity to changes in line speed; myriad material and multi-layer application possibilities; works in all tubing and jacketing applications with a wide range of materials; low residence time; compact design and a low tolerance stack-up error factor, all resulting in improved concentricity.

The 800 Series Hybrid extrusion tool greatly reduces stagnation, because overlapping layers are more inherently balanced than single layers and also because each semi-deflector is “tuned to flush.” Conventional deflectors must simultaneously achieve a balance between flushing, balancing and eliminating the weld line. There is less difference between the slowest moving material and the fastest moving material in the deflector channels, thus making the viscosity more consistent in the deflector.

For more information, please contact:

Bill Conley, Sales Manager

Guill Tool & Engineering

10 Pike Street

West Warwick , RI 02893

(401) 823-7600

www.guill.com

sales@guill.com

Bernal Industrial Named Guill Representative for Mexico

Firm has agents throughout the country, serving the extrusion industry

Guill dies and crossheads for plastic, rubber and other material extrusions are now being sold by Bernal Industrial throughout Mexico. With more than 50 years of experience, Guill is a recognized technology leader in the design and manufacture of extrusion tooling for various applications. These include medical tubing, multi-lumen, multi-layer, profile products, rubber, plastics, wire & cable and fiber optic sheathing.

Bernal Industrial operates as a consultative engineering representative agency, distributor and service provider for its lines. Daniel Bernal is the manager and director of Bernal Industrial. Besides its main office in El Paso, Texas, Bernal Industrial has Mexican offices in Baja California, Chihuahua, Tamaulipas, Nuevo Leon, Mexico City and Queretaro. Bernal also sells products for Nordson PPS (Xaloy, BKG, EDI), American Roller, Scantech, Regloplas, Getcha, Matsui and Pillar Tech, among others.

The company has been in business for 18 years and has 15 employees. During that time, Bernal Industrial has become a major force in Mexico by aligning themselves with industry leaders in the plastics and rubber processing market to provide cutting-edge technology to all the major markets in Mexico, including auto, aero, medical and appliance. Their team comprises industry professionals who have hands-on experience and can provide highly technical application assistance for the products that they bring to the market. Bernal Industrial currently contacts all plastic and elastomer processors in Mexico, including the affiliates of major U.S. and international companies.

Bernal will be promoting the complete line of Guill products. Asked about this partnership, Daniel Bernal commented, “We are looking forward to working with Guill and finding many new business opportunities for them throughout Mexico.”

For more information, please contact:

Thomas Baldock

Guill Tool & Engineering

10 Pike Street

West Warwick , RI 02893

(401) 823-7600

www.guill.com

tbaldock@guill.com

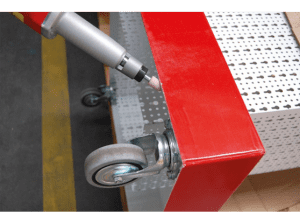

The New Suhner ASC 22 Battery-Operated Straight Grinder

High performance – mobile and unattached!

Power is not always available where you need it for tough-to-reach areas that need sanding, milling and drilling. For applications such as these, SUHNER now presents its battery-operated straight Die-grinder. With a rotation speed of 22,000 rpm, the ASC provides the user with a hand-held, mobile, high-performance Tool. This tool, which can be used around the World, is a great all-rounder that performs at all professional levels.

This new cordless tool is Li-Ion Battery powered and offers all the right settings for power tool work on high-grade projects in all types of steel.

It is also great for other sectors where these qualities are needed, such as the fire services, emergency services, or for locksmiths, caretaking and maintenance.

The ASC 22 is reliable and gets the work done rapidly, all without being attached to a power supply! The ASC 22 is not only highly effective, it is also silent.

For demanding users

This all-rounder is the right tool for anyone that wants to achieve precise, high-quality results.

The ASC 22 is the best choice for grinding with formed abrasives, for milling with carbide cutters and for drilling with normal or carbide drills. It is lightweight at just 1.9 kg, including its battery pack. Its ergonomic and well-balanced shape enables you to carry out very detailed work without becoming tired. With a slimline neck, it can also reach narrow areas easily.

Globally compatible

The machine has a chuck system that ensures quiet running with minimised vibrations. The user can choose between chucks of 6mm (mainly used in Europe) and 1/4” (for the USA and overseas markets). We provide four different connector cables so that the battery can be charged from almost any internationally used plug socket.

High performance battery technology

The powerful electric motor from the latest generation are driven by high-performance lithium-ion batteries, which are the best option because of their high output, low self-discharge and the fact that they have no memory effect. This means that charging your battery is problem-free every time. The powerful battery packs have a 4.0 Ah charge capacity and work on a voltage of 18 V.

Sophisticated system

Intelligent battery management ensures that all the components work together perfectly and that the available power is used optimally. In this process, the temperature of the battery and machine are continuously monitored so that overheating or overloading of the device is effectively prevented. The electric motor is protected from coarse dust by a detachable particle guard. The battery packs are housed in a shock-absorbent rubber jacket.

Practical set

The ASC 22 comes as a set consisting of the machine, two battery packs and a charger with four different connector cables in a practical, durable plastic case.

Everything you need for a job in a robust case: the battery-operated grinder, 2 battery packs and 4 connector cables for international use.

For more information, please contact:

SUHNER Industrial Products, LLC

43 Anderson Road SW

P.O. Box 1234

Rome, GA 30161

Phone 706/235-8046

Fax 706/235-8045

info.usa@suhner.com

www.suhner-abrasive-expert.com

Attention: Guido Broder, President

Exact Metrology Receives Official Certification for AS9100

Exact Metrology proudly announces it has received official AS9100 certification. The Aerospace Standard 9100 includes the requirements for aviation, space and defense organizations. This certification evidences Exact Metrology practices a Quality Management System (QMS) that consistently meets customer expectations. Exact Metrology management has been heavily involved with the QMS process. This starts with the setting of Quality Policy, Quality Goals and Objectives. Management Review looks at the data from QMS, sees that Quality Goals are met, sets new ones and strives for continuous improvement. The advantage of this stringent Management Review is that it provides a basis for reviewing goals and performance against goals that are periodically reviewed. As a result, according to company co-founder Dean Solberg, customer satisfaction has increased because, “…the Goals and Objectives of the QMS take the customer’s needs into account and the Exact team can react and plan accordingly.”

Benefits of implementing AS9100 include well defined and documented procedures to improve the consistency of output, quality is constantly measured, procedures ensure corrective action is taken whenever defects occur, reducied overall cost, appreciably lower defect rates and earlier detection, exposure to new markets and retention/increase of market share in existing sectors, internal operational efficiency and overall better process control and workflow.

The company is also ISO9001:2008 certified. This is the only ISO standard that requires certification and is an internationally recognized Quality Management System that governs the sale and service of 3D non-contact and contact measuring equipment for inspection and reverse engineering in the commercial, aerospace, medical, automotive and industrial sectors. The ISO9001:2008 certification highlights the commitment, dedication and service Exact Metrology employs for customers.

Exact is also certified by ITAR, the International Traffic Arms Regulation. As a result, Exact Metrology has a competitive advantage when attracting and retaining defense business. Prime contractors are obligated to comply with ITAR requirements and these same requirements must be employed by subcontractors. Subcontractors such as Exact Metrology, who demonstrate compliance with ITAR standards, are clearly more desirable resources for prime contractors. Finally, being ITAR certified gives Exact Metrology the opportunity to do business with defense companies overseas, a growing market for the company currently.

Exact Metrology also has a Federal Firearms License, giving them the ability to send and receive weapons for quality control and inspection.

For more information on these developments, please contact:

Dean Solberg

Exact Metrology, Inc.

20515 Industry Avenue Brookfield, WI 53045

Phone: 262-533-0800

Local: 866-722-2600

www.exactmetrology.com

deans@exactmetrology.com

Exact Metrology, with facilities in Cincinnati and Milwaukee and affiliated offices throughout the Midwest, is a comprehensive metrology services provider, offering customers 3D and CT scanning, reverse engineering, quality inspection, product development and 2D drawings. The company also provides turnkey metrology solutions, including equipment sales and lease/rental arrangements.

Continue readingExact Metrology Purchases CMM For Its Cincinnati Location

Exact Metrology has purchased a Brown & Sharpe CMM for its Cincinnati operation, according to company co-president Steve Young. A fully featured coordinate measuring machine, this CMM is a Global Excel 1222-10. It has a measuring volume of 48” on the x-axis, 88” on the y-axis and 40” on the z- axis. The machine also includes PC-DMIS CAD ++ and PolyWorks software. Additionally, the Global Excel 1222-10 has a motorized probe head with a laser scanner attachment.

This is the first conventional arm that Exact Metrology has purchased and it is equipped with laser scanning capabilities. Like all coordinate measuring machines, it only needs to be programmed to run. Additionally, the Brown & Sharpe CMM can simultaneously work on multiple parts, providing high accuracy and work protocol efficiency.

In use, the CMM will augment the full battery of 3D laser and CT scanning equipment, plus 3D printers, now onsite at the Cincinnati facility of Exact Metrology. Exact also operates a sister location in Brookfield, Wisconsin, near Milwaukee.

The new CMM will be installed in December.

For more information, please contact:

EXACT METROLOGY, INC.

Steve Young or Amy Cupp

11575 Goldcoast Drive Cincinnati, OH 45249

Phone: 513-831-6620

www.exactmetrology.com

info@exactmetrology.com

Exact Metrology is an ISO 9001:2008, AS 9001: 2008 and ITAR Certified Company.

Exact Metrology, with facilities in Cincinnati and Milwaukee and affiliated offices throughout the Midwest, is a comprehensive metrology services provider, offering customers 3D scanning, reverse engineering, quality inspection, product development and 2D drawings. The company also provides turnkey metrology solutions, including equipment sales and lease/rental arrangements.

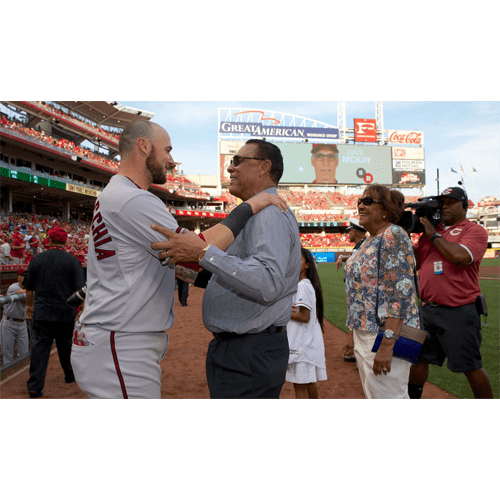

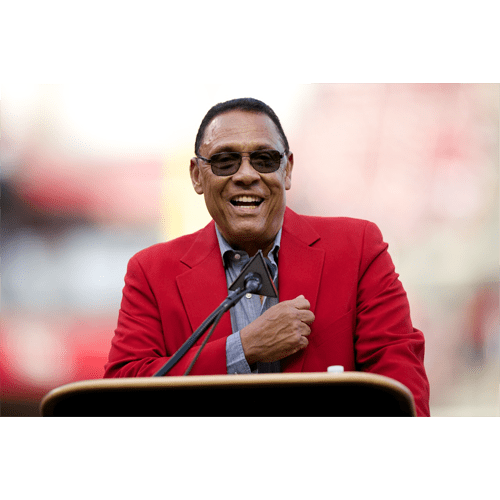

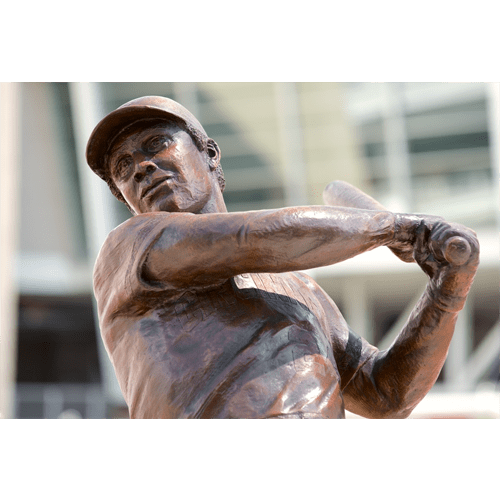

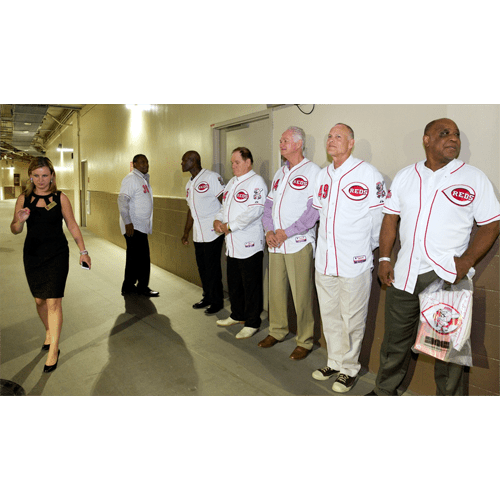

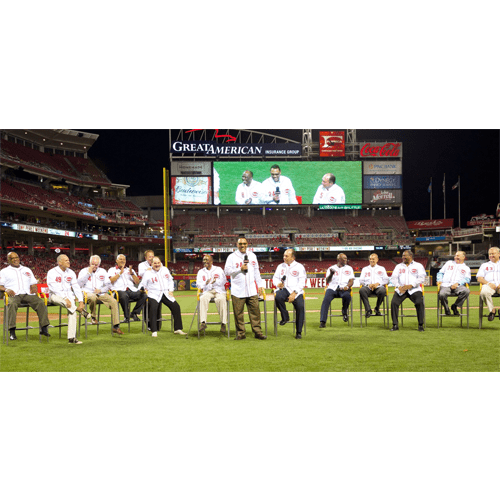

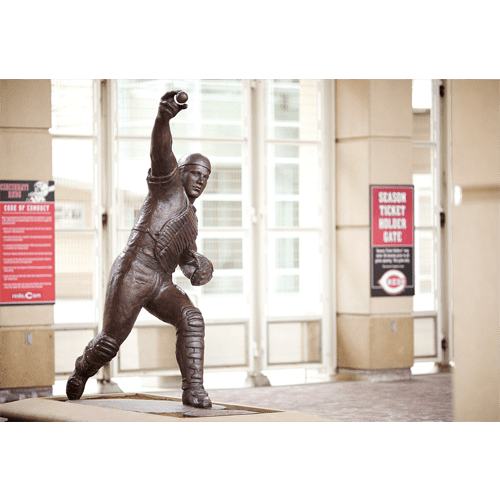

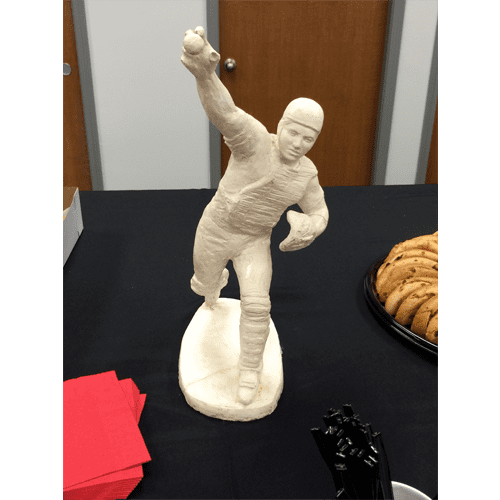

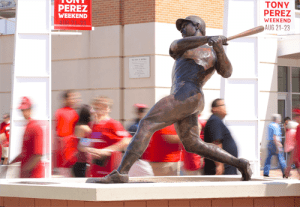

Continue readingExact Metrology Helps Local Artist Produce Statues for Great American Ballpark

Cincinnati artist Tom Tsuchiya combines his talents with 3D laser scanning from market leader

In preparing the statues, artist Tom Tsuchiya starts with an approximately 18” high ceramic model. He then supplies the model to the technicians at Exact Metrology’s Cincinnati facility. Exact is a leading supplier of 3D and CT imaging equipment. They also perform scanning services for numerous manufacturing industries, as well as a diverse assortment of civil engineering, fine arts, commercial and other concerns. Their subject projects recently included the Fermi Lab particle accelerator, the lions in front of the Chicago Art Institute, a construction site for materials consumption projection, a cross at Our Savior’s Lutheran Church in Hartland, Wisconsin, existing buildings for wiring and ductwork refurbishing, a painting for possible forgery, old sculptures for structural integrity and an actual crime scene for use in the investigation and courtroom proceedings.

Co-Presidents at Exact, Steve Young and Dean Solberg, are big sports fans, so this project was truly a labor of love. As Young, supervisor of the Cincinnati facility, explains, “We didn’t see a dry eye at the celebration for Tony Perez, a true gentleman and one of the brightest stars in a very crowded sky, that day.” Joining Perez for this momentous occasion were fellow teammates Johnny Bench, Pete Rose, Joe Morgan and other members from the famous “Big Red Machine” of the 1970’s.

For more information on this story and all Exact services and equipment offerings, please contact:

Steve Young or Amy Cupp

Exact Metrology, Inc.

11575 Goldcoast Drive

Cincinnati, OH 45249

Local: 513.831.6620

Toll Free: 866.722.2600

www.exactmetrology.com

info@exactmetrology.com

Exact Metrology is an ISO 9001:2008, AS 9001: 2008 and ITAR Certified Company.

Exact Metrology, with facilities in Cincinnati and Milwaukee and affiliated offices throughout the Midwest, is a comprehensive metrology services provider, offering customers 3D scanning, reverse engineering, quality inspection, product development and 2D drawings. The company also provides turnkey metrology solutions, including equipment sales and lease/rental arrangements.

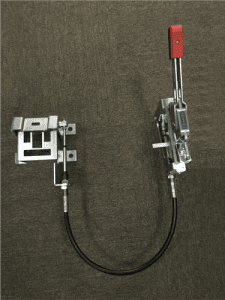

Continue readingNoark Electric Releases Two New Accessories for Molded Case Circuit Breakers (MCCB)

Noark’s Extended Rotary Handle (ERH) and Flange Handle Mechanism (FHM) can be used anywhere MCCBs are used

The Extended Rotary Handle (ERH), part of the MCCB family, is UL Listed with UL Type 1/3R/12 or 4/4X. It meets cULus standards in U.S. and Canada. The unit is offered in black/grey or red/yellow handles and is available in shaft lengths of 7.9/12.6/19.7 inches. It has a simple and robust NEMA handle operating mechanism and can be used anywhere MCCBs are found. A new safety feature of the ERH allows operation of the enclosed circuit breaker without the need to open the cabinet door. The external handle quickly shows the state of the circuit breaker without opening the panel and a new, larger handle design gives the user more leverage than previous models. It is available for the 65kAIC rated M1/M2 MCCBs, as well as the M3/M4 MCCBs.

The ERH has NEMA type extended rotary handle mechanisms to mount on front of an enclosure door and operate externally. They are used with the NOARK UL MCCB series. The mechanism includes three components: external handle, shaft and handle operating mechanism. The NOARK ERH is available as a kit or individual components and is available immediately for delivery.

The Flange Handle Mechanism mounts on the flange of an enclosure door, occupying less space inside the enclosure. The units are specially designed by NOARK for UL MCCB use. The flange mechanism includes three components: flange handle, flex shaft and operating mechanism. It is available as a kit or individual components and will be available for sale in December, 2016.

NOARK Electric will display these new products and many other components for the HVAC market at the upcoming AHR 2017 show in Las Vegas, January 30 through February 1. Visit Noark at booth N7939.

NOARK Electric (North America), located in Pomona, California, is a leading global electrical component and intelligent control system supplier. The company is establishing a representative and distribution network to serve its primary markets, which include the building trades and electric panel board builders in various industries. As a global supplier, NOARK currently operates four R&D centers, three distribution centers, 15 office locations and employs over 1,000 associates. Sales currently exceed $2 billion worldwide.

For more information on this product, consult your local sales representative found at www.noark-electric.com or email: nasales@noark-electric.com.

Continue reading