Contact us today:

(847) 934-4500

tdaro@bernardandcompany.com

Contact us today:

(847) 934-4500

tdaro@bernardandcompany.com

When IMTS 2014 announced their photo contest, we couldn’t wait to get to work!

#IMTS: Everywhere You Look – #Photo Contest! Send us your images spelling out I-M-T-S, we will choose our… http://t.co/pRbDeyo6NS

— IMTS (@IMTSchicago) February 24, 2014

@BernardandCo We are very excited to see how creative our #exhibitors will be. Can't wait to see your #IMTS photos! http://t.co/DRODctM0o0

— IMTS (@IMTSchicago) February 19, 2014

Presenting our entry:

“Chicago’s Favorites” featuring Bernard & Company, IMTS, Portillo’s Chicago-Style Hot Dogs/Fries and Italian Beef Sandwiches, Lou Malnati’s Deep Dish Pizza and Garrett’s Chicago Mix Popcorn. What could be better?? Nothing, I tell ya.

Do NOT miss IMTS this upcoming September!! Our clients, including Siemens Machine Tools, Siemens Production Machining, Rattunde, Advanced Machine & Engineering, Heimatec, TCT Stainless, GMTA, Suhner and Chemtool will all be exhibiting!

And if the photo above did not leave you reaching for a napkin to wipe the drool, IMTS will be home to over 100,000 decision makers showing new manufacturing technology and ideas. So come on over to Chicago and get a taste of everything IMTS will have to offer!

Continue reading

This Grieve walk-in oven features 4” insulated walls, aluminized steel exterior and interior, removable top-mounted heating chamber and a fully insulated floor. The oven is built with all safety equipment required by NFPA Standard 86 for flammable solvents, including a powered forced exhauster, airflow safety switch and purge timer.

Other controls on No. 806 include a fused disconnect switch, digital temperature controller and manual reset excess temperature controller.

For more information, please contact:

THE GRIEVE CORPORATION

500 Hart Road

Round Lake, IL 60073-2898

Phone: (847) 546-8225

Fax: (847) 546-9210

Web: www.grievecorp.com

Email: sales@grievecorp.com

Attention: Frank Calabrese, VP

This Grieve universal oven features 6” insulated walls, aluminized steel exterior, Type 304, 2B finish stainless steel interior, single front door with five 3” diameter ports and two 6” diameter ports equipped with slide dampers, plus an 8” x 10” Pyrex/Vycor viewing window and interior oven light.

Controls on No. 985 include a digital programming temperature controller, manual reset excess temperature controller with separate contactors and recirculating airflow safety switch.

For more information, please contact: THE GRIEVE CORPORATION, 500 Hart

Road, Round Lake, Illinois 60073-2835 USA. Phone: (847) 546-8225. Fax: (847) 546-

9210. Web: www.grievecorp.com. Email: sales@grievecorp.com. Attention: Frank

Calabrese.

Continue readingBOOTH E-5010: Click here to add Siemens to your IMTS Show Planner!

From the job shop to the retrofit operation, moldmakers to mass production departments at the world’s leading auto, aero and medical manufacturers, Siemens continues to push the envelope on CNC technology. With the introduction of the Sinumerik 808D at IMTS in 2012, we took a bold step into the job shop world, as this basic CNC brings the power, flexibility and reliable performance of Siemens technology to the job shop. Already accepted as an OEM component by numerous mill and lathe builders, the 808D provides job shops the unique opportunity to apply advanced and unmatched CNC power to their existing machines, breathing “new life into old iron,” as the saying goes.

The 808D rounds out the growing family of CNC models from Siemens, which now spans the range from the most basic 3-axis machines to dedicated milling and turning center controls in the Sinumerik 828D to CNC for the most advanced five-axis machining centers, with full robotic integration, secondary ops management and transfer line capability, all on a single control, the Sinumerik 840D sl solution line, still the benchmark by which all other CNC technology in the market is judged. Simply put, nobody matches the muscle of Siemens. Come to booth E-5010 and see the difference. Productivity in Motion!

For more information about Siemens CNC solutions for the machine tool industry, visit the website: www.usa.siemens.com/cnc.

Please forward all inquiries to:

SIEMENS INDUSTRY, INC.

DRIVE TECHNOLOGIES

MOTION CONTROL

MACHINE TOOL BUSINESS

390 Kent Avenue

Elk Grove Village, IL 60007

Phone: 847-640-1595

Fax: 847-437-0784

Web: www.usa.siemens.com/cnc

Email: SiemensMTBUMarCom.sea@siemens.com

Attention: John Meyer, Manager, Marketing Communication

Follow us on Facebook: www.facebook.com/SiemensCNC or Twitter: www.twitter.com/siemens_cnc_us.

—

Siemens Industry Sector is the world’s leading supplier of innovative and environmentally friendly products, solutions and services for industrial customers. With end-to-end automation technology and industrial software, solid vertical-market expertise, and technology-based services, the sector enhances its customers’ productivity, efficiency and flexibility. With a global workforce of more than 100,000 employees, the Industry Sector comprises the Industry Automation, Drive Technologies and Customer Services Divisions as well as the Metals Technologies Business Unit. For more information, visit http://www.usa.siemens.com/industry.

The Siemens Drive Technologies Division is the world’s leading supplier of products, systems, applications, solutions and services for the entire drive train, with electrical and mechanical components. Drive Technologies serves all vertical markets in the production and process industries as well as the infrastructure/energy segment. With its products and solutions, the division enables its customers to achieve productivity, energy efficiency and reliability. For more information, visit http://www.usa.siemens.com/drivetechnologies.

Continue readingMajor manufacturer of tube and bar processing machinery Rattunde today announced the appointment of the following individuals to new positions at the company, based in Caledonia, Michigan, near Grand Rapids. This announcement was made by company president Rick Stadler.

The new staffers include:

Chad has been a member of the IBEW (International Brotherhood of Electrical Workers) for 10 years and is also a Certified Master Electrician. Chad will be training new and current customers as well as commissioning new machines in the field. His other duties will include handling the customer help line and assisting the service team.

Janelle was brought onboard to fill a wide spectrum of duties. She will be responsible for pre- and post-sales communications between customers and internal resources, plus the planning and scheduling of machine installations. Janelle was an executive assistant for the past 3 years and has spent time in both inside and outside sales.

Will was hired by Rattunde to handle multiple functions. His primary duty will be to help maintain the Rattunde customer relationships that have been generated over the last 8 years in North America. A further reason he was hired is to help with market research, assisting Rattunde in its expansion into new markets. A third area of responsibility will be marketing. Will has a sales background, having worked the last 9 years in the automotive industry, selling components.

Carlos, who is fluent in Spanish, was hired for inside sales to support the Mexican and Latin American markets Rattunde currently sells and seeks to develop further. Carlos is responsible for quoting and fulfilling tooling and spare part orders for all North American customers, with special emphasis on the Mexican and Latin American companies. Carlos was previously in logistics.

For more information on this development, please contact:

RATTUNDE CORPORATION

4980 Kendrick Street SE

Grand Rapids, Michigan 49512

Phone: 616-940-3340

Fax: 616-940-2771

Web: www.rattunde-corp.com

Email: company@rattunde-corp.com

Attention: Richard Stadler or Alec Banish

This Grieve oven features a 5’ long open belt loading zone, 35’ long insulated heat zone with recirculated airflow and 1’ long open belt unloading zone, plus 4” insulated walls, aluminized steel interior and exterior. A 6’ wide, 1” x 1” galvanized steel, flat wire conveyor belt with ¼ HP motor drive, variable from 5 to 50 feet per hour, transports the workload. Side access doors are provided along the length of the workspace to inspect the load and service the heating chamber.

All safety equipment required by IRI, FM and NFPA Standard 86 for gas-heated equipment are provided on this belt conveyor oven, including a 1500 CFM, 2 HP powered forced exhauster.

Controls on No. 864 include a conveyor belt start/stop, digital indicating current proportioning temperature controller, manual reset excess temperature controller, variable SCR drive to control conveyor belt speed, pilot lights to indicate when blower and heat are energized, pushbutton electronic ignition, on-off heat switch and main oven control pushbuttons. The NEMA 12 control panel is equipped with a lockable fused disconnect switch.

For more information, please contact:

THE GRIEVE CORPORATION

500 Hart Road

Round Lake, IL 60073-2898

Phone: (847) 546-8225

Fax: (847) 546-9210

Web: www.grievecorp.com

Email: sales@grievecorp.com

Attention: Frank Calabrese, VP

Bernard & Company is proud to announce recent client acquisitions including Suhner Automation, Gehring Technologies GmbH, Chemcoaters, Gray Machinery and S & G Press & Machinery Sales, for which they will be providing full advertising, PR, social media, trade-show and online promotional activity.

Since 1926, Gehring L.P has been a globally operating machine tool company specializing in high performance honing technology.

Website | ThomasNet Profile | |

|

| 24800 Drake Rd. Farmington Hills, MI 48335 | (248) 427-3901

Founded in 2001, Chemcoaters‘ continuous, coil processing line is designed specifically for the most economical application of environmentally friendly waterborne coating sys-tems.

Website | |

|

|

|

| 700 Chase St. Gary, Indiana 46404 | (219) 977-1929

Established in 1966, Gray Machinery Company has over 40 years of experience buying and selling pre-owned machinery.

Website | | 77 E Palatine Rd. Prospect Heights, IL 60070-1811 | (800) 292-1493

Founded in 2000, S & G Press & Machinery Sales operates worldwide, buying and selling used stamping and manufacturing equipment; specializing in metal stamping presses, feed lines and various types of automation, fabricating and tool room equipment.

Website | |

| 16660 East 13 Mile Rd. Roseville, MI 48066 | (586) 563-5000

Since 1914, SUHNER Automation has been providing economical, low-cost manufacturing solutions and machining units for drilling, milling and tapping operations.

Website | ThomasNet Profile | | 43 Anderson Rd. Rome, GA 30161 | (706) 235-8046

Remember this? Star Wars is a great example of maximum creativity in the imagining and depicting of innovative, futuristic gadgets and concepts (meanwhile, creativity for costume design = minimal, pretty sure they all just wore potato sacks and bedsheets)

What’s even more impressive is that THIS IS HAPPENING.

Recently, Watry Industries, LLC exhibited at the AFS 118th Metalcasting Congress and handed out these cards at their booth:

Download the actable™ app for Android, iPhone or iPad and hold the scanner up to the card. Yes – you can even hold it up to a computer screen or the screen of another phone or tablet and scan! Or, if you’re stuck in the dark ages, you can print the card out and scan to play 🙂

See a quick video of the whole thing going down >>HERE<<.

Augmented reality is emerging full force and making big splashes (ex. Pepsi in London and Lego). Computer-generated sensory input (sight, sound, feel) can change and enhance the way we interact with just about anything!

Well done, Watry. We applaud this shiny new toy.

—

Watry is a permanent mold aluminum foundry in Sheboygan, Wisconsin. They take part design and do all of the following, all in-house.

That’s their single-source promise.

Dale Christel

Sales Manager

Watry Industries LLC

3312 Lakeshore Drive

Sheboygan, WI 53081

Office: 1-920-457-4886

www.watry.com

dchristel@watry.com

Connect with Watry Industries online:

During this year’s [MC]2 2014 MTConnect: Connecting Manufacturing Conference, Siemens announced today the appointment of TechSolve (Cincinnati) as a Solution Partner to offer solutions to customers with Sinumerik CNCs who are interested in or have already implemented MTConnect into their factories. Through this development, Siemens proactively responds to the growing demand in the market for MTConnect solutions among the end-user and machine builder sectors. TechSolve was a Founding Sponsor of the Institute and is a major supplier of MTConnect Adapters, translation products as well as support software and services that enable shops and production departments alike to more efficiently gather and analyze machine tool performance data, using the open-source communication standard of MTConnect.

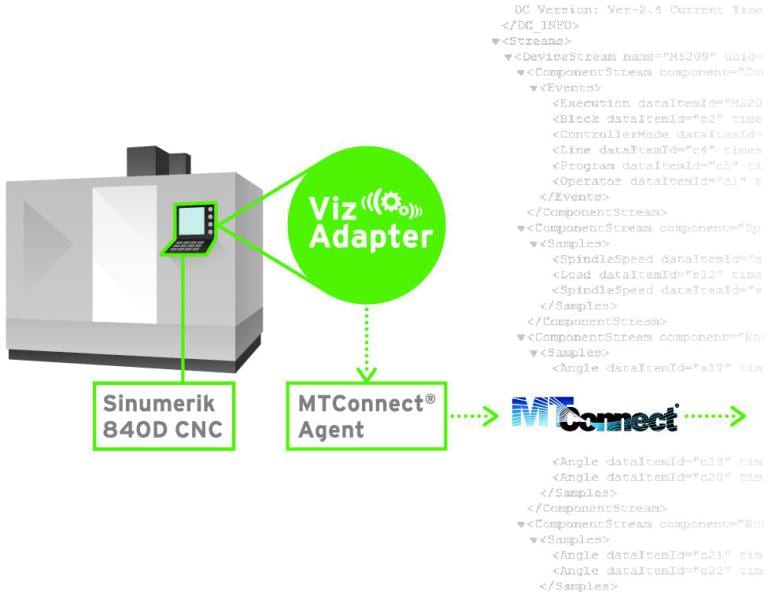

This schematic illustrates the typical scenario for a machine tool control modification at an end-user, where the Siemens CNC is modified with TechSolve Adapter software, allowing machine data to be sent through an agent in MTConnect compatible language. This facilitates a significantly greater degree of information gathering and analysis by the customer, across the open-source standard of MTConnect for greater interoperability between devices and software applications. Machine builders can also make such modifications to their controls, to suit customer needs or respond to market conditions.

In a typical machine tool end-user scenario, TechSolve applies its Adapter software to an existing machine’s CNC, such as the Siemens Sinumerik 840D, which enables data transfer through an MTConnect Agent. For older controls and legacy devices that do not have native communication output, TechSolve can also supply additional hardware and communication software to facilitate this process. The data can then be stored locally or cloud-based for further access and evaluation in an overall equipment effectiveness (OEE) strategy.

Likewise, TechSolve provides Adapter software to machine tool builders for integration into their control schemes to suit particular applications or customer-mandated specifications for MTConnect compatibility.

Ryan Legg, product manager, Sinumerik CNC, Siemens Industry, Inc., explains, “In the U.S. market especially, we are seeing growing demand for MTConnect. This appointment of TechSolve as a Solution Partner to support requests for MTConnect represents our company’s commitment to bring practical solutions to our customers through an experienced and reliable source of both products and services. When MTConnect is written into the specification on any job, we now have an ideal resource to complement our capabilities.”

Noting the open architecture of the Siemens CNC allows easy integration of the TechSolve solutions; Legg further explained the cross-platform advantages of this new relationship. “TechSolve has written their MTConnect Adapter for the Sinumerik CNC

in a way which allows complete flexibility regardless if the system architecture of the Sinumerik employs a PCU or if it is running in an embedded architecture without a PCU. Ultimately, this allows for more customers to take advantage of this offering.”

Ron Pieper, manager, VizProducts™ Group at TechSolve, observes, “To be affiliated with Siemens is a compliment to both of our products and services as well as our engineering talents. We believe this relationship will be mutually beneficial, as it will further promote the acceptance of MTConnect in the machine tool market, plus being a Solution Partner to Siemens will open new doors for our company.”

Pieper further comments on the market need for these solutions. “When all the data from the shop or factory floor is available as it occurs, the customer learns the reality of their situation, then can make confident steps to improve their game, so to speak.

They see where the inefficiencies are, where and why the downtime is occurring and how they might improve or streamline production. All of these factors are crucial in today’s competitive machining market.”

More information on the above-mentioned solutions will be available at the upcoming MTConnect Conference in Orlando, April 8-10, 2014, organized by the MTConnect Institute.

For more information about this announcement, please visit: www.usa.siemens.com/techsolve-pr.

For specific product information and inquiries, call (800) 879-8079 ext. Marketing Communications or send an e-mail to: SiemensMTBUMarCom.industry@siemens.com.

Follow us on Facebook: www.facebook.com/SiemensCNC or Twitter: www.twitter.com/siemens_cnc_us.

—

Siemens Industry Sector is the world’s leading supplier of innovative and environmentally friendly products, solutions and services for industrial customers. With end-to-end automation technology and industrial software, solid vertical-market expertise, and technology-based services, the sector enhances its customers’ productivity, efficiency and flexibility. With a global workforce of more than 100,000 employees, the Industry Sector comprises the Industry Automation, Drive Technologies and Customer Services Divisions as well as the Metals Technologies Business Unit. For more information, visit http://www.usa.siemens.com/industry.

The Siemens Drive Technologies Division is the world’s leading supplier of products, systems, applications, solutions and services for the entire drive train, with electrical and mechanical components. Drive Technologies serves all vertical markets in the production and process industries as well as the infrastructure/energy segment. With its products and solutions, the division enables its customers to achieve productivity, energy efficiency and reliability. For more information, visit http://www.usa.siemens.com/drivetechnologies.

TechSolve is a consulting firm that has helped organizations of all sizes leverage process improvement, machining expertise and innovation to enhance their competitive edge across ever-changing markets. We understand engineering and manufacturing, so we developed an array of machine monitoring software under the umbrella of VizProductsTM.

Our custom-tailored machine-monitoring and data-gathering solutions enable shops and production departments alike to more efficiently gather and analyze machine tool performance data, TechSolve can help manufacturers eliminate extraneous costs, increase productivity, and maximize profits. For more information please visit www.techsolve.org.

No. 910 is a 1000ºF, gas-fired, high-temperature walk-in oven from Grieve, currently used for heat cleaning large valve bodies at the customer’s facility. Workspace dimensions of this oven measure 60” W x 120” D x 78” H. 880,000 BTU are installed in a modulating natural gas burner to heat the oven chamber, while a 12,500 CFM, 10 HP recirculating blower provides combination airflow to the workload.

This Grieve oven features 8” thick insulated walls made from 2” of 1900ºF block and 6” of 10 lb/cf density rockwool; top-mounted heat chamber; 16 ga aluminized steel oven interior, 16 ga stainless steel heat chamber interior and 16 ga aluminized steel exterior. Inner and outer door gaskets are provided, with the inner gasket sealing directly against the door plug and the outer gasket sealing directly against the face of the oven. The 6” insulated oven floor features truck wheel guide tracks and Grieve also furnished the customer an 8000 lb capacity flatbed loading truck with this walk-in oven.

All safety equipment required by IRI, FM and NFPA Standard 86 for gas-heated equipment are provided on the oven, including a 1500 CFM, 2 HP powered forced exhauster.

Controls on No. 910 include a digital programming temperature controller.

For more information, please contact:

THE GRIEVE CORPORATION

500 Hart Road

Round Lake, IL 60073-2898

Phone: (847) 546-8225

Fax: (847) 546-9210

Web: www.grievecorp.com

Email: sales@grievecorp.com

Attention: Frank Calabrese, VP