Contact us today:

(847) 934-4500

tdaro@bernardandcompany.com

Contact us today:

(847) 934-4500

tdaro@bernardandcompany.com

Graham detailed the offer, saying it would apply to any make or model of rubber or TPE injection press. REP requires the molder to validate the scrapping of their old machine, thereby earning a predetermined credit, based on the old machine’s age and condition. The credit, up to $40,000, can then be applied to the purchase of any new REP injection press in the G9 series.

He further noted the advantages of a new machine. “Besides the higher quality parts a molder can produce, owing to the level of mold mechanics, material flow and control sophistication, a new press consumes less energy, has less downtime and less maintenance requirements, so it stays in production. Even REP presses from our earlier generations cannot match the productivity and resulting profitability of a new G9 machine. That’s not a brag, it’s a fact and it’s one we can document,” he said, noting the new machines offer better molding strategies, improved ergonomics and faster payback for the customer.

“It’s an offer you can’t refuse,” Graham joked.

REP Corporation is responsible for all sales and service in North America. However, this offer is being made to rubber molders worldwide by REP, based in Lyon, France.

For more information, please contact: REP CORPORATION 8N470 Tameling Court Bartlett, IL 60103-8146 Phone: 847-697-7210 Fax: 847-697-6829 Web: www.repinjection.com Email: tgraham@repcorp.com Attention: Tim Graham, President

PR agency contact: Tim Daro Bernard & Company 847-934-4500 tdaro@bernardandcompany.com

Continue reading

The unit has 4” insulated walls, an aluminized steel exterior and Type 430 stainless steel interior. It is also equipped with an integral leg stand with casters and leveling pads.

Controls onboard No. 945 include a digital indicating temperature controller, manual reset excess temperature controller with separate contactors, recirculating blower airflow safety switch and SCR power controller.

For more information, please contact: THE GRIEVE CORPORATION, 500 Hart Road, Round Lake, Illinois 60073-2835 USA. Phone: (847) 546-8225. Fax: (847) 546-9210. Web: www.grievecorp.com. Email: sales@grievecorp.com. Attention: FrankCalabrese.

NEWS RELEASE: THE GRIEVE CORPORATION Agency contact: Tim Daro 847-934-4500

DATE: March 22, 2010

Continue reading

The unit has 4” insulated walls and an aluminized stainless steel interior and exterior. A 3300 CFM, 2-HP recirculating blower provides horizontal airflow to the oven. Safety equipment, such as a 325 CFM 1/3 powered force exhauster, is included as required by the IRI, FM and the National Fire Protection Association Standard 86 for gas-fired equipment. The oven also features a 2” insulated floor with truck wheel guide tracks and a removable top-mounted heat chamber.

Controls onboard No. 813 include a recirculating blower airflow safety switch, circular chart temperature controller and a manual reset excess temperature controller.

For more information, please contact:

THE GRIEVE CORPORATION

500 Hart Road

Round Lake, Illinois 60073-2835

USA

Phone: (847) 546-8225

Fax: (847) 546-9210

Web: www.grievecorp.com

Email: sales@grievecorp.com

Attention: Frank Calabrese

Complete Set of Application-Ready “Tools” for Converting Applications

ATLANTA — Siemens Industry, Inc. announced today the introduction of the Converting Toolbox, a set of standardized automation tools for the integration of various machine components that previously had to be performed individually. It simplifies web processing applications and offers greater flexibility for machine designers and builders of paper, film, foil and other converting machinery. It is completely scalable and is provided at no cost to qualified machine designers, builders and integrators.

The Converting Toolbox enables machine builders to achieve considerably faster time to market by reducing the time required for engineering, programming, commissioning and documentation, as much as 80 percent in some cases. It offers modular open functions, for items such as:

The Converting Toolbox components take the form of pre-programmed functions. Sample applications demonstrate how each function can be efficiently and effectively implemented into a machine design. Such sample applications are ready-to-use after only minor modifications and include basic HMI functionality. This enables the machine function to be tested and optimized in a very short time frame.

When a functionality module needs to be modified, extended or changed, the Converting Toolbox’s completely open source code provides a wide and solid basis from which even the most specialized functions can be implemented quickly and easily.

Simotion®, the Siemens motion control system, is ideally suited as an operating platform for the Converting Toolbox because applications can be operated directly on an intelligent drive, very compactly and without need of an additional PLC. Simotion offers drive, controller and PC-based topologies. The Converting Toolbox also includes drives-based solutions using Siemens Sinamics® Drive Control Chart (DCC) graphical programming language.

For specific product information and inquiries, call (800) 879-8079 ext. Marketing Communications or send an e-mail to: SiemensMTBUMarCom.industry@siemens.com.

Continue reading

By using a Zimmermann FZ42 portal milling center, Volvo gets the power and torque needed to cut engine fan cases plus the accuracy to turn the machine tool into a coordinate measuring machine for inspection of finished parts

Located near Hartford, Conn., Volvo Aero Connecticut specializes in the machining of large components: fan cases for aircraft engines and gas turbines, fan and compressor structures, compressor rotors, low-pressure turbine cases (LPT) and military parts, usually from aluminum and titanium, as well as Inconel and Waspaloy. It currently manufactures the largest fan casing in the world, at 3.5 meters (11.5 feet) in diameter, for the massive GE90, the only aircraft engine in existence providing 127,900 pounds of thrust, to power the Boeing 777 line. Volvo Aerospace also produces numerous titanium fan cases for Rolls Royce engines.

With the large workpieces, high material removal rates and challenging geometries inherent in aerospace metals manufacturing, coupled with substrates that are often difficult to machine, such as titanium, there is always a need for powerful machining with superior accuracy. Such conditions present substantial hurdles at aerospace supply companies, as they seek to maintain that delicate balance between these seemingly opposing concepts.

As part of its program for the GEnx engine, to be used on the Boeing 787 Dreamliner, Volvo Aero Connecticut recently added a Zimmermann FZ42 machine tool, a five-axis, five-side portal milling center, to its already impressive manufacturing cells at the Hartford facility. The new machine joins other five-axis mills, vertical turning machines, four-axis machining centers and a deburring robot.

Key features on the FZ42 that led Volvo Aero Connecticut to make this acquisition included:

In addition, this FZ42 carries a high accuracy package that provides optimum temperature control of the structural machine parts through the use of a special fiber-reinforced compound in the massive side columns. Also facilitating this process are built-in cooling ducts in the portal and Z-axis slide, independent cooling circuits for the A-axis, C-axis and spindle, ground surfaces on the guideways for the Z-axis and side columns, plus a double-pitch measuring system on the A-axis and C-axis.

During the course of manufacturing, thermal expansion of both machine components and workpieces can substantially impact the positioning accuracy of the machine, the stability of the workpiece and the resulting effect on the finished part dimensions. This unique combination of temperature control and mechanical accuracy in the machine construction were an important deciding factor for Volvo Aerospace in acquiring the FZ42.

According to Martin Thorden, engineering manager at Volvo Aero Connecticut, “These features, combined with the onsite machine set-up provided by Zimmermann, were very important to us, especially on this new GEnx project.” Thorden further noted the importance of the control on the machine, a Sinumerik 840D CNC from Siemens. “We see a very big benefit in how well we are able to control the tool with the CNC. We have been able to use the control to take on additional tasks that were previously handled by our CAD/CAM system.” Specifically, he cited the unconventional approach Volvo Aerospace took in machining the big fan cases. They installed the machine without a rotary table, thus realizing over $500,000 in direct cost savings plus material handling time. As a result of that decision, they believed they needed a top-of-the-line control to probe and accurately machine all the features on the part.

Volvo Aero Connecticut, located near Hartford, comprises three buildings, the largest being 40,000 square feet, where various aerospace and military aircraft components are typically produced from aluminum, titanium, Inconel and Waspaloy.

After machining, Volvo Aero Connecticut can actually transition the machine tool into a coordinate measuring machine for inspection, according to Thorden, owing to the superior accuracy provided by the CNC, as well as the special 90 degree angle heads supplied with the machine, part of the MuST® spindle technology from Zimmermann.

Onboard the machine tool, a massive 120-position tool carriage holds various HSK63 and HSK100 tools that are used to machine the substrates worked here. Inside a series of four side stations, within the machine workspace, four additional specialty tools are stored and used for various operations in the machining and measuring process.

All motors and the drive package onboard the Zimmermann FZ42 at this Volvo Aero Connecticut facility are also made by Siemens.

In a typical machining sequence, the milling head on this machine, equipped with the Zimmermann MuST® spindle system, provides Volvo Aerospace numerous other advantages, according to Martin Thorden. All roughing and subsequent finish passes on any material can be achieved in one set-up, which reduces the preparation time and overall production costs by as much as 10%. There is also no need for additional machines and the corresponding materials handling time. The head design further enables Volvo Aero Connecticut to perform tasks other than milling, using the specialty heads stored on the side stations. Changing the spindle, instead of the milling head, enhances repeatability and further reduces the company’s spindle interface costs, according to Thorden.

The combination of increased accuracies, reduced equipment needs and faster throughput has highlighted this Zimmermann machine installation at Volvo Aero Connecticut.

For additional product information and inquiries:

Zimmermann Inc.

Phone: 248-305-9707

Web: www.zimmermann-inc.com

Email: Matthias@zimmermann-inc.com

Attention: Matthias Tockook

Volvo Aero Connecticut

Phone: 860-667-8502

Web: www.volvoaero.com

Email: Martin.Thorden@volvo.com

Attention: Martin Thorden

Siemens Machine Tool Business

John Meyer

Manager, Marketing Communications

Siemens Industry, Inc.

(847) 640-1595

www.usa.siemens.com/cnc

SiemensMTBUMarCom.industry@siemens.com

Follow us on Facebook: www.facebook.com/SiemensCNC or Twitter: www.twitter.com/siemens_cnc_us.

—

Siemens Industry Sector is the world’s leading supplier of innovative and environmentally friendly products, solutions and services for industrial customers. With end-to-end automation technology and industrial software, solid vertical-market expertise, and technology-based services, the sector enhances its customers’ productivity, efficiency and flexibility. With a global workforce of more than 100,000 employees, the Industry Sector comprises the Industry Automation, Drive Technologies and Customer Services Divisions as well as the Metals Technologies Business Unit. For more information, visit http://www.usa.siemens.com/industry.

The Siemens Drive Technologies Division is the world’s leading supplier of products, systems, applications, solutions and services for the entire drive train, with electrical and mechanical components. Drive Technologies serves all vertical markets in the production and process industries as well as the infrastructure/energy segment. With its products and solutions, the division enables its customers to achieve productivity, energy efficiency and reliability. For more information, visit http://www.usa.siemens.com/drivetechnologies.

Continue reading

Automated loading and parts handling system complement state-of-the-industry laser and machine control technology

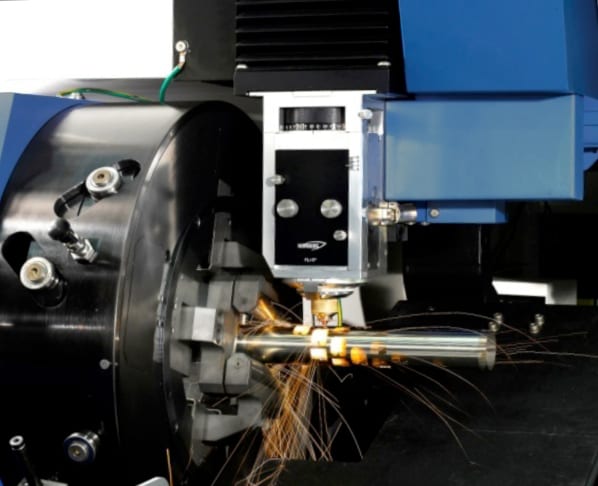

Han-Kwang USA announces immediate availability of its new Model TL 6015, a tube cutting laser system capable of handling 24’ long, 6.5” diameter workpieces up to 1/4” wall thickness in mild steel and 0.200” in stainless steel. Equipped with a powerful 2.5KW Panasonic laser and a versatile Siemens 840D CNC to control all functions of the machine, the TL 6015 can significantly increase the tube production in any department or shop, especially when used with Han-Kwang’s proprietary “Flex 3D” tube cutting software . The unit comprises an automatic bundle loading system with tube V-support, auto-centering rotary chucking system, laser cutting station and automatic parts removal station.

Maximum positioning speed on this new laser system is 4700 ipm for the X-

Han-Kwang S5 Cutting Head, featuring Auto Focus Control; adjusts focal length of cutting lens to automatically compensate for material variations and rapid changeover

axis and 120 rpm for the rotary A-axis. Max acceleration rate is 1G, while the laser beam is precisely controlled by the unique Han-Kwang Auto Focus Control (AFC). This AFC technology allows the machine to automatically adjust the focal length of the cutting lens to accommodate variations in the materials being processed or changes in material feed, which eliminates the downtime normally associated with manual adjustments.

A new generation of sensing board in the S5 laser cutting head on the TL 6015 translates into faster cutting speeds on round, square or rectangular shapes.

In a recent design modification, the entire loading section of the machine has been enclosed, as depicted in the attached illustration.

For more information or to arrange a demonstration, please contact:

HAN-KWANG USA INC. Phone: 630-916-0200 Web: www.hankwang.com

Agency contact: Tim Daro Bernard & Company tdaro@bernardandcompany.com www.bernardandcompany.com

Continue readingFrom: Tim Daro (Bernard & Company)

Sent: Mon 15/02/2010 14:47

To: Jon W (BMW Oracle Racing)

Cc: Fred Young (Forest City Gear); Wendy Young (Forest City Gear); Nicole Zermatten (Bernard & Company); Wendy McCormick (Bernard & Company)

Subject: Congratulations!

We all welcomed the news of your success in winning the Cup.

And the story on Forest City Gear is popping up all over the trade press, here in the States.

Good news, all around!

Thanks for your help, Jon. Enjoy the victory.

Tim

—–Original Message—–

From: Jon W (BMW Oracle Racing)

Sent: Mon 15/02/2010 14:47

To: Tim Daro (Bernard & Company)

Cc: Fred Young (Forest City Gear); Wendy Young (Forest City Gear); Nicole Zermatten (Bernard & Company); Wendy McCormick (Bernard & Company)

Subject: Congratulations!

Hi guys,

I don’t think we could’ve written a better script! The victory will carry the article a bit further for you I’m sure. It was incredible to pick up the America’s Cup last night. I’ve been chasing it for more than 10 years!

Bye for now.

Jon

Check out our press release on FCG and BMW Oracle teaming up.

Go to our Facebook page to see more pictures of the BMW Oracle.

Continue reading

We are very pleased to announce the promotion of Christian Schedler to the Product Manager position at this division.

In his new role, Christian will oversee P&L responsibility for the division, including its sales, application engineering, product management and project management functions.

Christian’s distinguished career has encompassed R&D, Engineering and Product Manufacturing. He has a broad assembly and service experience on machine tools and knows the market’s needs for productivity improvements. Prior to this promotion, he worked in service as a Global Service Rep for a German machine tool company and as a Designer of carbide saws at Advanced Machine & Engineering. Christian has the experience, energy and judgment necessary to lead the division to continued success, insuring its future growth objectives are achieved.

Advanced Machine & Engineering Co., is a manufacturer located in Rockford, IL, serving the Machine Tool Industry with precision components and accessories, including spindle interface components, workholding devices, and, through our sister company, Hennig, machine enclosures, chip removal and filtration systems. The Fluid Power – Safety markets are served with cylinder rod locks and safety catcher devises; and the Production Saw market with our Amsaw carbide saw machines and Speedcut blade products. AME has manufacturing partners and customers around the world and across the U.S. To learn more, visit www.ame.com.

Hennig, Inc. design and produces custom machine protection and chip/coolant management products for state-of-the-art machine tools. Hennig products are designed to protect against corrosion, debris and common workplace contaminants. Manufacturing facilities located in the U.S., Germany, Brazil, India, Japan, China and South Korea. Repair centers are located in Machesney Park, IL; Chandler, OK; Livonia, MI; Blue Ash, OH; Mexico City, Mexico and Saltillo, Mexico. To learn more, visit www.hennigworldwide.com.

For more information, contact:

Tim Waterman

ADVANCED MACHINE & ENGINEERING CO.

2500 Latham St.

Rockford, IL 61103

Phone: 815-316-5277

Fax: 815-962-6483

E-mail: info@ame.com

Connect with AME online:

Steps to take for avoidance of imperfections in the aesthetics and surface integrity of gearworks

Roscoe, IL-Forest City Gear recently disseminated the following tips to its employees and would like to share these ideas with the gearmaking community, as well as users and assemblers of gearworks. This information is provided for reference only and any further questions or comments should be directed to author Fred Young, CEO of Forest City Gear. He welcomes all feedback.

BY: Fred Young, CEO

TO: All Forest City Gear Employees

Recently and historically, we have had issues with gears that suffered from the above conditions, after heat treat. These issues can also appear during hot and humid times, as well. We previously had a sand/vapor blast unit that was used to clean off debris and contamination from gears, prior to further processing.

My suggestions for future handling, based on experience and a reading of the current technology, include the following:

I welcome all your suggestions to further our desire for achieving “Excellence without Exception.” (This is the company motto at Forest City Gear.) I think that if all hands are on the lookout to address the corrosion, discoloration, contamination and pitting issues and address corrective procedures prior to further processing-gear grinding, cylindrical grinding or other machine operations- this will help minimize our overall cost. It is very difficult to address these issues after grinding has occurred, as you all know.

The September/October (2009) issue of Gear Technology had an article starting on page 60 entitled, “Gear Corrosion During the Manufacturing Process,” which focused on issues of pitting caused by corrosion, which can be very serious and ultimately lead to gear failure in operation.

While the article discussed the REM Chemical process of isotropic superfinishing in particular, much of the information is germane to the points above and will contribute to your understanding and resolution of these problems. I encourage you to read it. The watchword at Forest City Gear is that all of us are responsible to be on the lookout and take steps to prevent this situation from future occurrence, to the greatest degree possible. It will be prudent to gather some examples and point out exactly what we are trying to prevent from going out the door, by reviewing it with all hobbing/secondary, shaping and grinding department personnel, at the earliest opportunity.

For more information on this announcement, please contact: FOREST CITY GEAR CO., INC. Web: www.forestcitygear.com

Editor Note: Please send any publication-generated inquiries from this article to Wendy Young at Forest City Gear, wyoung@forestcitygear.com. Thanks much.

PR agency contact: Tim Daro Bernard & Company 847-934-4500 tdaro@bernardandcompany.com

Release: FOREST CITY GEAR CO., INC.

Date: January 26, 2010

Continue reading

The unit has 4” insulated walls, aluminized steel exterior, type 304, 2B finish stainless steel interior with continuously backwelded seams, while the exterior is finished in white epoxy paint with a #4 brushed finish stainless steel door cover and control panel face. The oven is also equipped with double doors and positive latching door hardware.

A 1500 CFM, 2-HP recirculating blower provides horizontal airflow to the oven and two 30” x 24” x 6” thick stainless steel high temperature HEPA recirculating filters further purify the air. The ductwork is easily removable to expose filters for inspection or replacement.

Controls onboard No. 922 include a digital indicating temperature controller, manual reset excess temperature controller with separate contactors, recirculating blower airflow safety switch and solid state contactors.

For more information, please contact:

THE GRIEVE CORPORATION

500 Hart Road

Round Lake, IL 60073-2898

Phone: (847) 546-8225

Fax: (847) 546-9210

Web: www.grievecorp.com

Email: sales@grievecorp.com

Attention: Frank Calabrese, VP