Contact us today:

(847) 934-4500

tdaro@bernardandcompany.com

Contact us today:

(847) 934-4500

tdaro@bernardandcompany.com

At a time when the media are constantly touting the imminent demise of American manufacturing, there are numerous suppliers to one of this country’s greatest and most universally sought after technological achievements who might challenge that notion. In fact, they just might debunk it with extreme prejudice. These are the suppliers to the Undulator System on the Linac Coherent Light Source (LCLS) project, recently completed at Argonne National Laboratory (ANL) and supplied as an extension of the SLAC National Accelerator Laboratory in California.

On Friday, September 3, at ANL in Lemont, Illinois, several vendors to this project were acknowledged for their roles, during a presentation made by various key individuals in the project’s start-up and ongoing development. One of these vendors is M-1 Tool Works of McHenry, Illinois, who supplied a variety of machined metal components and assemblies used in the focusing operation on the light beams that create ultra-bright, ultra-short x-ray pulses from a high-energy electron beam. These x-ray pulses are a billion times brighter than the most powerful light source known and are used to capture images of molecules and detail their actions within an atomic structure. The first beam was generated in April, 2009 and the undulator was installed and fully functioning in the Spring of 2010.

Users of this new American technology from every continent are already lining up at SLAC to apply it for the investigation of atoms on various mechanical structures, raw materials, pharmaceuticals, industrial chemicals, military ordnance, space exploration hardware and hundreds of other products. Commercial, institutional, educational, governmental and advanced research concerns are all requesting use of this technology, according to the directors of the project.

M-1 Tool Works, a longtime supplier of precision components to such diverse fields as the aerospace industry, defense, medical, high tech, close tolerance and high reliability commercial industries, had previously done work for Fermilab and Lawrence Livermore National Laboratory. They were called upon by ANL to produce 36 assemblies, each comprising a central assembly and various close tolerance components. The materials used included tool steel, stainless steel, aluminum and specially annealed oxygen-free copper for the particular densities and electrical properties required on this application.

Functionally, the highly collimated electron beam travels through the undulator, where its motion is modified by a series of alternating magnets to create radiation saturation and the coherent alignment structure of the beam. This occurs in a two-mile section of the linear accelerator. First light was generated in April, 2009, light to the instrument was achieved in August of that year and the project was completed for commercial utilization in the summer of 2010. This $415 million project was completed by ANL on time and under budget.

Overall, the undulator section measures 433’ and runs in a 600’ section of the tunnel at SLAC. All the assemblies were built and tested at ANL in Illinois, then transported for assembly and final commissioning at Stanford. A Beam Position Monitor checks the dimension and orientation of the beam to sub-micron levels of accuracy.

For further information on this story, please contact:

M-1 TOOL WORKS INC.

1419 S. Belden Ave.

McHenry, IL 60050-8399

Phone: 815-344-1275

Fax: 815-344-1950

Web: www.m1toolworks.com

Email: ray.lindberg@m1toolworks.com

Attention: Ray Lindberg, Sales Manager

Agency contact:

Tim Daro

Bernard & Company

847-934-4500

tdaro@bernardandcompany.com

The unit has 7” insulated walls comprised of 5” of 2300°F ceramic fiber and 2” of 1700°F block insulation. The 6½” floor insulation is made of 4½” of 2300°F firebrick and 2” of 1900°F block insulation. The plate hearth is made of firebrick and is supported by firebrick piers.

Controls onboard No. 871 include a Partlow MRC 7000 recording and programming temperature controller and an electrically-operated vertical lift door.

For more information, please contact: THE GRIEVE CORPORATION, 500 Hart Road, Round Lake, Illinois 60073-2835 USA. Phone: (847) 546-8225. Fax: (847) 546-9210.

Web: www.grievecorp.com. Email: sales@grievecorp.com. Attention: Frank Calabrese.

Continue reading

A 600 CFM, 1/2-HP recirculating blower provides universal airflow to the oven. The oven is also equipped with positive latching door hardware, a solenoid operated door lock and an integral leg stand. Safety equipment is included for handling flammable solvents and the floor of the oven contains an explosion venting panel.

Controls onboard No. 898 include a digital indicating temperature controller, motor control push buttons and an on-off heat switch.

For more information, please contact: THE GRIEVE CORPORATION, 500 HartRoad, Round Lake, Illinois 60073-2835 USA. Phone: (847) 546-8225. Fax: (847) 546-9210. Web: www.grievecorp.com. Email: sales@grievecorp.com. Attention: Frank Calabrese.

Continue reading

Han-Kwang USA announces immediate availability of its new Series PL, specifically Model PL 3015, a long bed, 2D flying optic laser system capable of handling 60” wide x 120” long workpieces. With a long bed gantry arrangement, less motion is required on the machine, providing greater working stability and reduced maintenance requirements.

Model PL 3015 features rapid single axis speed of 4724 ipm, simultaneous X-Y axis speed of 7900 ipm and maximum cutting speed of 1181 ipm, all with positioning accuracies better than +/- 0.004” per 118” of travel and repeatability to 0.001”. A dual shuttle pallet system is onboard to maintain optimum productivity in processing.

This Han-Kwang laser system features a powerful Panasonic CO2 laser resonator in 2, 2.5, 4 and 6 KW versions, as well as the builder’s patented beam radius control, which optimizes the beam

All machine mechanical movements and laser cutting operations are controlled by the powerful Siemens SINUMERIK 840D CNC. With its open architecture, 10GM hard drive and plain language commands, the CNC enables faster start-up and reduced time to first part for the programmers and operators alike. Further, a remote service support feature allows online communication to the CNC manufacturer for troubleshooting assistance.

An optional rotary axis is available for tube cutting up to 12” OD with this Han-Kwang laser system. Fully automated materials handling systems, pallet towers and other equipment for production improvement are also offered by the company.

For more information, the name of a local Han-Kwang dealer or to arrange a demonstration, please contact:

HAN-KWANG USA INC. 1120 Garfield Street Lombard, IL 60148 Phone: 630-916-0200 Fax: 630-916-0300 Web: www.hankwangus.com Email: salesusa@hankwang.co.kr Attention: Robert Won or Erik Kim

Siemens CNC controls all machine movements, allows remote service support

Editor note: Robert Won, director for North American operations, is available for interviews to discuss the company, its laser technology and other aspects of the industry. Han-Kwang is Korea’s largest laser builder and the company has embarked on an aggressive marketing effort in North America.

Agency contact: Tim Daro Bernard & Company tdaro@bernardandcompany.com 847-934-4500

Continue reading

The unit has 4” insulated walls and a Type 304, 2B finish stainless steel interior with continuously welded seams. The exterior is finished in white epoxy paint and has a #4 brushed finish stainless steel door cover and control panel face.

A 600 CFM, 3/4-HP recirculating blower provides horizontal airflow to the oven and a 24” x 24” x 6” thick stainless steel high temperature HEPA recirculating filter helps to purify the air to the Class 100 standard. The oven is also equipped with a 12” x 12” x 6” thick HEPA fresh air filter with 2” prefilter. Safety equipment is included for handling flammable solvents, including explosion venting door hardware.

Controls onboard this Grieve cleanroom oven include a digital programming temperature controller and SCR power controller.

For more information, please contact: THE GRIEVE CORPORATION, 500 Hart Road, Round Lake, Illinois 60073-2835 USA. Phone: (847) 546-8225. Fax: (847) 546-9210. Web: www.grievecorp.com. Email: sales@grievecorp.com. Attention: Frank Calabrese.

Continue reading

The unit has 7” thick insulated walls, comprising 5” of 2300°F ceramic fiber and 2” of block insulation. The 7” floor insulation contains 4 1/2” of 2300°F firebrick and 2-1/2” of block insulation.

Controls onboard No. 862 include an automatic door switch to drive burners to low fire when the door is opened and an air-operated vertical lift door. All safety equipment required by the IRI, FM and the National Fire Protection Association Standard 86 for gas-heated furnaces is also included.

For more information, please contact:

THE GRIEVE CORPORATION

500 Hart Road

Round Lake, IL 60073-2898

Phone: (847) 546-8225

Fax: (847) 546-9210

Web: www.grievecorp.com

Email: sales@grievecorp.com

Attention: Frank Calabrese, VP

STAMA unveils a new concept in multi-spindle machining

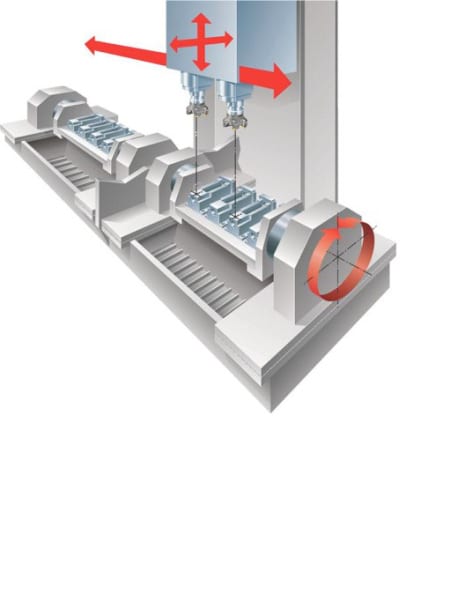

The “2 Plus 4” principle has represented the most economical and efficient means of multi-spindle machining in manufacturing. STAMA has implemented this principle, with 2 spindles and 4 clamped workpieces, in hundreds of existing projects worldwide, resulting in radically reduced cost per part scenarios for its customers. In today’s highly competitive market, however, STAMA has recently conducted discussions with its customers concerning greater factory floor utilization and “non-productive” capacity, leading to the question, are more than 2 spindles – perhaps even 4 – for the simultaneous machining of workpieces, economically more reasonable? This challenge has sparked an interesting development at STAMA, the 4-spindle TWIN2 concept that’s now being introduced to the world market for multi-spindle machining applications.

In answering this 2 vs. 4 question, a shop must first verify which productivity upsides will be realized by this concept. Figure 1 below shows the productivity benefits with a 4-spindle solution on completely different manufacturing processes with different primary machining times. Contrary to the “logical” expectations, the 4-spindle solution with 4 clamped workpieces doesn’t result in double the output, compared to a 2-spindle production with 4 clamped workpieces. In the relationship between the primary machining time and the overall cycle time of the process, the actual output will usually increase by 60% to 70% by adding 2 more spindles. Individual exceptions with short time-consuming machining operations can reflect an increase of more then 80%, according to STAMA research.

While twin spindle machining needs to double the capacity of the tool magazine, the four spindle solution requires a tool magazine to handle four times as many tools. The STAMA MC 531/TWIN² is equipped with 56 tool places in the standard version, for example, with options for magazines up to 120 tools.

One major key in four spindle machining, with short tool-to-part contact times, is the load and unload sequences of the workpieces. In such cases, as long as the machine isn’t equipped with a quick automatic loading/unloading system, pendulum machining is more advisable. This ensures parallel machining time while loading new workpieces. Time for loading and unloading can then be as long as the actual cycle time of the machine. This will also result in less time when the operator is interacting with the machine, thereby allowing the operator to run multiple stations in a work cell set-up, while keeping a constant touch time protocol on each machine.

Under these conditions, for many workpieces studied by STAMA and its customers, the “4 Plus 4” solution can result in major cost per part reduction. With over 25 years’ experience in TWIN spindle technology, the simplicity of a common Z-headstock for twin spindles from STAMA is well accepted and proven technology worldwide. The simplicity of this system is also used throughout this new TWIN² technology. Incorporating a state-of-the-art tool presetter, even single spindle manufacturing challenges with high accuracy demands can be realized with multi-spindle technology. The outstanding productivity and high workpiece quality achievable are the benchmarks by which STAMA TWIN spindle centers are known. The expansion to this 4-spindle TWIN2 machining center technology is the logical consequence of the company’s latest research and machine development strategies.

Already in full production use at a STAMA customer in one of the BRIC markets is a new four-spindle TWIN2 machining center, currently doing ABS housing manufacturing and connecting rod machining. This success for STAMA evidences the simplicity and practical application of the company’s highly productive manufacturing equipment.

Excellence in Manufacturing…the keystone of STAMA

STAMA America is the U.S. subsidiary of STAMA Maschinenfabrik GmbH in Germany.

For more information or to arrange a demonstration, please contact:

STAMA America 1063 Hawthorne Drive Itasca, IL 60143 Phone: (630) 233-8101 www.stama-america.com simon.knecht@stama-america.com

Simon Knecht, Director of Sales

PR agency contact: Tim Daro Bernard & Company 847-934-4500 tdaro@bernardandcompany.com

Continue readingCHICAGO, IMTS — At this year’s International Manufacturing Technology Show (IMTS) in Chicago, Siemens will introduce new solutions and services for machine tool manufacturers and end-users. Under the theme, “Productivity in motion,” the presentation will focus on turnkey solutions for the job shop, aerospace, automotive, mold and die and medical manufacturing industries.

For machine tool builders and end-users, Siemens will exhibit the newest innovations in CNC (computer numerical control), motor and drive technology as well as new value-added services ranging from condition monitoring and manufacturing IT to innovative solutions for CNC training and machine tool retrofit.

SOLUTIONS FOR THE JOB SHOP

For the job shop, the new Sinumerik 828D numerical control will be presented for the first time in the United States. Perfect for mid-range machine tools, the Sinumerik 828D is designed to address the needs of complex milling and turning machines in the job shop segment. It combines CNC, PLC, operator panel and axis control for six CNC measurement circuits in a single, robust operator panel.

The Sinumerik 828D is capable of full graphical, high-level language command and supports ISO programming that is customary in the United States. The new control is ideal for single-part and small-batch production. Programming time can be further reduced for small-batch production with the use of the ShopMill and ShopTurn graphical workstep programming system, while high-level language programming can be used in conjunction with programGuide to significantly reduce programming times for large-scale serial production.

With the introduction of the Sinumerik 828D, modern PC and mobile phone technology is now available to the mid-range machine tool. Extensive online help animations and a new type of input prompting system with moving picture sequences provide the basis for exceptional user convenience. USB, Compact Flash (CF) card and Ethernet ports enable high-speed data transfers onto storage media or integration of the control system into corporate networks. Through the use of its Easy Message functionality, the Sinumerik 828D offers production status monitoring by text messaging (SMS). Depending on the recipient’s profile setting, the machine will transmit information about workpiece machining status, report on the tool condition currently in use and send machine maintenance bulletins to a mobile phone, anytime and anywhere. These combined functions are designed to help keep machine downtime to a minimum.

For the aerospace market, the new Sinumerik 840D solution line is the latest in CNC technology that increases performance and user productivity. The Sinumerik 840D sl is a universal and flexible CNC system featuring the innovative Sinamics S120 drives that can be used for up to 31 axes. It is a distributed, scalable, open and inter-connecting system offering a wide range of specialized functions for milling, drilling, turning, grinding and handling technologies.

The Sinumerik 840D offers users innovative features that increase productivity on the manufacturing floor, especially the challenging segments of high-speed and five-axis aerospace machining.

SOLUTIONS FOR AUTOMOTIVE

In the automotive industry, Siemens continues to solidify its position with the Transline System Solution, the solution for automotive powertrain. This system integrates diverse metalcutting technologies such as milling, drilling, turning and grinding, and the assembly of powertrain parts, under a common system architecture. Since its implementation in 1993 at the Mercedes Benz NVM engine plant in Bad Canstatt, Germany, Transline has grown to become a recognized standard of excellence in the United States among both OEMs and end-users.

Based on the new Sinumerik 840D solution line and Simatic PLC, the Transline solution line transforms the company’s concept of “productivity in motion” into a real world application for total factory automation. By specifying Transline, machine tool users benefit from faster start-up times, better equipment serviceability and increased productivity.

SOLUTIONS FOR MANUFACTURING EXCELLENCE

Condition Monitoring and Manufacturing IT are two value-added services that are continuing their introduction to the U.S. machine tool market.

Condition Monitoring is an internet-based service from Siemens that supports maintenance processes while simultaneously forming a platform for cross-company service and support between OEMs and machine operators. Services can be configured over secure Internet connections from anywhere in the world via a standard PC, an internet connection and a web browser.

Manufacturing IT solutions from Siemens provide software tools for fast, easy integration of machines in a production network, while ensuring that production planning, scheduling and execution is always problem-free and based on the very latest data.

An entire line of powerful software modules for production machines ensures optimum integration of the machines in the IT-environment and supports a wide range of different functionalities including:

SOLUTIONS FOR CNC TRAINING

SinuTrain, the Siemens package of CNC training software on CD-ROM, provides milling and turning machine operators with a high degree of practical hands-on experience, prior to using the CNCs on their actual machines. It is designed to run on Windows XP operating systems and is the optimal solution for machine tool control-identical simulation training.

With SinuTrain, actual NC programs are developed and simulated, using a direct connection to the company’s CAD systems to further speed the program generation protocol. In this way, machine tool operators not only learn the control language commands, but they also visualize part programs on a P

C screen that are identical to the actual machine screen. As a further benefit, programs generated through SinuTrain on the PC software can then be used on the machines.

Other exhibits on display in the Siemens booth include the new 1FK7 high-inertia and 1PH8 servomotors, integrated motor spindles, linear motors and direct-drive torque motors that contribute to the increase in machine performance. The exhibition will also focus on machine tool retrofit, field service, customer service, spare parts and repair, all of which support the machine tool manufacturer and end-user.

For product information and inquiries:

SIEMENS INDUSTRY, INC.

DRIVE TECHNOLOGIES

MOTION CONTROL

MACHINE TOOL BUSINESS

390 Kent Avenue

Elk Grove Village, IL 60007

Phone: 847-640-1595

Fax: 847-437-0784

Web: www.usa.siemens.com/cnc

Email: SiemensMTBUMarCom.sea@siemens.com

Attention: John Meyer, Manager, Marketing Communication

Follow us on Facebook: www.facebook.com/SiemensCNC or Twitter: www.twitter.com/siemens_cnc_us.

—

Siemens Industry Sector is the world’s leading supplier of innovative and environmentally friendly products, solutions and services for industrial customers. With end-to-end automation technology and industrial software, solid vertical-market expertise, and technology-based services, the sector enhances its customers’ productivity, efficiency and flexibility. With a global workforce of more than 100,000 employees, the Industry Sector comprises the Industry Automation, Drive Technologies and Customer Services Divisions as well as the Metals Technologies Business Unit. For more information, visit http://www.usa.siemens.com/industry.

The Siemens Drive Technologies Division is the world’s leading supplier of products, systems, applications, solutions and services for the entire drive train, with electrical and mechanical components. Drive Technologies serves all vertical markets in the production and process industries as well as the infrastructure/energy segment. With its products and solutions, the division enables its customers to achieve productivity, energy efficiency and reliability. For more information, visit http://www.usa.siemens.com/drivetechnologies.

Continue reading

Han-Kwang USA recently attended the Fabtech Mexico show, co-located with the Metalform and Weldmex shows. Over 8000 visitors per day were in attendance to see over 400 exhibitors and hundreds visited the Han-Kwang booth to watch the company’s plate laser, Model FS3015, in action. Onsite for this exhibition were Han-Kwang’s director of North American sales, Robert Won, as well as engineer Philip Kim and the company’s distributors in Mexico.

Mr. Won commented, “The Mexican market has been excellent for Han-Kwang. We’re assisted by a very strong distributor, who has an extensive sales and service network to cover the entire region with us. Our sales recently have been quite strong, because of the quality of our machines and the quality of our representation in Mexico. I believe this will continue to be a very good market for our plate and tube lasers into the future.”

The FS3015 is a 5’ x 10’ plate laser with shuttle tables, flying optic design, fast-axial flow type Panasonic resonator, S5 high-speed cutting head, twin servos for precise gantry motion and Siemens CNC, motors and drives to power and control the machine’s total operation. This plate laser is available in 2, 2.5, 4 and 6KW models to handle any type of plate cutting with speed and precision position accuracy to +/- 0.004” per 120” of travel. The machine also has automatic focus control with multi-pulse piercing technology, unique to Han-Kwang.

This machine was specifically chosen for display at the booth during Fabtech Mexico, because of its performance and value combination for the local market.

Han-Kwang enjoyed a very successful exhibition at Fabtech Mexico, held May 11-13

For more information or to arrange a visit to Han-Kwang for a demonstration, please contact:

HAN-KWANG USA INC. 1120 Garfield Street Lombard, IL 60148 Phone: 630-916-0200 Fax: 630-916-0300 Web: www.hankwangus.com Email: salesusa@hankwang.co.kr Attention: Robert Won, Eric Kim or Jane Lee

Agency contact: Tim Daro Bernard & Company tdaro@bernardandcompany.com 847-934-4500

Continue readingFull product families, plus downloads of literature, CAD files, video and more are available at new website

Advanced Machine & Engineering Co., (AME) Rockford, IL announces the unveiling of www.ame.com, the company’s new corporate website. AME is a world leader in spindle interface and related machine tool components, plus metalcutting sawing systems, hydraulic/pneumatic rod locks, safety catchers for presses and other machinery/equipment/vehicle operation, as well as the company’s most recent acquisition, the Stotz brand of air gages for high-precision metrology. The company and its sister divisions together constitute the Goellner Group, an international company in service to the machine tool and related industries.

At the new website, visitors can easily navigate through the full spectrum of product families, organized by market and product type with application notes. Downloads are offered on product literature, CAD files for engineering integration, operational and informative videos, plus a unique ISO calculator that provides complete tolerance data on shafts and bores with the quick input of some key parameters.

Beyond the impressive product and equipment range, the many other services offered by the company, including product engineering, contract manufacturing, inspection, custom machine builds, repair, rebuilding and refurbishing are also detailed.

Finally, users can quickly locate both the group contacts for all engineering, sales and service functions, based on the particular products needed, as well as the North American sales network of the company. An area is also provided for accessing current and upcoming event information at the company, plus career opportunities and other news.

Advanced Machine & Engineering Co., located in Rockford, Ill., is a global manufacturer and distributor of precision machine components, fluid power components, fixturing/workholding, power drawbar and spindle interface components, and carbide sawing machines and blades, plus turnkey metalcutting saw systems. The company also designs and builds special machines for a variety of industries and provides machine rebuilding, retrofitting and contract manufacturing services. AME has partners and customers around the world and across the U.S. To learn more, visit www.ame.com.

For more information, contact:

Tim Waterman

ADVANCED MACHINE & ENGINEERING CO.

2500 Latham St.

Rockford, IL 61103

Phone: 815-316-5277

Fax: 815-962-6483

E-mail: info@ame.com

Connect with AME online: