Contact us today:

(847) 934-4500

tdaro@bernardandcompany.com

Contact us today:

(847) 934-4500

tdaro@bernardandcompany.com

Gear/Gearbox company names new manufacturing and marketing managers as growth continues

Excel Gear, Inc. of Roscoe, Illinois announces the appointment of Denis Bermingham as the manager of manufacturing engineering and special projects, plus William “Bill” Powers as the company’s marketing manager. Both appointments were made by company president N.K. “Chinn” Chinnusamy, who noted these hirings were made as the result of the company’s recent growth and anticipated expansion into new market segments.

Bermingham brings a strong engineering background in metalworking and machine tool building to his new position, as well as an extensive knowledge of metallurgy and heat treatment. He will oversee Excel’s manufacturing engineering and special projects, as well as continue the company’s ongoing implementation of lean manufacturing strategies. Denis brings 30 years of manufacturing and machine tool experience to Excel Gear. He worked the majority of his career at Ingersoll Milling Machine in Rockford, IL in the Manufacturing Engineering, Assembly, Engineering, and Prototyping departments. He has a degree in Industrial Technology and will be responsible for the various manufacturing functions at Excel.

He notes, “I joined Excel Gear to become part of the technical/manufacturing environment here. We can offer customers innovative solutions, with excellent quality and value. I’m very excited to be part of this team.”

Powers brings 30 years’ experience in the gear and machine tool business to Excel. Formerly an account manager, project manager and supervisor of customer training with Ingersoll, as well as other metalworking/automation systems firms, he has handled various sales, marketing and customer relations functions, giving him a well-rounded perspective on the dynamics of the industry. He has a degree in Business Administration and will oversee all the marketing and business development for Excel.

Bill observes, “Chinn has structured a first-class company at Excel, supplying engineering-based products, brought to market by a very highly-skilled and dedicated team. All customers receive the highest quality possible, backed by service and application assistance that’s second to none. It’s a great working environment and I look forward to the challenges of our changing markets.”

For more information on these appointments, please contact:

EXCEL GEAR, INC. 11865 Main Street, Roscoe, IL 61073. Phone: 815-623-3414 Fax: 815-623-3314 Web: www.excelgear.com Email: sales@excelgear.com N.K. Chinnusamy, President

ABOUT EXCEL GEAR

Excel Gear brings over 50 years of machine tool experience to the design, manufacturing and quality analysis of its various gear, gearbox, fluid bearing, spindle, CNC gimbal head, nutator and special equipment production. ANSYS software for FEA on stress, strain, deflection, as well as modal analysis, time and frequence domain, our Spindle Analysis Program, MATLAB/Simulink, AutoCAD/SolidWorks/CADAM and other programs are all utilized to effect the best solutions to customer requirements. Excel also builds two-axis CNC gimbal heads with 20,000RPM motorized spindle, 15,000RPM cartridge type spindle assemblies and CNC rotary tables for major machine tool companies. Our high-accuracy gear grinding equipment produces to AGMA 15 (DIN 2) tolerances for quality that meets or exceeds the increasing customer demands for high-speed and high power transmission with smooth, quiet operation. Recently, the company has entered the emerging wind turbine market to provide various gears and gearbox components.

PR agency: Tim Daro Bernard & Company tdaro@bernardandcompany.com 847-934-4500

Continue reading

Stotz Feinmesstechnik GmbH has been a leader in gaging technology for almost 60 years. They design, manufacture and sell air-electronic gages and control devices. They are constantly striving to improve their designs and develop new products to solidify their position as a leader in new measuring technology. Numerous patents within the last few years have solidified their position as a trendsetter for new measuring technology and pneumatic measuring systems. Their diverse customer base covers many industries, including manufacturers and suppliers in the automotive, aerospace and medical industries. Stotz gages can be manufactured to measure I.D., O.D. out-of-round, straightness, parallelism, perpendicularity, flatness, taper, match grinding applications and many other geometric tolerances. Air gaging is a very easy-to-use method of measuring and requires no special training, plus it is non-contact technology, so it does not mark the parts. The measurements are extremely accurate and very fast. There are no mechanical moving parts; therefore, air gages have a very long life expectancy. The gages, coupled with the Stotz advanced line of air-electronic columns, make the integration into a user’s measuring system an easy transition. This is true for both simple table top systems as well as more complex robotic measuring cells with feedback to machine tools as well as integrating with an SPC program. Some common parts that are measured using air gages are fuel injection components, transmission components, hydraulic components, bearings, connecting rods, crankshafts, camshafts, valve seats, hip stems, surgical screws and many different tapers such as HSK, CAT, BT, KM, Morse and Jacobs, both the male and female portions.

Advanced Machine & Engineering Co., is a manufacturer located in Rockford, IL, serving the Machine Tool Industry with precision components and accessories, including spindle interface components, workholding devices, and, through our sister company, Hennig, machine enclosures, chip removal and filtration systems. The Fluid Power – Safety markets are served with cylinder rod locks and safety catcher devises; and the Production Saw market with our Amsaw carbide saw machines and Speedcut blade products. AME has manufacturing partners and customers around the world and across the U.S. To learn more, visit www.ame.com.

Hennig, Inc. design and produces custom machine protection and chip/coolant management products for state-of-the-art machine tools. Hennig products are designed to protect against corrosion, debris and common workplace contaminants. Manufacturing facilities located in the U.S., Germany, Brazil, India, Japan, China and South Korea. Repair centers are located in Machesney Park, IL; Chandler, OK; Livonia, MI; Blue Ash, OH; Mexico City, Mexico and Saltillo, Mexico. To learn more, visit www.hennigworldwide.com.

For more information, contact:

Tim Waterman

ADVANCED MACHINE & ENGINEERING CO.

2500 Latham St.

Rockford, IL 61103

Phone: 815-316-5277

Fax: 815-962-6483

E-mail: info@ame.com

Connect with AME online:

Question:

“We’re really rethinking our rep/dealer/distributor force, in this internet age. What are your thoughts?”

Our President’s point-of-view…

Some companies, having actually received orders off their online rfq forms, have stumbled into thinking they no longer need those vital links (no pun at all, believe me) in their sales chain, namely, their reps, dealers, distributors or even their offshore agents. They tell us the age of the internet obviates the need for such personnel and the corresponding cost.

They are just plain wrong.

For numerous reasons, not the least of which are the local representation in a business community by someone who’s known to it AND the corresponding frequency of contact made, you all need these folks fronting your product message. For years, we’ve told our industrial clients that they’re not in the mail order or retail business. That’s as true today, even in the age of instant online purchases and even, I admit, in the age of one client who sold an $88,000 piece of equipment directly from their website to a company they’d never sold previously.

Your front line troops are exactly that, your first line of attack (or sometimes defense, when the internet rumors fly) in the market. Beyond sales contacts, they provide customer assistance in many, often unseen ways. We’ve worked for dozen of electrical clients over the years and there is no industry with a more multi-layered distribution channel to reach the various OEM, contractor and end user segments of that huge market. Quite naturally, the electrical market was one of the first ones we serve where clients began to think they could do quite nicely, eliminating a link in the sales chain. The smart ones have realized it’s not true, as each played and still plays a vital role in product delivery, but even more-so in product conditioning, product persuasion, product positioning and product promotion. Yes, just as their advertising, PR, direct/blast emailings, trade shows and other promotional tactics do, the reps, distributors and wholesalers in the territories each play a role in helping the overall marketing communication effort succeed.

Companies who overlook that fact are just dumb and will likely suffer the consequences of such short-sighted thinking.

The same applies to you capital equipment companies and even you contract manufacturers who might consider eliminating your reps or dealers. “Gee, Tim, we build a lot of custom stuff and our engineers can handle most everything online. We really wonder if those other guys are necessary.” The answer is a resounding YES. It’s a collateral consequence of the internet that MORE companies who once sold locally or regionally can now do business nationwide, even worldwide, owing to the online communication channel. However, along with this broader business base come all those “local” factors that must be taken into account. These might include local electrical codes, shipping restrictions, installation challenges and, on the international scene, currency and other cultural considerations. Having at least some regional representation can be very helpful in this process.

One longtime client of ours devotes an entire page of their catalog to extol the virtues of their reps, detailing the company’s philosophy for their use. Call me, I’ll share it with you, as I’ve handled the client personally for 35 years and wrote that page myself!

-TD

email Tim

Our Director of Social Media’s point-of-view…

The point of social media is to make you and/or your company MORE accessible, not less human. Social media should be used to help give your company and your products life and a personality.

Human connection; having a real person answer questions, solve problems and attend to clients or potential clients needs is still a necessary part of a thriving business.

One should not replace the other, they should work hand-in-hand to support each other.

-Wendy

email Wendy

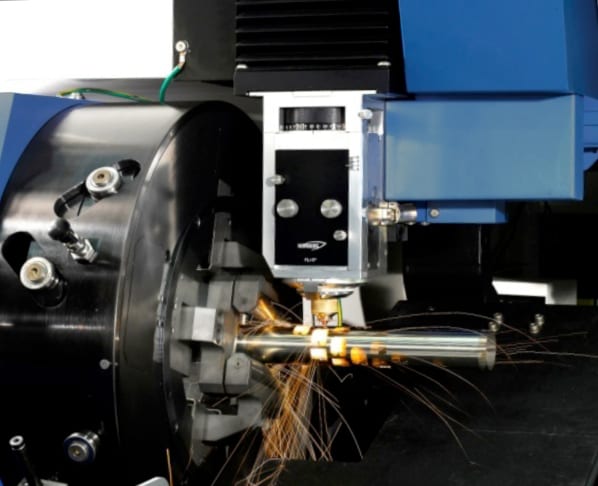

Han-Kwang USA announces the opening of its new 13,000 square-foot Chicago-area facility with showroom for laser machine demonstrations, as well as application engineering, parts and service departments. Typically, the new showroom will house multiple plate and tube cutting laser machines for customer use in test cuts and time studies, plus interested parties can see these powerful CO2 lasers in action, when considering a purchase or investigating laser technology for their shops and in-house fabrication processes.

In announcing this opening, Han-Kwang USA VP Robert Won commented, “This showroom is a further step in our company’s long-term commitment to the North American market. We have worked hard over the recent years to develop our business, build relationships with our North American dealer network and especially support our customers with the latest technology and application assistance.”

The parts department is fully stocked with all key consumable and mechanical components for the full range of Han-Kwang lasers currently in the field and offered by the company, including the new PS, PL and TL plate and tube cutters.

Additional key personnel at this new facility include Eric Kim, operations manager, and Jane Lee, administrative assistant.

For more information or to arrange a visit, please contact: HAN-KWANG USA INC. 1120 Garfield Street Lombard, IL 60148 Phone: 630-916-0200 Fax: 630-916-0300 Web: www.hankwangus.com Email: salesusa@hankwang.co.kr Attention: Robert Won, Eric Kim or Jane Lee.

Agency contact: Tim Daro Bernard & Company tdaro@bernardandcompany.com 847-934-4500

Release: HAN-KWANG USA INC.

Date: April 1, 2010

Continue readingHunter to represent Maus in U.S., Canada and Australia for grinding machine sales and service

This announcement was made by Maus CEO, Roberto Sammartin, and Hunter President, Bill Hunter.

Maus is a major supplier to the world foundry market of surface grinding and riser cutoff machinery, as well as automated work cells and complete transfer lines. The U.S. operation of Maus is based in Virginia Beach, Virginia.

Hunter Automated Machinery is likewise a longtime leading supplier to the foundry market, having pioneered automated matchplate molding machinery for sand casters. Today, through various affiliate and representative agreements, Hunter also brings a broad line of automated mold handling, core resetters and sand prep testing equipment to foundries worldwide. Hunter operates facilities in the U.S., Brazil, China and Italy.

According to Sandra Selwan, marketing manager for Maus in Italy, “We see great potential in this agreement, as our machines will now be represented by a name known to foundries worldwide. Coupled with our machine quality and innovative engineering, Maus believes the synergy between our company and Hunter will produce substantial mutual benefit.” Ms. Selwan made these comments from the CastExpo, where both companies were exhibiting their machinery and engineering capabilities to metalcasters from every corner of the world.

For more details, please contact:

MAUS SpA

Via Caltana, 28 35011 Campodarsego Padova, Italy

Phone: +39 0499299311

Email: Sandra_Selwan@maus.it www.maus.it

Attention: Sandra Selwan, Marketing Manager

MAUS USA

2505 International Parkway Virginia Beach, VA 23452

Phone: (757) 689-3725

Fax:(757) 689-2973

Web: www.maus.it

Email: Alberto.fabris@mausna.com

Attention: Alberto Fabris, VP

HUNTER AUTOMATED MACHINERY CORPORATION

2222 Hammond Drive Schaumburg, IL 60196

Phone: (847) 397-5110

Fax: (847) 397-8254

Email: info@hunterfoundry.com

Web: www.hunterfoundry.com

Conect with Hunter Foundry online:

Graham detailed the offer, saying it would apply to any make or model of rubber or TPE injection press. REP requires the molder to validate the scrapping of their old machine, thereby earning a predetermined credit, based on the old machine’s age and condition. The credit, up to $40,000, can then be applied to the purchase of any new REP injection press in the G9 series.

He further noted the advantages of a new machine. “Besides the higher quality parts a molder can produce, owing to the level of mold mechanics, material flow and control sophistication, a new press consumes less energy, has less downtime and less maintenance requirements, so it stays in production. Even REP presses from our earlier generations cannot match the productivity and resulting profitability of a new G9 machine. That’s not a brag, it’s a fact and it’s one we can document,” he said, noting the new machines offer better molding strategies, improved ergonomics and faster payback for the customer.

“It’s an offer you can’t refuse,” Graham joked.

REP Corporation is responsible for all sales and service in North America. However, this offer is being made to rubber molders worldwide by REP, based in Lyon, France.

For more information, please contact: REP CORPORATION 8N470 Tameling Court Bartlett, IL 60103-8146 Phone: 847-697-7210 Fax: 847-697-6829 Web: www.repinjection.com Email: tgraham@repcorp.com Attention: Tim Graham, President

PR agency contact: Tim Daro Bernard & Company 847-934-4500 tdaro@bernardandcompany.com

Continue reading

The unit has 4” insulated walls, an aluminized steel exterior and Type 430 stainless steel interior. It is also equipped with an integral leg stand with casters and leveling pads.

Controls onboard No. 945 include a digital indicating temperature controller, manual reset excess temperature controller with separate contactors, recirculating blower airflow safety switch and SCR power controller.

For more information, please contact: THE GRIEVE CORPORATION, 500 Hart Road, Round Lake, Illinois 60073-2835 USA. Phone: (847) 546-8225. Fax: (847) 546-9210. Web: www.grievecorp.com. Email: sales@grievecorp.com. Attention: FrankCalabrese.

NEWS RELEASE: THE GRIEVE CORPORATION Agency contact: Tim Daro 847-934-4500

DATE: March 22, 2010

Continue reading

The unit has 4” insulated walls and an aluminized stainless steel interior and exterior. A 3300 CFM, 2-HP recirculating blower provides horizontal airflow to the oven. Safety equipment, such as a 325 CFM 1/3 powered force exhauster, is included as required by the IRI, FM and the National Fire Protection Association Standard 86 for gas-fired equipment. The oven also features a 2” insulated floor with truck wheel guide tracks and a removable top-mounted heat chamber.

Controls onboard No. 813 include a recirculating blower airflow safety switch, circular chart temperature controller and a manual reset excess temperature controller.

For more information, please contact:

THE GRIEVE CORPORATION

500 Hart Road

Round Lake, Illinois 60073-2835

USA

Phone: (847) 546-8225

Fax: (847) 546-9210

Web: www.grievecorp.com

Email: sales@grievecorp.com

Attention: Frank Calabrese

By using a Zimmermann FZ42 portal milling center, Volvo gets the power and torque needed to cut engine fan cases plus the accuracy to turn the machine tool into a coordinate measuring machine for inspection of finished parts

Located near Hartford, Conn., Volvo Aero Connecticut specializes in the machining of large components: fan cases for aircraft engines and gas turbines, fan and compressor structures, compressor rotors, low-pressure turbine cases (LPT) and military parts, usually from aluminum and titanium, as well as Inconel and Waspaloy. It currently manufactures the largest fan casing in the world, at 3.5 meters (11.5 feet) in diameter, for the massive GE90, the only aircraft engine in existence providing 127,900 pounds of thrust, to power the Boeing 777 line. Volvo Aerospace also produces numerous titanium fan cases for Rolls Royce engines.

With the large workpieces, high material removal rates and challenging geometries inherent in aerospace metals manufacturing, coupled with substrates that are often difficult to machine, such as titanium, there is always a need for powerful machining with superior accuracy. Such conditions present substantial hurdles at aerospace supply companies, as they seek to maintain that delicate balance between these seemingly opposing concepts.

As part of its program for the GEnx engine, to be used on the Boeing 787 Dreamliner, Volvo Aero Connecticut recently added a Zimmermann FZ42 machine tool, a five-axis, five-side portal milling center, to its already impressive manufacturing cells at the Hartford facility. The new machine joins other five-axis mills, vertical turning machines, four-axis machining centers and a deburring robot.

Key features on the FZ42 that led Volvo Aero Connecticut to make this acquisition included:

In addition, this FZ42 carries a high accuracy package that provides optimum temperature control of the structural machine parts through the use of a special fiber-reinforced compound in the massive side columns. Also facilitating this process are built-in cooling ducts in the portal and Z-axis slide, independent cooling circuits for the A-axis, C-axis and spindle, ground surfaces on the guideways for the Z-axis and side columns, plus a double-pitch measuring system on the A-axis and C-axis.

During the course of manufacturing, thermal expansion of both machine components and workpieces can substantially impact the positioning accuracy of the machine, the stability of the workpiece and the resulting effect on the finished part dimensions. This unique combination of temperature control and mechanical accuracy in the machine construction were an important deciding factor for Volvo Aerospace in acquiring the FZ42.

According to Martin Thorden, engineering manager at Volvo Aero Connecticut, “These features, combined with the onsite machine set-up provided by Zimmermann, were very important to us, especially on this new GEnx project.” Thorden further noted the importance of the control on the machine, a Sinumerik 840D CNC from Siemens. “We see a very big benefit in how well we are able to control the tool with the CNC. We have been able to use the control to take on additional tasks that were previously handled by our CAD/CAM system.” Specifically, he cited the unconventional approach Volvo Aerospace took in machining the big fan cases. They installed the machine without a rotary table, thus realizing over $500,000 in direct cost savings plus material handling time. As a result of that decision, they believed they needed a top-of-the-line control to probe and accurately machine all the features on the part.

Volvo Aero Connecticut, located near Hartford, comprises three buildings, the largest being 40,000 square feet, where various aerospace and military aircraft components are typically produced from aluminum, titanium, Inconel and Waspaloy.

After machining, Volvo Aero Connecticut can actually transition the machine tool into a coordinate measuring machine for inspection, according to Thorden, owing to the superior accuracy provided by the CNC, as well as the special 90 degree angle heads supplied with the machine, part of the MuST® spindle technology from Zimmermann.

Onboard the machine tool, a massive 120-position tool carriage holds various HSK63 and HSK100 tools that are used to machine the substrates worked here. Inside a series of four side stations, within the machine workspace, four additional specialty tools are stored and used for various operations in the machining and measuring process.

All motors and the drive package onboard the Zimmermann FZ42 at this Volvo Aero Connecticut facility are also made by Siemens.

In a typical machining sequence, the milling head on this machine, equipped with the Zimmermann MuST® spindle system, provides Volvo Aerospace numerous other advantages, according to Martin Thorden. All roughing and subsequent finish passes on any material can be achieved in one set-up, which reduces the preparation time and overall production costs by as much as 10%. There is also no need for additional machines and the corresponding materials handling time. The head design further enables Volvo Aero Connecticut to perform tasks other than milling, using the specialty heads stored on the side stations. Changing the spindle, instead of the milling head, enhances repeatability and further reduces the company’s spindle interface costs, according to Thorden.

The combination of increased accuracies, reduced equipment needs and faster throughput has highlighted this Zimmermann machine installation at Volvo Aero Connecticut.

For additional product information and inquiries:

Zimmermann Inc.

Phone: 248-305-9707

Web: www.zimmermann-inc.com

Email: Matthias@zimmermann-inc.com

Attention: Matthias Tockook

Volvo Aero Connecticut

Phone: 860-667-8502

Web: www.volvoaero.com

Email: Martin.Thorden@volvo.com

Attention: Martin Thorden

Siemens Machine Tool Business

John Meyer

Manager, Marketing Communications

Siemens Industry, Inc.

(847) 640-1595

www.usa.siemens.com/cnc

SiemensMTBUMarCom.industry@siemens.com

Follow us on Facebook: www.facebook.com/SiemensCNC or Twitter: www.twitter.com/siemens_cnc_us.

—

Siemens Industry Sector is the world’s leading supplier of innovative and environmentally friendly products, solutions and services for industrial customers. With end-to-end automation technology and industrial software, solid vertical-market expertise, and technology-based services, the sector enhances its customers’ productivity, efficiency and flexibility. With a global workforce of more than 100,000 employees, the Industry Sector comprises the Industry Automation, Drive Technologies and Customer Services Divisions as well as the Metals Technologies Business Unit. For more information, visit http://www.usa.siemens.com/industry.

The Siemens Drive Technologies Division is the world’s leading supplier of products, systems, applications, solutions and services for the entire drive train, with electrical and mechanical components. Drive Technologies serves all vertical markets in the production and process industries as well as the infrastructure/energy segment. With its products and solutions, the division enables its customers to achieve productivity, energy efficiency and reliability. For more information, visit http://www.usa.siemens.com/drivetechnologies.

Continue reading

Automated loading and parts handling system complement state-of-the-industry laser and machine control technology

Han-Kwang USA announces immediate availability of its new Model TL 6015, a tube cutting laser system capable of handling 24’ long, 6.5” diameter workpieces up to 1/4” wall thickness in mild steel and 0.200” in stainless steel. Equipped with a powerful 2.5KW Panasonic laser and a versatile Siemens 840D CNC to control all functions of the machine, the TL 6015 can significantly increase the tube production in any department or shop, especially when used with Han-Kwang’s proprietary “Flex 3D” tube cutting software . The unit comprises an automatic bundle loading system with tube V-support, auto-centering rotary chucking system, laser cutting station and automatic parts removal station.

Maximum positioning speed on this new laser system is 4700 ipm for the X-

Han-Kwang S5 Cutting Head, featuring Auto Focus Control; adjusts focal length of cutting lens to automatically compensate for material variations and rapid changeover

axis and 120 rpm for the rotary A-axis. Max acceleration rate is 1G, while the laser beam is precisely controlled by the unique Han-Kwang Auto Focus Control (AFC). This AFC technology allows the machine to automatically adjust the focal length of the cutting lens to accommodate variations in the materials being processed or changes in material feed, which eliminates the downtime normally associated with manual adjustments.

A new generation of sensing board in the S5 laser cutting head on the TL 6015 translates into faster cutting speeds on round, square or rectangular shapes.

In a recent design modification, the entire loading section of the machine has been enclosed, as depicted in the attached illustration.

For more information or to arrange a demonstration, please contact:

HAN-KWANG USA INC. Phone: 630-916-0200 Web: www.hankwang.com

Agency contact: Tim Daro Bernard & Company tdaro@bernardandcompany.com www.bernardandcompany.com

Continue reading