Contact us today:

(847) 934-4500

tdaro@bernardandcompany.com

Contact us today:

(847) 934-4500

tdaro@bernardandcompany.com

Exact Metrology, a comprehensive metrology services provider, recently completed a job at Chicago Jet Group. Located in Sugar Grove, Illinois, the company started in 2003 with the idea of providing the highest level of professionalism and attention to detail in the corporate aviation industry. Chicago Jet Group specializes in aircraft acquisition, aircraft management, charter services, pre-purchase evaluation, aircraft avionics, aircraft consulting and aircraft maintenance. The company was retrofitting older Dassault Falcons avionics and needed a CAD model of the panel to see how it would fit.

Joe van der Sanden, application engineer from Exact Metrology, scanned the panel with an 85 series Hexagon Romer Absolute Arm. The Absolute Arm 7-axis delivers tactile probing and laser scanning in an ergonomic package. It is the best choice for ease of movement and ease of measurement. The flagship RS5 laser scanner offers high-speed 3D scanning

Reverse engineering was performed using Geomagic Design X. This software combines history-based CAD with 3D scan data processing and enables the creation of feature-based, editable solid models compatible with existing CAD software. Geomagic Design X allows users to re-use existing designs without having to manually update old drawings or re-measure and rebuild a model in CAD. This software is easy to learn and use, for it uses familiar history-based tools found in all major CAD products.

Chicago Jet Group was very pleased with the work performed by Exact Metrology and they would be happy to work with them again. A senior avionics technician at the company said, “This will save us months of measuring and drafting.”

Exact Metrology is ISO, AS9100 Certified as well as FFL and ITAR Registered.

Exact Metrology, with facilities in Cincinnati, Ohio, Moline, Illinois and Milwaukee, Wisconsin, plus affiliated offices throughout the country, is a comprehensive metrology services provider, offering customers 3D and CT scanning, reverse engineering, quality inspection, product development and 2D drawings. The company also provides turnkey metrology solutions, including equipment sales and lease/rental arrangements.

For information, please contact:

EXACT METROLOGY, INC.

Dean Solberg

20515 Industry Avenue

Brookfield, WI 53045

Local: 262-533-0800

www.exactmetrology.com

deans@exactmetrology.com

EXACT METROLOGY, INC.

Steve Young

11575 Goldcoast Drive

Cincinnati, OH 45249

Local: 513.831.6620

Toll Free: 866.722.2600

www.exactmetrology.com

stevey@exactmetrology.com

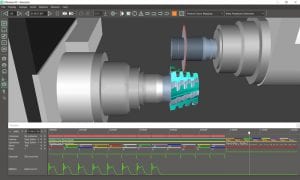

A sophisticated analytical hub provides increased intelligence on cutting tool designs to avoid costly collisions and missed calculations

Thomson Mathew, ANCA Software Product Manager says: “This upgrade responds directly to what our customers want and need for effective tool simulation. CIM3D V9 allows for customization based on regularly-used features no matter which industry. The simulation quality of ANCA’s software is unmatched and you can simulate complete grinding sequences.”

“We have automated many manual steps and introduced process verification and analysis in a central hub to get improved cycle time, and better wheel and tool life. Collisions can be detected automatically and overall CIM3D V9 is more enjoyable and easier to use.”

The new software offers clearer visualization with the customizable timeline panel – effectively a central dashboard for quicker and easier tool analysis. New tool programs can be verified for size, shape, machine clearance, cycle time estimates, and more.

Chris Wagner, Tool Grind Lead at Acutec Precision Aerospace, Inc. in the U.S has been using CIM3D for 20 years and can’t imagine going back to an earlier version after trialling the latest release. He said: “CIM3D V9 is worth its weight in gold. The new look and feel is current and clean. One of the best features is progressive grinding – it gives the ability to see the exact material being removed as the wheel moves through.”

“The resolution of the graphics is far better than any previous version. Determining protrusion length, cycle time estimation, using the scroll function on a mouse to increment the position, magnification and cross-hair positioning are other great features that make using CIM3D V9 more efficient and productive.”

ANCA’s software experts are in-house ensuring the features of CIM3D are responsive, user-friendly and tailored to the cutting tool industry.

The new features save time while simulating the programmed tool path exactly as it would be ground on the machine

UPDATED LOOK AND FEEL

BENEFITS: Ease of use, improved visualization and highly intuitive design

PROGRESSIVE MATERIAL REMOVAL

BENEFITS: Allows the user to view the state of the tool at any point of the grinding timeline

CLEAR VISUALIZATION WITH THE TIMELINE PANEL

BENEFITS: Central analysis hub for quick and easy access to save time

TOOL BALANCE ANALYSIS

BENEFITS: Ability to manufacture high performance cutting tools

SAVE TIME WITH BACKGROUND CALCULATIONS

Simplifies workflow by doing calculations in the background rather than having users kick this off. This saves time and the automatic display doesn’t allow for errors that are accidentally missed. Some of the tasks calculated automatically without needing to be initiated by users are:

BENEFITS: Simplifies workflow, saves time, less likely to miss collisions and reduced waiting time

MATERIAL REMOVAL RATE

BENEFITS: MRR can be used to optimize the feedrates for better wheel life and stable process

MEASUREMENT CAPABILITIES

BENEFITS: Quick and easy measurement methods to save time

CHANGES TO THE SECTIONING PLANE DIALOGUE

BENEFITS: Flexibility to measure any geometry on the cutting tools in any plane

MACHINE MODELS AND ACCESSORIES

BENEFITS: Additional accessories for improved collision detection analysis

For further information, please contact:

Sepideh Zandieh

PR and Communications Manager, ANCA

M: +61 439 316 131

Sepideh.Zandieh@anca.com

ANCA is a market leading manufacturer of CNC grinding machines. It was founded in 1974 in Melbourne, Australia where the company still has its global headquarters. ANCA has offices in the UK, Germany, China, Thailand, India, Japan, Brazil and the USA as well as a comprehensive network of representatives and agents worldwide. ANCA CNC grinders are used for manufacturing.

ANCA CNC grinders are used for manufacturing precision cutting tools and components across a diverse range of competitive industries including cutting tool manufacture, automotive, aerospace, electronics and medical.

ANCA website: www.anca.com

Continue reading

A new feature in the PolyWorks Inspector™ is multi-piece editing. Users can now make changes in one piece that can be propagated to other pieces. If a user has multiple pieces, they can make changes like creating, editing features, alignments, reporting items, etc. Then, these changes can be transmitted to past and future pieces/templates, create custom propagations or just apply the changes to the current piece. After choosing the propagate option, the user sees the changes in the other pieces and/or templates including report(s) or report items.

Another update of PolyWorks Inspector™ pertains to augmented GD&T. Center point features can now be reported with more capabilities. These include circularity, flatness, perpendicularity, etc. Users can also see MIN/MAX deviations and can view the color arrow deviation tags.

An online tutorial shows how to make sure the Hexagon Romer Absolute Arm is still in calibration. First, the bar artifact needs to be placed correctly to scan it. The ideal location is centered with the main axis of the arm at a distance away where it will be just below the elbow when the arm is extended out. To secure the bar, use pre-drilled tapped holes. They accept simple machinist fixturing to hold it in place. C-clamps can also be used to secure the bar to a rigid table. When doing a length checkout, only the 15 mm master probe should be used. Next, the user needs to open RDS Data Collector. Used with Hexagon Romer Absolute Arm, the software allows the operator to check the accuracy of the arm and probes and calibrate/align the probes and scanner as necessary. To start probing, move the probe to the first position. The probe needs to be properly seated in the conical feature at each end of the bar. Following the prompts in RDS, move the probe to the end conical features and pull the trigger to record a point. Once ten positions have been recorded, RDS will display the results. The MIN/MAX values should be below the standard values for the type of arm being used.

Exact Metrology is ISO, AS9100 Certified as well as FFL and ITAR Registered.

Exact Metrology, with facilities in Cincinnati, Ohio, Moline, Illinois and Milwaukee, Wisconsin, plus affiliated offices throughout the country, is a comprehensive metrology services provider, offering customers 3D and CT scanning, reverse engineering, quality inspection, product development and 2D drawings. The company also provides turnkey metrology solutions, including equipment sales and lease/rental arrangements.

For more information, please contact:

EXACT METROLOGY, INC.

Dean Solberg

20515 Industry Avenue

Brookfield, WI 53045

Local: 262-533-0800

www.exactmetrology.com

deans@exactmetrology.com

EXACT METROLOGY, INC.

Steve Young

11575 Goldcoast Drive

Cincinnati, OH 45249

Local: 513.831.6620

Toll Free: 866.722.2600

www.exactmetrology.com

stevey@exactmetrology.com

Exact Metrology, a comprehensive metrology service provider, is offering free training videos on the company’s YouTube channel. During these trying times, the company has started creating a series of training, tips and tricks, unboxing and product videos to provide additional information to their clients. The videos can be found at https://www.youtube.com/user/ExactMetrology/videos. Interested parties can bookmark the link and return often to see the latest creations.

The plan is to release three videos per week. The topics covered to date include PolyWorks Inspector™, Geomagic Design X and 3D data collection tools such as Hexagon Romer Arms, Artec scanners and GOM CT scanners. Customers can learn more about these topics on the Exact Metrology website. In addition, they can offer suggestions for upcoming videos by sending an email to training@exactmetrology.com.

Exact Metrology is an ISO 9001:2008 and AS9100 Certified Company

Exact Metrology, with facilities in Cincinnati, OH, Moline, IL and Milwaukee, WI and affiliated offices throughout the country, is a comprehensive metrology services provider, offering customers 3D and CT scanning, reverse engineering, quality inspection, product development and 2D drawings. The company also provides turnkey metrology solutions, including equipment sales and lease/rental arrangements.

Exact Metrology offers a complete line of portable scanning and measurement technologies as well as contract measurement for 3D laser scanning services, reverse engineering services, non-contact inspection, metrology services, and 3D digitizing. The company’s newest equipment includes a CT Scanner, the first in America being used for metrology rather than medical testing. Exact sells and rents metrology equipment solutions, in addition to providing testing as a service and application software training.

For more information, please contact:

EXACT METROLOGY, INC.

Dean Solberg

20515 Industry Avenue

Brookfield, WI 53045

Local: 262-533-0800

www.exactmetrology.com

deans@exactmetrology.com

EXACT METROLOGY, INC.

Steve Young

11575 Goldcoast Drive

Cincinnati, OH 45249

Local: 513.831.6620

Toll Free: 866.722.2600

www.exactmetrology.com

stevey@exactmetrology.com

ANCA is a partner to the NOTUS Emergency Ventilator Program, a Grey Innovation-led initiative supported by the Victorian Government and Advanced Manufacturing Growth Centre (AMGC) to manufacture and assemble components of ventilators

Coming to the aid of a medical system crushed world-wide by the COVID-19 pandemic, ANCA has joined an important consortium to rapidly manufacture invasive ventilators within Australia. This initiative directly addresses the critical supply of mechanical ventilation equipment to support COVID-19 patients requiring ventilation to survive. Banding together with other Australian manufacturing businesses, the consortium can harness various industry capabilities to make more ventilators sooner.

Co-founder and managing director, Pat Boland said: “ANCA is an advanced manufacturer that supplies to a wide range of industries, a key one being the medical industry. In fact, ANCA has been classified in the U.S. as an essential industry because so many of our customers are manufacturing medical components.”

ANCA is an Australian manufacturer of CNC machines that produce quality precision cutting tools. Their experience in advanced manufacturing means they can guarantee a micron precision, a capability which means the company could pivot and utilise its machine shop to manufacture parts for the ventilators. An Australian-based company, ANCA exports 98% of their product and boasts a global network to service global customers. Fully Australian and privately owned, ANCA machines have the capacity to machine components in brass, aluminium, plastic and steel and has skilled assembly capabilities.

Around the world it is predicted that total demand for ventilators could run into the tens of thousands, with existing manufacturers unable to meet demand.

“This is a global emergency and in my view it is incumbent on every individual in every organization to do everything they can to help deal with it. And in the case of ANCA, we have capabilities that are a good match and it’s the right thing to do. We are very good at manufacturing the kind of parts that are needed for ventilators and it is a really great way for us as an organization to give something back to the community,” said ANCA Group CEO, Chris Hegarty.

With production already in progress to meet tight timeframes; ANCA has hit the ground running with dedicated machinists willingly working weekends and over the Easter break to make parts and help combat coronavirus.

Production Operations manager, Mark Patman explains: “With an extremely tight timeframe, we’ve jumped in and started manufacturing the parts; it’s a team effort across the business to get it done. As a well-established global business, a lot of the processes required to deliver this type of project are already in place at ANCA. We can leverage off all our systems to be able to deliver the project.”

ANCA is utilizing a cross-functional team comprising manufacturing, supply chain, project management, stores logistics, and safety to support this crucial work.

Demonstrating agility in moving from machine tools to ventilators ANCA already has a working relationship with the AMGC and is pleased to be collaborating with Grey Innovation to ensure that Australia does not have a shortfall in ventilators, critical for our COVID-19 response. Answering the call from the Australian Government, rapid production will continue to supply contracts and contribute to the coronavirus crisis strategy.

For further information, please contact:

Sepideh Zandieh

Acting PR and Communications Manager, ANCA

M: +61 439 316 131

Sepideh.Zandieh@anca.com

ANCA is a market leading manufacturer of CNC grinding machines. It was founded in 1974 in Melbourne, Australia where the company still has its global headquarters. ANCA has offices in the UK, Germany, China, Thailand, India, Japan, Brazil and the USA as well as a comprehensive network of representatives and agents worldwide.

ANCA CNC grinders are used for manufacturing precision cutting tools and components across a diverse range of competitive industries including cutting tool manufacture, automotive, aerospace, electronics and medical.

Continue reading

This new version features a spindle speed increase of 25%

A new style timing belt drive multiplies the motor speed up to 13,050 RPM spindle speed. An AC inverter drive is used to increase the spindle speed up to 23,000 RPM at 87 Hz. Standard motor mounting on BEX 15 machining spindles is in the rear. Optional front motor mounting is available upon request. Additional optional features include frequency converter and direct drive servomotor.

The machining unit BEX 15 can be applied in axial and radial orientation, directly mounted to a Suhner linear slide assembly Type UA15-PH or UA15-CNC. In this combination, numerous operations such as milling or demanding drilling cycles including jump or peck feed can be accomplished easily.

Four optional toolholder systems (Collet ER25, ISO30, HSK50 and Weldon), standard air purge connections for spindle and belt housing including a number of additional options (for example, coolant through the spindle or automated tool change features) make this machining unit type BEX 15 adaptable and an optimal choice for demanding and specific inline machining requirements. BEX 15 with HSK spindle includes an integrated 4-point clamping system form C, for manual tool clamping.

For more information, please contact:

Lee Coleman, National Sales Manager-Machining Division

Suhner Industrial Products Corp.

25 Anderson Road SW

Rome, GA 30161 USA

Direct: 706-314-2927

Mobile: 706-409-1876

Fax: 706-235-8045

lee.coleman@suhner.com

www.suhner.com

Leading supplier of fast hole EDMs now offers added features of REALTIME

Beaumont Machine, located in Southwest Ohio, has updated its core fast-hole EDM machine, the FH40, with added features, including a faster response time.

According to company President Ed Beaumont, “Fast-Hole EDM has changed in the past five years from primarily producing cooling holes to the needs on shapes and diffusers. The additional need for a lower recast and virtually no microcracking has become the standard in aerospace. As a result, Beaumont Machine has been working on answers for our customers, focusing on the ability to work REALTIME with our power supply to control interconnection and closed-loop features. Doing so aids in delivering a better overall quality for our process. Other features that improve with the REALTIME process such as micro-pulse technology, breakthrough hole-start technology and blind hole drilling all benefit from this better interconnection between the power supply and control.”

This new design has been incorporated in the company’s mainstay fast hole machine, the FH40. Additional features of this machine include:

For more information, please contact:

Ed Beaumont

President

BEAUMONT MACHINE

4001 Borman Drive

Batavia, OH 45103

Phone: 513-701-0421

Web: www.beaumontmachine.com

Email: beaumach@msn.com

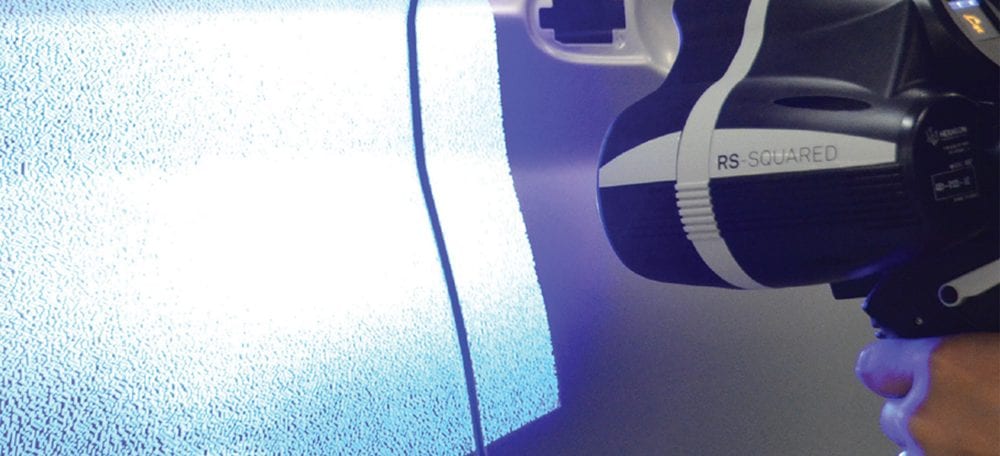

The Absolute Arm 7-axis system delivers tactile probing and laser scanning in a uniquely ergonomic package. It is the best choice for high-end portable measurement applications. The articulating arm offers unparalleled ease of movement and ease of measurement.

RS-SQUARED is a white light scanner that uses the Absolute Arm system to position large square ‘tiles’ of 3D scan data. This removes the need for time-consuming application of reference markers or spray, or complex mechanical processes such as fringe projection that requires a stable environment. Up to 4 data tiles are captured every second, which combined with minimal set-up time, creates a scanning system capable of generating point cloud data in very little time. As with other Absolute Arm scanners, the RS-SQUARED can be easily removed and remounted without needing time-consuming recalibration processes due to an innovative repeatable mounting system.

The RS-SQUARED area scanner represents a new direction for portable measuring arm technology, embracing the need for high-productivity by incorporating advanced white light scanning technology. Together with the Absolute Arm 7-axis, it offers the ultimate all-around portable measurement solution for medium-to-large sized components.

Exact Metrology is an ISO AS9100 Certified along with being FFL and ITAR Registered.

Exact Metrology, with facilities in Cincinnati, Moline and Milwaukee plus affiliated offices throughout the country, is a comprehensive metrology services provider, offering customers 3D and CT scanning, reverse engineering, quality inspection, product development and 2D drawings. The company also provides turnkey metrology solutions, including equipment sales and lease/rental arrangements.

For information, please contact:

EXACT METROLOGY, INC.

Dean Solberg

20515 Industry Avenue

Brookfield, WI 53045

Local: 262-533-0800

www.exactmetrology.com

deans@exactmetrology.com

EXACT METROLOGY, INC.

Steve Young

11575 Goldcoast Drive

Cincinnati, OH 45249

Local: 513.831.6620

Toll Free: 866.722.2600

www.exactmetrology.com

stevey@exactmetrology.com

Jason Kleinhenz received a biomedical engineering degree from the University of Cincinnati. He is currently the training and marketing manager at Exact Metrology.

Exact Metrology, a comprehensive metrology service provider, shares helpful safety tips for metrology workers during the COVID-19 pandemic. These tips are courtesy of Jason Kleinhenz, Exact Metrology marketing and training manager.

With much of the workforce operating from home, keeping up with quality inspection and reverse engineering is difficult during this time. However, there are solutions to counteract this problem. Some companies employ several of these tactics daily, but in these trying times they are much more relevant to maintain effective production.

If you are in the workplace, follow all the stated guidelines. These include staying 6 feet away, washing/sanitizing touched surfaces and washing your hands. Also remember to clean the objects you’re working with such as data collection tools and computers.

Only one person should collect the data from the object(s). That person is responsible for handling the objects and the data collection tools. Of course, the designated person also needs to clean and sanitize all objects, tools and surfaces.

Workers must save and upload data sets (and/or workspaces) to the cloud. Due to security threats, a company’s IT team should use a virtual private network (VPN) and/or file transfer protocol (FTP). This reduces the chances of data being hacked or stolen.

Have another person, or a team, work separately to download (receive) the data sets, or workspaces and process them. They will have their own safety procedures in place (essentially the same as the data collector). If possible, the processing person(s) should write programs at the same time the data is collected. This saves time and money as two operations are occurring at the same time. Most likely, this is not possible in reverse engineering projects. However, in quality inspection projects, this is a massive time-saving practice.

Communicating between the collector and processor(s) can be done quickly, and virtually, with online services like Skype and Zoom. The good old-fashioned phone works well for quick conversations too. There are some software packages that allow seamless workspace sharing between different people and teams such as a package through PolyWorks® by InnovMetric.

These techniques and tools can help companies reach their quality and reverse engineering objectives during social distancing. Exact Metrology is available to answer any questions about how to maximize efficiency or help with projects.

Exact Metrology is an ISO AS9100 Certified along with being FFL and ITAR Registered.

Exact Metrology, with facilities in Cincinnati, Moline and Milwaukee plus affiliated offices throughout the country, is a comprehensive metrology services provider, offering customers 3D and CT scanning, reverse engineering, quality inspection, product development and 2D drawings. The company also provides turnkey metrology solutions, including equipment sales and lease/rental arrangements.

For information, please contact:

EXACT METROLOGY, INC.

11575 Goldcoast Drive

Cincinnati, OH 45249

Local: 513.831.6620

Toll Free: 866.722.2600

www.exactmetrology.com

info@exactmetrology.com

Refurbishing Offers a Less Expensive Option During These Uncertain Economic Times

As machinery ages, it begins to decline in performance and consume more replacement parts. Wardwell’s braiding machines are excellent candidates to be refurbished with new parts and updated features. Options can include high-efficiency motors, drives, broken wire detection, empty bobbin detection, core run-out sensors and longitudinal taping systems. The advancements in mechanical and electronic components make retrofit a cost-effective option to improve performance on existing machines.

Wardwell, Central Falls, Rhode Island, began in 1911 as a supplier of braiding machines to the manufacturers of textile products and later developed machinery models for reinforced hose and composite structures. Since the 1970s, the company’s focus has been on specialized braiding machines that serve the wire and cable industry. Today, Wardwell is a global supplier of braiders, winders and payoffs for the wire and cable industry.

For more information, please contact:

Cynthia Chen

Wardwell Braiding Co.

Phone: 401-724-8800 X 183

Fax: 401-723-2690

E-mail: cchen@wardwell.com

Web: www.wardwell.com