Contact us today:

(847) 934-4500

tdaro@bernardandcompany.com

Contact us today:

(847) 934-4500

tdaro@bernardandcompany.com

The company’s biggest challenge is not only finding people to work, but finding those with enough knowledge to operate the equipment

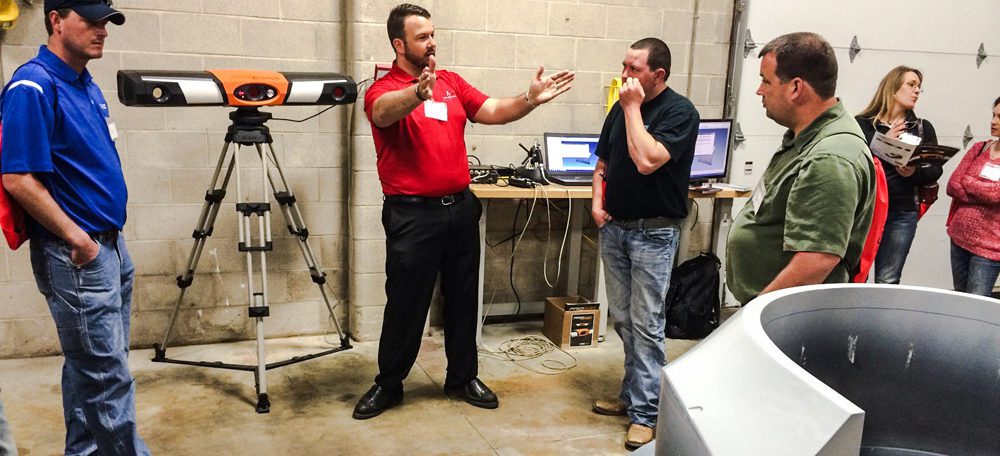

Exact Metrology: A Division of In-Place Machining Company and a comprehensive 3D metrology service provider and hardware sales company, provides extensive training to both customers and operators, from the basic to the most advanced operation.

Dean Solberg, Vice President of Metrology at Exact Metrology: A Division of In-Place Machining, believes there are several challenges facing the industry today. With the older workforce retiring, it is no longer a problem of finding new workers to take their place, but more about finding people who want to work and have the necessary skills to work.

When detailing training, Solberg mentioned that they offer customers “everything from basic operation of the equipment we offer for sale all the way to high level programming and operation of the equipment/software we sell.” Additional training options include DMIS, PolyWorks, Geomagic Design X and Geomagic Wrap. Training is available for the operation of anything from handheld metrology (Artec) to CT systems, geospatial systems, laser trackers and arms.

The company frequently partners with educational institutions, being present at career fairs and visiting colleges. They recently held a trade fair with the Milwaukee School of Engineering, presenting the latest in scanning technology to a consortium the school drives for additive manufacturing. The consortium is funded by a group of larger manufacturers based in Wisconsin.

According to Solberg, the biggest challenge the company faces is “finding people with enough knowledge and understanding to operate the equipment.” He added that in their “classroom” environment, there are plateaus of knowledge. Thus, attendees with advanced skills get bored because there are also those that are less knowledgeable. All training is in-person and dedicated to the customer.

While training hasn’t changed much in the last few years, Solberg finds that many manufacturers of equipment are trying to simplify the software they offer in order to appeal to lower skilled operators. He states that the wage issue drives a lot of the lower level operators, saying, “You can’t afford to hire a scanner operator and pay then $30.00/hour. So you dumb the operation of the software down and hire a $20.00/hour operator.

Regarding the future, the metrology industry follows the trends of the machine tool business (although metrology is about ten years behind). However, Solberg is optimistic given that “You are now beginning to see more automation in the metrology field with more coming every day. An example is cobots, even robotically loaded CMM and CT scanners. Plus, you’re seeing more GO/NO GO gauges on the shop floor”. He concludes that as time progresses, there will be more process control tools on the shop floor, making quality more predictive than reactive.

In-Place Machining Company: On-Site Machining Solutions In-Place, Any Place in the World.

In-Place Machining Company, with facilities in Wisconsin, Washington, Virginia, Ohio, and Ontario, Canada, is the premier provider of high-precision engineered on-site machining, metrology, and large scale cutting & drilling services for a wide range of renewable energy, aerospace, industrial, and military customers throughout the world.

Exact Metrology: A Division of In-Place Machining Company, is ISO9001, AS9100 Certified as well as ITAR Registered.

Exact Metrology: A Division of In-Place Machining Company, with facilities in Cincinnati, Ohio, Moline, Illinois and Milwaukee, Wisconsin, plus affiliated offices throughout the country, is a comprehensive metrology services provider, offering customers 3D and CT scanning, reverse engineering, quality inspection, product development and 2D drawings. The company also provides turnkey metrology solutions, including equipment sales and lease/rental arrangements.

For more information, please contact:

EXACT METROLOGY, INC.

Dean Solberg

20515 Industry Avenue

Brookfield, WI 53045

Local: 262-533-0800

www.exactmetrology.com

deans@exactmetrology.com

Platinum Tooling, the importer and master distributor of live tools, angle heads, Swiss machine products, knurling and marking tools manufactured by various international suppliers, is now the importer of Rineck shrink fit tooling and shrink fit machine technology in the United States and Mexico. The announcement was made by Platinum Tooling president, Preben Hansen, at their headquarters in Prospect Heights, Illinois, near Chicago.

Established in 1966, Rineck started as a job shop for small parts, then became a producer of hydraulic parts for the mining industry and is now a globally recognized manufacturer of tool holding technology. Rineck’s investment in state-of-the-art manufacturing equipment and commitment to innovation, research and development allows them to constantly look for ways to achieve the optimal balance of quality, consistency and affordability.

Rineck offers standard and custom shrink fit tool holders with various connections including CAT, HSK, BT, SK, PSC and straight shank extensions. In addition, ER shrink fit collets are available. For added rigidity, flange or dual contact holders are available for CAT and BT tapers. A clamping range from 3 mm to 32 mm is possible for both slim and standard styles. All tools are available in inch and metric sizes.

Rineck produces a wide range of standard shrink fit tool holders as well as custom tooling. In addition to standard 4.5° taper tools, 3° slim and extra slim tools are available. Most holders come standard with length adjusting screws. Coolant delivery to the cutting tool can be achieved either through the center or flange of the tool holder utilizing coolant jets or slots.

In addition to shrink fit tool holders, Platinum Tooling will offer shrink fit machine technology.

Equipped with an elevation cooling system, heated tools can be moved to a cooling tank with a push of a button. The machine’s smart design keeps accessories stored but close at hand during operation.

For this new line of shrink fit tooling and machine technology, Platinum Tooling will handle application engineering, sales and service through a network of distributors across the United States and Mexico.

For further information, please contact:

Preben Hansen, President

PLATINUM TOOLING TECHNOLOGIES, INC.

16 E. Piper Lane Suite 128

Prospect Heights, IL 60070

Phone: 847-749-0633

Fax: 847-749-2445

Email: phansen@platinumtooling.com

Platinum Tooling Technologies, Inc. in Prospect Heights, IL, near Chicago, serves its growing North American customer base with an extensive inventory of machine tool accessories. Its experienced staff is dedicated to providing the most innovative tooling and technology. Platinum Tooling Technologies, Inc. serves the auto, aero, medical, woodworking, composites and other industries, as well as an ever-increasing number of machine tool OEMs, through its network of manufacturers’ representatives. Platinum Tooling is the master importer of Heimatec, Henninger, Tecnicrafts, AMF Tooling and Hommel + Keller QUICK® tools for North America.

Continue reading

In this episode, Hugh Ingham from ANCA takes viewers back to to basics through an in-depth overview of machine fundamentals including the human machine interface (HMI), general machine layout and kinematic layout. The video is below.

Hugh Ingham started at ANCA as an applications engineer in 2015, and for three years, was involved in testing and the development of new standard products, as well as grinding applications for custom solutions. In that time, he had multiple opportunities to travel to Thailand, Japan and South Korea gaining firsthand knowledge of customers’ experiences.

In 2018, Hugh was seconded for two years to ANCA Germany, functioning as both an applications and mechanical design engineer to deliver custom solutions to customers. This experience proved invaluable, as working directly with customers in Europe and seeing how they used ANCA’s products and how they could be improved – helps shape the way he approaches his job today. The scope and encouragement to explore new ideas, build new skills and develop as an engineer has driven Hugh’s passion for ensuring end-users get the most out of their technology.

In 2020, Hugh returned to Australia and since then has been continuing to develop custom solutions for a wide range of applications including medical, automotive, aerospace and more. Hugh is the host of ANCA Academy – a dedicated TV show for customers to learn more about ANCA’s products and solutions.

ANCA is a market leading manufacturer of CNC grinding machines. It was founded in 1974 in Melbourne, Australia where the company still has its global headquarters. ANCA has offices in the UK, Germany, China, Thailand, India, Japan, Brazil and the USA as well as a comprehensive network of representatives and agents worldwide.

ANCA CNC grinders are used for manufacturing precision cutting tools and components across a diverse range of competitive industries including cutting tool manufacture, automotive, aerospace, electronics and medical.

Continue reading

Allows all Siemens CNC community members to interact with a product expert and get answers to programming and operations questions on-demand

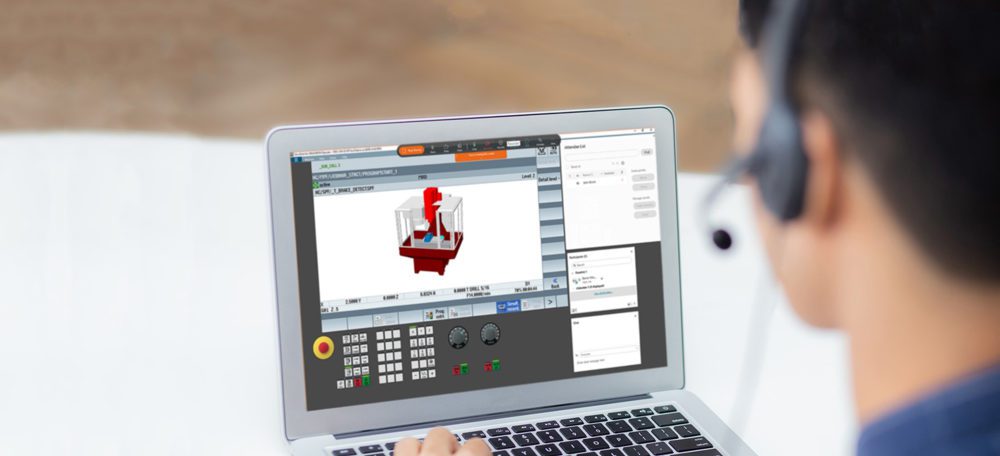

Siemens today introduced the Virtual Product Expert (VPE), a new support program for its CNC machine tool users, machine builders, dealers and importers. Through the VPE program, customers can now interact directly with a SINUMERIK CNC product expert and have their specific operation and programming questions answered — from the basic functions of the control to the most advanced machining technology aspects of the hardware and software suites. Best of all, this service is offered to all Siemens CNC community members at no cost.

Machine tool customers can contact Siemens to arrange an online session, tailored to their specific needs, regardless of where the programmer, operator or the machine are located. Sessions are typically one-hour in length and are being scheduled on a first-come, first-served basis.

John Meyer, the Marketing Communications Manager for the Siemens Machine Tool Business, notes, “With the rapid advancement in our SINUMERIK CNC technology on both the automation hardware and software sides, we see our Virtual Product Expert program as a vital part of our support offering. We know it will benefit our machine tool users, who are looking for immediate answers to their operation and programming challenges in order to keep their production running. It’s like having a Siemens CNC expert in your back pocket.”

For more information on the Virtual Product Expert, please visit: http://usa.siemens.com/vpe.

For additional machine tool CNC training offered by Siemens, users can visit: http://usa.siemens.com/cnc-training.

Follow us on social media:

www.twitter.com/siemens_cnc_us www.facebook.com/siemens.cnc.us

Siemens Digital Industries (DI) is an innovation leader in automation and digitalization. Closely collaborating with partners and customers, DI drives the digital transformation in the process and discrete industries. With its Digital Enterprise portfolio, DI provides companies of all sizes with an end-to-end set of products, solutions and services to integrate and digitalize the entire value chain. Optimized for the specific needs of each industry, DI’s unique portfolio supports customers to achieve greater productivity and flexibility. DI is constantly adding innovations to its portfolio to integrate cutting-edge future technologies. Siemens Digital Industries has its global headquarters in Nuremberg, Germany, and currently employs approximately 75,000 people internationally.

Siemens Corporation is a U.S. subsidiary of Siemens AG, a global powerhouse focusing on the areas of power generation and distribution, intelligent infrastructure for buildings and distributed energy systems, and automation and digitalization in the process and manufacturing industries. Through the separately managed company Siemens Mobility, a leading supplier of smart mobility solutions for rail and road transport, Siemens is shaping the world market for passenger and freight services. Due to its majority stakes in the publicly listed companies Siemens Healthineers AG and Siemens Gamesa Renewable Energy, Siemens is also a world-leading supplier of medical technology and digital healthcare services as well as environmentally friendly solutions for onshore and offshore wind power generation. For more than 160 years, the company has innovated and invented technologies to support American industry spanning manufacturing, energy, healthcare and infrastructure. In fiscal 2018, Siemens USA reported revenue of $23.7 billion, including $5.0 billion in exports, and employs approximately 50,000 people throughout all 50 states and Puerto Rico.

Continue reading

Representatives from ANCA and Fravic Daunert recently witnessed the signing of the contract at IMTS 2022

Fravic Daunert, a specialist in the distribution and commissioning of machine tools and accessories was developed with the union of two companies, the Fravic Group and Daunert Machine Tools. The first is a company that is established in the industrial sector that focuses on distributing machine tools including turret lathes, Swiss lathes, machining centers, CNC grinding machines, and much more. The second is a Spanish company, based in Barcelona that has specialized in the distribution of machine tools and accessories in a variety of industries for over 105 years.

According to Guillermo Ramirez, the CEO in Mexico of Fravic Daunert, the partnership between Fravic Group and Daunert Machine Tools was established a year ago to “serve the Mexican market with brands that Daunert represents in Europe.” To ensure proximity to local industry, Fravic Daunert has two offices in Mexico, one in Sahagún City, Hiladgo state and another in Queretaro State.

With a 2020 manufacturing output of $232 billion in Mexico, ANCA knew that they wanted to grow the company’s presence in the country. ANCA President, Russell Riddiford said, “ANCA is already established in the Mexican market, with over 160 machines installed around the country, but we know that the manufacturing industry in Mexico is a strong market for us, and we want to make sure we focus on continued growth in the region.” What better way to continue that growth, then to partner with a company you trust?

ANCA has been well represented by Daunert in Spain for many years. The partnership is already established, and proven, so the decision to partner with them in Mexico was simple. The partnership between ANCA and Fravic Daunert in Mexico has been in the works for months, but it was finalized in September at IMTS 2022 in Chicago, IL. Fravic Daunert will distribute the entire range of ANCA products, including ANCA’s world class CNC tool and cutter grinders, as well as the accessories that accompany them.

Present at the signing was Mr. Riddiford, as well as Mr. Ramirez, and brothers Fritz and Max Daunert, from Fravic Daunert. Fritz is the vice president, while Max holds the position of general manager. Sales representatives will promote and represent ANCA products in San Luis Potosi, Guanajuato, Queretaro, Aguascalientes, Puebla, State of Mexico, Mexico City and Tlaxcala in conjunction with ANCA regional manager, Denny Smaic.

This partnership with ANCA is significant because it is, “A great opportunity, since in the Mexican market ANCA machines are widely used in the automotive, aerospace, medical and electrical industry for companies to manufacture their own tools.” This allows a reduction of costs, as well as greater efficiency and probability. Ramirez concluded, “This in the long run has a very positive impact on the economy and productivity.”

For further information, please contact:

Amanda Bakun

Group PR and Communications Manager, ANCA

M: +1 248 497 1168

amanda.bakun@anca.com

ANCA is a market leading manufacturer of CNC grinding machines. It was founded in 1974 in Melbourne, Australia where the company still has its global headquarters. ANCA has offices in the UK, Germany, China, Thailand, India, Japan, Brazil and the USA as well as a comprehensive network of representatives and agents worldwide.

ANCA CNC grinders are used for manufacturing precision cutting tools and components across a diverse range of competitive industries including cutting tool manufacture, automotive, aerospace, electronics and medical.

Guillermo Ramirez

CEO in Mexico, Fravic Daunert

T: +52 791 596 21 36

M: +52 771 220 99 21

guillermo.ramirez@fravicdaunert.com.mx

Formally the president of Accurate Pattern Inc., a Wisconsin pattern-maker, Williams works as a trainer for the company’s educational initiative

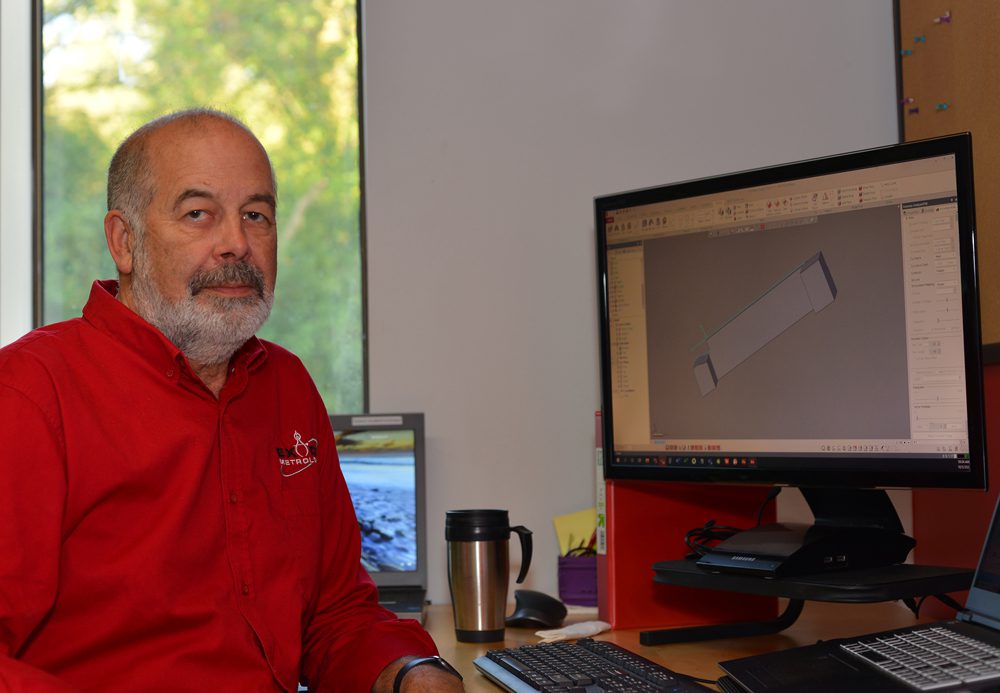

Exact Metrology: A Division of In-Place Machining Company and a comprehensive 3D metrology service provider and hardware sales company, has hired Bruce Williams at their Brookfield, Wisconsin location to help customers with their metrology applications.

His educational background includes attending Milwaukee Area Technical College and Phoenix University (Brookfield, Wisconsin). Williams’ first job was in 1974 at J.P. Pattern Inc. (Butler, Wisconsin). For eleven years, he had several roles in the company including patternmaking journeyman, sales and supervisor. In 1985, Williams started working at Premold Corporation (Oconomowoc, Wisconsin), working sales and as a general manager. From 1985 to 2021, he was the founder/president of Accurate Pattern Inc. (Butler, Wisconsin). They specialize in wood, metal and plastic patterns. Although Williams decided to retire in 2021, he works as a manufacturing adjunct instructor at Waukesha County Technical College (Pewaukee, Wisconsin).

Once he decided to “retire,” Williams reached out to Greg Groth, Exact Metrology applications engineer and Dean Solberg, vice president of metrology, both of whom he has had long business relationships with. He commented that “I have always admired Dean and Greg in their technical expertise and the culture they promote.” He is excited to work as an Exact Metrology trainer, specializing in 3D Systems Design X reverse engineering software.

Exact Metrology offers training options on all hardware and software options related to digitizing, reverse engineering, measurement and metrology. In his role, Williams will lead the recently implemented educational initiative for the company. This will involve working with schools of all types as well as multiple trade associations to help educate the current and future workforces on the application of advanced metrology, especially robots and cobots, CT technology and advanced laser scanning in the quality area at all types of companies across America. The educational initiative means that, “The training is specific to each customer with small in-person classes. The instructors are experts in the field and use practical examples including the customer’s own parts and data.”

Describing the experience, Williams commented, “This is a great place to share my years of pattern/tooling experience in combination with the latest technologies in metrology and modeling. It is satisfying to see customers and colleagues succeed as we help each other.”

In the future, he plans to keep learning and growing with others through his teaching, work at Exact Metrology and industry involvement.

In-Place Machining Company: On-Site Machining Solutions In-Place, Any Place in the World.

In-Place Machining Company, with facilities in Wisconsin, Washington, Virginia, Ohio, and Ontario, Canada, is the premier provider of high-precision engineered on-site machining, metrology, and large scale cutting & drilling services for a wide range of renewable energy, aerospace, industrial, and military customers throughout the world.

Exact Metrology: A Division of In-Place Machining Company, is ISO9001, AS9100 Certified as well as ITAR Registered.

Exact Metrology: A Division of In-Place Machining Company, with facilities in Cincinnati, Ohio, Moline, Illinois and Milwaukee, Wisconsin, plus affiliated offices throughout the country, is a comprehensive metrology services provider, offering customers 3D and CT scanning, reverse engineering, quality inspection, product development and 2D drawings. The company also provides turnkey metrology solutions, including equipment sales and lease/rental arrangements.

For more information, please contact:

EXACT METROLOGY, INC.

Dean Solberg

20515 Industry Avenue

Brookfield, WI 53045

Local: 262-533-0800

www.exactmetrology.com

deans@exactmetrology.com

ANCA USA (Wixom, MI), a market leading manufacturer of CNC grinding machines, has announced that Amanda Bakun will take on the newly created position of Marketing and Communications Manager for the Americas.

Johanna Boland, Group Communications and Strategy Manager said, “It has been really exciting at ANCA over the past five years in the marketing communications space. We have built an outstanding team who are leading the way in our social media, thought leadership, customer communications and even an e-commerce platform amongst other marketing activities. We have a powerful and positive brand at ANCA, and I am confident that Amanda will both nurture and grow our reputation in the Americas as well as celebrate what is key to our success – our customers.”

Since ANCA was founded in 1974, the cutting tool industry has continued to grow, in both size and application. ANCA CNC grinders are used for manufacturing precision cutting tools and components across a diverse range of competitive industries including cutting tool manufacture, automotive, aerospace, electronics and medical.

Russell Riddiford, GM Americas said “I am confident that the North/South American segment of the market is going to continue to grow, and because of that we are investing in our growth strategy. We have fantastic customers and exceptional technology in a dynamic market – marketing is key to connecting these groups together.”

“By the appointment of a local marketing and communications manager, ANCA will deliver a program of activities so that new and existing customers can remain up to date on all the latest news and innovations. This is especially important as we continue to diversify, expand, and grow our brand presence in a variety of different markets. We also pride ourselves on an aggressive product development strategy, investing more than 10% of our revenue annually into research and development – we need to ensure we are communicating these new solutions to the market,” says Johanna Boland.

Although Amanda is new to ANCA, she is not new to the industry. She brings over 12 years of experience in content strategy and marketing in manufacturing. Amanda has worked for several organizations in the industry, most recently a leader in turning and grinding machines. ANCA is confident that her addition to the team will have a big impact on the region. At ANCA, Amanda will be responsible for the content marketing strategy, communications, and marketing efforts for the North and South American markets. “It is an exciting time to join the ANCA team as the company expands its product offerings in a variety of unique and diverse industries. I am honored to join the team and look forward to using my skills and experience to accelerate ANCA’s growth in the America’s,” says Amanda. Amanda has earned a BS in Marketing from Grand Valley State University in Michigan, an MBA from Walsh College in Michigan, and MS in Marketing Research from Michigan State University.

ANCA is a market leading manufacturer of CNC grinding machines. It was founded in 1974 in Melbourne, Australia where the company still has its global headquarters. ANCA has offices in the UK, Germany, China, Thailand, India, Japan, Brazil, Mexico, and the USA as well as a comprehensive network of representatives and agents worldwide.

For further information, please contact:

Johanna Boland

Group PR and Communications Manager, ANCA

M: +61 407799779

Johanna.Boland@anca.com

ANCA is a market leading manufacturer of CNC grinding machines. It was founded in 1974 in Melbourne, Australia where the company still has its global headquarters. ANCA has offices in the UK, Germany, China, Thailand, India, Japan, Brazil and the USA as well as a comprehensive network of representatives and agents worldwide.

ANCA CNC grinders are used for manufacturing precision cutting tools and components across a diverse range of competitive industries including cutting tool manufacture, automotive, aerospace, electronics and medical.

Continue reading

On display at the Milwaukee area and Cincinnati, Ohio locations, the ScanCobot offers the perfect combination for simple automated inspection tasks

Exact Metrology: A Division of In-Place Machining Company and a comprehensive 3D metrology service provider and hardware sales company, recently announced the arrival of the GOM ScanCobot at their Milwaukee area office. The machine was set up, programmed and run by Phil Rediger, Exact Metrology applications engineer.

The ScanCobot is a mobile measuring station with a collaborative robot, a motorized rotation table and powerful software. According to Rediger, “…The software figures out the optimal positions to scan to get the most comprehensive profile possible on the part.” The device provides cleaner, more accurate data than manual scans. To measure a part completely, the sensor must face the part from different directions. The robot arm has an ATOS Q scanner mounted on the end effector. Combined with the motorized rotation table, the robot articulates the 3-view scanner around it.

Measurement planning, digitizing and inspection take place in the virtual measuring room (VMR) of the powerful software GOM Inspect Pro. The VMR is the central control and measurement planning software that represents the complete measuring procedure. In the software, the CAD data set of the part to be inspected is imported together with the associated measurement plan. The sensor positions and robot paths are computed fully automatically. Additionally, automatic teaching allows the user to work with the system without the need for specific robot programming skills.

Thanks to the Blue Light Equalizer and fast data processing, ATOS Q offers a superior performance. The Blue Light Equalizer enables high-speed fringe projection and is so powerful that even on uncooperative surfaces short measuring times can be achieved. Two different ATOS Q scanners are available. Both can handle a 500mm cube part.

The ScanCobot can easily and quickly be moved from one location to another. Only a standard socket is required for commissioning. It can also be used with a tripod for select scanning.

Exact Metrology offers the device for sale or service and is designed for multiple, repeat scans on a production line, as one-off scans. Currently, the company is focused on promoting this product for diecast and injection molded parts. However, the uses are many, including composite and additive parts.

In-Place Machining Company: On-Site Machining Solutions In-Place, Any Place in the World.

In-Place Machining Company, with facilities in Wisconsin, Washington, Virginia, Ohio, and Ontario, Canada, is the premier provider of high-precision engineered on-site machining, metrology, and large scale cutting & drilling services for a wide range of renewable energy, aerospace, industrial, and military customers throughout the world.

Exact Metrology: A Division of In-Place Machining Company, is ISO9001, AS9100 Certified as well as ITAR Registered.

Exact Metrology: A Division of In-Place Machining Company, with facilities in Cincinnati, Ohio, Moline, Illinois and Milwaukee, Wisconsin, plus affiliated offices throughout the country, is a comprehensive metrology services provider, offering customers 3D and CT scanning, reverse engineering, quality inspection, product development and 2D drawings. The company also provides turnkey metrology solutions, including equipment sales and lease/rental arrangements.

GOM GmbH

GOM, a company of the ZEISS Group, specializes in industrial 3D coordinate measuring technology, 3D computed tomography and 3D testing. From product development to production and worldwide distribution, GOM offers machines and systems for manual and automated 3D digitizing, evaluation software, training and professional support from a single source. In industries such as automotive, aerospace, energy and consumer goods, more than 17,000 GOM system installations are in use internationally. At more than 60 locations and with more than 1,200 metrology specialists, GOM guarantees profound advice and first-class service. Since mid-2019, GOM has been a part of the ZEISS Group and has formed the Center of Excellence for optical metrology. With more than 31,000 employees in 50 countries and annual revenue totaling more than 6.4 billion euros, ZEISS is an internationally leading technology enterprise operating in the fields of optics and optoelectronics.

To see the ScanCobot in action, view below:

For more information, please contact:

Exact Metrology: A Division of In-Place Machining Company

Dean Solberg

20515 Industry Avenue

Brookfield, WI 53045

Local: 262-533-0800

www.exactmetrology.com

deans@exactmetrology.com

JG Group from Poland were second time winners of the virtual category for their beautiful and highly creative model of a Hummingbird that attracted significant industry votes

The first ever Mexican winner, SJ Tools wowed the market with a cutting tool that combined multiple features into a single tool where all features were finished with a very accurate surface finish. The complexity of the design was possible through ANCA’s flexible iGrind software that offers its users a myriad of advanced features. SJ Tools drill point was special with a roughing tip just below the drill point to carry out high speed drilling and chip management.

Into its fifth year, ANCA’s industry first competition announced winners live at the international trade show IMTS in Chicago, IL earlier this month. The ‘Oscars’ of the Cutting Tool industry, participants and winners achieve important brand recognition with a reach of over two million across extensive media and social media coverage as well as money and other prizes.

Patrick Boland, Co-Founder at ANCA comments: “Every year I am delighted by the skill and creativity of our customers and how they apply the ANCA technology to design and manufacture market leading cutting tools. I think it is very important to recognize the amazing results we see across our industry and ANCA’s Tool of the Year is a chance to get together and celebrate our vibrant and innovative industry.”

JG Group won the virtual category with an excellent display of creativity and third runners up for the main ANCA Tool of the Year. The effort and creative thinking process coupled with intimate knowledge of the iGrind and the CIM3D software enabled them to design a life size model of the “Hummingbird” which was both beautiful and an impressive application of design.

Aleksandra Semeniuk, Design Manager at JG GROUP has been producing cutting tools as well as machine parts and tooling for industry since 2005. “The ANCA Tool of the Year competition inspires tool companies all around the world and brings a breath of fresh air to our daily work, stimulates creativity and allows us to break down barriers.”

No Simple Tool – SJ Tools takes the ANCA Tool of the Year major award

Edwin Juarez, CEO of SJ Tools said: “In this very competitive world with the technology that exists in cutting tools, it’s a great achievement for me as well as the whole team that works at SJ Tools (designing, sharpening, grinding, machining area, polishing, honing, quality, purchases, sales and administration).”

“Our tool was designed for a customer which machines aluminium. With this tool we could eliminate five tools and machine it with one. The first and second operation performed was roughing and a chip breaker on the tip to break the chip, giving better output and avoiding obstructions. The third operation interpolates to create a pocket. In the fourth and fifth we made two internal slots in which we did roughing and finishing, also super polishing and honing. At the same time, we managed to reduce cycle times, production cost and inventory cost.”

“There is no simple tool. That is why I want to highlight the engineering, design and manufacturing team since they worked hard analyzing each of our client’s operations to be able to create this tool. The experience and dedication of each team member that works at SJ Tools leads us to these achievements. It was created by observing, analyzing and detecting the needs of our client, and thus be able to create this solution.”

Independent judge, John Saunders who is the President of Saunders Machine Works (SMW) and founder of YouTube channel NYC CNC said, “Congratulations to the winners! The application of both software and the ANCA grinding technology was truly remarkable. The complexity, detail, and quality of the tools was outstanding. Thank you to ANCA for inviting me to be part of the tool of the year competition and helping to share our passion for educating the manufacturing community about the precision and capabilities of CNC tool grinding.”

Winner Main category: SJ Tool

Winner Virtual category: JG Group

ANCA Tool of the Year

There are two competition categories to recognize both the functionality and creativity of cutting tool manufacturers.

The winner of #MadeonANCA receives $10,000 AUD worth of ANCA innovations for parts, accessories or software that fit your grinding needs and the winner of the most innovative virtual tool will receive the full CIM software package.

SPONSORS

The competition was based on the passion and the craft of tool making and celebrated our highly skilled tool grinding community.

The top five finalist tools were judged on the following criteria:

For further information, please contact:

Johanna Boland

Group Corporate Communications Manager

M: +61 407799779

Johanna.Boland@anca.com

ANCA is a market leading manufacturer of CNC grinding machines. It was founded in 1974 in Melbourne, Australia where the company still has its global headquarters. ANCA has offices in the UK, Germany, China, Thailand, India, Japan, Brazil and the USA as well as a comprehensive network of representatives and agents worldwide.

ANCA CNC grinders are used for manufacturing precision cutting tools and components across a diverse range of competitive industries including cutting tool manufacture, automotive, aerospace, electronics and medical.

Continue reading

Leader in 3D Scanning reintroduces itself to the public following new partnerships

Exact Metrology: A Division of In-Place Machining Company and a comprehensive 3D metrology service provider and hardware sales company, recently exhibited at the Coordinate Metrology Society Conference (CMSC).

Held in Orlando, Florida, the conference provided attendees with the opportunity to try the latest innovative coordinate metrology equipment and educate themselves in metrology principles. It also included numerous technical presentations from industry experts and hands-on workshops providing training opportunities on metrology hardware and software solutions.

Present in booth 219, Dean Solberg, Vice President of Metrology at Exact Metrology: A Division of In-Place Machining Company, said that it was exciting to be back meeting face-to-face with this unique group of metrology technology professionals. He added that the goal of being at the CMSC this year, was to re-introduce Exact Metrology to the industry and share the additional solutions and measurement service offerings the company now provides as part of the Measurement & Alignment Services Group of In-Place Machining Company. Partnering with them in this group is OASIS Alignment Services: A Division of In-Place Machining Company, a long-time supporter of the CMS and provider of 3D metrology and alignment services.

Demonstrated in the Exact Metrology booth was the handheld Artec Leo 3D Scanner. The Leo seamlessly captures 3D renderings, offering onboard automatic processing through an intuitive touchscreen. The scanner captures a 360-degree view, loading it on the touchscreen for your review. After the images have been compiled into a 3D image, you can rotate and review the final product. Scanning 80 frames per second, the Artec Leo offers fast, detailed scans of small and large objects. The wide-angle lens allows you to accurately capture large objects, and the high-accuracy scanning lets you move in close to capture intricate details. Additionally, the touch panel screen, built-in battery, and wireless connectivity allow you to capture 3D images without the need for additional equipment.

While at the conference, Exact Metrology representatives had the opportunity to interact with metrology experts from several industries including automotive, aviation, defense, marine (shipbuilding), agriculture and construction.

Talking about the purpose of attending CMSC Mr. Solberg said, “It is always exciting for us to support and be a part of the CMSC and learn about the latest advancements in metrology. Staying ahead of the curve allows us to provide only the best measurement solutions and services to our current customers – and to our now expanded customer base of both In-Place Machining Company and OASIS.”

In-Place Machining Company: On-Site Machining Solutions In-Place, Any Place in the World.

In-Place Machining Company, with facilities in Wisconsin, Washington, Virginia, Ohio, and Ontario, Canada, is the premier provider of high-precision engineered on-site machining, metrology, and large scale cutting & drilling services for a wide range of renewable energy, aerospace, industrial, and military customers throughout the world.

Exact Metrology: A Division of In-Place Machining Company, is ISO9001, AS9100 Certified as well as ITAR Registered.

Exact Metrology: A Division of In-Place Machining Company, with facilities in Cincinnati, Ohio, Moline, Illinois and Milwaukee, Wisconsin, plus affiliated offices throughout the country, is a comprehensive metrology services provider, offering customers 3D and CT scanning, reverse engineering, quality inspection, product development and 2D drawings. The company also provides turnkey metrology solutions, including equipment sales and lease/rental arrangements.

OASIS Alignment Services: A Division of In-Place Machining Company

OASIS Alignment Services: A Division of In-Place Machining Company, provides 3-Dimensional Metrology Services, Precision Alignment Inspections and Diagnostics and Mechanical Services across a wide range of industries including aerospace, automotive, power generation, shipbuilding, pulp and paper, converting, printing, plastics, textiles and more. OASIS has completed thousands of successful projects since its inception in 1982 and continues to set industry standards in alignment procedures, specialized tooling and reporting techniques. OASIS operates service centers in New Hampshire, North Carolina, Florida, Ohio, Wisconsin, California, Washington, and Ontario and Québec, Canada. For more visit www.oasisalignment.com

About Artec 3D

Artec 3D is an international company, headquartered in Luxembourg, with offices in the United States (Santa Clara, California), China (Shanghai) and Russia (Moscow). Artec 3D develops and produces innovative 3D solutions and products. Artec has a team of professional experts in the collection and processing of 3D surfaces as well as biometric facial recognition. Artec 3D’s products and services can be used in many industries, such as in engineering, medicine, media and design, entertainment, fashion, historic preservation, security technology and many more.

For more information, please contact:

EXACT METROLOGY, INC.

Dean Solberg

20515 Industry Avenue

Brookfield, WI 53045

Local: 262-533-0800

www.exactmetrology.com

deans@exactmetrology.com