Contact us today:

(847) 934-4500

tdaro@bernardandcompany.com

Contact us today:

(847) 934-4500

tdaro@bernardandcompany.com

From time to time…

After 43 years in the agency business, always as a copywriter, I’ve seen many “evolutions” in the agency business. I started in a world of print, when direct mail was the sizzle product and bingo cards were the “proof of performance” metric…a word we never used, as we said yardstick. Funny. New ads and PR took 30-45 days to appear, now we have our PR online in 30 minutes or less.

Today, the emergence of the internet and social media have radically altered the face of industrial marcom, which remains a lap behind the consumer world, but not because our business lacks the talent or foresight to implement the changes in technology.

Rather, the fundamental driver in our business…and yours, as captains of industry…is one that hasn’t changed a bit, over time. It’s the fact that all 33 of our clients sell to only a small slice of the viewing public. We have several clients with less than 1000 prospects in all North America, including one who sells tiremaking machinery. Talk about a limited head count. At the opposite end, we have a client who sells every market you can name with a piece of discretionary capital equipment, as I call it. Requires a very different approach.

Continue readingSUHNER presents new grinding, milling and polishing system

Intelligent technology for tool and mold making

In many technical fields, ultrafine grinding is one of the tasks that gives the product its final polish – in the truest sense of the word. This applies equally to both precision and the visual appeal.

One of the leading manufacturers of professional surface treatment tools and machines for over a hundred years, SUHNER now offers an innovative grinding, milling and polishing system, SUNmic 60.

The central element is an intelligent control unit with touch panel that can accept a range of micro motors and tool hand pieces depending on the application. The control part has modern features such as touch screen operation on a glass display, the option to save settings and a rotation speed regulator with tangible resistance.

Key settings are easily legible on a large digital display.

Micro motor system

The actual tools are driven by powerful micro motors whose 280 W place a lot of power in the user’s hand. The compact, brushless BL/DC motors provide an extraordinarily wide speed range of 1000–60,000 rpm and deliver a high torque. In practice, they can be compared with pneumatic technologies but do not need a compressed air supply, operate at lower energy levels and emit virtually zero noise, without exhaust air or oil mist emissions.

One further benefit is that they run virtually free of vibration. The high concentricity safeguards clean and reproducible results in all areas of operation. A special heavy-duty clamping system prevents the millers from shifting. Chuck diameters range from 2.35, 3.0 and 6.0 mm to 1/8 and 1/4 inch.

The new SUNmic 60 micro motor system can be connected to a 90–240 V source, and can therefore be used anywhere in the world. It offers a large number of combinations. The tools range from straight, angle and filing hand pieces to belt grinders. The control unit can be connected to two BL/DC motors and an AC motor.

Advantage: The new control unit is compatible with available micro motors. This is a true multi-purpose tool for many applications.

The new system can be used everywhere a precision finish is desired – for instance, grinding, milling, brushing and polishing in tool and mold making; in aircraft, engine and motor building; in engine tuning; and much more. SUHNER offers a range of matching machines, tools and abrasives that have been tailored specifically to each of these applications. Also an illustrated mold making tool catalog is available.

The new SUNmic 60 micro motor system has been designed for complex milling, grinding, brushing and polishing work in tool and mold making; in aircraft, engine and motor building; and similar applications.

Together with the brushless BL/DC motors, the hand pieces deliver the maximum in performance.

The high concentricity and low-vibration running can only benefit the final results.

The most important properties of SUNmic 60:

Knowhow on site

SUHNER provides demo services for field expertise. This offers interested parties expert advice, free of charge, from experienced field workers. The demo services vehicle carries all the usual tools, attachments and abrasives, plus the right end to end solution can be found directly onsite based on the actual workpieces.

For more information, please contact:

SUHNER Industrial Products, LLC

43 Anderson Road SW

P.O. Box 1234

Rome, GA 30161

Phone 706/235-8046

Fax 706/235-8045

info.usa@suhner.com

www.suhner-abrasive-expert.com

Attention: Aaron Beck, National Sales Manager, Abrasives & Power Tools

This Grieve belt conveyor oven has a 48” long open belt loading zone and a 10’ long insulated heat zone with recirculated airflow. Features include a 30” wide, 1” x1” high carbon steel flat wire conveyor belt with 1/4-HP motor drive, variable from 1.4 to 27 inches per minute. Additional features include 4” insulated walls, aluminized steel interior and exterior and a manually operated vertical lift door at unload with viewing window. The oven also has a photo cell to automatically stop the belt when parts reach the unload position.

Controls on the No. 897 include a digital indicating temperature controller, manual reset excess temperature controller with separate contactors, recirculating blower airflow safety switch and SCR power controller.

For more information, please contact: THE GRIEVE CORPORATION, 500 Hart Road, Round Lake, Illinois 60073-2835 USA. Phone: (847) 546-8225. Fax: (847) 546-9210. Web: www.grievecorp.com. Email: sales@grievecorp.com. Attention: Frank Calabrese.

Continue reading

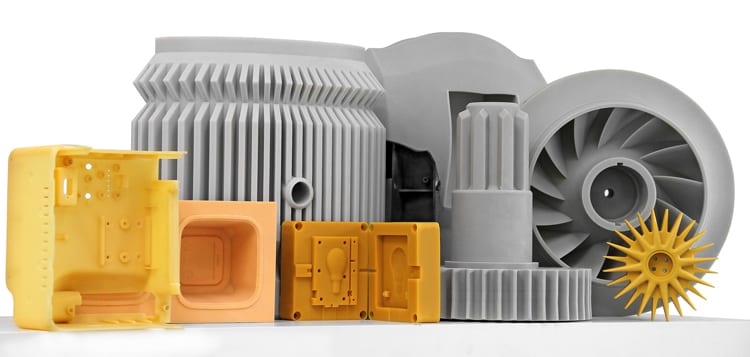

Leading supplier of 3D printers partners with longtime supplier of metrology equipment

Effective immediately, Exact Metrology is now the greater Midwest dealer for EnvisionTEC, a Detroit-based manufacturer of 3D printers and materials.

Exact Metrology offers a complete line of portable scanning and measurement technologies, as well as contract measurement for 2D and 3D laser scanning services, reverse engineering services, non-contact inspection, metrology services, 3D digitizing and training, long-range scanning plus its CT scanning services, usable by all types of manufacturing, packaging and product integrity concerns, as well as civil engineering, architects and municipal infrastructure developers.

For more information on this agreement, please contact:

Dean Solberg

Exact Metrology, Inc.

20515 Industry Avenue

Brookfield, WI 53045

Local: 262-533-0800

Toll Free: 866-722-2600

www.exactmetrology.com

deans@exactmetrology.com

Or

Steve Young

Exact Metrology, Inc.

11575 Goldcoast Drive

Cincinnati, OH 45249

Local: 513-831-6620

Toll Free: 866-722-2600

www.exactmetrology.com

stevey@exactmetrology.com

Exact Metrology is an ISO 9001:2008, AS9100 Certified and ITAR Registered Company.

Exact Metrology, with facilities in Cincinnati and Milwaukee and affiliated offices throughout the Midwest, is a comprehensive metrology services provider, offering customers 3D scanning, reverse engineering, quality inspection, product development and 2D drawings. The company also provides turnkey metrology solutions, including equipment sales and lease/rental arrangements.

Continue reading

This Grieve walk-in oven has 6” insulated walls and an aluminized steel exterior with white epoxy paint. Type 304, 2B finish stainless steel interior with continuously backwelded seams and inert atmosphere construction are also onboard, including a pressure regulator, flow meter, pressure gauge, inner oven walls sealing directly against ½” thick silicone rubber door seal, blower shaft seal, positive latching door hardware, adjustable offset door hinges, outlet with pressure relief, interior seams welded gas-tight and all wall penetrations fitted with compression fittings. The oven has a 4” insulated floor with truck wheel guide tracks mounted on top of the floor.

Controls on the No. 1038 include a digital programming temperature controller plus a paperless event recorder.

For more information, please contact: THE GRIEVE CORPORATION, 500 Hart Road, Round Lake, Illinois 60073-2835 USA. Phone: (847) 546-8225. Fax: (847) 546-9210. Web: www.grievecorp.com. Email: sales@grievecorp.com. Attention: Frank Calabrese.

Continue readingNo. 913 is 500°F (260°C), truck oven from Grieve, currently used for curing rubber parts hanging from the oven’s ceiling at the customer’s facility. Workspace dimensions of this oven measure 48” wide x 52” deep x 96” high. 24 KW are installed in Nichrome wire tubular heating elements, while a 1000 CFM, 1-HP recirculating blower provides combination airflow.

Controls on the No. 913 include a digital indicating temperature controller, manual reset excess temperature controller with separate contactors, recirculating blower air flow safety switch and a 10” diameter circular chart recorder.

For more information, please contact: THE GRIEVE CORPORATION, 500 Hart Road, Round Lake, Illinois 60073-2835 USA. Phone: (847) 546-8225. Fax: (847) 546-9210. Web: www.grievecorp.com. Email: sales@grievecorp.com. Attention: Frank Calabrese.

Continue readingMarket Leader in 3D and CT Scanning Details a Typical Airfoil Procedure

Exact Metrology, a leading supplier of 3D laser and CT scanning equipment and services details the steps to a successful airfoil evaluation.

The scan can occur at the customer’s facility or at Exact Metrology’s. In many cases, it is most cost effective for the digitizing or scanning to take place at the Exact facility. However, in certain instances, when turnaround time is of great importance or downtime of the scanned component is critical, the scanner is mobile and available for onsite operation.

The airfoils that are typically provided by customers will be received by Exact Metrology for full documentation with photos, measurements and any surface markings or serial numbers recorded prior to any high definition scanning.

Setup

The mobility of the Exact scanner allows a high degree of flexibility in performing onsite scans (Option A) at a customer facility or the more cost efficient in-house scan at the Exact facility (Option B).

Due to the reflective nature of the blades, a thin coating of Magnaflux spray is applied. The SKD-S2 spray is a second phase of the crack checking processes. Phase 1 is a die penetrant that will not be used typically. The spray meets the requirements for AMS 2664, ASTM E165 and is ASME approved. (Health – 1, Flammability – 4, Reactivity -0, No Specific Hazard). See MSDS 0166 for more information on the SKD-S2 product.

When scanning the blade, Exact uses a fixture device. Targets will also be used to constrain data during the alignment phase. Targets will be placed using magnets on either side of the air foil. The fixture itself will also act as an alignment constraint while holding the airfoil in place and allowing Exact technicians to capture maximum data on the part without moving or touching the part. A manual or automatic turntable may be used to allow enhanced scanning and registration access to the part.

Scanning

The part is positioned on the rotating table or on a stationary marble top and scanned from multiple perspectives. This procedure is repeated multiple times to provide complete coverage of the part. Known geometric objects, cubes and spheres are often placed in the scene for quality assurance and validation during the validation stage.

The scanner used on these projects is a Breuckmann Stereo 3D Scanning system. This device uses a unique halogen structured white light projection system with dual 6.6 mega-pixel cameras. The scanner is the highest resolution scanner available on the market and was specially built for Exact Metrology in Germany.

Registration

The registration process can be done with or without targets. Both registration methods have different techniques with similar results. Essentially, the targeting procedure uses an automated fitting of point clouds or scan worlds together, based upon three common positions on the part or scene. This process has been simplified with modern software technology. The software will then analyze every point with overlap and run a best fit algorithm over hundreds of iterations to find the tightest and best alignment. The result of this process will yield a fully registered and organized point cloud.

Validation

It is important to verify the automated method with targeting and adding known geometric shapes to the scan. All scans are documented with notes, computer logging and digital photos accompanying the recorded scan setup within the software. A CD copy of all digital data is recorded prior to returning the part or teardown.

MODELING PROCESS:

Once the data is gathered and the registration process is complete, the point cloud or data set can now be worked. The first step is to triangulate or mesh the points together. As part of this early process, points are “intelligently” removed from the network by algorithms in the software. Essentially, the points of redundancy and overlap are decimated and averaged. This mesh is further manipulated by reducing the triangles and points along flatter areas and retaining more triangles in areas of curvature and complexity. This poly mesh can now be exported as a complete *.STL file or similar format.

Surfacing

The process of fitting NURBs and geometry to the poly mesh or point cloud can be a time-consuming and arduous process. A surface is basically draped over the mesh and smoothed to be reflective of the actual part. Once this task is completed and a complete watertight object is created, the model is ready to be exported to nearly any format via various methods. The end file format is entirely up to the client and the limitations of existing conversion tools available today. A final 3D solid model can be provided as a “dumb solid” with no parametry or history tree as an imported object. The available formats include: Siemens NX, Pro/E Wildfire, AutoCAD, AutoCAD Inventor, SolidWorks, as well as generic formats such as IGES, STEP, ParaSolid (X_T) and others.

Parametric Modeling

The final deliverable is a parametric model. Unlike a solid model, the parametric model possesses relationships of all dimensions within the CAD. With these relationships, the CAD model can be manipulated and fine-tuned without disturbing the overall geometry of the part. For this workpiece, the specific parameters of each cross section within the model can be independently modified without disturbing neighboring cross sections. The end result is a Pro/Engineer CAD model with known geometry that is fully adjustable and possesses a design history.

For more information on this application, please contact:

Dean Solberg

Exact Metrology, Inc.

20515 Industry Avenue

Brookfield, WI 53045

Phone: 262-533-0800

Local: 866-722-2600

www.exactmetrology.com

deans@exactmetrology.com

Exact Metrology is an ISO 9001:2008 and AS9100 Certified Company.

Exact Metrology, with facilities in Cincinnati and Milwaukee and affiliated offices throughout the Midwest, is a comprehensive metrology services provider, offering customers 3D and CT scanning, reverse engineering, quality inspection, product development and 2D drawings. The company also provides turnkey metrology solutions, including equipment sales and lease/rental arrangements.

Exact Metrology offers a complete line of portable scanning and measurement technologies as well as contract measurement for 3D laser scanning services, reverse engineering services, non-contact inspection, metrology services, and 3D digitizing. The company’s newest equipment includes a CT Scanner, the first in America being used for metrology rather than medical testing. Exact sells and rents metrology equipment solutions, in addition to providing testing as a service and application software training.

Continue reading

Effective immediately, Siemens announces the standard 12-month warranty on newly purchased Sinamics DCM DC drive products, including DC converters, base drives, enclosure cabinets and control modules, has been extended by two years, to a total of three years from date of manufacture.

This extended warranty, according to company sources, applies to new orders only and previously placed orders cannot be included in this offer. The extended warranty is exclusive of any other extended warranty program or initiative offered by Siemens or its sales distribution network.

The offer applies to all products in the DCM drive products line and no registration or application is required for compliance.

Siemens has extended the warranty on its Sinamics DCM DC drive products, including DC drives, base drives, enclosure cabinets and control modules, by two years, to a total of three years from date of manufacture, effective immediately.

Contact for journalists:

Siemens

John Meyer

(847) 640-1595

john.meyer@siemens.com

Siemens

Hollie Davis

(770) 751-4882

hollie.davis@siemens.com

For specific product information and inquiries, call (800) 879-8079 ext. Marketing Communications or send an e-mail to: mc.us@siemens.com. Or, go to the website for full details: www.usa.siemens.com/drives.

About Siemens USA

Siemens Corporation is a U.S. subsidiary of Siemens AG, a global powerhouse focusing on the areas of electrification, automation and digitalization. One of the world’s largest producers of energy-efficient, resource-saving technologies, Siemens is a leading supplier of systems for power generation and transmission as well as medical diagnosis. With approximately 348,000 employees in more than 190 countries, Siemens reported worldwide revenue of $86.2 billion in fiscal 2015. Siemens in the USA reported revenue of $22.4 billion, including $5.5 billion in exports, and employs approximately 50,000 people throughout all 50 states and Puerto Rico.

High performance – mobile and unattached!

Power is not always available where you need it for tough-to-reach areas that need sanding, milling and drilling. For applications such as these, SUHNER now presents its battery-operated straight Die-grinder. With a rotation speed of 22,000 rpm, the ASC provides the user with a hand-held, mobile, high-performance Tool. This tool, which can be used around the World, is a great all-rounder that performs at all professional levels.

This new cordless tool is Li-Ion Battery powered and offers all the right settings for power tool work on high-grade projects in all types of steel.

It is also great for other sectors where these qualities are needed, such as the fire services, emergency services, or for locksmiths, caretaking and maintenance.

The ASC 22 is reliable and gets the work done rapidly, all without being attached to a power supply! The ASC 22 is not only highly effective, it is also silent.

For demanding users

This all-rounder is the right tool for anyone that wants to achieve precise, high-quality results.

The ASC 22 is the best choice for grinding with formed abrasives, for milling with carbide cutters and for drilling with normal or carbide drills. It is lightweight at just 1.9 kg, including its battery pack. Its ergonomic and well-balanced shape enables you to carry out very detailed work without becoming tired. With a slimline neck, it can also reach narrow areas easily.

Globally compatible

The machine has a chuck system that ensures quiet running with minimised vibrations. The user can choose between chucks of 6mm (mainly used in Europe) and 1/4” (for the USA and overseas markets). We provide four different connector cables so that the battery can be charged from almost any internationally used plug socket.

High performance battery technology

The powerful electric motor from the latest generation are driven by high-performance lithium-ion batteries, which are the best option because of their high output, low self-discharge and the fact that they have no memory effect. This means that charging your battery is problem-free every time. The powerful battery packs have a 4.0 Ah charge capacity and work on a voltage of 18 V.

Sophisticated system

Intelligent battery management ensures that all the components work together perfectly and that the available power is used optimally. In this process, the temperature of the battery and machine are continuously monitored so that overheating or overloading of the device is effectively prevented. The electric motor is protected from coarse dust by a detachable particle guard. The battery packs are housed in a shock-absorbent rubber jacket.

Practical set

The ASC 22 comes as a set consisting of the machine, two battery packs and a charger with four different connector cables in a practical, durable plastic case.

Everything you need for a job in a robust case: the battery-operated grinder, 2 battery packs and 4 connector cables for international use.

For more information, please contact:

SUHNER Industrial Products, LLC

43 Anderson Road SW

P.O. Box 1234

Rome, GA 30161

Phone 706/235-8046

Fax 706/235-8045

info.usa@suhner.com

www.suhner-abrasive-expert.com

Attention: Guido Broder, President

Exact Metrology proudly announces it has received official AS9100 certification. The Aerospace Standard 9100 includes the requirements for aviation, space and defense organizations. This certification evidences Exact Metrology practices a Quality Management System (QMS) that consistently meets customer expectations. Exact Metrology management has been heavily involved with the QMS process. This starts with the setting of Quality Policy, Quality Goals and Objectives. Management Review looks at the data from QMS, sees that Quality Goals are met, sets new ones and strives for continuous improvement. The advantage of this stringent Management Review is that it provides a basis for reviewing goals and performance against goals that are periodically reviewed. As a result, according to company co-founder Dean Solberg, customer satisfaction has increased because, “…the Goals and Objectives of the QMS take the customer’s needs into account and the Exact team can react and plan accordingly.”

Benefits of implementing AS9100 include well defined and documented procedures to improve the consistency of output, quality is constantly measured, procedures ensure corrective action is taken whenever defects occur, reducied overall cost, appreciably lower defect rates and earlier detection, exposure to new markets and retention/increase of market share in existing sectors, internal operational efficiency and overall better process control and workflow.

The company is also ISO9001:2008 certified. This is the only ISO standard that requires certification and is an internationally recognized Quality Management System that governs the sale and service of 3D non-contact and contact measuring equipment for inspection and reverse engineering in the commercial, aerospace, medical, automotive and industrial sectors. The ISO9001:2008 certification highlights the commitment, dedication and service Exact Metrology employs for customers.

Exact is also certified by ITAR, the International Traffic Arms Regulation. As a result, Exact Metrology has a competitive advantage when attracting and retaining defense business. Prime contractors are obligated to comply with ITAR requirements and these same requirements must be employed by subcontractors. Subcontractors such as Exact Metrology, who demonstrate compliance with ITAR standards, are clearly more desirable resources for prime contractors. Finally, being ITAR certified gives Exact Metrology the opportunity to do business with defense companies overseas, a growing market for the company currently.

Exact Metrology also has a Federal Firearms License, giving them the ability to send and receive weapons for quality control and inspection.

For more information on these developments, please contact:

Dean Solberg

Exact Metrology, Inc.

20515 Industry Avenue Brookfield, WI 53045

Phone: 262-533-0800

Local: 866-722-2600

www.exactmetrology.com

deans@exactmetrology.com

Exact Metrology, with facilities in Cincinnati and Milwaukee and affiliated offices throughout the Midwest, is a comprehensive metrology services provider, offering customers 3D and CT scanning, reverse engineering, quality inspection, product development and 2D drawings. The company also provides turnkey metrology solutions, including equipment sales and lease/rental arrangements.

Continue reading