Contact us today:

(847) 934-4500

tdaro@bernardandcompany.com

Contact us today:

(847) 934-4500

tdaro@bernardandcompany.com

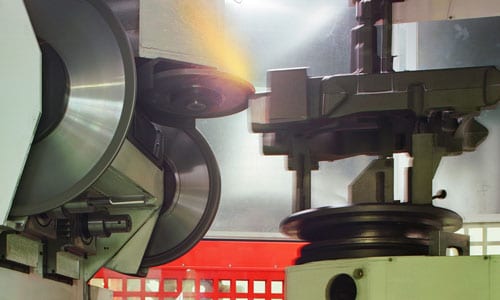

Major Indian caster anticipates dramatic improvement in surface quality and production rates from new Italian grinding/fettling center

Mr. N. Krishna Samaraj, managing director for Magna, stated it was the company’s expectation that this machining system, scheduled for start-up after July, 2011, will result in significant improvements in the surface quality and production rates at the company. Magna is a vertically integrated foundry, as it performs various machining, surface treatment and heat treating operations, in addition to its full foundry capabilities for various products sold to the valve, refrigeration, rail, hydraulics, automotive, wind turbine and other industries worldwide.

Magna runs a fully automated sand prep and mold line, as well, using equipment from its longtime supplier, Hunter Automated Machinery, who represents Maus in various world market areas. Magna currently runs a Hunter HMP20E Automatic Molding Machine (1994) and an HLH 20 Type II mold handling system (2007).

The sale of this Maus grinding/fettling machine was finalized between Mr. N. Krishna Samaraj for Magna and Mr. Ashwin Katke of Carraro, the parent company of Maus, with offices in India.

For further information on this announcement, interested parties may contact:

MAGNA ELECTRO CASTINGS LIMITED 43, Balasundaram Road Coimbatore – 641 -018 Tamilnadu, India Phone: +91 4322 2240109 Email: magnacast@vsnl.com Web: www.magnacast.com Attention: Mr. N. Krishna Samaraj, Managing Director

Or

MAUS SpA Via Caltana, 28 35011 Campodarsego Padova, Italy Phone: +39 0499299311 Sandra Selwan, Marketing Manager Sandra_Selwan@maus.it www.maus.it

Or

HUNTER AUTOMATED MACHINERY CORPORATION 2222 Hammond Drive Schaumburg, Illinois 60196-1094 USA Phone: +1 847 397 5136 Email: kpurdy@hunterauto.com Web: www.hunterauto.com Attention: Kevin Purdy, Vice President

Editor Note: Please direct all publication-generated inquiries to Kevin Purdy at Hunter. Thanks!

Agency contact for Hunter: Tim Daro Bernard & Company Palatine, Illinois (Chicago) USA +1 847 934 4500 tdaro@bernardandcompany.com

Significantly reduces inventory, changeover time for lathe and mill/turn users

See the U-Tec video HERE.

Heimatec, a world leader in live tools, angle heads and multi-spindle drill heads, today announced immediate availability of its newest development, recently unveiled at IMTS.

U-Tec® is the company’s patented flexible tool adapter system that allows a standard ER output live tool to accept various adapters for different applications. This allows users the ability to have quick changeover of tools on almost any lathe, using a single live tool, without having to commit to a quick-change system on the initial purchase. A facemill adapter, for example, can be quickly positioned into the standard holder, without the need for a completely new base being installed. This significantly reduces inventory costs as well as changeover time, for the busy shop.

The U-Tec® system, according to Heimatec Inc. President Preben Hansen, “…represents a real improvement in lathe and mill/turn tooling design. U-Tec® allows great user flexibility, while a polygonal drive system ensures extremely high power transmission stability and faster set-up with absolutely no loss in performance or accuracy, because the live tool base remains in position and only the adapter and collet get swapped.”

He went on to explain the unique collet nuts on the U-Tec® system have internal threading for rigid mounting and that this new tool adapter system enables the actual cutting tool to be brought into closer proximity to the bearing, thus further improving performance in use. This benefit results from the short and compact tool length design. Internal coolant up to 2000 psi(140 bar) is provided standard.

Every adapter in the U-Tec® system comes complete with any necessary clamping nuts and adapters are immediately available in face mill style, ER extensions, side lock, shrink fit, hydraulic and blank.

The U-Tec® system is available for all major turning machines on the market today. Heimatec currently manufactures over 10,000 live tool types.

For further information and literature on this new product, please contact:

Preben Hansen, President

HEIMATEC INC.

16 E. Piper Lane Suite 129

Prospect Heights, IL 60070

Phone: 847-749-0633

Fax: 847-749-2445

Email: info@heimatecinc.com

Website: www.heimatecinc.com

—

Heimatec is an international tooling manufacturer, based in Renchen, Germany. Its experienced staff is dedicated to providing customers the most innovative tooling technology possible. In 2010, the company opened Heimatec Inc. in Prospect Heights, IL, near Chicago, to serve its growing North American customer base with sales and service, plus an extensive inventory of products. Heimatec serves the auto, aero, medical, off-highway, rail, energy, woodworking, composites and other industries, as well as an ever-increasing number of machine tool OEM’s worldwide.

Continue reading

42 kW installed in nickel chrome wire coils, supported by a stainless steel frame, heat the workspace, while a heat resistant alloy recirculating blower, powered by a 5-HP motor, provides vertical downward airflow to the workload.

This tempering furnace features 7” thick insulated walls, comprising 1” of 2300°F ceramic fiber blanket, 2” of 1700°F ceramic fiber blanket, 2” of block insulatin and 2” of rockwool insulation. The 6-1/2” thick furnace floor comprises 4-1/2” of 2300°F firebrick and 2” of block insulation. 16 ga. Stainless steel interior lagging and a stainless steel subway grating hearth are also included.

No. 885 has an electrically-operated vertical lift door with an automatic door switch to shut off the heaters when the door is opened.

Grieve’s inert atmosphere construction includes a continuously welded outer shell, a high-temperature door gasket, sealed heater terminal boxes, an inert atmosphere inlet and inert atmosphere outlet, plus a recirculating blower shaft seal.

This furnace also has an inert atmosphere flowmeter and digital programming temperature controller onboard.

For more information, please contact:

THE GRIEVE CORPORATION

500 Hart Road

Round Lake, IL 60073-2898

Phone: (847) 546-8225

Fax: (847) 546-9210

Web: www.grievecorp.com

Email: sales@grievecorp.com

Attention: Frank Calabrese, VP

6.6 kW installed in Nichrome wire heating elements provide the heat, while a 600 CFM, 1/3-HP recirculating blower furnishes a universal pattern airflow to the workload.

This oven features an aluminized steel exterior, Type 430 stainless steel interior and 4” thick insulated walls, plus a silicone rubber door gasket and explosion-venting latches. A 500 lb. capacity subway grating shelf and seven angle iron shelf supports are included.

No. 891 has a digital indicating temperature controller to display actual and set point readings.

For more information, please contact:

THE GRIEVE CORPORATION

500 Hart Road

Round Lake, IL 60073-2898

Phone: (847) 546-8225

Fax: (847) 546-9210

Web: www.grievecorp.com

Email: sales@grievecorp.com

Attention: Frank Calabrese, VP

No. 877 is a 500°F electric walk-in oven from Grieve, currently in use for a variety of heat processing applications at a customer’s facility. Workspace dimensions of this unit measure 108”W x 144”D x 84”H.

This jumbo walk-in oven features an aluminized steel interior and exterior, 4” thick insulated walls, exceptionally heavy-duty walls with high-temperature stainless steel spring insert door gaskets, a brushed stainless steel control panel face and rear-mounted heat chamber.

No. 877 also includes a digital programming temperature controller and a manual reset excess temperature controller with separate heating element control contactors.

For more information, please contact:

THE GRIEVE CORPORATION

500 Hart Road

Round Lake, IL 60073-2898

Phone: (847) 546-8225

Fax: (847) 546-9210

Web: www.grievecorp.com

Email: sales@grievecorp.com

Attention: Frank Calabrese, VP

350,000 BTU/HR installed in a modulating natural gas burner heat the workspace, while a 3000 CFM, 2-HP recirculating blower furnishes vertical downward airflow to the workload. This oven features an aluminized steel interior and exterior, 4” thick insulated walls and two 12” diameter tubeaxial fans, each driven by a _-HP motor to push/pull air through the cooling zone. A side oven door allows access to the heat chamber.

No. 876 includes a 16”W, B36-24-14 conveyor belt with 3”H flex plate edges, driven by a 1/3-HP motor with variable speed from 1.3 to 26 feet per minute.

All safety equipment required by IRI, FM and NFPA Standard 86 for gas-heated equipment is onboard, including a 325 CFM, 1/3-HP powered forced exhauster.

For more information, please contact:

THE GRIEVE CORPORATION

500 Hart Road

Round Lake, IL 60073-2898

Phone: (847) 546-8225

Fax: (847) 546-9210

Web: www.grievecorp.com

Email: sales@grievecorp.com

Attention: Frank Calabrese, VP

No. 876

Continue reading

Workspace dimensions of this oven measure 36” wide x 48” deep x 36” high. 24KW installed in Incoloy-sheathed tubular heating elements furnish the heat, while a 1400 CFM, 1 ½-HP recirculating blower provides front to back horizontal airflow to the workload.

This Grieve oven has 10” insulated walls, aluminized steel exterior and Type 304, 2B finish stainless steel interior, plus three roller rails at the bottom of the workspace to support 2,500 lb. loads. The oven includes an integral, heavy-duty leg stand.

Safety and control equipment on-board this Grieve oven include a 975 CFM blower to pull air through an air jacket on the inner oven for cooling, a digital indicating temperature controller, manual reset excess temperature controller with separate contactors, recirculating blower airflow safety switch, 10” diameter circular chart recorder and SCR power controller.

Grieve inert atmosphere oven construction features include all interior seams welded gas-tight, all wall penetrations welded inside and fitted with compression fittings outside, inner oven walls extended through oven throat area to seal directly against silicone rubber door seal, 2-point cam action positive latching door hardware, inert atmosphere inlet with pressure regulator, atmosphere flowmeter, and pressure gauge to indicate interior oven pressure.

For more information, please contact:

Workspace dimensions measure 24” wide x 48” deep x 24” high. 53KW installed in heavy-gauge, high-temperature Kanthal AF alloy wire, rod overbend design heaters provide maximum operating temperatures to 2200OF.

This Grieve furnace features 9” insulated walls, consisting of 4 ½” thick 2600OF firebrick, 2 ½” thick 2300OF firebrick and 2” thick block insulation. A firebrick plate hearth is supported on firebrick piers. An electrically-operated vertical lift door is provided, with remote foot pedal control.

Special inert atmosphere construction on No. 854 includes a continuously welded outer shell, high-temperature door gasket, sealed heater terminal boxes, inert atmosphere inlet, outlet and flowmeter.

Safety and control equipment on-board this Grieve furnace include a digital indicating temperature controller, manual reset excess temperature controller with separate contactors and a four-channel strip chart recorder.

For more information, please contact:

THE GRIEVE CORPORATION

500 Hart Road

Round Lake, IL 60073-2898

Phone: (847) 546-8225

Fax: (847) 546-9210

Web: www.grievecorp.com

Email: sales@grievecorp.com

Attention: Frank Calabrese, VP

No. 848 is a special high-temperature 1000oF electrically-heated, top-loading oven from Grieve, currently used for preheating large steel molds at a customer’s facility.

This Grieve oven features 8” insulated walls, an aluminized steel interior and exterior, reinforced ¼” steel plate top, air-operated rear-hinged door, wear bars at the sides of the workspace and a floor reinforced for 2,000 lb. load on a removable subway grate.

Safety and control equipment on No. 848 include a digital indicating temperature controller, manual reset excess temperature controller with separate contactors, and a recirculating blower airflow safety switch.

For more information, please contact:

THE GRIEVE CORPORATION

500 Hart Road

Round Lake, IL 60073-2898

Phone: (847) 546-8225

Fax: (847) 546-9210

Web: www.grievecorp.com

Email: sales@grievecorp.com

Attention: Frank Calabrese, VP