Contact us today:

(847) 934-4500

tdaro@bernardandcompany.com

Contact us today:

(847) 934-4500

tdaro@bernardandcompany.com

When implementing mechanical and hydraulic presses and handling equipment, for instance in the automotive industry, a predominantly modular design ensures the highest degree of flexibility and shortest engineering and installation times for customized systems. The Metal Forming Solution Package provides all of the functions required to automate press systems, therefore supporting press manufacturers when quickly implementing their specific press concepts.

View the Metal Forming Solution Package Brochure and visit Siemens at Fabtech, Booth S-4686!

Additional information can be found on the Siemens US metalforming website.

See below for customer reference videos:

For specific product information and inquiries, call (800) 879-8079 ext. Marketing Communications or send an e-mail to: SiemensMTBUMarCom.industry@siemens.com.

—

Siemens Industry Sector is the world’s leading supplier of innovative and environmentally friendly products, solutions and services for industrial customers. With end-to-end automation technology and industrial software, solid vertical-market expertise, and technology-based services, the sector enhances its customers’ productivity, efficiency and flexibility. With a global workforce of more than 100,000 employees, the Industry Sector comprises the Industry Automation, Drive Technologies and Customer Services Divisions as well as the Metals Technologies Business Unit. For more information, visit http://www.usa.siemens.com/industry.

The Siemens Drive Technologies Division is the world’s leading supplier of products, systems, applications, solutions and services for the entire drive train, with electrical and mechanical components. Drive Technologies serves all vertical markets in the production and process industries as well as the infrastructure/energy segment. With its products and solutions, the division enables its customers to achieve productivity, energy efficiency and reliability. For more information, visit http://www.usa.siemens.com/drivetechnologies.

Continue readingMultiple machines and services from longtime leader in stamping presses to be displayed at FABTECH Booth 4363

The HEIM Group has been designing and manufacturing presses for over 65 years. The company’s HEIM and ROUSSELLE press brands are known worldwide for their quality construction and performance. Built in the Chicago factory, using American-made components, whenever possible, the presses have a reputation for dependable operation, competitive price and superior support from dealers and inside staff.

Click to see the presses in action!

For more information, please stop by Booth S4363 at FABTECH or contact:

The Heim Group

6360 W. 73rd. St.

Chicago, IL 60638

Phone: 708.496.7400

Fax: 708.496.7428

Email: info@theheimgroup.com

Website: www.theheimgroup.com

Attention: Gina Petraitis

Hennig chip conveyors on Niigata machining centers maintain efficiencies and production on ductile iron castings used in heavy truck and military drive train projects at Michigan shop

The shop machines over 98% of its workpieces from ductile iron and the iron sludge build-up in the coolant tank is an all too familiar problem for the production personnel. As Accurate’s engineering manager Mark Tario explains, “We approach every machine with a keen eye on machine uptime and an absolute ease of maintenance. We had experimented with other systems to handle cast ductile iron fines and knew their benefits as well as their shortcomings.” Mark notes the company had actually designed two systems in-house to improve the handling of chips and the cleaning of coolant. While the benefits had been appreciable, they felt there was still a shortfall and the team at Accurate began a systematic search for a better solution.

One of the potential vendors, Hennig, was an established force in the market, as the company’s chip conveyors and machine enclosures are found on many of the global machine tool builders’ equipment. A particular development from Hennig caught the attention of the team at Accurate, namely, a magnetic chip disc filtration system that represented a substantial improvement over the traditional drum screen filtration system used on most competing brands. The relative ease of changeover immediately impressed the Accurate engineers, both from the production and maintenance perspectives. As Mark explains, “Replacing the drum filter screens is not an easy task, in fact it can be downright miserable. The Hennig disc arrangement seemed to us a much easier system to operate and maintain. The incorporation of a rare earth drum & scraper assembly inside the conveyor appeared to be a great solution for minimizing the amount of cast iron fines reaching the coolant tank side of the system.” Mark notes the heavier-duty mechanical components and drive chains used on the Hennig conveyor were also impressive, providing a greater wear life and reduced downtime likelihood.

Every aspect of the machine-to-conveyor connection was planned out by the Accurate team, including the layout of the coolant tank covers and the access ports. This attention to detail is something in which the company takes great pride. “The Hennig team was very good on this job and they realized that nothing less than their best efforts would satisfy us,” Tario notes.

Among the many issues Accurate had to overcome, downtime for maintenance was the most prominent. The machining of cast iron, by definition, creates considerable problems arising from the frequent need to replace conveyor chains, drum screens and other mechanical components that get infiltrated by the iron fines and literally lock up. The conveyor chains on the Hennig system, for example, were found stronger than the typical styles used on competing brands, which often required adjustments and repairs several times annually and were usually in need of total replacement, once a year. Depending on the severity of the repair or replacement operation, this situation resulted in many hours or even several days to rectify. Practically speaking, the maintenance personnel would get completely soaked and filthy with the coolant and sludge as a result.

Another common problem for the maintenance personnel are coolant related failures. On the HMCs at Accurate, a substantial amount of “through the spindle coolant” is used to improve productivity. However, this generous use of coolant can create an immediate and dangerous problem, if the coolant runs low and the machine has no safeguard-warning device, especially when drilling and tapping. Nearly half the Accurate systems had no such devices originally, resulting in some damage conditions on the high-speed drills used here. A third of the later systems used at the company had a communication device to put the machine’s CNC into a single block state when the coolant tank ran low, but had no protection to shut off the pump to prevent dry running. Mark notes, “On our third generation systems, we changed from a diaphragm style pump to a screw pump, where dry running would be very bad, to say the least. With our fourth generation Hennig conveyors, however, we have all the protections of the previous generations plus all the necessary controls to shut down the pumps to prevent very costly system component damage.”

Accurate has already installed four Hennig systems, just received an additional three and has plans to purchase two more shortly, for a total of nine in the shop. All are connected to Niigata HMCs that have an opening in the back of the machine with a horseshoe-shaped channel where the conveyor fits. The overall machine size is 10’ wide by 30’ long.

Other Accurate personnel involved in this project who contributed to the story include Greg Mann, plant manager, Dennis Shepp, maintenance technician and Jim Weeks, shift supervisor and maintenance technician.

To see a video of this installation, please go to http://youtu.be/GDPHtJdFul4

—

Hennig, Inc. designs and produces custom machine protection and chip/coolant management products for state-of-the-art machine tools. Hennig products are designed to protect against corrosion, debris and common workplace contaminants. Manufacturing facilities located in the USA, Germany, France, Brazil, India, Japan, Czech Republic, England and South Korea. Repair centers are located in Machesney Park, IL; Chandler, OK; Livonia, MI; Blue Ash, OH; Mexico City, Mexico; and Saltillo, Mexico.

To learn more about Hennig products & services, visit www.hennigworldwide.com or call 1-888-HENNIG6 (436-6446).

For more information, please contact:

Tim Waterman

Hennig, Inc.

2500 Latham St.

Rockford, IL 61103

Phone: 815-316-5277

Fax: 815-962-6483

E-mail: info@hennig-inc.com

Connect with Hennig online:

For more information on Accurate Gauge in this story, please contact:

Accurate Gauge & Manufacturing, Inc.

2943 Technology Drive

Rochester Hills, MI 48309

Phone: 248-853-2400

Web: www.accurategauge.com

Email: mark@accurategauge.com

Mark Tario, Engineering Manager

Ann Arbor, Michigan – GMTA (German Machine Tools of America) represents various top-quality German metalworking machine builders, including Profilator, Pittler, Praewema and WMZ. These machines are sold to the North American market by GMTA primarily for gear and spline production, as well as other power transmission applications. The company’s target markets include automotive, off-highway, OCTG and other heavy equipment manufacturing. Machines are provided for gear honing, gear grinding, Scudding®, polygon milling, turning, gear tooth pointing and multiple machining operations.

Maik Schminke is named Manager of Controls Engineering & Programming

In the news…

-Effective October 1, Maik Schminke was named Manager of Controls Engineering & Programming at the Ann Arbor facility of GMTA. According to GMTA President Walter Friedrich, “This appointment fills our need to provide and support customers with machine tool controls, SPS, PLC and CNC programming.” Schminke has worked for the past 12 years at the German partner to GMTA, Diskus, part of the large DVS Group in Germany). Prior to Diskus, he worked at Pittler, another GMTA partner company in Germany and also a DVS Group company. Schminke completed his apprenticeship program, while at Pittler.

-EMO was a BIG success for all the partners to GMTA. Walter Friedrich and Scott Knoy from GMTA attended the show and saw many North American customers and friends, then visited their partner companies. As it was Oktoberfest in Germany, Walter and Scott also sampled several local brews. A good time was had by all!

-Plans are underway to have an open house at the newly renovated GMTA facility in Ann Arbor, Michigan. This expanded facility now houses parts and service, a full machine demo center, sales and corporate management for this growing machine tool company. GMTA is the exclusive North American distributor for leading German machine tool builders and tooling suppliers, concentrated in the gear and spline production machine markets.

For more information on this announcement, please contact:

GMTA (German Machine Tools of America)

4630 Freedom Drive

Ann Arbor, MI 48108

Phone: 734-973-7800

Fax: 734-973-3053

Web: www.gmtamerica.com

Email: scott@gmtamerica.com

Attention: Scott Knoy, VP

Connect with GMTA online:

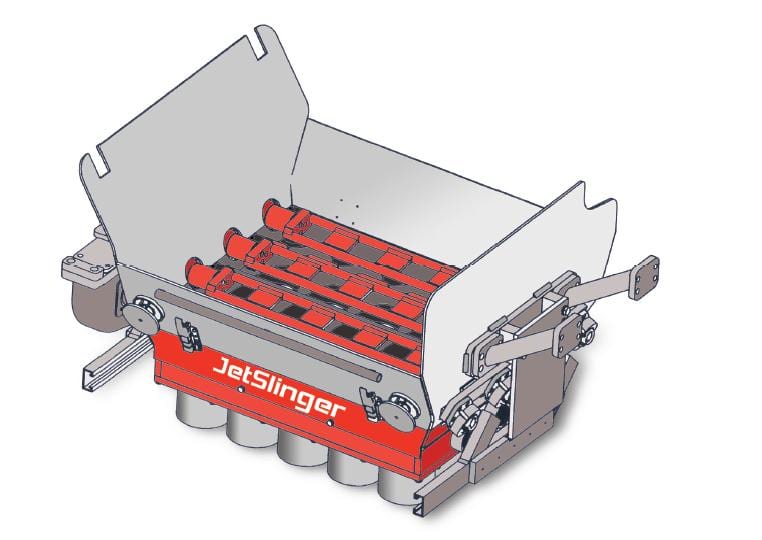

Impact-assisted flask filling addition to Hunter’s new HLM and successful XL product lines, JetSlinger helps increase mold production up to 300 percent.

The JetSlinger™ is an air amplification apparatus based on the Venturi principle that accelerates sand into the cope and drag flasks on these Hunter machines. It creates a powerful vacuum and jet exhaust that draws sand mixtures through an array of nozzle assemblies built into a manifold mounted directly below Fillaerator blades, then slings them into a flask. It was invented by company president Bill Hunter. The JetSlinger™ design holds U.S. Patent Number US7819168B2, one of nearly 150 domestic and international patents granted to Hunter since its founding in 1964.

Key features and benefits of JetSlinger™ include:

“In contrast to the conventional blow fill machines, no shroud, seals or vented flask assemblies, nor is the usual attendant maintenance required,” according to company president Bill Hunter. “Furthermore, JetSlinger™ allows foundries far greater flexibility, as well as the access needed to produce various castings with the use of chaplets, ram-up cores and exothermic risers,” he adds.

With its perpendicular fill, this impact-assisted device produces molds more quickly and with substantially improved surface quality, owing to the powered pre-compaction of the sand. This action results in greater uniformity of mold density and wall hardness, without sacrificing the accessibility and flexibility of a gravity fill machine. Additionally, the JetSlinger™ achieves a flask filling operation that compensates for the types of mold quality limitations that are often caused by the flowability of the sand and pattern configuration during the high-pressure squeeze cycle. The basic operation of the JetSlingerTM is as follows:

1) Sand mixture is loaded into a hopper

2) Hopper gates open

3) Rotating Fillaerator blades aerate the mixture

4) Mixture is delivered into the Venturi action air acceleration manifold

5) Mixture under pressure dispersed (slung) through 20 nozzles into the flask

6) Flask fills with pre-compaction around pattern plate.

Click HERE to see the JetSlinger™ in action!

ABOUT THE COMPANY

Hunter Foundry Machinery Corporation was founded in 1964 as Hunter Automated Machinery Corporation with the invention of the first gravity-filled automated matchplate molding machine. This established the company’s history of innovation and launched the foundry industry into a new industrial revolution. Pioneered by William “Al” Hunter in his garage, the original HMP-10 machine streamlined the laborious metal casting process by offering foundries unimagined new production capabilities, producing as many molds in one hour as most had been able to produce in an entire day. As industry demands grew Hunter responded with advanced solutions such as automated mold handling equipment and coresetters.

Now in its 50th year, Hunter Foundry Machine Corporation’s inventions have earned nearly 150 patents around the world. With more than 1,800 molding machines and mold handling systems installed around the world, Hunter’s sales and service reach extends from its manufacturing sites in North America, South America and China through its offices in the U.S., Europe, Brazil, India and Shanghai to every corner of the globe. Sales and technical support, as well as the company’s $12 million parts inventory, serve to maintain each machine’s original production capability, as well as Hunter’s preeminence in the world market.

FOR MORE INFORMATION PLEASE CONTACT:

HUNTER FOUNDRY MACHINERY CORPORATION

2222 Hammond Drive – Schaumburg, Illinois 60196-1094 – USA

Phone: +1 847 397 5136

info@hunterfoundry.com

www.hunterfoundry.com

Attention: Bill Hunter, CEO

Ann Arbor, Michigan – GMTA (German Machine Tools of America) represents various top-quality German metalworking machine builders, including Profilator, Pittler, Praewema and WMZ. These machines are sold to the North American market by GMTA primarily for gear and spline production, as well as other power transmission applications. The company’s target markets include automotive, off-highway, OCTG and other heavy equipment manufacturing. Machines are provided for gear honing, gear grinding, Scudding®, polygon milling, turning, gear tooth pointing and multiple machining operations.

In the news…

-DVS, the parent company of Pittler, Praewema and WMZ in Germany, has plans to expand its North American operations, owing to the success achieved with GMTA in this market

-Scudding® technology, pioneered by Profilator, continues to impact the North American gear and spline markets, due to its superior performance compared to other methods of production; several competitors trying to offer it, proving that indeed, “Imitation is the sincerest form of flattery.”

-The renovation of the GMTA facility in Ann Arbor, Michigan is now complete with plans in the works for future expansion of the campus. Additional floorspace, showroom capacity and training facilities, plus more personnel, are planned, according to company VP Scott Knoy.

-Now in final runoff with anticipated start-up in June, GMTA has provided eight machines (16 spindles total) for the advanced cylinder lining program to the Caterpillar operation in Mapleton, Illinois; project for GMTA valued at $15,000,000

-Order received from Chrysler for Phase III transmission line at IPT1 in Indiana

-GMTA and DVS will have joint booth space, considerably expanded, at IMTS 2014

For more information on this announcement, please contact:

GMTA (German Machine Tools of America)

4630 Freedom Drive

Ann Arbor, MI 48108

Phone: 734-973-7800

Fax: 734-973-3053

Web: www.gmtamerica.com

Email: scott@gmtamerica.com

Attention: Scott Knoy, VP

Connect with GMTA online:

The NOARK value proposition centers on products that improve the profitability and maintain the highest levels of performance for customer end products, through the combination of local support with local inventory, exceptional value and superior product quality, backed by the industry’s first 5-YEAR WARRANTY.

ALL ABOVE NOARK PRODUCTS ARE UL489 LISTED.

NOARK Electric, Inc., the North American headquarters of the company, was previously located in Rockford, IL and, due to its rapid growth and inventory commitments, has recently moved to a larger facility in Oak Creek, WI, just south of Milwaukee.

The company is currently in the process of establishing a representative and distribution network to serve its primary markets, which include the building trades and electric panel board builders in various industries.

A global supplier, NOARK currently operates four R&D centers, three distribution centers, 15 office locations and employs over 1000 associates. Sales for the company exceed $2 billion worldwide.

For more information, please contact:

NOARK Electric, Inc.

9817 South 13th Street

Oak Creek, WI 53154

Phone: 414-304-8189

Website: www.noark-electric.com

Email: tony.diaz@noark-electric.com

Attention: Tony Diaz

Heimatec is a world leader in the development and manufacturing of live tools, angle heads and multi-spindle drill heads. With U.S. head quarters located in the Chicagoland area and company head quarters and manufacturing in Renchen Germany, we are dedicated to supplying our customers the most innovative tooling technology possible.

Check out the new look at www.heimatecinc.com!

For more info on Heimatec:

Preben Hansen, President

HEIMATEC INC.

16 E. Piper Lane Suite 129

Prospect Heights, IL 60070

Phone: 847-749-0633

Fax: 847-749-2445

Email: info@heimatecinc.com

Website: www.heimatecinc.com

—

Heimatec is an international tooling manufacturer, based in Renchen, Germany. Its experienced staff is dedicated to providing customers the most innovative tooling technology possible. In 2010, the company opened Heimatec Inc. in Prospect Heights, IL, near Chicago, to serve its growing North American customer base with sales and service, plus an extensive inventory of products. Heimatec serves the auto, aero, medical, off-highway, rail, energy, woodworking, composites and other industries, as well as an ever-increasing number of machine tool OEM’s worldwide.

Continue readingNOARK ENTERS NORTH AMERICAN MARKET AT AHR 2013, BOOTH 5700

A name you may not yet know, but NOARK Electric provides reliable products and efficient solutions to intelligent power and energy systems worldwide. This global supplier of electrical components and intelligent control systems will be presenting an assortment of UL 489 Listed circuit breakers, relays and contactors at the upcoming AHR Expo in Dallas. This show represents the company’s first trade show in the North American market.

The NOARK value proposition centers on products that improve the profitability and maintain the highest levels of performance for customer end products, through the combination of local support with local inventory, exceptional value and superior product quality, backed by the industry’s first 5-YEAR WARRANTY.

Among the many offerings to be displayed at AHR Booth 5700 will be the following NOARK products:

ALL ABOVE NOARK PRODUCTS ARE UL489 LISTED.

Booth personnel will include Paul Xu, VP of Strategy & Marketing, Ken Hilborn, Sales & Marketing Director, Tony Diaz, Product Marketing Manager and Kirk Wilson, West Region Manager.

NOARK Electric, Inc., the North American headquarters of the company, was previously located in Rockford, IL and, due to its rapid growth and inventory commitments, has recently moved to a larger facility in Oak Creek, WI, just south of Milwaukee.

The company is currently in the process of establishing a representative and distribution network to serve its primary markets, which include the building trades and electric panel board builders in various industries.

A global supplier, NOARK currently operates four R&D centers, three distribution centers, 15 office locations and employs over 1000 associates. Sales currently exceed $2 billion worldwide.

For more information, please stop by booth 5700 at AHR Expo or contact:

NOARK Electric, Inc.

9817 South 13th Street

Oak Creek, WI 53154

Phone: 414-304-8189

Website: www.noark-electric.com

Tony Diaz

Email: tony.diaz@noark-electric.com

24,000 RPM max. styles available for all popular machine tools

Heimatec, a world leader in live tools, angle heads and multi-spindle drill heads, announces immediate availability of its newest development, a line of 1:4 live tool speed multipliers in 24,000 RPM max. styles, available for all popular live tool lathes currently on the market.

These speed multipliers are provided as axial or radial drilling and milling heads, with either external or internal coolant design, and mounting configurations to suit virtually any machine tool turret set-up, including all VDI and BMT sizes.

Radial milling and drilling head style speed multiplier from Heimatec, ER 16 variation

Speed multipliers for Haas and Nakamura machines are now in stock with others in production for short lead time deliveries.

According to Heimatec President Preben Hansen, “As our presence in the American machine tool market continues to expand, so does our product line. These speed multipliers are a great addition to our line. They give us more to offer the job shop and large production departments, through our growing network of reps and distributors, serving the market here.”

For further information and literature, or to arrange a demo on this new line, please contact:

Preben Hansen, President

HEIMATEC INC.

16 E. Piper Lane Suite 129

Prospect Heights, IL 60070

Phone: 847-749-0633

Fax: 847-749-2445

Email: info@heimatecinc.com

Website: www.heimatecinc.com

—

Heimatec is an international tooling manufacturer, based in Renchen, Germany. Its experienced staff is dedicated to providing customers the most innovative tooling technology possible. In 2010, the company opened Heimatec Inc. in Prospect Heights, IL, near Chicago, to serve its growing North American customer base with sales and service, plus an extensive inventory of products. Heimatec serves the auto, aero, medical, off-highway, rail, energy, woodworking, composites and other industries, as well as an ever-increasing number of machine tool OEM’s worldwide.

Continue reading