Contact us today:

(847) 934-4500

tdaro@bernardandcompany.com

Contact us today:

(847) 934-4500

tdaro@bernardandcompany.com

EMAG has a long history, starting back in 1867 in Bautzen, Germany, as an iron foundry and engineering works. Re-established 60 years ago in Eislingen, Germany, in 1952 to make lathes and special-purpose machines, today it makes manufacturing systems for precision metal components from its headquarters in Salach, Germany. Its machines range from basic round-part vertical turning centers to machining centers with as many as six axes handling large workpieces. They perform turning, milling, grinding, hobbing, drilling and more as singular purpose setup or combination machines.

EMAG’s equipment differs from typical vertical lathe machining centers, whose head stock is mounted, typically horizontally, and a turret turns to do the machining. “Our turret is mounted in a concrete base, so it’s not moving,” Loetzner explains. “We have a head stock that moves outside of that design. That gives us better precision and better tool life.”

Another example comes from Precima Magnettechnik in Brückeburg, Germany, whose customers expect absolute perfection from, in this case, housings for brakes used mainly for wind turbines. Precima had had issues with machine vibration causing negative effects on tool life and surface finish. However, the rigidity of EMAG’s turning machines and the vibration damping quality of the base allows for the very high feed rates and cutting speeds required in precision hard-machining. Precima now runs four vertical pick-up turning machines from EMAG.

In one recent case study, EMAG needed to provide grinding, turning and turn-grind machines to a major agricultural equipment builder, and the machine builder relied on the 840D CNC. “We needed to devise a control solution that would satisfy all the needs of the various machines we were supplying to this demanding customer, based on a common platform, to enable easier design, integration, startup, commissioning on-site and training for our customer’s operations and maintenance personnel,” Loetzner said at the time.

The CNC also enables remote monitoring over a wireless network so that process engineers can see what the operator sees on each machine. The agricultural equipment customer mentioned has used the remote monitoring capability on a wide variety of EMAG machines for several years, with all data communicated through a single information network that’s accessible by both EMAG and Siemens. Through this arrangement, they have been able to significantly reduce downtime, service calls and troubleshooting identification time.

While happy with the precision capabilities, EMAG’s focus on future development is trying to decrease the downtime between producing components. “On the automation and the part handling, the challenge is you want the machine to run and make parts all the time, right? But once a part is done, you have to take it out and put the other in,” Loetzner says. “Those non-productive times are the biggest enemies.”

“While we have shown the industry we can master any part to highest precision, over the last five years we’ve been more and more focused on tightening non-productive time,” Loetzner says. At IMTS in Chicago in September, 2012, EMAG showed a new machine generation that significantly reduces the non-value add times. “Our chip-to-chip time was between 6 and 7 seconds for typical automotive gear,” Loetzner says. “Now it would be a second or less.”

For more information:

Kristal Kilgore

EMAG LLC

38800 Grand River Avenue

Farmington Hills, MI 48335

Tel: (248) 875-0313

Fax: (248) 477-7784

E-mail: kkilgore@emag.com

Web: www.emag.com

Check out Cutting Tool Engineering’s coverage of EMAG’s VL 2 P at IMTS 2012 HERE.

Contact for press and publishers:

EMAG LLC

38800 Grand River Avenue

Farmington Hills, MI 48335

Tel: (248) 875-0313

Fax: (248) 477-7784

E-mail: info@usa.emag.com

Web: www.emag.com

Attention: Peter Loetzner

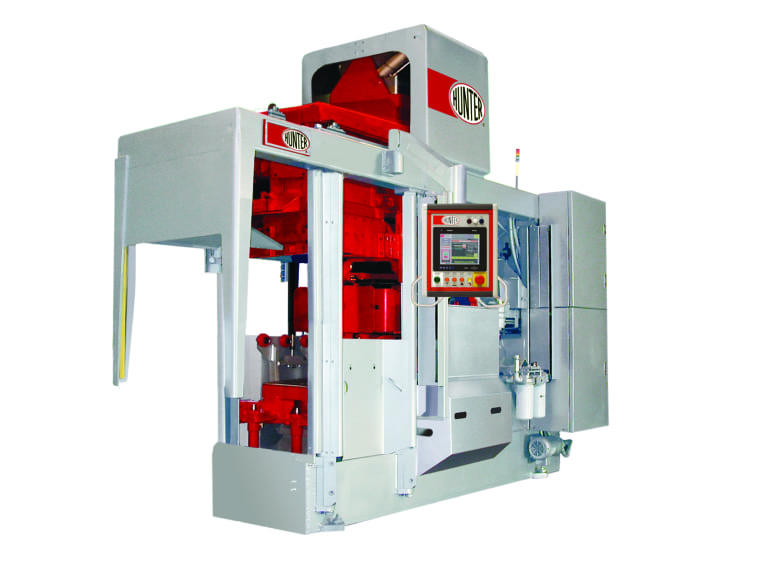

Continue readingSkeppshult Gjuteri AB buys XL 2430 automatic matchplate molding machine from Hunter for cast iron cookware production

The foundry, located on the Nissan River in southern Sweden, is the last remaining cast iron cookware production facility in Scandinavia. Skeppshult cookware and other household items carry a 25-year guarantee, owing to the quality of materials, production and craftsmanship provided by this manufacturer.

The Hunter XL 2430 is used at Skeppshult Gjuteri AB for the production of sand molds, the technology employed at this cast iron foundry.

This sale was made through the European office of Hunter in Milan, Italy and overseen by the director of European Operations for the company, Dr. Paolo Nazari. The local Hunter representative for this success was HYBE Maskin AB of Halmstad, Sweden.

ABOUT THE COMPANY

Hunter Foundry Machinery Corporation was founded in 1964 as Hunter Automated Machinery Corporation with the invention of the first gravity-filled automated matchplate molding machine. This development established the company’s history of innovation and launched the foundry industry into a new industrial revolution. Pioneered by William “Al” Hunter in his garage, the original HMP-10 machine streamlined the laborious metal casting process by offering foundries unimagined new production capabilities, producing as many molds in one hour as most had been able to produce in an entire day. As industry demands grew, Hunter responded with advanced solutions such as automated mold handling equipment and coresetters.

Now in its 50th year, Hunter Foundry Machinery Corporation’s inventions have earned nearly 150 patents around the world. With more than 1,800 molding machines and mold handling systems installed around the world, the Hunter sales and service reach extends from its manufacturing sites in North America, South America and China through its offices in the U.S., Europe, Brazil, India and Shanghai to every corner of the globe. Sales and technical support, as well as the company’s $12 million parts inventory, serve to maintain each machine’s original production capability, as well as Hunter’s preeminence in the world market.

FOR MORE INFORMATION, PLEASE CONTACT:

HUNTER AUTOMATED MACHINERY CORPORATION

2222 Hammond Drive Schaumburg, IL 60196

Phone: (847) 397-5110

Fax: (847) 397-8254

Email: info@hunterfoundry.com

Attention: Bill Hunter, CEO

Web: www.hunterfoundry.com

Connect with Hunter Foundry online:

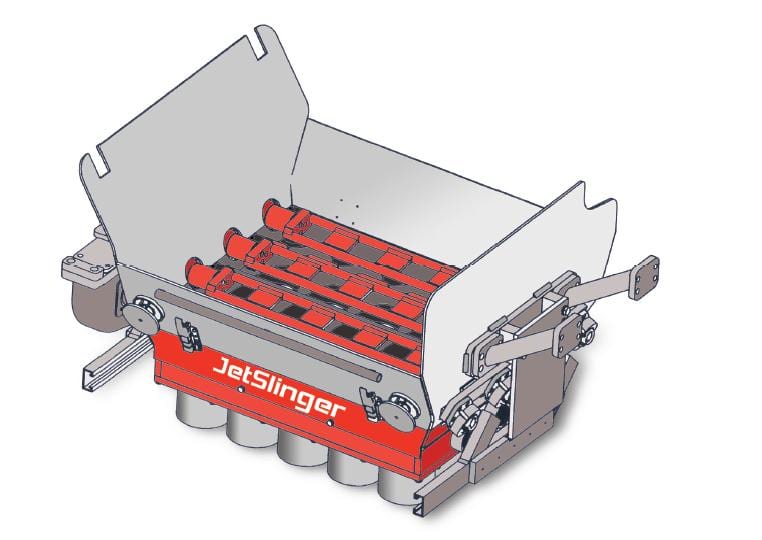

Impact-assisted flask filling addition to Hunter’s new HLM and successful XL product lines, JetSlinger helps increase mold production up to 300 percent.

The JetSlinger™ is an air amplification apparatus based on the Venturi principle that accelerates sand into the cope and drag flasks on these Hunter machines. It creates a powerful vacuum and jet exhaust that draws sand mixtures through an array of nozzle assemblies built into a manifold mounted directly below Fillaerator blades, then slings them into a flask. It was invented by company president Bill Hunter. The JetSlinger™ design holds U.S. Patent Number US7819168B2, one of nearly 150 domestic and international patents granted to Hunter since its founding in 1964.

Key features and benefits of JetSlinger™ include:

“In contrast to the conventional blow fill machines, no shroud, seals or vented flask assemblies, nor is the usual attendant maintenance required,” according to company president Bill Hunter. “Furthermore, JetSlinger™ allows foundries far greater flexibility, as well as the access needed to produce various castings with the use of chaplets, ram-up cores and exothermic risers,” he adds.

With its perpendicular fill, this impact-assisted device produces molds more quickly and with substantially improved surface quality, owing to the powered pre-compaction of the sand. This action results in greater uniformity of mold density and wall hardness, without sacrificing the accessibility and flexibility of a gravity fill machine. Additionally, the JetSlinger™ achieves a flask filling operation that compensates for the types of mold quality limitations that are often caused by the flowability of the sand and pattern configuration during the high-pressure squeeze cycle. The basic operation of the JetSlingerTM is as follows:

1) Sand mixture is loaded into a hopper

2) Hopper gates open

3) Rotating Fillaerator blades aerate the mixture

4) Mixture is delivered into the Venturi action air acceleration manifold

5) Mixture under pressure dispersed (slung) through 20 nozzles into the flask

6) Flask fills with pre-compaction around pattern plate.

Click HERE to see the JetSlinger™ in action!

ABOUT THE COMPANY

Hunter Foundry Machinery Corporation was founded in 1964 as Hunter Automated Machinery Corporation with the invention of the first gravity-filled automated matchplate molding machine. This established the company’s history of innovation and launched the foundry industry into a new industrial revolution. Pioneered by William “Al” Hunter in his garage, the original HMP-10 machine streamlined the laborious metal casting process by offering foundries unimagined new production capabilities, producing as many molds in one hour as most had been able to produce in an entire day. As industry demands grew Hunter responded with advanced solutions such as automated mold handling equipment and coresetters.

Now in its 50th year, Hunter Foundry Machine Corporation’s inventions have earned nearly 150 patents around the world. With more than 1,800 molding machines and mold handling systems installed around the world, Hunter’s sales and service reach extends from its manufacturing sites in North America, South America and China through its offices in the U.S., Europe, Brazil, India and Shanghai to every corner of the globe. Sales and technical support, as well as the company’s $12 million parts inventory, serve to maintain each machine’s original production capability, as well as Hunter’s preeminence in the world market.

FOR MORE INFORMATION PLEASE CONTACT:

HUNTER FOUNDRY MACHINERY CORPORATION

2222 Hammond Drive – Schaumburg, Illinois 60196-1094 – USA

Phone: +1 847 397 5136

info@hunterfoundry.com

www.hunterfoundry.com

Attention: Bill Hunter, CEO

New technology provides safer, cleaner work environment, as well as cost savings, for foundries by capturing and recycling unused pattern spray.

SCHAUMBURG, IL — Hunter, the first name in automated matchplate molding machines and mold handling equipment, announced today the introduction of its new CESAR™ vacuum pattern spray recovery system. The CESAR system will be made available to the world market at the company’s Cast Expo 2013 Booth #473, where it will be mounted on Hunter’s new HLM-10 linear motion molding machine. CESAR will run throughout Cast Expo 2013, one of the foundry industry’s leading events, being held April 6-9th at America’s Center in St. Louis, MO.

According to Hunter Foundry Machinery Corporation president and CEO Bill Hunter, who invented the system, “CESAR” stands for Contain, Evacuate, Separate And Recover. “This relates to the proper disposition of pattern spray typically used in sand molding operations, to act as a release agent between the mold and the pattern plate,” Hunter said. “We invented it in response to our customer’s needs, in recognition both of modern foundry and global environmental standards and to help improve their return-on-investment (ROI).

In operation, the closed-loop CESAR System from Hunter executes the following:

Most typical molding machines include a spray head positioned in the sand filling station and a spray evacuation device positioned near the rotary cradle or the spray head. The spray is then dispersed onto the pattern plate as it enters the rotary cradle. But uncontained, excess spray can go onto other parts, as well as into the foundry atmosphere. This is why Hunter created its new CESAR System.

“In our new CESAR System the evacuation device – a slotted tube on the circumference of the rotary cradle – connects to an inline vacuum pump. Then, a cyclonic separator and water separator capture release agent vapor from the air collected in the tube,” Hunter stated, adding that CESAR provides a cleaner, safer working environment in the sand foundry while providing not only substantial savings to a foundry’s operation but also a positive environmental benefit to that foundry’s “green” initiative.

ABOUT THE COMPANY

Hunter Foundry Machinery Corporation was founded in 1964 as Hunter Automated Machinery Corporation with the invention of the first gravity-filled automated matchplate molding machine. This established the company’s history of innovation and launched the foundry industry into a new industrial revolution. Pioneered by William “Al” Hunter in his garage, the original HMP-10 machine streamlined the laborious metal casting process by offering foundries unimagined new production capabilities, producing as many molds in one hour as most had been able to produce in an entire day. As industry demands grew Hunter responded with advanced solutions such as automated mold handling equipment and coresetters.

Now in its 50th year, Hunter Foundry Machine Corporation’s inventions have earned nearly 150 patents around the world. With more than 1,800 molding machines and mold handling systems installed around the world, Hunter’s sales and service reach extends from its manufacturing sites in North America, South America and China through its offices in the U.S., Europe, Brazil, India and Shanghai to every corner of the globe. Sales and technical support, as well as the company’s $12 million parts inventory, serve to maintain each machine’s original production capability, as well as Hunter’s preeminence in the world market.

FOR MORE INFORMATION PLEASE CONTACT:

HUNTER AUTOMATED MACHINERY CORPORATION

2222 Hammond Drive Schaumburg, IL 60196

Phone: (847) 397-5110

Fax: (847) 397-8254

Email: info@hunterfoundry.com

Attention: Bill Hunter, CEO

Web: www.hunterfoundry.com

Connect with Hunter Foundry online:

Expanding its pioneering position as the industry’s preeminent innovator, this new corporate name reflects the company’s single focus and dedication.

Founded in 1964 as Hunter Automated Machinery Corporation, the company’s reputation as a global foundry equipment leader has built steadily, beginning with its creation of the first truly automated matchplate molding machine developed by the company founder, the late William Allan “Al” Hunter. Since that time it has expanded into linear and rotary mold handling lines, sand handling, preparation and testing equipment, and more.

“Ever since my father founded our company nearly 50 years ago, our reputation has been built on the successful development of new products and technologies for the global foundry industry. It has been our privilege to serve this industry with the latest innovations, as was my father’s vision, ever since,” said Hunter.

“As an inventor, his primary focus was pioneering the automation of matchplate molding and mold handling processes to facilitate our industry’s most backbreaking tasks,” Hunter observed, adding, “As an entrepreneur, he named our company Hunter Automated Machinery Corporation to reflect a potential for creating forward-thinking solutions for other industries, as well.”

“Today we’re looking both at our history and ahead, to our legacy of innovation within the foundry industry,” Hunter stated. “Accordingly, we are announcing at Cast Expo 2013 the renaming of our company to Hunter Foundry Machinery Corporation, as a reflection of our single-focus past, present, and future exclusively within this industry,” he noted.

According to Hunter, the company has always been 100% dedicated to the foundry market. “It’s not only our business focus, it’s our inspiration,” he said. “The great people in this industry motivate our company to constantly and tirelessly pursue better ideas, technologies and production solutions for foundries worldwide. Our new name is a clear reflection of our business now, more than ever.”

The company’s introduction of the first gravity-filled automated matchplate molding machine established its history of innovation, and launched the foundry industry into a new industrial revolution. Its original HMP-10 machine streamlined the laborious metal casting process by offering foundries unimagined new production capabilities, producing as many molds in one hour as most had been able to produce in an entire day. As industry demands grew Hunter responded with advanced solutions such as automated mold handling equipment and coresetters.

Hunter’s inventions have earned the company nearly 150 patents around the world. With more than 1,800 molding machines and mold handling systems installed around the world, Hunter’s sales and service reach extends from its manufacturing sites in North America, South America and China through its offices in the U.S., Europe, Brazil, India and Shanghai to every corner of the globe. Sales and technical support, as well as the company’s $12 million parts inventory, serve to maintain each machine’s original production capability, as well as Hunter’s preeminence in the world market.

FOR MORE INFORMATION PLEASE CONTACT:

HUNTER AUTOMATED MACHINERY CORPORATION

2222 Hammond Drive Schaumburg, IL 60196

Phone: (847) 397-5110

Fax: (847) 397-8254

Email: info@hunterfoundry.com

Attention: Bill Hunter, CEO

Web: www.hunterfoundry.com

Connect with Hunter Foundry online:

New HLM-10 Linear Motion Machine, First of Hunter’s New Product Line, Unveiled at Cast Expo 2013

Minimizing maintenance while promoting stability, HLM Series combines and integrates magnetically coupled rodless cylinders and linear bearings for movements of squeeze platen, cope flask, sand measuring hopper, and other components on machine. Separation of hydraulic power system facilitates maintenance, while linear motion-operated, programmable access doors maximize operator protection. Linear motion machine also features CESAR™ vacuum pattern spray recovery system.

See the HLM in action HERE!

Hunter Demos JetSlinger™ Air-Amplification Product At Cast Expo 2013

JetSlinger™, the newest add-on to industry innovator Hunter Foundry Machinery Corporation’s latest products, helps ensure improved pattern definition, as well as uniformity of mold hardness and surface integrity.

JetSlinger™ is an available option for the new Hunter HLM linear-motion machine, as well as a retrofit option for the company’s XL automated matchplate molding machines. It is an air amplification apparatus based on the Venturi principle that accelerates sand into the cope and drag flasks on these Hunter machines.

See the JetSlinger™ in action HERE!

FOR MORE INFORMATION PLEASE CONTACT:

HUNTER AUTOMATED MACHINERY CORPORATION

2222 Hammond Drive Schaumburg, IL 60196

Phone: (847) 397-5110

Fax: (847) 397-8254

Email: info@hunterfoundry.com

Attention: Bill Hunter, CEO

Web: www.hunterfoundry.com

Connect with Hunter Foundry online:

Ann Arbor, Michigan – GMTA (German Machine Tools of America) represents various top-quality German metalworking machine builders, including Profilator, Pittler, Praewema and WMZ. These machines are sold to the North American market by GMTA primarily for gear and spline production, as well as other power transmission applications. The company’s target markets include automotive, off-highway, OCTG and other heavy equipment manufacturing. Machines are provided for gear honing, gear grinding, Scudding®, polygon milling, turning, gear tooth pointing and multiple machining operations.

In the news…

-DVS, the parent company of Pittler, Praewema and WMZ in Germany, has plans to expand its North American operations, owing to the success achieved with GMTA in this market

-Scudding® technology, pioneered by Profilator, continues to impact the North American gear and spline markets, due to its superior performance compared to other methods of production; several competitors trying to offer it, proving that indeed, “Imitation is the sincerest form of flattery.”

-The renovation of the GMTA facility in Ann Arbor, Michigan is now complete with plans in the works for future expansion of the campus. Additional floorspace, showroom capacity and training facilities, plus more personnel, are planned, according to company VP Scott Knoy.

-Now in final runoff with anticipated start-up in June, GMTA has provided eight machines (16 spindles total) for the advanced cylinder lining program to the Caterpillar operation in Mapleton, Illinois; project for GMTA valued at $15,000,000

-Order received from Chrysler for Phase III transmission line at IPT1 in Indiana

-GMTA and DVS will have joint booth space, considerably expanded, at IMTS 2014

For more information on this announcement, please contact:

GMTA (German Machine Tools of America)

4630 Freedom Drive

Ann Arbor, MI 48108

Phone: 734-973-7800

Fax: 734-973-3053

Web: www.gmtamerica.com

Email: scott@gmtamerica.com

Attention: Scott Knoy, VP

Connect with GMTA online:

Grieve Corporation introduces No. 821, a 650°F electric inert atmosphere walk-in oven, currently in use for annealing plastic rods at a customer’s facility.

Workspace dimensions inside this unit measure 36” wide x 156” deep x 48” high. 80 kW power is installed in Incoloy sheathed tubular heating elements, while a 7800 CFM, 5 HP recirculating blower provides horizontal airflow across the workloads.An aluminized steel exterior and interior are featured on this unit, which also includes 5” thick insulated walls throughout.

Special construction for inert atmosphere processing includes all the following components: pressure regulator, flowmeter, pressure gauge, internal high-temperature gasketing, bellow-type doorway seal, 1/2” thick cellular silicone rubber atmosphere seal, blower shaft seal, positive latching door hardware, adjustable offset door hinges, outlet with pressure relief, interior seams welded gas-tight and all wall penetrations equipped with compression fittings.

An additional 1500 CFM blower is furnished to pull air through an air jacket on the inner oven for cooling. An oxygen analyzer, 0-5% range, is also provided on this oven.

A flatbed loading truck with 3500 lb. capacity and integral channel support sides, plus a transfer dolly with oven-to-dolly and dolly-to-truck latches, was also provided to the customer.

This entire package was completely designed, engineered, built and fully tested by Grieve.

For more information, please contact:

THE GRIEVE CORPORATION

500 Hart Road

Round Lake, IL 60073-2898

Phone: (847) 546-8225

Fax: (847) 546-9210

Web: www.grievecorp.com

Email: sales@grievecorp.com

Attention: Frank Calabrese, VP

No. 838 is a 500oF gas-fired belt conveyor oven from Grieve, currently used for heating and curing battery cans at a customer’s facility.

Workspace dimensions of this oven measure 30” wide x 25’ deep by 18” high, with 4’ long open belt loading and unloading zones at each end. A 10,000 CFM, 7 ½-HP recirculating blower provides vertical downward airflow to the load, while a 350,000 BTU/HR modulating natural gas burner provides heat to the workspace.

No. 838 features a 24” wide, B-42-24-16 balanced weave conveyor belt with roller chain edge drive, powered by a 1/3-HP motor drive with variable speeds from 5-100 ipm.

This Grieve conveyor oven has an aluminized steel interior and exterior, with 4” insulated walls throughout. Side doors allow access to the entire workspace.

All safety and control equipment required by IRI, FM and NFPA Standard 86 for gas-heated equipment is on-board this unit, including a 325 CFM, 1/3-HP powered forced exhauster.

For more information, please contact:

THE GRIEVE CORPORATION

500 Hart Road

Round Lake, IL 60073-2898

Phone: (847) 546-8225

Fax: (847) 546-9210

Web: www.grievecorp.com

Email: sales@grievecorp.com

Attention: Frank Calabrese, VP