Contact us today:

(847) 934-4500

tdaro@bernardandcompany.com

Contact us today:

(847) 934-4500

tdaro@bernardandcompany.com

Ann Arbor, Michigan –Effective June 11, 2012, American Wera is now officially renamed German Machine Tools Of America (GMTA) and continues to represent various top-quality German metalworking machine builders, including Profilator, Pittler, Praewema, WMZ and MAE. These machines are sold for gear and spline production, vertical turning, flexible machining solutions (blank to finish part solutions), as well as bar, pipe and tube straightening plus wheelset pressing. The company’s target markets include automotive, off-highway, OCTG, rail, wind energy, aerospace and other heavy equipment manufacturing.

This announcement was made jointly by GMTA President Walter Friedrich and Vice President of Sales Scott Knoy.

“The reason for the name change is simply that the parent company wished to use a name that is more representative of all the lines we handle in North America,” said Knoy.

Originally formed as the North American subsidiary for Wera in Germany, GMTA today provides application engineering, sales and service for a broad range of machine tools and metal fabricating equipment. GMTA has representatives throughout the U.S., Canada and Mexico.

Other key company individuals include Claudia Hambleton, Treasurer; Doug VanDeven, Service/Parts Manager and Shawn Wilkin, Senior Service Engineer. Joseph Kemple remains the dedicated Product Manager for the MAE line of straightening and wheelset presses.

For more information on this announcement, please contact:

GMTA (German Machine Tools of America)

4630 Freedom Drive

Ann Arbor, MI 48108

Phone: 734-973-7800

Fax: 734-973-3053

Web: www.gmtamerica.com

Email: sales@gmtamerica.com

Attention: Scott Knoy, VP

Facebook: GMTA

Twitter: @GMTA_US

Fourth annual event to include Banner and Pioneer executives, presenting how to effectively address FDA supplier control concerns through strategic OEM/Supplier partnerships

Carol Stream, Illinois – Banner Medical executives Vince Adams, Vice-President of Sales, Marketing & Strategic Planning, and Bob Khin, Quality Assurance Director, along with Peter Johns, Supplier Quality Manager for Pioneer Surgical, will participate on a faculty panel at the upcoming Supplier Quality Management Congress sponsored by FDAnews, to be held at the Bethesda North Marriott Hotel & Conference Center in Bethesda, Maryland from July 31-August 2, 2012. The Banner Medical / Pioneer Surgical alliance has long been recognized in the industry as a successful strategic OEM / Supplier partnership formed to address the challenging supplier and raw material control issues which has been a focus of the FDA and of the Industry itself for the past decade. The partnership model, which the two companies have developed together, has produced positive results and yielded best practices that have been recognized by many and already adopted by some within the Medical Device industry.

This year’s Supplier Management Congress mark’s the fourth annual event and is designed to bring together suppliers, producers, top regulators / policy makers, legal and advisory consultants to the industry, for the purpose of assuring the integrity of Device raw materials and supply chains. FDA representatives as well a dozen other OEM and Supplier executives will participate as the faculty for this three-day event.

Attendees will include various manufacturers and suppliers to the industry, who will learn about risk management, recalls, liability issues and the new regulations recently instituted by FDA to better control the international drug and device supply chain to the medical markets.

Banner supplies medical and orthopedic device manufacturers with medical-grade materials to meet the highest quality standards. It operates two ISO 13485 and ISO 9001 certified, FDA CFR part 820 compliant facilities in Carol Stream, Illinois and Charlotte, North Carolina. The company provides its GuardiaNTM customer support solution program for supply chain management and medical materials stocking, plus its AssuraNce® protocol that assures all products made for the medical market are produced on equipment validated per the FDA requirements. Banner’s EsseNtial Quality SystemsTM is a patent-pending IT-based quality program that manages the company’s materials selection and production processes to deliver medical-grade bar and plate stock.

Banner Medical is a strategic business unit of Banner Services Corporation, a provider of precision ground bar as well as centerless grinding, turning and straightening, among other machining services.

For more information on this development, please contact:

BANNER MEDICAL 494 East Lies Road,Carol Stream, IL 60188-9425

Phone: 800-323-9732

Fax: 630-653-7555

Web: www.banner-medical.com

Email: getinfo@banner-medical.com

Agency contact:

Tim Daro or Wendy McCormick

Bernard & Company

847-934-4500

tdaro@bernardandcompany.com

wendy@bernardandcompany.com

This Grieve walk-in oven features 5” insulated walls, top-mounted heat chamber, aluminized interior and exterior plus a free-standing oven rack with two 6000 lb. capacity shelves for the workpieces.

Controls on No. 951 include a digital indicating temperature controller, manual reset excess temperature controller with separate contactors and recirculating blower airflow safety switch.

For more information, please contact: THE GRIEVE CORPORATION, 500 Hart

Road, Round Lake, Illinois 60073-2835 USA. Phone: (847) 546-8225. Fax: (847) 546-

9210. Web: www.grievecorp.com. Email: sales@grievecorp.com. Attention: Frank

Calabrese.

Continue readingBill Hunter assumes 100% ownership of pioneering company in automatic matchplate molding machinery for sand casting

Schaumburg, Illinois (USA)-Hunter Automated Machinery today announced the completion of an asset buyout of the company and all its foreign subsidiaries by current President Bill Hunter. In his words, “We have successfully crossed the bridge of generational transition with this arrangement.” Mr. Hunter bought the assets of the company held by his three sisters, Dianne, Linda and Heather. All were the children of Al Hunter, the late founder of the company that began building the automatic matchplate molding machine Al invented, in 1964. Today, Hunter machines and mold handling lines are operating in foundries worldwide. Hunter operates plants in the USA, Brazil and China. The company has European headquarters in Italy and regional offices in India.

Karen Hunter, corporate secretary, Bill Hunter, president and John Purtill, corporate attorney at signing

Bill Hunter noted, “I am very thankful to my sisters, who worked closely with me on this agreement, allowing us to keep the company in the family. Likewise, I will always honor the memory of my father, who taught me much about this business and left a legacy of innovation and achievement in the global foundry market. We fully intend to continue and build on the company’s long-standing traditions of technology, quality and service to the industry.”

The agreement was finalized on June 27, 2012.

For further information on this announcement, interested parties may contact:

HUNTER AUTOMATED MACHINERY CORPORATION

2222 Hammond Drive Schaumburg, IL 60196

Phone: (847) 397-5110

Fax: (847) 397-8254

Email: info@hunterfoundry.com

Attention: Bill Hunter, CEO

Web: www.hunterfoundry.com

Connect with Hunter Foundry online:

Texas foundry buys new equipment, including Hunter XL matchplate molding machine, to respond to customer needs with fast pattern changes, shorter runs and on-the-fly flexibility in job scheduling, deliveries

Schaumburg, Illinois (USA)-In the heart of Limestone County sits Coolidge, Texas, halfway between Dallas and Houston. This classic American small town is home to another classic, Frazier & Frazier Industries, a ductile and gray iron foundry, established in 1972 by C.W. Frazier as a traditional cope-and-drag sandcasting operation with two squeezers and run today as a formidable shop by Plant Manager Will Frazier. An ISO 9002 Certified process operation, F&F combines the best of the old ways with the newest casting technologies and equipment in the market. As Will Frazier points out, “This is one of the biggest reasons we’ve continued to prosper, while so many other foundries have disappeared. We recognize what works and what doesn’t, to best suit our current business and market conditions.”

Once a heavy production shop, F&F today continues to support their large batch customers, but has reshaped the business model in many ways, according to Frazier. “We have traditionally worked in pieces from a few ounces up to 150 pounds or more. The large runs were more typical in days past, while we saw a new business environment emerging, several years ago, when the market began to decline overall.” He continued to explain how many of the company’s traditional customers began to reduce their inventories and thus placed shorter run orders with much tighter lead times. In something of a “perfect storm” scenario, this combination of increased job numbers and more urgent shipping requirements literally changed the pace of business at F&F. Frazier notes, “It’s not unusual for us to come in on a Sunday to finish a job for a customer who really needs it…and we rarely charge a premium, because we know how tough things are, for most of our accounts.”

While the oil & gas market applications are prominent here, as they are with most foundries in the region, F&F currently sells to end product manufacturers for the automotive, agricultural, wind energy, municipal water works and other market segments, a strategy that has helped to maintain a better balance in this shop’s workload. With its own sales force plus several manufacturers’ rep organizations in the field, Frazier & Frazier boasts customers in a wide variety of markets and as far away as Indiana, a relatively rare achievement in the foundry business, especially when larger, heavier workpieces are involved.

With over 8000 patterns in-house, F&F today experiences as many as 15 pattern changes per day per machine on the floor. This further complicated the job scheduling and work flow. Will Frazier and his team of Bob Pranger, general manager and Harlon Easton, vice president of sales, quickly saw the need for more automation in the machinery lineup.

F&F still does hand-rammed oil and air set cores, but over the years they’ve acquired automatic coresetting equipment, as well as automated molding machines, including the most recent purchase, a Hunter XL2024 automatic matchplate molding machine, which is used with the already in-place Hunter mold handling turntable system at F&F, as are other molding machines here. Three melting units feed the certified chemically correct iron to the molding stations. Currently, this shop does approximately 70% of its work in ASTM Class 60-100 ductile and 30% in Class 15-50 gray iron.

The XL2024 is a fully automated matchplate molding system, using gravity-fill technology pioneered by Hunter. It produces sand molds up to 20” x 24” with shallow 6-1/2” cope and 5-1/2” drag (165mm/140mm) at 180 cycles per hour, using 400 lbs. (181kg) of sand. Variable squeeze surface pressures to 142 psi (10kg/cm2) can be achieved in production.

This latest Hunter machine continued the tradition of leading-edge sandcasting technology used at Frazier & Frazier. Although several generations of Hunter and other brands of machines have been used here, when a new machine was planned, Will Frazier notes there were some key criteria to be met. “We’d been having critical problems with another machine builder, getting parts and service. We always knew the Hunter folks were excellent in those areas based on past experience, plus they were willing to provide considerable application engineering assistance and set-up help with the new machine. Coupling that with their stability as a company and great reputation in the world foundry market, we looked at all our options and settled on the XL2024.” Frazier further cites his long relationship with Hunter’s Mike Hughes as a factor. “Mike came down here several times to help us and, since the machine has been up and running, he’s stayed in close touch with us, even though we’ve had no performance issues with the machine.”

Will Frazier also points out that, currently, over 20% of the orders at F&F are rush and the quick changeover time of the Hunter machine makes it a highly productive piece of equipment and a definable competitive advantage in the market for his shop.

Frazier & Frazier provides its customers with metal castings as well as CNC machining, heat treating and galvanizing services, when needed. The shop has a fully equipped quality inspection department, highlighted by CMM and other state-of-the-art lab apparatus.

For further information on this story, interested parties may contact:

FRAZIER & FRAZIER INDUSTRIES, INC.

817 South First Street P.O. Box 279

Coolidge, Texas 76635 USA

Phone: 254-786-2293

Fax: 254-786-2284

Web: www.ffcastings.com

Email: willfrazier@ffcastings.com

Attention: Will Frazier, Plant Manager

Or

HUNTER AUTOMATED MACHINERY CORPORATION

2222 Hammond Drive Schaumburg, IL 60196

Phone: (847) 397-5110

Fax: (847) 397-8254

Email: info@hunterfoundry.com

Attention: Bill Hunter, CEO

Web: www.hunterfoundry.com

Connect with Hunter Foundry online:

Minnesota foundry includes multiple layers from their organization to decide on the right casting process simulation tool

Dotson Iron Castings in Mankato, Minnesota is an iron foundry that melts and pours 100+ tons of ductile iron castings daily, using 20X24 horizontal, high pressure, green sand molding machines. Products include over 3,000 different castings for over 300 customers in a wide range of applications including medical, transportation, agriculture, construction and recreation equipment. The raw casting weights here range from 2 to 50 pounds with typical production quantities ranging from 25 pieces to several thousand.

Dotson prides itself on engineering excellence, providing customers a higher total value with castings designed and produced in a highly automated, quick response foundry and machining facility.

Operating as a foundry for over 130 years, Dotson credits its success to satisfying customer needs by not only managing, but exceeding, their expectations. The goal is to provide customers with quality products in a fast, flexible, cost effective manner.

As a company best practice, Dotson includes its employees in making all important decisions that will impact not only the job of each of the individuals, but the foundry as a whole. Dotson has a program called, “The $10,000 Project.” As the name implies, any purchase made by the foundry of $10,000 or more is done through a detailed process involving the employees who will be most affected by the purchase of the product or equipment being considered.

Any product or project that costs over $10,000 must have a cross-functional group examine all viable options. Members of the group choose what they consider the best product or piece of equipment to help them accomplish their goals. They then make onsite visits, make comparisons and do cost justifications. With the information they have gathered, they then make multiple presentations to the group explaining the “what” and the “why” of the product, equipment or service they have chosen for consideration.

When Dotson’s owner Denny Dotson and President /CEO Jean Bye wanted to expand their capabilities in terms of serving customers with solidification solutions, MAGMASOFT®, provided by MAGMA Foundry Technologies (Schaumburg, IL) was one of the many software packages considered. “We certainly are a foundry that differentiates ourselves on our engineering services and to do that you must have the right tools,” Jean Bye said. “We researched and explored our options for a few years before making the decision to purchase simulation software for the foundry,” Denny Dotson adds.

The $10,000 Project is a lengthy process with the participants sometimes making three or four presentations to support their argument. Deciding on the simulation software that best supported the needs of this foundry took a long time, due to the importance of doing numerous comparisons. When comparing the benefits of all the products being considered, “…it came down to weighing out the factors and deciding which ones would have the greatest impact on the overall foundry operation,” Bye stated.

When the $10,000 Project is complete and a decision has been made, nobody can say they weren’t onboard. “They might not have gotten their way,” Bye notes, “but they certainly understand all the reasons why the decision was made, because it was well thought out by the entire group.”

Dotson saw the addition of simulation software as more then just an engineering tool; rather it represented a smart business tool specifically designed to improve yield as well as positively impact sales. There was a lot to consider in the justification process beyond the product’s capabilities. Ease of use, speed of use, accuracy of results, presentation of these results, reputation of the provider’s company, customer care, quick response time from company representatives when there was a question or assistance was needed, as well as which company Dotson felt was more technologically advanced with new innovations. In addition, a significant benefit Dotson saw with simulation was the ability to identify jobs that would require some type of stress relief before actually making the tool or gating system. “It’s much more difficult to go back to the customer after the fact and tell them this is your cost, than it is before you cut the tool. There are always options before anything is created,” Engineering Process Manager Jim Headington points out.

“Moving from opinion or educated guess to a factual report supporting changes has made it quicker and easier to communicate the need for making changes with our customers,” adds Jay Zins, Control Manager at Dotson.

When discussing the impact simulating the process has on time to first quality part, Headington explains, “Time isn’t always the most important issue at hand. Cost and the integrity of the tool by the time you’re done with it are the real keys. When you find yourself adding material to a production tool, it’s never a good thing. Once you scab on that material, no matter how you put it on, you’ve really jeopardized the integrity of the tool. This is all now done virtually, instead of through trial and error.”

On one recent customer project, Dotson ran approximately 30 virtual iterations on a particular part. Not only did having the ability to simulate the entire molding process save a significant amount of time, being able to run a large number of iterations also helped them be sure that the quality of the part was not compromised. “Once in a while, on projects like this, we do 30 simulated iterations, simply because we now can,” Josh Jaycox, Quality Assurance Engineer adds.

While all new jobs at Dotson are run through MAGMASOFT®, retro jobs, especially the high yield jobs, are also now simulated. A significant part of the justification process was improving yield. When considering yield improvements, Dotson recognizes that the improvement in the first year will normally be significant, as they hadn’t run simulation before, whereas moving forward, improving yield would be less significant, as all new jobs are now run through the simulation and, as a result, are more efficient from the very beginning. “Running the software on a casting will also help us see that it may be possible to make a riser smaller, this will help in de-gating and reduce grinding time.” Jaycox said.

Sales and Marketing Manager Matt Schindle adds, “The benefit to the customer is that they know we are not going to build a tool, we are not going to spend a dollar of their money, until we have done the solidification on it. It gives us more credibility and it gives the customer reassurance.”

“It’s almost like having a third party in the room giving our observations credibility,” Bye adds.

Seeing the importance of being sure their foundry and their engineers have the tools to be the best they can be, Dotson found the addition of MAGMASOFT® to be a natural next step. When considering the in-depth justification process and the criteria involved in bringing a new product or tool into the foundry, they learned their decision regarding process simulation to be a great benefit to the company overall. Dotson realizes customers now expect and rely on the fact that their parts are run through this virtual process with the end result being the highest quality castings possible.

Choosing MAGMASOFT®, Dotson believes all their performance and value criteria were met and, in many cases, even exceeded. MAGMA’s reputation in the world foundry market and their customer care program, as well as the added benefits of their training programs and annual user group meetings, help Dotson feel more confident in their partnership with MAGMA, according to Jaycox and Headington.

For more information on this story, please contact:

Christof Heisser

President

MAGMA Foundry Technologies, Inc.

10 N. Martingale Road, Suite 425

Schaumburg, IL 60173

Phone 847-969-1001 ext. 225

Email cheisser@magmasoft.com

Web www.magmasoft.com

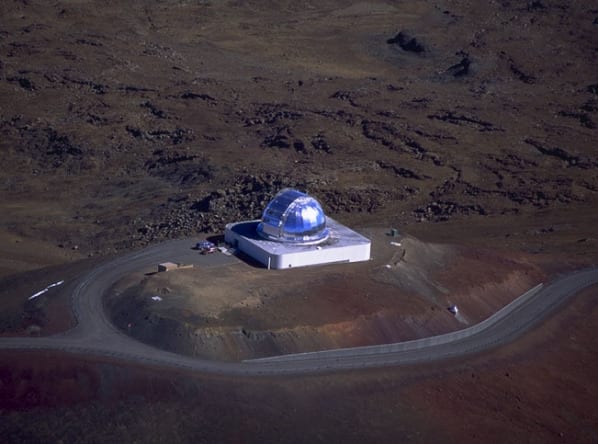

Machining center used at University of Hawaii Institute For Astronomy to produce one-off diffraction gratings for remote sensing instruments used with telescopes and other research instrumentation

University of Hawaii Institute For Astronomy telescopes are able to see the solar system and into deep space with greater clarity than at any other location on the planet, according to Dr. Ritter.

When you enter the laboratories at the University of Hawaii’s Maikalani Institute For Astronomy (IFA) Advanced Technology Research Center on the island of Maui and hear talk of light years, dark energy and space telescopes, it quickly becomes apparent that this is not your typical machine shop. The machining for instrumentation developed here involves some of the most sophisticated techniques on Earth, which is a pun of cosmic irony, as the workpieces produced here are primarily used to help evaluate happenings in deep space.

The Maikalani facility provides laboratory workspace for Physicists and Astronomers performing advanced

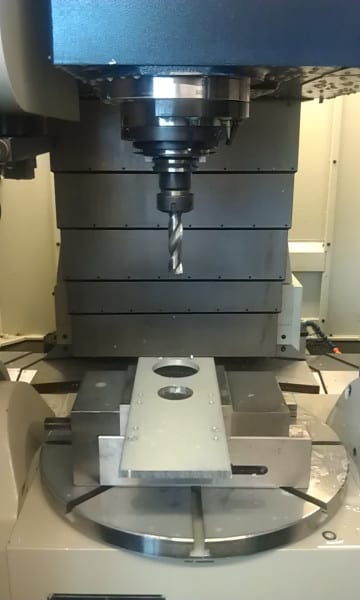

As Ritter explains, “Accuracy is everything in optics. Most of the machining centers I evaluated were in the +/-25 micron (~0.001”) range for accuracy. We settled on a 3+2 axis machine with 100 nanometer precision scales with interferometric remapping on the 840D sl CNC. Because we do experimental fabrication work and optics typically need to be made to micron level tolerances, it was imperative to have a feedback control on the machine tool with a known accuracy and predictable degrees of variation.” As an example, though not suitable for visible light, the optics Ritter discussed required accuracies of a few microns-good enough for infrared optics. Other technologies being developed by Ritter at IFA include novel photonic meta-materials for future space telescopes intended for studying exoplanets and the evolution of our universe.

Dr. Ritter cited the age-old challenge for educational

Sample parts produced on Spinner machine, mostly copper and aluminum, include many that become diffraction gratings used on highly sensitive instruments for deep space exploration projects

While invariably the smart guys in any room, Dr. Joe and John Valliant are not machinists by trade, so they were using both Shopmill and CAD/CAM programs like Mastercam with the highly-specialized G-code generator and post-processor needed to create precision path cuts, then running them directly on the mill to quickly begin cutting, an absolute necessity in their one-off world of custom parts.

“For some optics, the millions of coordinates we use for every workpiece are pushing the control to the limit, but it responds well. Plus, the teach-in functionality of the Sinumerik 840D sl CNC and its software package keep us running very efficiently,” according to Valliant, who worked in the lab as a University of Hawaii-Maui college student and has learned CNC machining on the go. In an environment where 0.1 of a wavelength of light is the desired target for accuracy, this is no small achievement. Valliant adds, “Once you’re comfortable with this machine and the control, the process is very intuitive.”

Dr. Ritter, who is constantly pushing the boundaries on novel orbital space telescope designs, notes that the state of Hawaii and the island of Maui in particular have some of the best conditions on Earth for nighttime telescopic observation, as well as the best in the world for daytime solar viewing. The National Science Foundation will soon build the world’s largest solar telescope on Maui. Maui is a little known hotbed of technology development. In addition to solar research and deep space observations, the Institute for Astronomy partners with many nations to push the boundaries of human knowledge, while training future scientists.

Mac McPherson, the Spinner machine dealer and importer for North America, adds, “We do

“Na Kilo Hoku” means “the watchers of the stars” and the instrument components made here certainly help them do just that — and also gain knowledge from the cosmos for us all.

For more information on this story, please contact:

Joe Ritter, Ph.D

Physicist and Lab Director

University of Hawaii Institute For Astronomy

Maikalani Advanced Technology Research Center

34 Ohia Ku St.

Pukalani, HI 96768

Phone: 808-573-9521

Web: www.ifa.hawaii.edu

Or

Robert McPherson

MacHill Machinery Solutions, LLC

(dealer for Spinner machines)

2245 C-132 Ashley Crossing Drive

Charleston, SC 29445

Phone: 843-873-6888

Web: www.machillmachinery.com

Or

SIEMENS INDUSTRY, INC.

DRIVE TECHNOLOGIES

MOTION CONTROL

MACHINE TOOL BUSINESS

390 Kent Avenue

Elk Grove Village, IL 60007

Phone: 847-640-1595

Fax: 847-437-0784

Web: www.usa.siemens.com/cnc

Email: SiemensMTBUMarCom.sea@siemens.com

Attention: John Meyer, Manager, Marketing Communication

Follow us on Facebook: www.facebook.com/SiemensCNC or Twitter: www.twitter.com/siemens_cnc_us.

—

Siemens Industry Sector is the world’s leading supplier of innovative and environmentally friendly products, solutions and services for industrial customers. With end-to-end automation technology and industrial software, solid vertical-market expertise, and technology-based services, the sector enhances its customers’ productivity, efficiency and flexibility. With a global workforce of more than 100,000 employees, the Industry Sector comprises the Industry Automation, Drive Technologies and Customer Services Divisions as well as the Metals Technologies Business Unit. For more information, visit http://www.usa.siemens.com/industry.

The Siemens Drive Technologies Division is the world’s leading supplier of products, systems, applications, solutions and services for the entire drive train, with electrical and mechanical components. Drive Technologies serves all vertical markets in the production and process industries as well as the infrastructure/energy segment. With its products and solutions, the division enables its customers to achieve productivity, energy efficiency and reliability. For more information, visit http://www.usa.siemens.com/drivetechnologies.

Continue readingWisconsin foundry adding value to parts produced

Watry Industries LLC, a large permanent mold aluminum foundry located in Sheboygan, Wisconsin, takes pride in working closely with its customers to co-develop and optimize casting design. In addition to offering casting design assistance and permanent mold casting production in its 172,000 square foot facility, Watry also performs heat treating, precision machining, powder coating and assembly operations in-house.

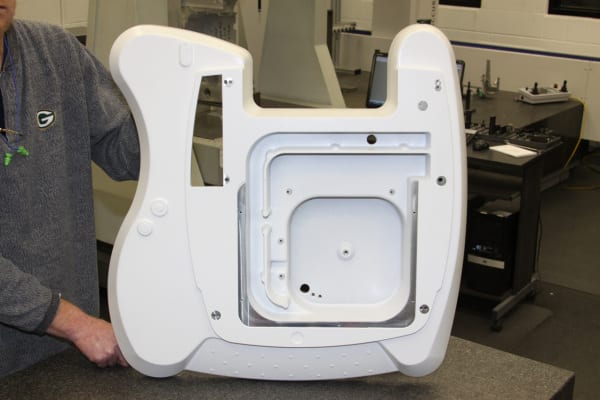

Watry Industries LLC, a large permanent mold aluminum foundry located in Sheboygan, Wisconsin, takes pride in working closely with its customers to co-develop and optimize casting design. In addition to offering casting design assistance and permanent mold casting production in its 172,000 square foot facility, Watry also performs heat treating, precision machining, powder coating and assembly operations in-house. Watry worked closely with its customer to assist in the design process for this part, as well as two other castings used on the same program, from concept through tooling and into production. Several other production processes were considered for making this part, including injection molded plastic, structural foam, plastic cowling over steel fabrication and several casting processes including sand cast, permanent mold and high pressure die cast. After investigation, mechanical strength concerns eliminated some of the plastic construction methods and a thorough cost analysis eliminated the fabrication options as being too expensive. Aluminum castings had a proven track record in similar applications, and a cost analysis was done to compare the various cast processes. Based on the combination of part cost and tooling cost (total cost of ownership) the result of all these studies was that permanent mold was selected as the best process for the application.

Watry worked closely with its customer to assist in the design process for this part, as well as two other castings used on the same program, from concept through tooling and into production. Several other production processes were considered for making this part, including injection molded plastic, structural foam, plastic cowling over steel fabrication and several casting processes including sand cast, permanent mold and high pressure die cast. After investigation, mechanical strength concerns eliminated some of the plastic construction methods and a thorough cost analysis eliminated the fabrication options as being too expensive. Aluminum castings had a proven track record in similar applications, and a cost analysis was done to compare the various cast processes. Based on the combination of part cost and tooling cost (total cost of ownership) the result of all these studies was that permanent mold was selected as the best process for the application.Dale Christel

Sales Manager

Watry Industries LLC

3312 Lakeshore Drive

Sheboygan, WI 53081

Office: 1-920-457-4886

www.watry.com

dchristel@watry.com

Connect with Watry Industries online:

Experts at the nuances of powder coating parts produced in all metalcasting processes, as well as powder application on stampings, extrusions, weldments and assemblies, Watry is able to provide their services on castings made by other processes as well as steel, iron and various alloys.

Watry is capable of masking features before painting as well as blowing off un-cured powder in areas where masking is not practical. The Nordson Cyclo-Kinetic reclaim booth, utilizing both manual and automatic guns, is capable of applying the most demanding and high temperature powders, reaching the most difficult areas on any workpiece. In addition, reclaiming the powder that does not adhere to the part during the application process helps control overall costs.

Watry’s roof mounted cure oven, encompassing over 250 feet of conveyor track and operating at temperatures up to 500º F, can cure powder on the largest and heaviest parts at very high line speeds, providing another cost-controlling feature.

Strict quality control systems and procedures include film thickness checks, adhesion testing, color verification and paint hardness testing to ensure compliance to customers’ most demanding requirements.

To watch a video on the Watry powder coating operation, please visit http://www.watry.com/video_library.html

For more information on this release, please contact:

Dale Christel

Sales Manager

Watry Industries LLC

3312 Lakeshore Drive

Sheboygan, WI 53081

Office: 1-920-457-4886

www.watry.com

dchristel@watry.com

Connect with Watry Industries online:

This Grieve cabinet oven features 6” insulated walls and Type 430 stainless steel interior, all-welded construction plus explosion-venting latches on the heavy-duty door.

Controls on No. 858 include a digital programming and recording temperature controller, manual reset excess temperature controller with separate contactors and recirculating blower air flow safety switch.

For more information, please contact:

THE GRIEVE CORPORATION, 500 Hart

Road, Round Lake, Illinois 60073-2835 USA. Phone: (847) 546-8225. Fax: (847) 546-

9210. Web: www.grievecorp.com. Email: sales@grievecorp.com. Attention: Frank

Calabrese.

Continue reading