Contact us today:

(847) 934-4500

tdaro@bernardandcompany.com

Contact us today:

(847) 934-4500

tdaro@bernardandcompany.com

Turning-milling centers with coordinated drive and CNC engineering achieve superior accuracy and repeatability

Hamuel CEO Dr. Markus Stanik (right) and his sales manager Jochen Schaede agree: “The Sinumerik 840D sl CNC complements perfectly the capabilities of our five-axis turning-milling centers in the HSTM Series. Because of this fact, we can usually convince leading turbine manufacturers from the aerospace and automotive industries about the dynamics, high-performance and precision of these machines.”

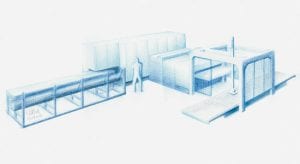

The complete machining of turbine blades requires striking a balance between powerful roughing and ultra-precise finishing, a task for which the modern five-axis turning-milling centers are ideal, when robust machine construction is combined with high-quality drive and control engineering. Experience is the solid basis on which the Hamuel Maschinenbau GmbH & Co. KG, Meeder, Germany, can offer a great deal: with 85 years of machine tool manufacturing, 35 years of CNC machining, 25 years of five-axis simultaneous machining and over 10 years in the construction of five-axis turning-milling centers. CEO Dr. Markus Stanik knows that experience by itself cannot be any yardstick for the quality of machine tools, noting, “It certainly helps us, together with the right partner companies, to design and build the machines so that our customers can be successful in the marketplace.” This machine builder and its many customers have developed correspondingly positive accomplishments together. Today, Hamuel stands on three standards:

The latter, as evidenced by Hamuel’s HSTM (high-speed turning-milling) series, has been marketed since 1999 and makes a decisive contribution to the sales and success of the company. Leading turbine manufacturers from the aerospace and power-generating industries have been particularly impressed by the dynamic response, capability and precision of these machines. Even the smallest faults are unacceptable on turbine blades

Form deviations are unacceptable for products such as turbine blades and blisks because even the smallest error would significantly reduce the efficiency of the power plant or aircraft turbine.

The HSTM that runs on the Sinumerik 840D sl CNC controllers is used mainly to manufacture turbine blades and blisks (turbine disks) deployed in stationary steam and gas turbines as well as in mobile turbines for aircraft jet engines and large turbochargers. These products always consist of high-strength materials, such as titanium or high-alloyed steels. Form deviations are taboo in such applications, because even the smallest error would significantly reduce the efficiency of the turbines. Correspondingly high and comprehensive are the requirements placed on the machine tools. Hamuel sales manager, Dipl.-Ing. Jochen Schaede, explains: “Our customers normally manufacture large turbine blades longer than approximately 1000 mm from forging blanks. In contrast, shorter workpieces are milled from a solid piece of material with a stock-removal ratio of approximately 80 percent. This makes it obvious that our machines must not only rough-cut very productively but also finish with high precision.” Whereas productivity takes precedence for rough-cutting, accuracy is more important for the subsequent finishing of the spatial free-form surfaces. “With regard to accuracy, our high-performance machining centers achieve a precision in the micrometer range coupled with excellent surface quality,” added Schaede.

Form deviations are unacceptable for products such as turbine blades and blisks because even the smallest error would significantly reduce the efficiency of the power plant or aircraft turbine.

Key to this capability is the combination of compact machine construction together with perfectly matched drive and control engineering. The basis is the robust machine design with a one-piece machine base – either as welded construction cast with special concrete or latterly directly as polymer-concrete made from a single piece of material. The careful distribution of the masses ensures the best dynamic rigidity. The experience of the developers at Hamuel paired with the knowledge of the Siemens mechatronic experts make such results possible, as Jochen Schaede confirmed: “Thanks to various simulation tools, the Siemens engineers could provide us with very exact data to which we could add or remove masses. It was certainly advantageous that we could procure all components required for the dynamics from Siemens starting with the spindle, including the axis drives, and ending with the CNC. This means we needed only a few iteration loops in order to obtain a perfect dynamic rigidity in the machines.” It is also important that all components are arranged so that the horizontally clamped turbine blades and blisks can be machined optimally. This is also facilitated by the 45°-inclined orientation of the axes that ensures a favorable swarf removal further augmented by the permanent rinsing of the machine internal area. The accessibility has also been enhanced by this inclined axis orientation. Such designed and built HSTM machines equipped with precise direct drives from Siemens achieve a maximum positioning accuracy of 5 µm with traversal speeds exceeding 40 m/min in all linear axes. Indeed, the extremely fast rotary axes have a positioning accuracy of 3 µm. This allows the user to achieve maximum productivity, accuracy and surface finishes in the range of Ra = 0.8 µm, and so fully meet the industry requirements placed on the blade machining. CNC ensures optimized surface transitions at the inlet and outlet edges One of the biggest challenges for the turbine-blade manufacturing industry concerns the critical surface transitions (leading and trailing edges) of the turbine blades. To achieve a high quality, the milling paths described with curve interpolation points must have a constant machining speed. As a consequence, the leading and trailing edges demand extreme angular accelerations. The number of curve interpolation points to be described is correspondingly quite high.

The manufacturing of precise free-form surfaces for turbine blades demands the highest performance from the CNC. The excellent block-cycle times of the Sinumerik 840D sl and its look-ahead function improved as part of the new “Advanced Surface” motion control, which play a significant role here.

The controller now faces the challenge to reliably process the generated NC steps that are supported by the fast block cycle times and the look-ahead function of the CNC. “Hardly any other controller can supply the drive information for all five axes in the required short time as reliably as the Sinumerik 840D sl controller,” confirmed Jochen Schaede, who added, “The new Advanced Surface motion control that includes among other things an optimized look-ahead function is also excellent. And I would also like to mention the five-axis high-speed turning-milling of free-form surfaces requires a continuous spatial reorientation of the geometry vectors.” This leads to the use of the Traori (transformation orientation) principle in the Sinumerik 840D sl. Hamuel’s customers can therefore achieve reproducible results with the best-possible surface finish, exact contour accuracy and with the maximum possible machining speed.

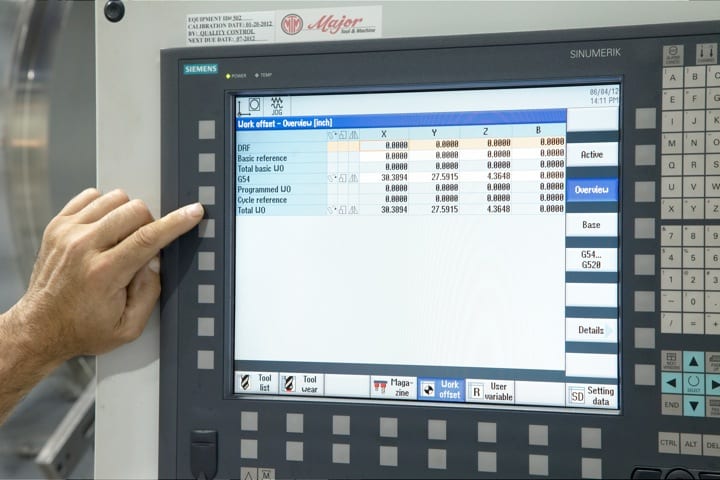

Despite being a high-end controller that offers many modern features, the Sinumerik 840D sl CNC is easy-to-use.

In addition to the primary properties of precision, productivity and reliability, Hamuel also appreciates other properties of the Siemens drive and control engineering – an example: the DRIVE-CLiQ interface. When this digital connection is used, all appropriately equipped drive components are detected automatically. Only a cable for the connection is required to achieve this result. Equivalent circuit diagram data for the motors and the characteristic values of the installed encoder systems are all stored. This avoids the need for manual data input during the commissioning and so makes this task more reliable and much faster, according to Hamuel engineers. Sales manager Schaede is also impressed with the “know-how” protection onboard the control. With the help of innovative software, his customers can protect all their programs and their application know-how, using individual passwords and so largely prevent unauthorized access. According to Hamuel, the Teleservice offered by Siemens has proven to be an important advantage for its machine users who often operate globally. It allows not only software problems to be rectified but also updates to be installed fast and reliably without needing to be present onsite. Manufacturing operations save time and money and they always remain up-to-date with the latest software releases, via this service. Powerful motor spindle with Hirth gearing

Leading turbine manufacturers are particularly impressed by the dynamics and high-performance of the HSTM machines. The perfect interaction of the robust Hamuel machine construction and the high-quality Siemens drive and control engineering provide the basis for this satisfaction.

The capability of the turning-milling center also depends greatly on the 54-kW motor spindle made by Weiss Spindeltechnologie GmbH (a Siemens subsidiary). Equipped with a HSK A63 tool holder, it is able to provide the high torque required for roughing plus speeds as high as 16,000 rpm for finishing. This means an optimum cutting speed is always guaranteed. As a practical detail, the Hamuel engineers also emphasize the integrated Hirth gearing that makes it possible to clamp the spindle and relieve load on the bearings during the turning process. The machine sizes in the HSTM Series are oriented to the length of the workpieces to be produced in standard ranges from ≤ 500 mm (HSTM 300) to 1750 mm (HSTM 1500). On special request, Hamuel also builds larger machines. A project for machining blades as large as 2500 mm in length is currently running in the field. CEO Markus Stanik explains, “Thanks to our modular machine construction, we are able to satisfy special requests and build turning-milling centers in these dimensions.”

The manufacturing of precise free-form surfaces for turbine blades demands the highest performance from the CNC. The excellent block-cycle times of the Sinumerik 840D sl and its look-ahead function improved as part of the new “Advanced Surface” motion control, which play a significant role here.

New developments already in the introductory phase are also evolving at Hamuel. For example, in the near future, a special gas will be able to be used to cool the tool in the HSTM machines. A machine base made of mineral casting is also now offered. One of the first machines of this type has already been presented at EMO. “This material not only exhibits excellent properties with regard to vibration suppression but we have also been able to reduce somewhat our dependency on steel suppliers,” noted Markus Stanik. For the machine user, this makes itself apparent directly in improved surface quality and a significantly longer tool service life. CNC gantry milling machines of the HSM (high-speed milling) series In addition to the component production and the construction of the HSTM series, the company’s HMS Series machines are another mainstay for Hamuel. These simultaneous five-axis machining centers are designed for high-speed cutting (HSC). They feature not only the modern Siemens drive and CNC control engineering, but also the optimized milling-head systems and the high-performance high-speed spindles, providing this capability. HSM machines allow high-performance roughing and ultra-precise finishing. With regard to the size of the HSM machines, the manufacturer adapts the designs specifically based on the customer requirements. As a component producer, Hamuel also has its own machines in constant use at its factory.

For more information about Siemens CNC solutions for the machine tool industry, visit our website: www.usa.siemens.com/cnc.

For more information on the this story, contact:

SIEMENS INDUSTRY, INC.

DRIVE TECHNOLOGIES

MOTION CONTROL

MACHINE TOOL BUSINESS

390 Kent Avenue

Elk Grove Village, IL 60007

Phone: 847-640-1595

Fax: 847-437-0784

Web: www.usa.siemens.com/cnc

Email: SiemensMTBUMarCom.sea@siemens.com

Attention: John Meyer, Manager, Marketing Communication

Follow us on Facebook: www.facebook.com/SiemensCNC or Twitter: www.twitter.com/siemens_cnc_us.

—

Siemens Industry Sector is the world’s leading supplier of innovative and environmentally friendly products, solutions and services for industrial customers. With end-to-end automation technology and industrial software, solid vertical-market expertise, and technology-based services, the sector enhances its customers’ productivity, efficiency and flexibility. With a global workforce of more than 100,000 employees, the Industry Sector comprises the Industry Automation, Drive Technologies and Customer Services Divisions as well as the Metals Technologies Business Unit.

The Siemens Drive Technologies Division is the world’s leading supplier of products, systems, applications, solutions and services for the entire drive train, with electrical and mechanical components. Drive Technologies serves all vertical markets in the production and process industries as well as the infrastructure/energy segment. With its products and solutions, the division enables its customers to achieve productivity, energy efficiency and reliability.

About Hamuel Maschinenbau GmbH & Co. KG, Meeder, Germany

Hamuel was founded in 1927 and is now part of the Hamuel Reichenbacher company group. More than 2000 CNC machines from this enterprise group are currently in use globally for the machining of a wide range of materials. The focus of Hamuel Maschinenbau comprises three areas: the production of machine-tool components, CNC gantry milling machines (HSM) and five-axis CNC turning-milling centers (HSTM).

Continue readingHighlights include two-sided machining and servo drive technology

Recently, Northern Italian machine tool manufacturer Biglia introduced its multi-functional turning centers of the ‘Quattro’ series with the Sinumerik 840D sl CNC. The mechanical concept, together with the scalable control, provides users with the most diverse standard turning and milling operations. The result is increased flexibility and higher speeds for end users. That quality machine tools are built in Northern Italy is nothing new. And this fact is confirmed again by the “Quattro” series from the machine tool manufacturer Biglia. These machines are multifunctional turning centers that are valued throughout Europe for their high reliability and performance power. The machines are available in different versions from 11 to 15 CNC axes. They are also intended for different turning diameters (45, 52, 65, 71 and 80 mm).

Biglia has equipped its turning centers of the ‘Quattro’ series with the Sinumerik 840D sl CNC control. The individual machines have 11 to 15 NC axes.

The two opposing spindles form a special feature of the “Quattro” series. This allows the workpiece to be machined from two sides, which reduces the machining time. The second spindle can also be moved linearly in two directions (lengthwise and crosswise). This provides some leeway in the case of additional milling operations, but it can also be used for automatic workpiece unloading. Two turrets, mounted on the y-axis, ensure proper positioning of the necessary tools.

The turning centers from Biglia have two spindles and two independent tool turrets for simultaneous machining.

This innovative machining technology allows the creation of not only rotary but also prismatic workpieces – including polygons. Dealing with everything in one setup not only reduces cycle times, it also enhances accuracy. The machines are developed on the basis of a modular concept that ensures flexible application options – from the universal CNC lathe, to complete machining of complex workpieces with powered tools (c- and y-axis).

Getting it right, from the start

By offering the Siemens Sinumerik 840D sl CNC control, Biglia now wants to expand its previous options and its own market by combining its technologies with that of the Siemens control. “In this project, which is of personal significance to all of us who worked on it and of strategic significance for Biglia, we wanted to do everything perfect right from the start and to get the most out of it,” says Giovanni Delmondo, Business Development Manager for machine tools with Siemens Italy. The result is an all-round successful machine series with a highly modern control that already includes the innovative system expansions of recent months – including increased energy efficiency options offered by the control and drive systems from Siemens.

To illustrate this, Giovanni Delmondo points out that “the fans on the spindles are shut down automatically when they are not required, or certain services such as hydraulics, lubricant supply, or compressed air are deactivated during machine standstill times. This is handled via special screen forms on the control and is extremely simple, using the Run MyScreens function.”

Also notable is the standard energy efficiency solution from Siemens in the Sinamics S120 drives onboard this machine series. This includes automatic power factor correction or regenerative feedback of the energy generated in braking operations, a substantial factor in energy savings.

Performance and scalability

The centerpiece of the automation concept of these Biglia turning centers is the Sinumerik 840D sl control. This is a universal and flexible CNC system, implemented in the Sinamics S120 design (see Fig. 3). It is suitable for up to 31 NC axes. Whether you are turning, drilling, milling, grinding, laser-machining, nibbling or punching, the Sinumerik 840D sl is suitable for use in the most diverse machining technologies. The CNC control also has PLC (programmable logic controller) functionalities, so that a special PLC can be eliminated, if applicable.

This high-end control from Siemens is ideally suited to medium and complex tasks and production and can be adapted to the task, thanks to scalable hardware. The CNC is also characterized by openness, so the operator interface and also the software present few limits to specific job adaptability. This applies all the way to supplementing the NC core of the control; however, a special license is required for this adaptation.

On the Biglia turning centers, the control was equipped with the Sinumerik Operate user interface, making operation simple and intuitive. Three different methods of parts programming are possible: Classic ISO code programming, programming with the help of the integrated ProgramGuide with graphical support of the selected cycles, and the new two-channel ShopTurn with graphical 3D simulation. The user is led step-by-step through the cycles, whether for simple metal removal, drilling, thread cutting, pocket milling, groove milling or engraving. Complex programming cycles for complex contours are also possible. The “ProgramSync” function for automatic synchronization of the machining programs via two channels ensures a significant increase in machine productivity. The control is equipped with a 15″ monitor and integral keyboard.

The Quattro series from Biglia also uses the highly effective personnel and machine protection system provided by the Sinumerik control concept with the Sinumerik Safety Integrated package.

Biglia is also breaking new ground with servo drives. Thus, the new servo motor generation 1PH8 from Siemens is used for the main spindle motors in this series. The linear axes are further equipped with the new 1FK 7 G2 series of permanent-magnet synchronous motors. These motor types from Siemens enable onsite replacement of the encoders without having to dismantle the complete motor. This combination of machine and CNC control in the Quattro turning centers from Biglia provides users with greater flexibility.

For more information about Siemens CNC solutions for the machine tool industry, visit our website: www.usa.siemens.com/cnc.

For more information on the this story, contact:

SIEMENS INDUSTRY, INC.

DRIVE TECHNOLOGIES

MOTION CONTROL

MACHINE TOOL BUSINESS

390 Kent Avenue

Elk Grove Village, IL 60007

Phone: 847-640-1595

Fax: 847-437-0784

Web: www.usa.siemens.com/cnc

Email: SiemensMTBUMarCom.sea@siemens.com

Attention: John Meyer, Manager, Marketing Communication

Follow us on Facebook: www.facebook.com/SiemensSiemensCNC or Twitter: www.twitter.com/siemens_cnc_us.

—

Siemens Industry Sector is the world’s leading supplier of innovative and environmentally friendly products, solutions and services for industrial customers. With end-to-end automation technology and industrial software, solid vertical-market expertise, and technology-based services, the sector enhances its customers’ productivity, efficiency and flexibility. With a global workforce of more than 100,000 employees, the Industry Sector comprises the Industry Automation, Drive Technologies and Customer Services Divisions as well as the Metals Technologies Business Unit.

The Siemens Drive Technologies Division is the world’s leading supplier of products, systems, applications, solutions and services for the entire drive train, with electrical and mechanical components. Drive Technologies serves all vertical markets in the production and process industries as well as the infrastructure/energy segment. With its products and solutions, the division enables its customers to achieve productivity, energy efficiency and reliability.

Continue reading

Matt Lorig

Machine Tool Business appoints new business development manager for Asian builder relations plus dealer support manager for Eastern U.S.

May 15, 2012 — The Siemens Machine Tool Business, part of the Drive Technologies — Motion Control group within Siemens Industry, Inc. has appointed Matt Lorig as business development manager for the company’s Asian builder base. As such, Lorig will engage in direct sales of the company’s CNC, motor and drive packages to Asian builders and importers in North America, plus maintain existing business in a response mode to better serve this growing customer segment for Siemens. Matt brings over 20 years in industrial automation to this new position, much of it in the machine tool industry with a major Japanese supplier. He has expertise in CNC, robotics, servo technology and general motion control.

Chris Pollack

In related news, Christopher Pollack assumes the duties of dealer support manager for the Eastern United States. His primary responsibility will be field support for the growing dealer network in the region that sells machine tools with Siemens CNC technology onboard. This will include technical CNC training, software support and hands-on utilization demonstrations for dealer customers, both onsite and at dealer events. Chris brings extensive knowledge of CNC technology to this position, plus a working knowledge of MasterCam and SolidWorks. He is a certified Class A machinist and was most recently an applications engineer at Fryer Machine Systems.

For more information on the this story, contact:

Siemens Industry, Inc. Drive Technologies — Motion Control (Machine Tools)

390 Kent Avenue Elk Grove Village, IL 60007

Phone: 847-640-1595

Fax: 847-437-0784

Web: www.usa.siemens.com/cnc

Email: SiemensMTBUMarCom.industry@siemens.com

Attention: John Meyer, Manager, Marketing Communications

Follow us on Facebook: www.facebook.com/SiemensCNC or Twitter: www.twitter.com/siemens_cnc_us.

—

Siemens Industry Sector is the world’s leading supplier of innovative and environmentally friendly products, solutions and services for industrial customers. With end-to-end automation technology and industrial software, solid vertical-market expertise, and technology-based services, the sector enhances its customers’ productivity, efficiency and flexibility. With a global workforce of more than 100,000 employees, the Industry Sector comprises the Industry Automation, Drive Technologies and Customer Services Divisions as well as the Metals Technologies Business Unit.

The Siemens Drive Technologies Division is the world’s leading supplier of products, systems, applications, solutions and services for the entire drive train, with electrical and mechanical components. Drive Technologies serves all vertical markets in the production and process industries as well as the infrastructure/energy segment. With its products and solutions, the division enables its customers to achieve productivity, energy efficiency and reliability.

Continue reading

A variety of complex underwater electrical connector casings are made by Gisma, using Siemens Sinumerik CNC-controlled Spinner lathe technology.

Gisma specializes in the production of underwater connectors typically used in offshore energy generation. Siemens Sinumerik-controlled Spinner CNC machine tools contribute significantly to the success of the company.

Special connectors are required to safely and reliably connect electrical and fiber-optic cables deep underwater. With maintenance more difficult, all of the parts must meet the most rigorous technical requirements in terms of reliability and service life. Products from Neumünster, Germany-based Gisma Steckverbinder GmbH are designed to be fail-safe and to withstand maximum pressure loads, while still operating on the basic “push and pull” principle. In addition to shipyards, the offshore oil and gas industry, and the military, Gisma is now receiving an increasing number of orders from offshore energy companies. Gisma works closely with its customers on all of its developments – most recently on a single-pole, wet-mateable power connector for use in offshore underwater turbines, which was designed to handle operating voltages of 12 kV at 400 A and is guaranteed to be fail-safe for 25 years.

Manufacturing repeatability to the nearest micron

To meet the high standards required in underwater technology, manufacturing accuracy to the nearest micron is required, especially for fiber-optic connectors. In addition, the materials must all be corrosion-resistant. The highest levels of functional safety are also required to enable the machining of seawater-resistant bronze and stainless steels, along with more sophisticated materials such as duplex and super-duplex steels, titanium and high-performance plastics. The demands placed on the cutting machines and controllers used in the production of these parts are correspondingly high. For many years, Gisma has relied on Spinner milling and turning centers equipped with Siemens Sinumerik CNCs. “The machines rarely fail, mostly because of the high-quality drive and control technology,” says production manager Michael Königsmann. He is particularly impressed by the TC77 universal turning machine from the 800 series, which will be used, among other purposes, to turn the casings for a new high- performance connector measuring up to 3000 mm long. The TC 77 is built on a rigid Meehanite cast iron base with large tempered steel guide rails, allowing a high cutting capacity, along with good damping and rigidity characteristics. It is equipped with a water-cooled motor spindle, which allows precision turning to within a few hundredths of a millimeter, shortly after switching on. The machine also has a counter spindle and features 12 tool stations with driven tools. “This lets us manufacture some workpieces in a single run, whereas previously it would have taken several,” explains the production manager. In accordance with VDI/DGQ 3441, the machine achieves repeat accuracy of 2 µm in the x- and z-axes.

Consistent CNC strategy since 2000

The sophisticated Sinumerik 840D sl CNC plays an equally important role in reducing manufacturing time. Since the year 2000, Gisma has used only Siemens controllers in its production facility. “By standardizing the controller, we have created an environment where we can deploy our employees flexibly all over the shop floor and operator error has become a thing of the past,” explains Tobias Frerck, Gisma’s managing director. “We have always had great results with Sinumerik controllers and knew we could rely on our competent regional service partners on those rare occasions when something went wrong.” For newly developed products, production manager Königsmann and his staff usually create the CNC programs on external PCs in DIN ISO and then send them over the network to the most suitable machine. If there is a need to manufacture new connectors based upon an existing family of parts, the required CNC programs can usually be adjusted directly on the machine itself. And, just as during initial setup, the Sinumerik 840D sl’s fully integrated and user-friendly ShopTurn software comes into its own here. The animated graphical user interface is completely intuitive, meaning that it can be easily picked up even by temporary staff. The Sinumerik Safety Integrated software package provides additional safety when working in setup mode, allowing operators to monitor the production process with the machine door open. Safety mode allows speeds of up to 2 m/min, and the software ensures that the drives stop quickly after a maximum of 1 to 2 mm, should any problems arise. If anything is unclear when an operator is entering data, he or she can push a single button on the operator console to bring up a help menu. Switching to a text-based DIN interface is just as straightforward, for example, when an experienced programmer feels that he or she can more quickly and easily describe a complex contour using a DIN statement. As always, the main focus remains on achieving the highest possible standards in terms of both the manufacturing and the finished product.

For more information on this article, please contact:

SIEMENS INDUSTRY, INC.

DRIVE TECHNOLOGIES

MOTION CONTROL

MACHINE TOOL BUSINESS

390 Kent Avenue

Elk Grove Village, IL 60007

Phone: 847-640-1595

Fax: 847-437-0784

Web: www.usa.siemens.com/cnc

Email: SiemensMTBUMarCom.sea@siemens.com

Attention: John Meyer, Manager, Marketing Communication

Follow us on Facebook: www.facebook.com/SiemensCNC or Twitter: www.twitter.com/siemens_cnc_us.

—

Siemens Industry Sector is the world’s leading supplier of innovative and environmentally friendly products, solutions and services for industrial customers. With end-to-end automation technology and industrial software, solid vertical-market expertise, and technology-based services, the sector enhances its customers’ productivity, efficiency and flexibility. With a global workforce of more than 100,000 employees, the Industry Sector comprises the Industry Automation, Drive Technologies and Customer Services Divisions as well as the Metals Technologies Business Unit. For more information, visit http://www.usa.siemens.com/industry.

The Siemens Drive Technologies Division is the world’s leading supplier of products, systems, applications, solutions and services for the entire drive train, with electrical and mechanical components. Drive Technologies serves all vertical markets in the production and process industries as well as the infrastructure/energy segment. With its products and solutions, the division enables its customers to achieve productivity, energy efficiency and reliability. For more information, visit http://www.usa.siemens.com/drivetechnologies.

Continue reading

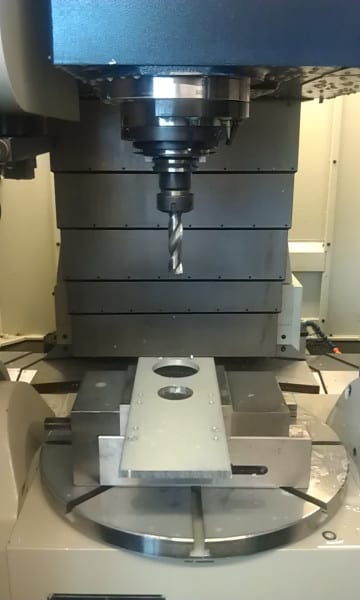

CNC upgrade enhances performance and precision

Major Tool & Machine (MTM) is a large job shop, producing precision milled and turned hardware throughout the company’s 500,000 square foot Indiana facility. Performance is essential, because MTM contracts with aerospace, energy, nuclear and defense companies on many mission-critical, one-off projects. Owner and CEO Steve Weyreter will tell you openly, MTM is more competitive by way of a significant CNC technology change, starting with an aggressive retrofit strategy.

Günther Zimmermann, CNC Controls Engineer at MTM, says the company’s retrofit program and the decision to change to the Siemens SINUMERIK CNC platform have brought a new enthusiasm and momentum to the company. Over the last two years the change has also brought significant time and cost reductions, especially in the areas of programming, maintenance engineering, and machine operations.

“The initial goal in early 2010 was to retrofit two Cincinnati U5 Gantry machines,” Zimmermann recounts. “We evaluated two CNC technology platforms and after considerable analysis our CEO Steve Weyreter announced that Siemens would best support the company’s future.”

The decision to reduce costs by moving to a single CNC platform was the least difficult decision for the company to make, Zimmermann explains. The larger challenge for MTM was the integration of a new CNC technology platform that was new to the company.

Bill Henderson, MTM’s manager of large machining and maintenance, agrees that the decision to change to a Siemens CNC platform integrated with advanced part and tool probing was critical, because the shop manages constant changeovers from one complex job to the next, making setup times a critical time/cost constraint for the company. Another big advantage is the increased flexibility by only having to train machinists and maintenance personnel on one type of control.

Naturally, there’s a resistance to change,” Henderson says. “People are comfortable with what they normally run, but after our discussions with the people on the plant floor, they understood the overall objective. Our retrofit program is not finished, yet it’s already showing tremendous benefits.”

Heads-up interchangeability

An advantage MTM gained by its retrofit strategy has been the ability to interchange heads and rotary tables from machine to machine. Easy-to-use head storage and tool management programming provided by the Siemens CNC platform support the new interchange capability.

Retrofitter Doug Huber says having Siemens as a new CNC technology partner has made a difference for Major Tool & Machine, but it’s also been an evolutionary uplift for his own retrofitting company, Indiana Automation.

“Indiana Automation has increasingly retrofit using Siemens controls in recent years, Huber explains. “On a retrofit, we always try to exceed what the original machine could do, and that’s just kind of inherent when you put on a Siemens 840D. Major Tool’s first retrofits were the Cincinnati U5 machines, a bridge model and two gantry models. These are five-axis machines and five-axis is the 840D’s forte. The processing power of the control is so much better, that it just whips through the blocks faster. So right off, cycle time is a major performance enhancement.”

Huber says something else happened this time. As his firm finished retrofitting the first three giant machines with Siemens five-axis controls, drives and motors, the reaction within the company was not just that the machines were now predictably more efficient, but that they performed as very different machines. A new advantage is the ability to interchange machining heads from machine-to-machine, and all driven by the Siemens CNC platform.

“On many of the U5 machines, the axes come off with the heads,” Huber explains, “and we rebuilt these machines to accept any one of three different heads. That’s one of Major Tool’s key strategies. They insist on having flexible machine capabilities, so that they can run all kinds of different parts. They have straight heads for serious metal cutting, contour heads for five-axis work and finesse work. They have 90-degree heads for more flexibility than a straight head, but it’s also not as fragile as the contour head. And they wanted to interchange all of these heads to automatically go pick up a head out of the shuttle and, on the fly, reconfigure the axes and the zero positions. To do this, the compensation tables all had to be updated. Everything needed to be done with the macro program so that each head came on ready to run.”

The interchangeable head strategy was a challenge, Huber says, because the machines were not originally capable of sharing heads. But with support from Siemens, the strategy has worked, including the ability to interchange rotary tables as well as heads. “Each head or rotary table has a configuration file that has all the settings and compensations and travels with it from machine to machine. So now when you mount that head the control just runs the configuration file that goes with it and its all set up for you. We also incorporated Siemens Tool Management for each machine’s 60-pocket tool chain. We used the feature on these machines to manage all the different tooling MTM uses, both in the automatic tool changer as well as the ones manually loaded.”

Huber says, “MTM’s ability to smoothly transition to more advanced CNC is largely due to the HMI’s ease of use. The Operate interface is a huge help to us and to Major Tool. The HMI helps make better parts. And it didn’t take very long for the operators to fall in love with it.”

Leveraging the machinist’s skills

Central to MTM’s retrofit program has been the Siemens SINUMERIK 840D sl control, which features the SINUMERIK Operate interface. The highly intuitive interface enables both programmers and operators to easily capitalize on the broad capabilities of the control.

“I had never used a Siemens control before,” admits MTM machinist Mike Burthay. “I have extensive knowledge of G-code and CNC controls and I would say the Siemens 840D sl with the Operate interface is the easiest one I’ve ever run. It’s user friendly, that’s exactly the words for it.”

Burthay reports several ways in which the Siemens SINUMERIK Operate interface has made his life easier. “There’s not as much G-code,” he says. “The control does it all for you as long as you put in the parameters as to size, length, width. Then once you’re in Job Mode, there’s a screen where you can tool change or jog the machine around to certain positions, or turn the spindle on, turn the coolant on, anything that traditionally required G-code. So now you can push a cycle stop button to pause the machine, enter a change such as turning coolant on, then restart the program.

Programming as easy as 1-2-3: Using the SINUMERIK Operate interface, a machinist can turn on coolant flow by 1) pressing Cycle Stop to stop the machine, 2) Coolant On, and 3) Restart.

“Another function I love is Block Search, which allows me to start or restart right in the middle of a program. Say you’re finishing a pocket and you have to run the tool two or three times to get a tight tolerance, I can enter in a line number and hit Block Search, the control picks up every line before that, restarts the spindle and everything for you.”

Burthay says the Siemens control also enables him to program parts right on the machine whenever necessary, using a simple yet robust program called ShopMill. “I can go into ShopMill, type in some parameters and it will kick out that G-code program for me automatically. Say I want to drill a hole two inches deep. I open ShopMill, pick my tool, tell it the depth and these steps are all interactive on the screen. It even shows me 3D motion images of the tool path, confirms the drill going down as expected into the part. So I hit go and it puts a drill cycle into the program for me.”

Programmed for collaborative growth

Lead Programmer, Tim Hayden, has from the beginning conducted all processor setups for the newly retrofitted machines. Hayden says integrating the Siemens CNC platform has been an empowering experience he had not expected, given the fact that he had never before set up a post processor to run a Siemens control, nor had he ever before operated a Siemens control.

“Now, when I look at the Siemens control, I think man, it would have been so much better to have had it all along,” Hayden says, “because the other control I’ve been using is just a lot more cryptic. The Siemens control with the SINUMERIK Operate interface is more powerful for writing macros and the language seems modern, whereas the other control seems like it is still based on an old FORTRAN type language.”

Work offsets for compound angles can be scaled and rotated using the Frames function of the Siemens SINUMERIK Operate interface. Many advanced machining operations can be managed simply, without the use of time-intensive manual G-code programming.

Hayden points to the Frames coordinate and offset programming function of the Siemens interface as an example of improved programming convenience.

“We do a lot of work on compound angles,” Hayden explains, “and with the Siemens Frames function, you can scale and rotate your coordinate system on the control, just plug it in with your work offsets. Whereas, on the other control you will see a G54 request, you’ve got to enter G-code. You can’t just plug it into your work offsets like you can with the Siemens control.”

Hayden says the SINUMERIK Operate interface brings greater programming flexibility. The HMI enables him to enter G-code using a comparatively more advanced manual data entry (MDI) function; however the HMI has all but eliminated the need for G-code entry by way of its intuitive design and evolved capabilities.

Another example of such HMI evolution is in the area of data management.

“When we post a program, we no longer have to use a G-code based MDI,” Hayden explains. “We no longer need to type in T= and enter a nine digit number and then enter M6 to make a tool change. With the Operate HMI, you pick your tool off a screen and hit cycle start. It’s just as easy to program going to a position. Instead of doing things the old way by typing G0X0Y0Z0 into the MDI, you open the Operate interface, click position, then click how you want to wrap it and then you just type the numbers into those fields. So it’s a lot more user friendly.”

Hayden says the Siemens CNC platform has supported greater collaboration at MTM between him and the machinists, and this is helping the company find ways to increase performance and efficiency. He agrees with his coworkers’ assessments that shorter setup times and greater operator freedom are making a significant difference.

“One of our production bottlenecks has been programming,” Hayden says. “The machinists that run our machines are professionals, they’re not button pushers, and with the SINUMERIK Operate interface, we can now rely on them to control and program certain parts right on their machines, while we programmers work on the more complex projects.”

“Siemens was the best fit for all of us,” Hayden concludes. “Siemens CNC is set up as an open control, and with that kind of flexibility, it seems anything is possible.”

See Siemens CNC at Major Tool & Machine in action HERE!

For more information, contact:

SIEMENS INDUSTRY, INC.

MOTION CONTROL

MACHINE TOOL BUSINESS

John Meyer

Manager, Marketing Communications

Siemens Industry, Inc.

(800) 879-8079 ext. Marketing Communications

www.usa.siemens.com/cnc

SiemensMTBUMarCom.industry@siemens.com

Follow us on Facebook: www.facebook.com/SiemensCNC or Twitter: www.twitter.com/siemens_cnc_us.

—

Siemens Industry Sector is the world’s leading supplier of innovative and environmentally friendly products, solutions and services for industrial customers. With end-to-end automation technology and industrial software, solid vertical-market expertise, and technology-based services, the sector enhances its customers’ productivity, efficiency and flexibility. With a global workforce of more than 100,000 employees, the Industry Sector comprises the Industry Automation, Drive Technologies and Customer Services Divisions as well as the Metals Technologies Business Unit. For more information, visit http://www.usa.siemens.com/industry.

The Siemens Drive Technologies Division is the world’s leading supplier of products, systems, applications, solutions and services for the entire drive train, with electrical and mechanical components. Drive Technologies serves all vertical markets in the production and process industries as well as the infrastructure/energy segment. With its products and solutions, the division enables its customers to achieve productivity, energy efficiency and reliability. For more information, visit http://www.usa.siemens.com/drivetechnologies.

Continue reading

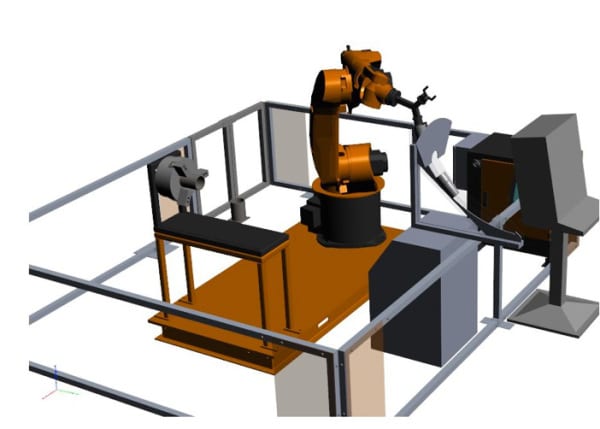

CHICAGO — At this year’s International Manufacturing Technology Show (IMTS) in Chicago, Siemens will demonstrate its recent collaboration with KUKA Robotics. In the Siemens booth E-5010, a KUKA robot will be articulating parts, simulating the operation on a CNC machine tool. Key to this development is the machine builder’s ability to integrate mxAutomation from KUKA directly through the Siemens Sinumerik CNC platform, thereby allowing the operator of the machine to run both the machine tool and robot from the single control panel.

The motion sequence of the robot is entirely engineered within the Sinumerik 840D sl CNC, then transferred by the 840D sl’s PLC function to the mxAutomation interpreter on the KR C4. All program changes to a six-axis robot can easily be input on a second channel of the CNC and fully operated. This scenario provides the ability to not only run a machine tool’s automation sequence more efficiently, but also make more changes on-the-fly to minimize machine downtime, with no special knowledge of robot programming language.

During the operation of the machine tool, all changes made can be visualized directly on the CNC screen, further minimizing operator actions. Siemens is the first CNC supplier to show this capability for single-screen operation of the machine tool and robotic materials handling on the CNC.

In operation, the KRC4 integrator and mxAutomation convert the robot language into the same commands used for multi-axis machine tool functions. A single Profinet cable runs between the robot and the CNC. According to KUKA’s Andreas Schuhbauer, key technology manager for machine tool automation (Augsburg, Germany), “mxAutomation allows the machine tool builder a single I/O language for integrating robotics on the CNC, while the end user operator can run both the machine tool and the robot from a single screen on the control.” mxAutomation for Sinumerik CNC was a joint development between KUKA and Siemens. KUKA created plug-in function modules for the Siemens Step 7 PLC engineering software and provided its robot knowledge to Siemens for creation of the second channel logic on the CNC, Andreas Schuhbauer further noted. All safety functions and test functions for load / unload, brake test, gripper, robot communication and safe operation of the robot are provided through the Siemens Profinet and Profisafe platforms.

Future developments for mxAutomation are planned, including a wider application range for robots in the CNC machine tool environment.

Join the user community by following us on Facebook: www.facebook.com/SiemensCNC and talking to us on Twitter: www.twitter.com/siemens_cnc_us. Siemens Industry Sector is the world’s leading supplier of innovative and environmentally friendly products, solutions and services for industrial customers. With end-to-end automation technology and industrial software, solid vertical-market expertise, and technology-based services, the sector enhances its customers’ productivity, efficiency and flexibility. With a global workforce of more than 100,000 employees, the Industry Sector comprises the Industry Automation, Drive Technologies and Customer Services Divisions as well as the Metals Technologies Business Unit. The Siemens Drive Technologies Division is the world’s leading supplier of products, systems, applications, solutions and services for the entire drive train, with electrical and mechanical components. Drive Technologies serves all vertical markets in the production and process industries as well as the infrastructure/energy segment. With its products and solutions, the division enables its customers to achieve productivity, energy efficiency and reliability.

For more information on this story, please contact

SIEMENS INDUSTRY, INC. DRIVE TECHNOLOGIES MOTION CONTROL MACHINE TOOL BUSINESS

390 Kent Avenue Elk Grove Village, IL 60007

Phone: 847-640-1595 Fax: 847-437-0784

Web: www.usa.siemens.com/cnc

Email: SiemensMTBUMarCom.sea@siemens.com

Attention: John Meyer, Manager, Marketing Communication

Follow us on Facebook: www.facebook.com/SiemensCNC or Twitter: www.twitter.com/siemens_cnc_us.

—

Siemens Industry Sector is the world’s leading supplier of innovative and environmentally friendly products, solutions and services for industrial customers. With end-to-end automation technology and industrial software, solid vertical-market expertise, and technology-based services, the sector enhances its customers’ productivity, efficiency and flexibility. With a global workforce of more than 100,000 employees, the Industry Sector comprises the Industry Automation, Drive Technologies and Customer Services Divisions as well as the Metals Technologies Business Unit. The Siemens Drive Technologies Division is the world’s leading supplier of products, systems, applications, solutions and services for the entire drive train, with electrical and mechanical components. Drive Technologies serves all vertical markets in the production and process industries as well as the infrastructure/energy segment. With its products and solutions, the division enables its customers to achieve productivity, energy efficiency and reliability.

Continue reading

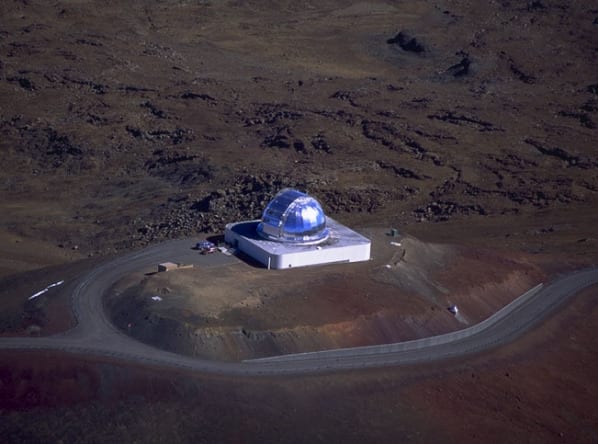

Machining center used at University of Hawaii Institute For Astronomy to produce one-off diffraction gratings for remote sensing instruments used with telescopes and other research instrumentation

University of Hawaii Institute For Astronomy telescopes are able to see the solar system and into deep space with greater clarity than at any other location on the planet, according to Dr. Ritter.

When you enter the laboratories at the University of Hawaii’s Maikalani Institute For Astronomy (IFA) Advanced Technology Research Center on the island of Maui and hear talk of light years, dark energy and space telescopes, it quickly becomes apparent that this is not your typical machine shop. The machining for instrumentation developed here involves some of the most sophisticated techniques on Earth, which is a pun of cosmic irony, as the workpieces produced here are primarily used to help evaluate happenings in deep space.

The Maikalani facility provides laboratory workspace for Physicists and Astronomers performing advanced

As Ritter explains, “Accuracy is everything in optics. Most of the machining centers I evaluated were in the +/-25 micron (~0.001”) range for accuracy. We settled on a 3+2 axis machine with 100 nanometer precision scales with interferometric remapping on the 840D sl CNC. Because we do experimental fabrication work and optics typically need to be made to micron level tolerances, it was imperative to have a feedback control on the machine tool with a known accuracy and predictable degrees of variation.” As an example, though not suitable for visible light, the optics Ritter discussed required accuracies of a few microns-good enough for infrared optics. Other technologies being developed by Ritter at IFA include novel photonic meta-materials for future space telescopes intended for studying exoplanets and the evolution of our universe.

Dr. Ritter cited the age-old challenge for educational

Sample parts produced on Spinner machine, mostly copper and aluminum, include many that become diffraction gratings used on highly sensitive instruments for deep space exploration projects

While invariably the smart guys in any room, Dr. Joe and John Valliant are not machinists by trade, so they were using both Shopmill and CAD/CAM programs like Mastercam with the highly-specialized G-code generator and post-processor needed to create precision path cuts, then running them directly on the mill to quickly begin cutting, an absolute necessity in their one-off world of custom parts.

“For some optics, the millions of coordinates we use for every workpiece are pushing the control to the limit, but it responds well. Plus, the teach-in functionality of the Sinumerik 840D sl CNC and its software package keep us running very efficiently,” according to Valliant, who worked in the lab as a University of Hawaii-Maui college student and has learned CNC machining on the go. In an environment where 0.1 of a wavelength of light is the desired target for accuracy, this is no small achievement. Valliant adds, “Once you’re comfortable with this machine and the control, the process is very intuitive.”

Dr. Ritter, who is constantly pushing the boundaries on novel orbital space telescope designs, notes that the state of Hawaii and the island of Maui in particular have some of the best conditions on Earth for nighttime telescopic observation, as well as the best in the world for daytime solar viewing. The National Science Foundation will soon build the world’s largest solar telescope on Maui. Maui is a little known hotbed of technology development. In addition to solar research and deep space observations, the Institute for Astronomy partners with many nations to push the boundaries of human knowledge, while training future scientists.

Mac McPherson, the Spinner machine dealer and importer for North America, adds, “We do

“Na Kilo Hoku” means “the watchers of the stars” and the instrument components made here certainly help them do just that — and also gain knowledge from the cosmos for us all.

For more information on this story, please contact:

Joe Ritter, Ph.D

Physicist and Lab Director

University of Hawaii Institute For Astronomy

Maikalani Advanced Technology Research Center

34 Ohia Ku St.

Pukalani, HI 96768

Phone: 808-573-9521

Web: www.ifa.hawaii.edu

Or

Robert McPherson

MacHill Machinery Solutions, LLC

(dealer for Spinner machines)

2245 C-132 Ashley Crossing Drive

Charleston, SC 29445

Phone: 843-873-6888

Web: www.machillmachinery.com

Or

SIEMENS INDUSTRY, INC.

DRIVE TECHNOLOGIES

MOTION CONTROL

MACHINE TOOL BUSINESS

390 Kent Avenue

Elk Grove Village, IL 60007

Phone: 847-640-1595

Fax: 847-437-0784

Web: www.usa.siemens.com/cnc

Email: SiemensMTBUMarCom.sea@siemens.com

Attention: John Meyer, Manager, Marketing Communication

Follow us on Facebook: www.facebook.com/SiemensCNC or Twitter: www.twitter.com/siemens_cnc_us.

—

Siemens Industry Sector is the world’s leading supplier of innovative and environmentally friendly products, solutions and services for industrial customers. With end-to-end automation technology and industrial software, solid vertical-market expertise, and technology-based services, the sector enhances its customers’ productivity, efficiency and flexibility. With a global workforce of more than 100,000 employees, the Industry Sector comprises the Industry Automation, Drive Technologies and Customer Services Divisions as well as the Metals Technologies Business Unit. For more information, visit http://www.usa.siemens.com/industry.

The Siemens Drive Technologies Division is the world’s leading supplier of products, systems, applications, solutions and services for the entire drive train, with electrical and mechanical components. Drive Technologies serves all vertical markets in the production and process industries as well as the infrastructure/energy segment. With its products and solutions, the division enables its customers to achieve productivity, energy efficiency and reliability. For more information, visit http://www.usa.siemens.com/drivetechnologies.

Continue readingBOOTH E-5010

For machine tool builders and end-users, Siemens will exhibit the newest innovations in CNC (Computer Numerical Control), motor and drive technology, as well as new value-adding services ranging from condition monitoring and manufacturing IT to innovative solutions for CNC training and machine tool retrofits.

Highlighting the booth for attendees will be a raffle to win a Harley-Davidson motorcycle, as well as the opportunity to register for a 60-day free trial license on Sinutrain, the full suite of Siemens CNC training modules.

NEW CNC SOLUTION FOR THE SHOPFLOOR

New at IMTS 2012, Siemens will introduce a shop floor CNC specifically designed and engineered for the 230V, three-phase) economy-priced market, with up to three-axis plus spindle control capability in milling or turning applications. Offered as a package with Siemens Sinamics drives and Simotics motor solutions, this new control will be demonstrated on a knee mill, during the show. This new CNC will be available for both OEM machine builds and in-the-field retrofit.

SOLUTIONS FOR THE JOB SHOP

Introduced at IMTS 2010 and already a world-class force in the mid-range machine tool market, the Sinumerik 828D will be running on various machines and simulators in the booth. New for IMTS 2012, the Sinumerik 828D BASIC T (turning) and BASIC M (milling) will also be on display, expanding this range of Siemens CNC to enhance job shop performance in all segments of this market.

The Sinumerik 828D BASIC T is designed to address the needs of shopfloor turning machines.

It combines CNC, PLC, operator panel and axis control for five axes/spindles, including live tooling. Milling and drilling operations on a turning machine, both for face and peripheral surfacing, are therefore possible. In tandem with the new Sinamics S120 Combi drives package, the 828D BASIC T represents a new level of efficiency and virtually maintenance-free operation, as the fans, hard disks and batteries of past CNC generations are eliminated.

Likewise, the new Sinumerik 828D BASIC M class features the same quality performance as the T class, for use on milling machines. Even in complex moldmaking operations, mirror-smooth surfacing and reduced machining times are enabled. Again, in tandem with Sinamics S120 Combi drives package and Simotics feed and spindle motors, the 828D BASIC T will operate a milling machine at the highest level of performance possible. Superior axis and spindle dynamics within a broad speed bandwith yield quality workpieces, every time.

All the other benefits of the Siemens CNC family, including the Sinumerik Operate graphical user interface platform as well as ShopMill and ShopTurn easy programming are offered in these new 828D CNCs.

The Sinumerik 828D is capable of full graphical, high-level language command and supports ISO programming that is customary in the United States. This control family is ideal for single-part and small-batch production. Programming time can be further reduced for small-batch production with the use of the ShopMill and ShopTurn graphical workstep programming system, while high-level language programming can be used in conjunction with programGuide to significantly reduce programming times for large-scale serial production.

Also included with this expansion of the Sinumerik 828D family of CNC, modern PC and mobile phone technology are also available to the mid-range machine tool. Extensive online help animations and a new type of input prompting system with moving picture sequences provide the basis for exceptional user convenience. USB, Compact Flash (CF) card and Ethernet ports enable high-speed data transfers onto storage media or integration of the control system into corporate networks.

Through the use of its Easy Message functionality, the Sinumerik 828D family offers production status monitoring by text messaging (SMS). Depending on the recipient’s profile settings, the machine tool can transmit information about workpiece machining status, report on the tool condition currently in use and send machine maintenance bulletins to a mobile phone, anytime and anywhere. These combined functions are designed to help keep machine downtime to a minimum.

STILL THE HIGHEST STANDARD IN CNC

Still the highest technology standard in the industry, the Sinumerik 840D sl CNC makes

another series of advancements, all being demonstrated at this year’s show. The system platform

offers a comprehensive range of functions for machine tools. This universal control covers wide-ranging machining technologies used in metalworking operations such as turning, drilling, milling, grinding, laser machining, nibbling and punching, plus it can be used in multi-tasking machines such as turn-mill or mill-turn centers. Whatever the application, Sinumerik 840D sl leads to maximum productivity for the job shop or industrial-scale production department, as well as optimum surface quality for all mold and tool building applications.

Sinumerik Operate is the graphical user interface that provides an integrated milling function for turning machines or integrated turning function for milling machines.

With the benefit of modern touchscreen operation, the new Sinumerik operator panel OP 019, now extended to include the new Power Control Unit (PCU) 50.5, allows high-speed key actuation at the large 19-inch glass front, which conforms to the IP66 protection rating. Another new feature of the OP 019 design is the wide LEDs, which allow the operator to clearly visualize every key actuation, no matter what the angle of vision, and an integrated key lock helps safeguard against operating errors. The new operator panel is able to provide a basic machine display with three or four channels showing up to 13 axes.

Sinumerik CTRL-E is the new green high achievement in CNC operation, designed for the strict requirements of the international energy efficiency standard EN16001. It provides a full assessment of the energy consumed by the machine tool in every cycle, on every part produced and throughout the machine’s life cycle. Specific power loads can be shut down automatically during downtimes, plus generated braking energy can be stored or fed back into the power grid. In this way, Siemens Sinamics drives package are achieving up to 99% energy efficiency, while Simotics motors are likewise running 90%+ levels, unprecedented in the machine tool market previously.

Sinumerik Integrate is an onboard CNC solution that allows machine tool data to be integrated quickly, simply and reliably into other company processes. This IT integration of production processes allows managers, machine operators, part programmers, maintenance engineers and machine tool builders to be inter-connected with each other and integrated into the overall system by means of defined processes. Sinumerik Integrate facilitates this network by concentrating IT-related functions into a single process suite, using six different available modules that cover every aspect of the machine tool integration process.

SOLUTIONS FOR AEROSPACE

For the aerospace market, the Sinumerik 840D sl is the latest in CNC technology that increases performance and user productivity. It is a universal and flexible CNC system featuring the innovative Sinamics S120 drives that can be used with up to 31 axes. It is a distributed, scalable, open and

inter-connecting system, offering a wide range of specialized functions for milling, drilling, turning, grinding and handling technologies, with full kinematic transformations for optimum machining and surface quality.

The Sinumerik 840D offers users innovative features that increase productivity on the manufacturing floor, especially the challenging segments of high-speed and five-axis

aerospace machining.

Connectivity is the watchword in aerospace at this year’s show. From a single solution provider, machine builders and end users alike can enjoy full and seamless connectivity of their CNC and PLC technologies, plantwide and worldwide among facilities, as Siemens provides its international network of support to all facilities, in all operating and conversational languages. Hardware and software solutions from a single source are available, to the scale and scope needed by any aerospace OEM or tier vendor.

SOLUTIONS FOR AUTOMOTIVE

In the automotive industry, Siemens continues to solidify its position with the Transline System Solution, the solution for automotive powertrain. This system integrates diverse metalcutting technologies such as milling, drilling, turning and grinding, and the assembly of powertrain parts, under a common system architecture. With the introduction of the Flexible Assembly Configuration System (FACS), Siemens has now also streamlined the line changeover world in dramatic fashion. What took weeks now takes hours.

Based on the new Sinumerik 840D sl, Simatic PLC and Simotics motor technologies, Transline solution line transforms the company’s concept of “productivity in motion” into a real-world application for total factory automation. By specifying Transline, machine tool users benefit from faster start-up times, better equipment serviceability and increased productivity. Operator cross-training and workcell operation are further enhanced.

SOLUTIONS FOR MANUFACTURING EXCELLENCE

During the show, Siemens will also have displays of its Totally Integrated Automation (TIA) services, as well as Siemens Safety Integrated and other production network offerings. TIA Portal, enables the design and configuration of all process automation from a single computer screen, along the entire process supply chain. Siemens Safety Integrated for Factory Automation comprises advanced drive technologies, automation systems, operator control and machine monitoring, fail-safe communications and safe industrial control advancements.

SOLUTIONS FOR CNC TRAINING, CUSTOMER SUPPORT AND MOBILE APPS

SinuTrain, the Siemens package of CNC training software on CD-ROM, provides milling and turning machine operators with a high degree of practical hands-on experience, prior to using the CNCs on their actual machines. It is designed to run on Windows XP or Windows 7 operating systems and is the optimal solution for machine tool control-identical simulation training. It installs and operates with less memory, so other work can easily be accomplished during simulation of the machining.

With SinuTrain, actual NC programs are developed and simulated, using a direct connection to the company’s CAD systems to further speed the program generation protocol. In this way, machine tool operators not only learn the control language commands, but they also visualize part programs on a PC screen that are identical to the actual machine screen. As a further benefit, programs generated through SinuTrain on the PC software can then be used on the machines.

A FREE 60-DAY TRIAL LICENSE of Sinutrain will be available to all show attendees.

My Documentation Manager allows Siemens CNC users to customize online service and operations manuals to suit their specific machine tools.

New mobile apps for iOS and Android devices that are now available from Siemens will be demonstrated, including Easy CNC with G-code compatibility conversion, Motion World, the Siemens customer magazine for CNC automation and CNC4you.

Other exhibits on display in the Siemens booth include the new Simotics 1FK7 / 1FT7

high-inertia servomotors, the 1PH8 main spindle motor, linear motors and direct-drive torque motors that contribute to the increase in machine performance. The exhibition will also focus on machine tool retrofit, field service, customer service, spare parts and repair, all of which support the machine tool builder and end-user. Special displays will also feature Siemens solutions for medical part manufacturing and power generation.

In the booth’s theater area, educational seminars about CNC technology, Product Lifecycle Management (PLM) developments, factory automation and more will be presented.

Finally, Siemens will have active participation in the Automation Pavilion being held at IMTS 2012, directly adjacent to the Siemens booth in the East Hall.

For more information about Siemens CNC solutions for the machine tool industry, visit our website: www.usa.siemens.com/cnc.

Please forward all inquiries to:

SIEMENS INDUSTRY, INC.

DRIVE TECHNOLOGIES

MOTION CONTROL

MACHINE TOOL BUSINESS

390 Kent Avenue

Elk Grove Village, IL 60007

Phone: 847-640-1595

Fax: 847-437-0784

Web: www.usa.siemens.com/cnc

Email: SiemensMTBUMarCom.sea@siemens.com

Attention: John Meyer, Manager, Marketing Communication

Follow us on Facebook: www.facebook.com/SiemensCNC or Twitter: www.twitter.com/siemens_cnc_us.

—

Siemens Industry Sector is the world’s leading supplier of innovative and environmentally friendly products, solutions and services for industrial customers. With end-to-end automation technology and industrial software, solid vertical-market expertise, and technology-based services, the sector enhances its customers’ productivity, efficiency and flexibility. With a global workforce of more than 100,000 employees, the Industry Sector comprises the Industry Automation, Drive Technologies and Customer Services Divisions as well as the Metals Technologies Business Unit. For more information, visit http://www.usa.siemens.com/industry.

The Siemens Drive Technologies Division is the world’s leading supplier of products, systems, applications, solutions and services for the entire drive train, with electrical and mechanical components. Drive Technologies serves all vertical markets in the production and process industries as well as the infrastructure/energy segment. With its products and solutions, the division enables its customers to achieve productivity, energy efficiency and reliability. For more information, visit http://www.usa.siemens.com/drivetechnologies.

Continue readingA Detroit-based manufacturer of workhorse diesel engines for trucks that run millions of miles tests the durability and performance of each engine with dynamometers. This testing burns more than two million gallons of fuel each year and generates tremendous amounts of heat that is released through cooling towers in the roof. In a pilot project using Siemens Sinamics® variable frequency AC drives to control two dynamometers, the company is capturing the wasted heat energy and returning it to the factory grid, saving about $150,000 a year in utility costs. Once deployed across all 30 test stands, this solution could save $2.2 million and reduce CO2 emissions by 15 metric tons each year, making the operation more sustainable, more compliant and more profitable.

Burning more than two million gallons of diesel fuel a year should do more than simply heat the skies above Detroit, Michigan.

For years, though, that was all one leading manufacturer of diesel engines was getting from the heat produced during virtually non-stop operation of a diesel engine testing facility the size of a major league stadium. Then the company had a brilliant idea: Why not capture the energy generated by its testing and put it back into its own grid to lower its utility costs?

As part of one of the largest truck manufacturing companies in the world, the engine maker produces diesel engines for trucks, heavy equipment and other applications requiring lots of horsepower over long time periods. Its truck engines are the 600 horsepower workhorse engines that power big semi-trailer truckson the nation’s highways. They are designed to run millions of miles and non-stop testing helps ensure they can go the distance.

Although there are different types of dynamometers, this diesel engine producer uses one with an eddy-current clutch, which puts an electrical flux around the rotor of a motor providing resistance to the engine. The test beds are cooled via a water-to-air cooling system that circulates cool water through the hot machinery. The rotational force generated by the engine is used to pump the heated water up to the cooling towers on the roof where it the cool Detroit air absorbs the heat. After the cooling towers, the water is ready to be used to cool the system again.

In 2008, and the testing labs’ facilities manager and environmental engineering manager began discussing the possibility of recovering the energy produced by the engines and feeding it back into the facility’s own grid. They thought the electricity generated internally could help offset the 2.1 megawatts of electricity it buys each year from the local utility.

The Solution

With the help of AEM, Inc., a long-time Siemens channel partner, the diesel engine producer developed a pilot solution based on recovering the wasted energy by replacing the eddy-current dynamometer of two test stands with an induction motor and four-quadrant Sinamics® S150 variable frequency drive (VFD). The motor will be holding back against the customer’s test engine and thus generating energy. The S150 VFD has an “active front end” design that provides regeneration capability to recover the energy previously wasted as heat and return it to the company’s own power grid.

Planning and designing the solution using Siemens variable frequency drives began in 2008 and the deployment occurred in mid-2009.

The Results

While the pilot solution is a significant departure from the company’s existing test bed technology, the expected maintenance and environmental savings has the facilities team considering a full migration to the Siemens solution.

Given economies of scale in converting the rest of the test stands, the recovered energy will make this Siemens customer more energy self-sufficient. And the energy cost-savings would add up to potentially an additional $2.1 million a year. The company would also prevent about 15 metric tons in CO2 emissions each year.

For further tech detail on the Siemens S150 drives, please visit:

For further information on this story, please contact:

SIEMENS INDUSTRY, INC.

DRIVE TECHNOLOGIES

MOTION CONTROL

MACHINE TOOL BUSINESS

390 Kent Avenue

Elk Grove Village, IL 60007

Phone: 847-640-1595

Fax: 847-437-0784

Web: www.usa.siemens.com/cnc

Email: SiemensMTBUMarCom.sea@siemens.com

Attention: John Meyer, Manager, Marketing Communication

Follow us on Facebook: www.facebook.com/SiemensCNC or Twitter: www.twitter.com/siemens_cnc_us.

—

Siemens Industry Sector is the world’s leading supplier of innovative and environmentally friendly products, solutions and services for industrial customers. With end-to-end automation technology and industrial software, solid vertical-market expertise, and technology-based services, the sector enhances its customers’ productivity, efficiency and flexibility. With a global workforce of more than 100,000 employees, the Industry Sector comprises the Industry Automation, Drive Technologies and Customer Services Divisions as well as the Metals Technologies Business Unit. For more information, visit http://www.usa.siemens.com/industry.

The Siemens Drive Technologies Division is the world’s leading supplier of products, systems, applications, solutions and services for the entire drive train, with electrical and mechanical components. Drive Technologies serves all vertical markets in the production and process industries as well as the infrastructure/energy segment. With its products and solutions, the division enables its customers to achieve productivity, energy efficiency and reliability. For more information, visit http://www.usa.siemens.com/drivetechnologies.

Continue readingThrough the use of Siemens SINUMERIK CNC technology, plus PLC and HMI, on a combination servo-controlled cold saw cut-to-length and brush deburring system, Rattunde customer achieves triple the output on small engine exhaust components

Rattunde ACS + BDM tube and bar production system at Cosmos.

Rattunde Corporation of Grand Rapids, Michigan is the five-year-old subsidiary of Germany’s Rattunde & Co. GmbH, a machine tool builder of tube, pipe and bar processing equipment. The company is already making its mark in the American manufacturing industry, as demonstrated by a recent success it had at Cosmos Manufacturing of South Chicago Heights, Illinois, a major supplier of small engine exhaust tubes to the leading outdoor power equipment manufacturers in the country.

The Rattunde system, incorporating a servo-controlled cutoff saw and brush deburring mechanism, is consistently producing up to 11,000 parts per hour at Cosmos, according to Mike Jemilo, the end user’s general manager. “This number represents triple the output production for Cosmos.” He continues, “Better still, it’s been in operation more than a year and we have not reported a single reject, with only routine maintenance and zero downtime due to machine problems. This is truly a win-win scenario for the machine tool builder and us alike.”

At the heart of the Rattunde system, according to Richard Stadler, company president, is the computer numerical control (CNC) system used by this builder. It consists of a Sinumerik 840D CNC, Simatic S7 PLC with various analog and Profibus modules, plus numerous Simotics servomotors, motor protection devices, circuit breakers and other components supplied by Siemens.

Machine performs all servo-controlled saw cut-to-length, washdown, brush deburring and packing operations on a single line, controlled by Siemens CNC and HMI.

At Cosmos, this Rattunde system is used to process mill-length tubes to customer-specified dimensions, using a fully NC-controlled cold saw. Cut-to-length parts are then automatically measured for dimensional accuracy and brush deburred. Production of these parts runs up to 11,000 units per hour, according to Cosmos’ Mike Jemilo. Because of the overall improvements in automation, speed and parts handling, plus the precision of the Sinumerik CNC system, Cosmos is further experiencing significant reductions in parts handling, secondary operations and final assembly.