Contact us today:

(847) 934-4500

tdaro@bernardandcompany.com

Contact us today:

(847) 934-4500

tdaro@bernardandcompany.com

However the drawback of such reputation is that some customers think they cannot afford REP technology or don’t need advanced features knowing well they are unnecessary for their simple parts production.The G10 Core line was designed to target these customers’ needs.

Presented for the first time at the end of 2016, much less expensive than the G10 Extended, the G10 Core meets the needs of lean manufacturing, for uncomplicated and standard processes, while delivering the usual REP quality and reliability.

The G10 Core is available with clamping forces from 1 600 to 5 100 kN : V410 Core, V510 Core and V710 Core.

These machines feature all of the REP technology at optimized cost. The G10 Core is a G10, it has the same patented injection unit as the G10 Extended with separate injection and plasticization functions. Unlike other so-called budget machines, it is CE-certified . For customers who need simple solutions without stripping kit, process control customization or other particular features, it is the ideal solution!

For more information on this announcement, please contact:

REP Corporation

8N740 Tameling Court

Bartlett, IL 60103-8146

Phone: 847-697-7210

www.repinjection.com

tgraham@repcorp.com

Attention: Tim Graham, President.

Long-established technology of Coordinate Measuring Machines (CMM) is today being challenged in myriad markets by fast-emerging, highly advanced science of blue light scanning

For over 50 years, the benchmark for accuracy in measuring solid objects, whether machined, molded, die cast, welded or forged, was the coordinate measuring machine. Using a solid granite base table typically, along with a vertical, horizontal, gantry or bridge-mounted arm and touch probe, measurements would be taken and compared in blocks to an engineering file, first as 2D drawings and today as CAD files hosted in the cloud.

During the last two decades, however, a “new kid in town” has arrived on the scene, with power, size, point capability and price value that are rapidly leaving the CMM technology in the dust.

3D laser scanning, plus the latest trend of industrial CT scanning, which is based on the same technology used for medical MRI, permit an array of points to be read, both external and now internal, on a wide variety of substrates and manufacturing techniques. 3D scans are made on many types of metals, composite, thermoplastic, elastomeric, wood, fiber and fabric materials, while CT scanning permits internal exploration of a thick aluminum casting, injection molded plastic or rubber part, even prepared foods, packaging, archaeological finds and fine art. The old joke is, with CT scanning, we would have known about Venus de Milo’s arm problems, long before they occurred. CT scanning can produce results for porosity, dimensional, failure analysis, volume and fiber orientation, all while leaving the part undamaged.

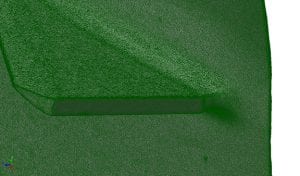

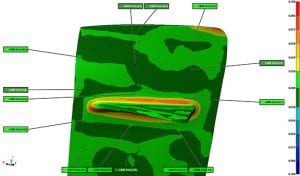

3D laser scan can capture millions of points, instantly comparing them to a CAD file or cloud-resident data

In contrast to conventional tactile CMM techniques, laser and especially CT scanning captures all surface points simultaneously, on even the most complex, convoluted surface areas. As an example, where a typical touch probe might capture 300 points of reference for comparison to a CAD overlay, the laser or CT will capture millions of points. Typical systems today can offer measurement accuracies to 4+L/100µm referring to the VDI 2630 metrology guideline.

A customer recently came to us with the following scenario. An engineer at his company was boasting of having produced the “perfect part,” based on CMM deviation points. Our contact had used our scanning services in the past. We performed a quick blue light 3D scan on the object and quickly determined the part was out of spec on several faces, as certain critical points had been missed in the CMM protocol. Our millions of scan data points were fit to the deviation map and the problem was tracked backed to the production source and rectified. Today, this company is a regular customer.

CT scan enables the internal examination of a die cast, molded or other solid part, even food and packaging, to detect issues of porosity or void analysis without destruction of the object, as well as seal integrity

The above example does not indicate CMM technology has outlived its usefulness, by any means. We continue to use it in our operations for certain measurements in many applications.

One important point to note is that the same software that manipulates the data from the CMM can be used with 3D scanners and CT equipment alike. As there are substantial cost savings to be realized in the purchase of a 3D scanning device or the new generation of table top CT scanners, depending on the parts being examined, the transition from CMM to 3D or CT is more feasible today, economically. The driving factors for a company, when evaluating the service vs. purchase issue are two.

The easier factor is raw cost, where a 3D scanner is typically half the cost of a CMM for measuring comparable part sizes. The other is more complex, namely the talent of the personnel doing the work. Experienced technicians have the ability to scan and process large data sets on a wide variety of substrates, geometries and part sizes effectively. Coupled with the part volumes being processed and other factors, it is often more practical and profitable for a company to use a scanning service on an as-needed basis.

3D printing allows quick sampling of modified designs, as well as finished prototypes, producing parts directly from the scanned data

An additional point to note in evaluating CMM vs. scanning is the time involved. To derive those 300 touch points referenced above might take four hours, while the 2.5 million points derived from a 3D scan would take 30 minutes. Since Polyworks software can be used on a CMM or 3D laser scanner, the time and money savings quickly accumulate. Plus, in this manner, companies can develop something of a “universal metrology” scenario at their companies by augmenting the existing CMM technologies with 3D and even CT scanning capabilities, making their QC department more powerful from the outset. One practical note: We can train QC, R&D and production department personnel usually in three days or less to expand their capability from CMM to include 3D and CT scanning.

In terms of the data created, the 3D scanning produces color maps, inspections, first article inspections or other outputs. What you do with the data after completing the scanning is endless.

On the topic of substrates, it should be noted that CT scanning today offers the ability to evaluate a wide variety of dual thickness and dual density materials, with disparate examples ranging from an automotive firewall that might have differing thermoplastics or rubber and TPE materials co-molded to a candy bar with chocolate and nuts.

NOTE: The author welcomes all contact and questions regarding this article. In full disclosure, Exact Metrology performs 3D laser and CT scanning, plus sells, rents or leases the equipment to perform such scanning procedures.

For more information on this article, please contact the author:

Matthew Martin

Exact Metrology, Inc.

www.exactmetrology.com

11575 Goldcoast Drive

Cincinnati, OH 45249

513-831-6620

matthewm@exactmetrology.com

Exact Metrology is an ISO 9001:2008, AS9100 Certified and ITAR Registered Company.

Exact Metrology, with facilities in Cincinnati and Milwaukee and affiliated offices throughout the Midwest, is a comprehensive metrology services provider, offering customers 3D laser and CT scanning, reverse engineering, quality inspection, product development, 3D printing and 2D drawings. The company also provides turnkey metrology solutions, including equipment sales and lease/rental arrangements.

Continue readingMarket leader in live tooling can supply complete range of products for new Haas BMT Turret

Heimatec, a market leader in live tooling for the North American machine tool industry, announced today that it has an extensive line of tooling available for the new Haas BMT turret.

The line includes a variety of driven tools (axial and radial drilling & milling heads) as well as static tool holders. Heimatec also offers specialty tools for this turret including multi-spindle, adjustable angle, and speed multipliers. For detailed download catalogs, please see the Heimatec website at: http://heimatecinc.com/catalogs/

Heimatec already offers the most complete line of live tools available in the machine tool industry today, with over 40,000 designs in its database. These BMT turret tools are already proven and in production allowing Heimatec to provide immediate support and the most innovative tooling technology possible.

Heimatec North American distribution headquarters are located in Prospect Heights, Illinois (Chicagoland area) with world headquarters and all manufacturing based in Germany. A team of manufacturers’ representatives covers the North American market for Heimatec.

For more information please contact:

Preben Hansen, President

Heimatec Inc.

16 East Piper lane, Suite 129,

Prospects Heights, IL 60070

USA

Tel: 847-749-0633

www.heimatecinc.com

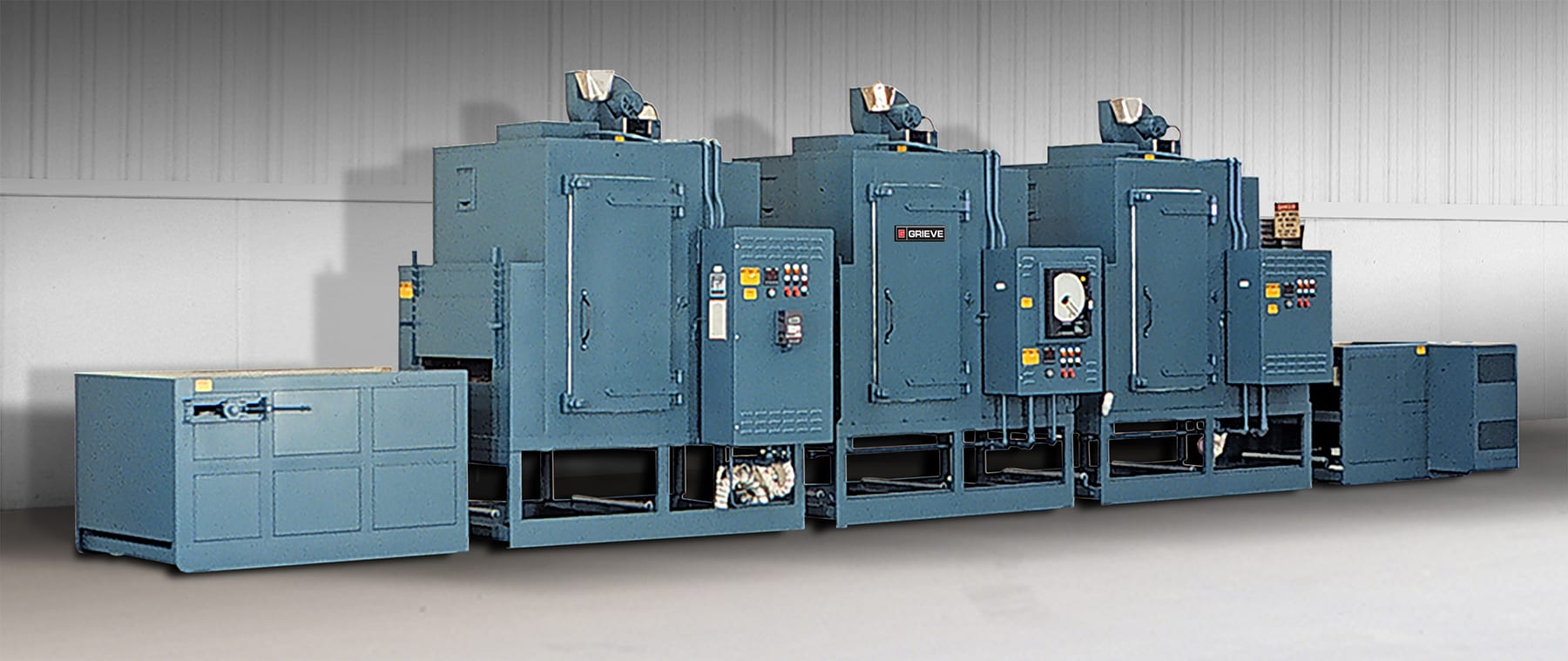

This Grieve oven has 6” insulated walls, an aluminized steel exterior and Type 430 stainless steel interior. The oven features a 12”wide x 8” high door installed in main door. Additional safety features include those required by IRI, FM and National Fire Protection Association Standard 86 for gas heated equipment, including a 325 CFM, ½-HP powered forced exhauster.

Controls on the No. 843 include a digital indicating temperature controller.

For more information, please contact: THE GRIEVE CORPORATION, 500 Hart Road, Round Lake, Illinois 60073-2835 USA. Phone: (847) 546-8225. Fax: (847) 546-9210. Web: www.grievecorp.com. Email: sales@grievecorp.com. Attention: Frank Calabrese.

Continue reading

Will direct North American sales and marketing efforts for tube & bar processing machine builder

Mr. Hisey comes to Rattunde, a builder of metal tube & bar processing machines for high-production component manufacturing in the automotive, off-highway, consumer durable and other markets, from one of the leading industrial saw blade manufacturers, where he was the National Sales Manager and General Manager. Hisey had occasion to work with Rattunde during that time and became familiar with the company. He replaces Alec Banish, the former Director of Business Development, who left the company recently to pursue another career outside the industry.

For Rattunde, according to Rick Stadler, “Jon brings us a wealth of knowledge and experience from the cold sawing industry, plus he already had a good working knowledge of our machines. We have some very aggressive plans to grow the business and expand our market presence in North America. I know Jon will be a real asset in that process.”

Hisey assumed the position on October 23, 2017. He will operate from the company headquarters in Michigan. Jon is 53 and attended Michigan State University.

For more information on this development, please contact:

RATTUNDE CORPORATION

5080 Beltway Drive SE

Caledonia, MI 49316

Phone: 616-940-3340

Web: www.rattunde-corp.com

Email: r.stadler@rattunde-corp.com

Attention: Richard Stadler

This Grieve conveyor oven has a 4’ long open belt loading zone and 4’ long open unloading zone. Features include three 6’ long insulated heat zones with independent recirculated airflow and temperature control, 6” insulated walls and aluminized steel exterior. Type 304, 2B finish stainless steel interior with continuously backwelded seams. Additional features include 24” wide, 1” x 1” 304 stainless steel flat wire conveyor belt with ½ HP motor drive, variable from 0.1 to 2 feet per minute. The oven is sectioned into five pieces for shipping. The oven has safety equipment for handling flammable solvents, including explosion venting door hardware.

Controls on the No. 865 include digital indicating temperature controllers and a 3-pen circular chart recorder.

For more information, please contact: THE GRIEVE CORPORATION, 500 Hart Road, Round Lake, Illinois 60073-2835 USA. Phone: (847) 546-8225. Fax: (847) 546-9210. Web: www.grievecorp.com. Email: sales@grievecorp.com. Attention: Frank Calabrese.

Continue reading

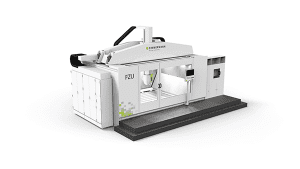

The demands for prototype, tool and mold making are increasing. Only those who can supply high quality output, quickly and flexibly, can succeed against the powerful competition worldwide. Zimmermann is responding to this trend with the new FZU. This 5-axis gantry milling machine is not only extremely compact but, thanks to its thermo-symmetrical design and accuracy, it also provides the ideal entry point to the Zimmermann machine line with maximum productivity. Plastics, casting resins such as Ureol and aluminum are particularly suitable for machining. “This development will enable us to close the gap in the lower weight class,” states Frieder Gänzle, General Manager and Partner at Zimmermann in Germany.

Frieder Gänzle, General Manager and Partner at F. Zimmermann GmbH: “We don’t want to be chasing trends; instead we want to help shape the market.”

“The basic expectations, which prototype, tool and mold makers need to meet today, have not necessarily changed over the years, they have simply grown,” sums up Frieder Gänzle. Customers in the automobile industry, he notes, especially expect components with almost perfect surface finishes and ever higher accuracies. Manufacturers introduce new models or variants to the market at ever shorter intervals. Whereas prototype, tool and mold makers could previously plan in the longer term, they must respond today to inquiries considerably faster.

“We cultivate a very special relationship with prototype, tool and mold makers,” says Gänzle. “Together, we have evolved consistently in recent years. We are very appreciative of our strong business in this sector.” Zimmermann is continuously exchanging technology information with its user base. In discussions, it has become clear that this sector requires powerful, compact machines with maximum productivity and open time. And, importantly, Zimmermann must offer an attractive price/performance ratio, while meeting all these requirements. “We have evolved even further towards heavy-duty cutting, over the years,” reports Gänzle. “As a result, even the smallest machine in our portfolio, the FZ33 compact, has become more popular. We have continuously pushed it upwards from a technological point of view.” Its focus is on aluminum cutting, but steel can also be machined. This enables Zimmermann to offer customers a very efficient, flexible and space-saving machine, while the corresponding design improvements have also had an effect on the price. “The requirement we were presented was for an entry-level model which rounds off our program at the lower price point,” explains Gänzle. The result is the FZU, a 5-axis gantry milling machine which is optimized for weight and stability.

Pre-assembled machine concept

With the FZU, Zimmermann is developing an extremely compact universal machine for prototype, mold and tool making with an attractive price/performance ratio.

In contrast to the established FZ33 and other machines that Zimmermann offers today, the company is taking a different path with the FZU. “We can narrow down the special features of this gantry machine to three main characteristics,” describes Gänzle. The first point: “We are following the trend towards modern manufacturing machines and designing them as space-saving, pre-assembled units.” This means Zimmermann assembles the machines in-house and can then transport them to the customer by truck or ship without having to dismantle them. Onsite, they are ready for use in a very short commissioning time; erection and start-up require minimum effort. For the customer, this means quickly available machines which can be installed without constructing foundations. “In the design, we have kept to the usual transport sizes. At the same time, the new FZU achieves a remarkable working range for its size,” explains Gänzle.

Thermo-symmetrical design

It is important to match the machine to the required dynamics. Adverse environmental conditions and long machine running times necessarily give rise to thermal expansion effects. In spite of the customers’ increased accuracy requirements, the machine must always achieve outstanding surface finishes. The Zimmermann engineers have therefore designed the FZU gantry machine to be thermo-symmetrical. This means that the milling spindle, guides and other accuracy-determining components are arranged so that their heating is either compensated or they can expand in uncritical directions. “This is the second important characteristic,” emphasizes Gänzle. The base frame consists of a steel welded construction which forms a continuous U-shape. The machine gantry’s centrally guided Z-slide has an octagonal section – and not a rectangular one like comparable machines – which makes it particularly stable. Thanks to its design, it therefore has impressive rigidity for its size. “With a weight of approximately 35 tons, a length of 3,500mm, width of 7,500mm and a height of just under 5,000 mm, we have been able to build a light and compact machine,” says Gänzle.

In-house head implemented throughout

VH10 spindle head design from Zimmermann, with 34kW and 24,000 rpm standard performance in a rugged design.

The third characteristic relates to the new VH10 milling head, which achieves an extremely high power density. “This new development has enabled us to reassess our portfolio,” reports Gänzle. This is because the VH10 head will replace the VH12, which is not a Zimmermann product. Alongside the VH20, VH30 and VH60, the VH10 is now the smallest head in the range. Users will also benefit from the fact that Zimmermann has suitable spare heads in stock and can supply them on request in the event of stoppages, for example, due to a crash. “We strive to respond quickly and provide the customer with optimum support,” emphasizes Gänzle.

Thanks to its slender design, the VH10 spindle head has only minimal interference contours. Compared to the VH12, it achieves almost double the clamping force. This is due to the fact that Zimmermann fits two side cheeks instead of one onto the unit. The VH10 is therefore considerably more stable in operation. In order to minimize throughput times, a powerful 34 kW spindle with a maximum speed of 24,000 rpm is used in the milling head as standard. “The FZU is therefore ideally suitable for the materials typically found in this business sector, such as Ureol, clay and aluminum. In the future, we will also use the new milling head in larger machines on which processers can produce one-to-one models – for example, on our FZ37,” says Gänzle.

Standardized and yet individual

In order to provide a high-quality machine at an attractive price, the designers at Zimmermann have turned their attention to remaining competitive with regard to price through increased component standardization, while at the same time addressing individual customer requirements. As with all machines produced, Zimmermann therefore also relies on a modular system with the FZU. Among other things, this approach enables different size variants and power levels to be produced. There are also numerous equipment options which offer the customer maximum flexibility.

Zimmermann is therefore able to provide a very efficient solution with the new FZU. It is often the little things that give rise to success and customer satisfaction. “We place great importance on details – an aspect which cannot always be measured in the numbers,” explains Gänzle, who cites two examples: “For instance, the machining area is fully clad with stainless steel sheets in order to guarantee maximum resistance to abrasion. The FZU is also the first gantry milling machine to be equipped with our innovative, new NXP 24-inch multitouch controller, which is already used on our FZH horizontal machining center.” Another increasingly important topic is ergonomics. The door is divided asymmetrically to enable components to be easily fed to the machine. A small, easy-to-open door leads into the machining area, while the large door is used for loading. Operators therefore have a relatively large field of view, rapid access to the machining area and ample space for loading – ergonomic advantages which are not to be underestimated. Another detail is that a cabinet has been installed directly in front of the FZU. “This was the idea of one of our designers,” says Gänzle. “The tables, which users in the various plants position in front of the machines to place their accessories and service tools, caught his attention. With our solution, everything which is part of day-to-day operations can be safely stowed close at hand within the machine.” Added to this, there are extraction equipment and special chip management systems. “It is often the simple ideas which make the machine operator’s everyday tasks much easier,” sums up Gänzle.

Comprehensive service

To provide the best possible support to businesses, Zimmermann concentrates on high-quality and reliable service in close proximity to the customer. After all, this is exactly what characterizes a good relationship between supplier and user. “Customers expect high availability over the entire system lifecycle,” says Gänzle. “We provide comprehensive machine care.” This includes a customer hotline, by means of which users can reach a competent contact person, even outside of normal working hours, as well as a remote diagnosis system that allows a rapid response in an emergency. If mechanical components are defective or malfunction, the machine builder usually guarantees immediate shipment from its factory. In addition, the application engineers work together with the customer to optimize each individual combination of heads, spindles, tools and clamping equipment for the machines. Zimmermann therefore not only sells machines, but also complete solutions. Plans are in process for further upgrades to the stocking and service personnel staff in North America, as well. Zimmermann recently opened a new facility in Wixom, Michigan, near Detroit.

Goal: To be technologically out in front

“We don’t want to be chasing trends; instead, we want to help shape the market,” says Gänzle. “Basically, we therefore aspire not to do the same things as our competitors.” To be technologically out in front, the machine builder never stands still with regards to machine development. The FZU is therefore being continuously optimized – without at the same time losing sight of the price/performance ratio. There appears to be substantial market interest in these machines, according to company research. The initial discussions with users were highly promising. “We are confident of meeting our customers’ requirements with this new development, both in Germany and internationally,” says Gänzle. The statement that the concept of the FZU could be transferred to the other machines in the program underlines how convinced he is of this new solution. Zimmermann will be presenting the machine to a specialist audience at WESTEC 2017, CMTS 2018 AMB in September, 2018. As further indication of emerging market interest, three users have already decided to purchase this new gantry milling machine.

About the company

For more information on this development, please contact the North American headquarters:

ZIMMERMANN INC.

30587 Century Drive

Wixom, MI 48393

Phone: 248-956-8511

www.zimmermann-inc.com

Ms. Lena Kiesel, Marketing Manager

lena@zimmermann-inc.com

Continue reading

Major supplier of multi-spindle machine tools and grinders taps longtime industry pro to lead company to next levels

Jeff Reinert brings over thirty years of related experience to the position, having been involved with all aspects of manufacturing, sales, marketing and management in the machine tool industry. Jeff was most recently the president and CEO for North American Operations at Index, another leading machine tool builder. Jeff held that position for nine years. While at Index, he nearly doubled the sales of the company, reorganized the service, parts and training departments, plus opened a new office in the emerging Mexican market for the company. He was also previously the president of Machine Tools of Indiana, a dealer company he founded in 2001 and ran successfully for seven years.

Jeff attended Vincennes University, Valparaiso University and Purdue, where he studied electrical & mechanical engineering.

In commenting on his new position, he observes, “Schütte has a solid reputation as a builder of top quality, multi-spindle machine tools and, based on that foundation, we plan to accelerate the company’s growth curve to take us into more markets with a decidedly aggressive posture, including greater visibility in the media, at shows and through industry association participation. Complementing this sales growth strategy will be a buildup in our service, engineering and customer support programs.” Jeff also noted the long-range plans for Shütte include upgrades to the current facility in Jackson, Michigan, with more machines on the floor for demonstration of the company’s capabilities, testing and production scenarios for enhancing the customer experience.

“My personal goal is to bring Schütte to the forefront of the industry, in both the multi-spindle and grinding technology arenas. We can shine as a great team, with excellent machines backed by a high-quality group of dedicated individuals. It’s an exciting time and I look forward to meeting the challenges.”

For further information, please contact:

SCHÜTTE L.L.C.

4055 Morrill Road

Jackson, MI 49201

Phone: 517-782-3600

www.schutteusa.com

Brittany Parks, Marketing

bparks@schutteusa.com

Continue reading

Increase in plant and office capacity responds to global growth for tube & bar processing machine builder

Global manufacturer of tube and bar processing machinery Rattunde today announces a substantial increase in its plant and office capacity at the company’s global headquarters in Ludwigslust, Germany, near Hamburg. The announcement was made by company president Ulrich Rattunde.

At a company gathering in early July, Mr. Rattunde announced that he had signed an agreement to purchase the entire facility of a neighboring company literally across the street from the existing Rattunde facility in Ludwigslust, namely Alstom, the multi-national rail transport and power generation firm. This acquisition was completed on July 25, 2017.

The new 175,000 sq. ft. manufacturing facility for Rattunde is more than double the current size, thus permitting substantial expansion in the production of machines for this builder of tube & bar processing equipment. Rattunde markets globally to a variety of industrial OEM’s and contract manufacturers. In tandem with its U.S. facility in the Grand Rapids, Michigan area, the company is now better positioned to serve its established install bases in Europe and North America, with the added capacity enabling continued growth and expansion into the emerging markets of Asia and South America.

In tandem with the larger manufacturing facility, Rattunde will now also enjoy 18% more office space for its design, engineering, sales and service personnel in Germany.

Rattunde Corporation president (North America) Rick Stadler observes, “Everyone in the company is excited by the potential of the new headquarters. We will not only have greater capacity to respond to current customer delivery needs, but this development will enhance our competitive status around the world. It’s a very exciting time for Rattunde.”

Stadler also mentioned the recently opened Rattunde facility in Mexico, where the company has substantial and expanding business engagements.

For more information on this development, please contact:

RATTUNDE CORPORATION

5080 Beltway Drive SE

Caledonia, MI 49316

Phone: 616-940-3340

Web: www.rattunde-corp.com

Email: r.stadler@rattunde-corp.com

Attention: Richard Stadler

Universities and technical schools trying to keep up with advances in digital manufacturing often find themselves behind industry. However, I was privileged to visit one university, the University South Carolina, which will now be an important exception. Founded in 1801, USC is one of the oldest universities in the US with a history of creating the most innovative learning programs dating back to its first curriculum obtained from Oxford University. Today, USC is establishing a one of a kind Digital Factory Lab that combines technology and coolness to inspire and educate its students.

Ramy Harik is one of the professors at USC and he told me that these new resources will be put to good use. Already his students have been involved in working with composites, designing new ways of analyzing data for the helicopter AH-64 Apache airframe and developing insights into that aircraft’s mechanical operation for the Army. More innovations are sure to come. For instance, beginning this fall students will also be able to pursue a major in aerospace engineering.

In recent years, the state of South Carolina has become a magnet for sophisticated manufacturing particularly in aerospace, automotive and tire. As a result of working with these companies to deploy high-tech manufacturing and by supporting vocational learning in the state through USC’s College of Engineering and Computing and the McNAIR Center for Aerospace Innovation and Research, USC has grown into a major research university. Specifically, the McNAIR Center is aligned with two dozen educational and government partners, and a group of industry partners that include The Boeing Company, Fokker Aerostructures, KUKA Robotics, Ingersoll Machine Tools, Gulfstream and more.

To date, South Carolina’s business, education and state government partnerships have created jobs for more than 55,000 South Carolinians in the larger aerospace industry. As Raj Batra, President, Siemens Digital Factory Division, U.S., said, “Aerospace companies throughout South Carolina are heavily reliant on automation and digitalization as well as well-trained employees. Our partnership with the University of South Carolina will provide valuable experiential training with both software and hardware, providing the next generation workforce with the skills they need to be successful.”

Far from lagging, educators in South Carolina are working hard to stay out front. While I was at dinner, USC’s Hossein Haj-Hariri, Dean of the College of Engineering and Computing, told me “We are going to work very hard to make this the best investment that Siemens has ever made.” I am proud to be part of a company that will match that enthusiasm and make this a program known for enabling students to be competitive for jobs throughout the world.

Governor Henry McMaster, we are ready to help you build the workforce of tomorrow.

Siemens Industry, Inc.

Alisa Coffey

(678) 427-8319

alisa.coffey@siemens.com

About Siemens USA

Siemens Corporation is a U.S. subsidiary of Siemens AG, a global powerhouse focusing on the areas of electrification, automation and digitalization. One of the world’s largest producers of energy-efficient, resource-saving technologies, Siemens is a leading supplier of systems for power generation and transmission as well as medical diagnosis. With approximately 348,000 employees in more than 190 countries, Siemens reported worldwide revenue of $86.2 billion in fiscal 2015. Siemens in the USA reported revenue of $22.4 billion, including $5.5 billion in exports, and employs approximately 50,000 people throughout all 50 states and Puerto Rico.