Contact us today:

Author Archives: Bernard & Company

Exact Metrology Discusses CT Scanning Technology For 3D Printed Work

Exact Metrology, a comprehensive metrology service provider, participated in a webinar on February 20, 2020. The general subject involved testing and inspecting parts that are 3D printed. Josh Schradin, a project manager at Exact Metrology, gave a presentation on industrial CT (Computed Tomography) for additive manufacturing.

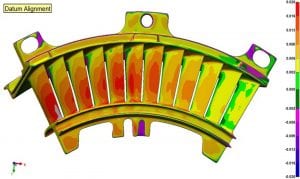

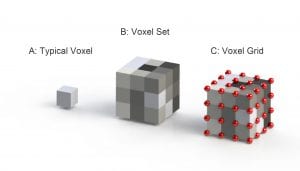

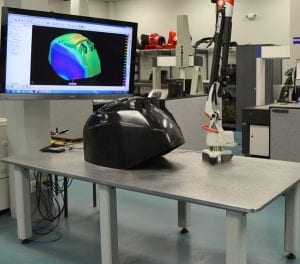

A CT scan, also known as an X-ray Computed Tomography (X-ray CT) or a Computerized Axial Tomography scan (CAT scan) uses computer-processed combinations of several X-ray images taken from different angles to produce cross-sectional (tomographic) images or “virtual slices” of specific areas of a scanned object. This allows the user to see inside the object without cutting or damaging it. The basic components of a CT system are its X-ray source, the sample on a rotary table and a detector (see image 1).

Magnification is also an important part of CT scanning. Moving the object closer to the X-ray source provides a larger shadow, optimizing the resolution of the final image, while having an object closer to the detector provides a smaller shadow that decreases the final resolution.

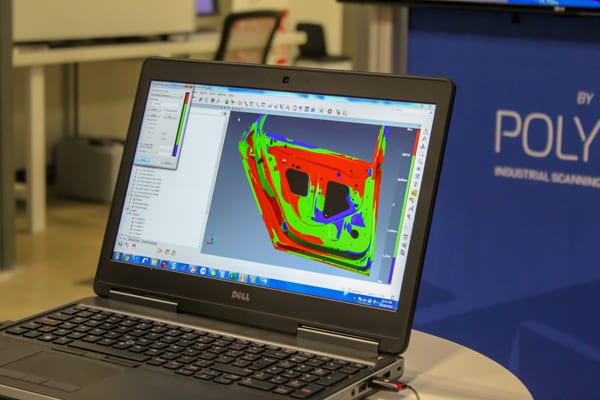

Trapped powder can be located during the printing process either by magnification or using a color map that shows deviation to the nominal model (see image 8).

Product content positon allows manufacturers to audit their products and determine if embedded objects are placed properly.

Exact Metrology is an ISO AS9100 Certified along with being FFL and ITAR Registered.

Exact Metrology, with facilities in Cincinnati, Ohio, Milwaukee, Wisconsin and Moline, Illinois and affiliated offices throughout the Midwest, is a comprehensive metrology services provider, offering customers 3D and CT scanning, reverse engineering, quality inspection, product development and 2D drawings. The company also provides turnkey metrology solutions, including equipment sales and lease/rental arrangements.

For more information, please contact:

For information, please contact:

EXACT METROLOGY, INC.

Dean Solberg

20515 Industry Avenue

Brookfield, WI 53045

Local: 262-533-0800

www.exactmetrology.com

deans@exactmetrology.com

Steve Young

Exact Metrology, Inc.

11575 Goldcoast Drive

Cincinnati, OH 45249

Toll Free: 866-722-2600

Local: 513-831-6620

www.exactmetrology.com

stevey@exactmetrology.com

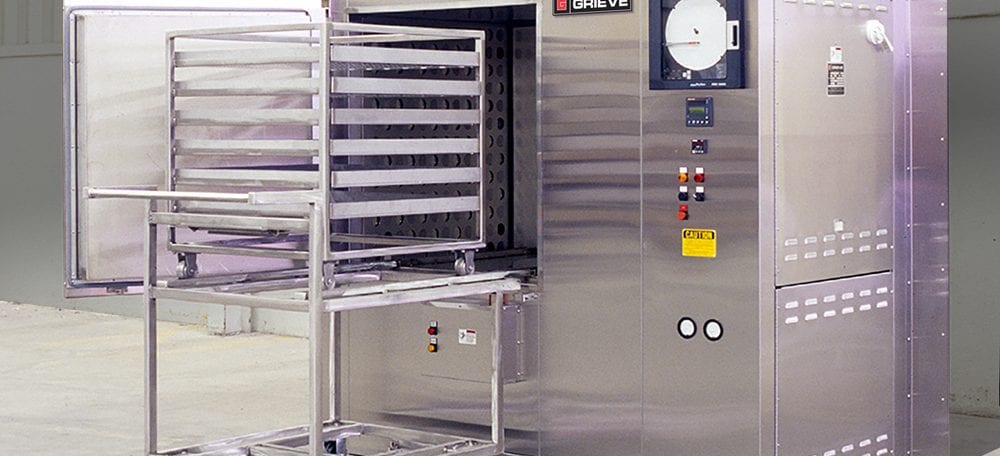

500ºF Class 100 Cleanroom Electric Cabinet Pass-Through Oven From Grieve

This Grieve cleanroom oven features 4” thick insulated walls throughout and a Type 304, 2B finish stainless steel interior with 1/2” inside radius corners, all seams welded, ground and polished. The stainless steel exterior has a #4 brushed finish. The unit is equipped with front and rear access doors for pass-through to the cleanroom plus an integral wall sealing flange. A red pilot light onboard the oven signals when the opposite door is open. All door hardware is chrome plated.

For Class 100 cleanroom compliance, this cabinet oven has a 12” x 12” x 6” thick HEPA fresh air filter with 2” prefilter and a 30” x 24” x 6” thick stainless steel high temperature HEPA recirculating filter.

Controls on No. 971 include a minihelic pressure gauge and DOP validation port across each set of filters, digital programming temperature controller, manual reset excess temperature controller with separate contactors, recirculating blower airflow safety switch, 10” diameter circular chart temperature recorder, fused disconnect switch and an SCR power controller.

A stainless steel loading truck with six removable pans and a transfer dolly with oven-to-dolly and dolly-to-truck latches are also furnished with this Grieve oven.

For more information, please contact:

THE GRIEVE CORPORATION

500 Hart Road

Round Lake, Illinois 60073-2835

Phone: (847) 546-8225

Fax: (847) 546-9210

Web: www.grievecorp.com

Email: sales@grievecorp.com

Attention: Frank Calabrese.

Schuler Accepts High One-Off Burdens on 2019 Earnings for Future Concept

With products like servo press lines, Schuler reached consolidated sales of € 1.136 billion in 2019. © Schuler

As expected, the strategic realignment of press manufacturer Schuler resulted in high one-off burdens on earnings in 2019. Due to cyclical effects, new orders were down but performed much better than the German machine tool industry as a whole. Consolidated sales reached € 1.136 billion (prior year: € 1.212 billion). Earnings before interest, taxes and goodwill amortization (EBITA) fell to minus € 75.5 million (plus € 45.3 million).

As part of its future concept, Schuler invested heavily in 2019 in the restructuring of its manufacturing sites; in its focus on core competencies in press construction, automation and service; and in the strengthening of the Group’s innovation capabilities. The company has thus responded to the far-reaching structural changes taking place in the global automotive industry.

“Group’s inner strength permits extensive realignment”

“As a press manufacturer, Schuler is part of the dramatic transformation of the global automobile industry toward electromobility, autonomous vehicles, and digital networking. In 2019, we identified and began to implement the resulting strategic and structural consequences for our company,” stated CEO Domenico Iacovelli at the presentation of the company’s results for fiscal year 2019 in Göppingen, Germany.

“This obviously had a significant impact on earnings. However, there was no alternative. Schuler has the financial strength, the global footprint, and the technological quality to be able to withstand such a one-off burden for the workforce, the balance sheet, and earnings in a market environment characterized by challenging transformation processes and political risks. This makes us confident that we can expand our leading position in metalforming technology in the medium term and thus achieve better results once again,” added Iacovelli.

Normal operating business slightly profitable

Together with the previously announced writedowns on the intangible goodwill of subsidiaries AWEBA and Yadon, the structural measures to realign the company amounting to € 84 million, and other one-off items, Schuler recognized negative special items of almost € 96 million in 2019. Net income after taxes was minus € 121.9 million (plus € 13.5 million). In its normal operating business – in other words EBITA before restructuring costs – Schuler generated a slightly positive result of € 8.5 million in a very challenging business environment.

New orders well above one billion euros

In the future, Schuler will strengthen its offerings in the field smart networking, among others. © Schuler

Schuler started its fiscal year 2020 with an order backlog of € 868 (€ 926) million. New orders received in 2019 amounted to € 1.092 (€ 1.255) billion. Europe accounted for the largest share of new orders (€ 562 million, thereof Germany € 293 million), followed by the Americas region (€ 253 million), and China (€ 221 million). With a decline in consolidated new orders of 13 percent in 2019, Schuler performed much better than the German machine tool industry as a whole, which suffered a decline of 22 percent according to the latest figures of sector association VDW.

Schuler CFO Thomas Kamphausen explained that the company had borne the full load of costs incurred by its structural adjustments in 2019. “We do not anticipate any further significant additional special items in 2020. Major cost reductions resulting from our structural adjustments are to be expected as early as 2021,” he said. “As far as our regular business development in 2020 is concerned, it is too early to estimate any effects of the Corona virus disruptions on our revenue and profits at this point.”

At the end of 2019, Schuler’s equity ratio amounted to 35.4 (40.1) percent – and was thus still above the industry average. The number of Group employees fell to 6,276 (6,574). At year-end 2019, headcount in Germany amounted to 3,962 (4,195).

Future concept: focus, localization and innovation

Announced in summer 2019, Schuler’s future concept is based on three main pillars. As the name CORE suggests, Schuler will focus in the future on its core business of building cutting-edge presses, as well as the optimization and digitalization of automation systems for the manufacturing processes of its internationally operating clients in the automotive, industrial, hydraulic and other sectors. In addition, Schuler is systematically strengthening its offerings in the field of service and smart networking.

In 2019, Schuler sold its die construction unit for the production of car body panels to Deutsche Werkzeugbau, a company set up by a strategic investor group. However, its core business of cutting-edge die construction for customers in the metalforming industry was spun off from Schuler Pressen GmbH and established as a separate growth business under the umbrella of the AWEBA Group, a subsidiary of Schuler.

Schuler Innovation Rate 2019 grows to 45.4 percent

The second pillar of Schuler’s future concept is a significant acceleration of new development and time-to-market processes in the field of press construction. The Group’s calculation basis for this objective, the Schuler Innovation Rate (SIR), doubled to 45.4 (prior year: 22.9) percent in 2019. This figure indicates that current product innovations accounted for almost half of all new orders received in Schuler’s main business fields of Automotive, Hydraulic and Industry during the past fiscal year. This enabled Schuler to offset a large part of the reduced demand from the automobile industry for classic forming technology products.

The third pillar of the future concept is a strict focus on localizing production and added value. Together with Group investment Yadon, Schuler China mainly serves customers throughout Asia. Schuler’s Brazilian operations focus in particular on the North and Latin American markets. Germany remains the location for machines and equipment produced for Schuler’s European customers. The high quality standards at all sites create a manufacturing network which can flexibly balance out peaks in demand between the regions. Within Germany, Schuler has pooled its press production in Erfurt and is expanding its home base in Göppingen to become a central innovation site. In the coming months, an additional service center with its own production and assembly capabilities serving customers throughout Germany will also be set up in Göppingen.

Schuler Group at a glance (IFRS)

About the Schuler Group – www.schulergroup.com

Schuler offers customized first-rate technology in all areas of forming – from the networked press to press shop planning. In addition to press, our product includes automation and software solutions, dies, process know-how and service for the entire metalworking industry. Our customers include automotive manufacturers and suppliers, as well as companies in the forging, household appliance and electronics industries. Press from the Schuler Group mint coins for more than 180 countries. When it comes to the digital transformation of the forming technology, we support our customers worldwide as a supplier of innovative system solutions. In its fiscal year 2019, Schuler posted sales of € 1.136 billion. Founded in 1839 with headquarters in Göppingen, Germany, Schuler AG has about 6,000 employees at production sites in Europe, China and America, as well as service companies in more than 40 countries. The company is majority-owned by the Austrian ANDRITZ Group.

For further information on Schuler Inc., North America, please contact:

Guido Broder, VP

Schuler Incorporated

7145 Commerce Blvd.

Canton, MI 48187 USA

734-207-7200

info@schulerinc.com

www.schulergroup.com

High Dynamic Turning With the Freeturn Standard Range Tooling From CERATIZIT Is Now Available

The 360º “revolution” in Turning

High Dynamic Turning with the FreeTurn standard range tooling from CERATIZIT is now available

In September 2019, CERATIZIT launched the first standard range of products for its innovative High Dynamic Turning (HDT) with FreeTurn process at EMO. The tool manufacturer has taken the next step in revolutionizing turning. CERATIZIT was joined by leading machine tool and control system manufacturers as well as providers of CAD/CAM systems. This new development is now available and will be showcased to the North American market at IMTS in Chicago in September, 2020.

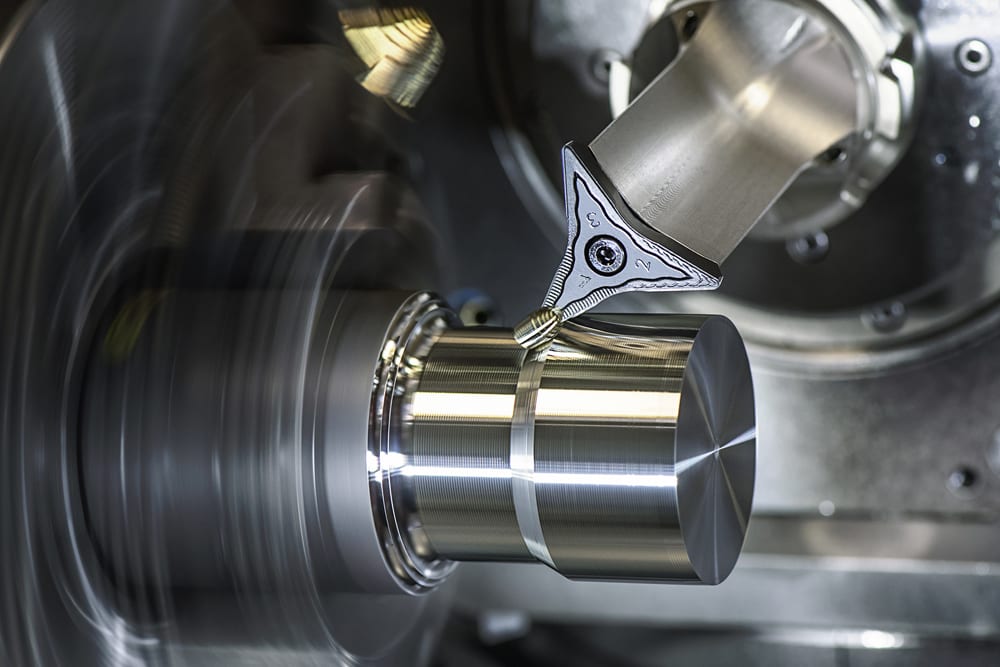

High Dynamic Turning (HDT) from CERATIZIT has turned conventional turning methods into a new direction. This new turning technology, combined with the company’s dynamic FreeTurn tooling, means that it is now possible to carry out all traditional turning operations such as roughing, finishing, contour turning, face turning and longitudinal turning with just one tool. HDT with FreeTurn represents a completely new method of turning.

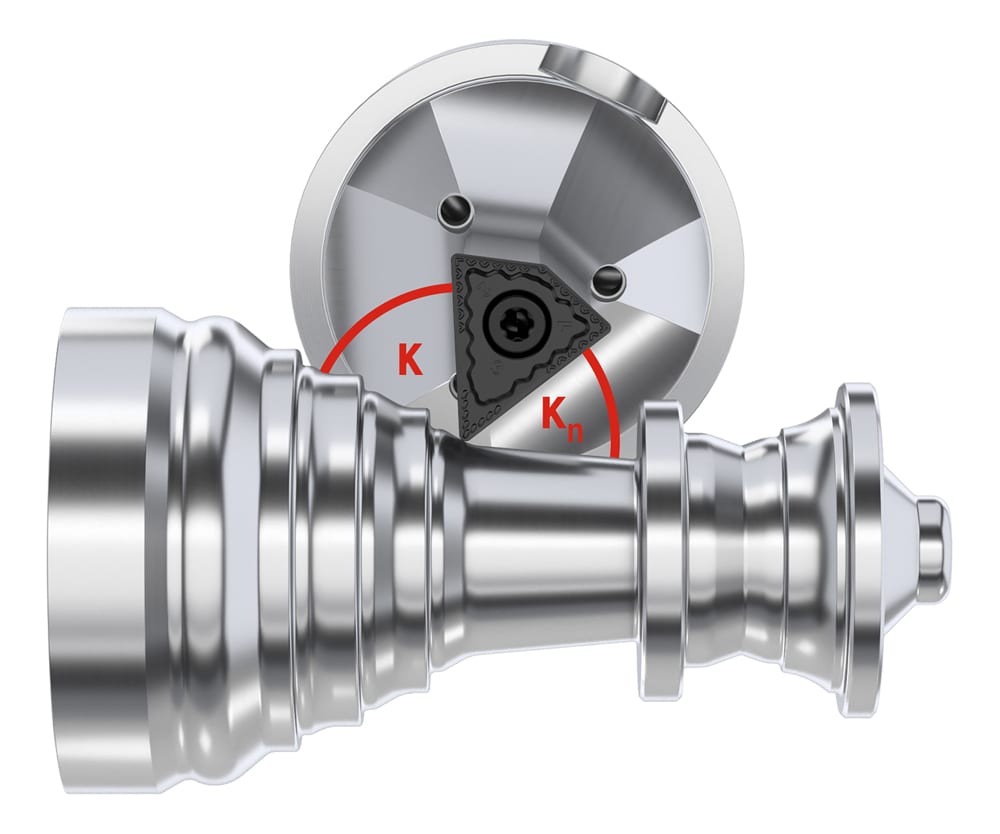

For 100 years, new cutting materials, new chip breakers and a few new tooling systems have been invented to optimize turning. However, the actual basic turning process has remained essentially unchanged. Even today, a contour is created with an indexable insert at a fixed angle to the workpiece. This method has not changed, even with the addition of controllable axes in modern turning-milling centers, machines which are intended to serve one purpose, namely, to manufacture a component as completely as possible within a single machine work envelope. CERATIZIT has taken advantage of the features on these turning-milling centers and developed the High Dynamic Turning (HDT) System. The simple idea behind HDT: the tool approach and point of contact in the machine can be varied as opposed to conventional turning with a fixed tool.

Utilizing the milling spindle for 360° degrees of freedom

Instead of the classic, static position of the insert in the holder, the milling spindle is now used to produce the corresponding approach angle to the workpiece. The use of the spindle drive, in conjunction with the slim, axial tool design of the FreeTurn tools by CERATIZIT, creates a degree of freedom of 360° without the risk of collision, thus providing unprecedented flexibility. Due to the rotation around its own tool axis, the cutting edge change can be done without interrupting the cutting process. Additionally, the angle of approach is freely variable at any time and can even be changed while cutting. This not only enables flexible machining of almost every workpiece contour, but also optimum chip breaking, higher feed rates and an increase in tool life. Depending on the machine capabilities, the technology can be used functionally in all areas of turning operations. The approach of the milling spindle on the Y/Z axis on turning-milling centers is widespread. As a result, further possibilities can be achieved with HDT that seemed previously unachievable. For example, cutting from above and below is possible. Depending on the machining area and workpiece size, this freedom can be an important factor in production.

FreeTurn inserts with more than 2 variable features

In the future of HDT, the static turning tools of the past will be replaced by dynamic tools. One such dynamic tooling solution is FreeTurn by CERATIZIT. The defining characteristic of FreeTurn tooling is its simple structure. The tool holder, together with its slim shank and axial concept which optimizes the direction of the cutting forces into the spindle, form a stable unit. At the cutting end, there is a multi-sided insert, which is simply screwed in place. The principle is quite simple: the patented FreeTurn insert can consist of several cutting edges with different properties. This allows for different angle points, corner radii or chip breakers – even different coatings and cutting materials are conceivable. The tool can therefore be adapted to the machining requirements, offering the further advantage of replacing several tools on a job. This, in turn, leads to significant savings in tool change times, tool magazine loadouts and tool costs overall. The result is making components with highly complex contours without limitation, using only one FreeTurn tool. This flexibility ensures complex component holding can be quickly and effectively adapted to the new machining situation.

The future of turning starts now!

With High Dynamic Turning and the FreeTurn tools by CERATIZIT, a new era in turning has arrived. In terms of efficiency, HDT exceeds the conventional turning process many times over and, as the experts from CERATIZIT are demonstrating daily, will replace the classic approaches, sooner than later. This new turning technology will continue to open and reveal possibilities in the future to make turning processes faster and more precise. The future of turning will rapidly change with HDT and CERATIZIT developers are looking forward to supporting their customers along this journey, according to a company spokesman.

Saving tools and machining time

In one recent application at Spanish wheel manufacturer ROTOR, an indexable insert with two different cutting edges was used to manufacture an aluminium wheel hub. One cutting edge is used for roughing (1500 rpm, ap = 2 mm, f = 0.4 mm/rev) and one for finishing (2000 rpm, ap < 1 mm, f = 0.25 mm/rev). When using HDT, the approach angle can be changed during machining, making it possible to machine all contours in just one setup, even undercuts that would not be possible with a standard approach angle of 90°. The tool is also able to cut in both directions, saving time-consuming rapid moves and increasing efficiency. In comparison to the turning process normally used by ROTOR for wheel hubs, this machining process used four fewer tools and reduced the machining time by 30%.

The first HDT solutions

Since CERATIZIT presented High Dynamic Turning and FreeTurn tools, a number of major machine and control system manufacturers have begun developing solutions for an automated process. CAD/CAM providers have also begun to develop solutions for programming HDT-specific program sequences. A number of promising CAM programs were on display at EMO 2019, including Open Mind and Siemens NX. CERATIZIT HDT and FreeTurn tools also generated considerable interest during the live presentations from machine manufacturers DMG Mori and Mazak.

FreeTurn is ready now!

From the beginning of the HDT process, CERATIZIT has relied on an open source model, supplying all interested parties with the relevant information to allow them to help develop their HDT turning process.

Meanwhile, the tool manufacturer devoted its attention to its core business, developing a standard range of FreeTurn tools. Four indexable insert geometries were initially launched. This range included indexable inserts for machining steel/stainless steel (2x roughing and 1x finishing, 3x roughing, symmetrical) and for aluminium (3 cutting edges, symmetrical). This initial range covers a number of applications. The holders are available with a range of different overhang lengths for each size and are available for the HSK-T and PSC machine interfaces. CERATIZIT is making this insert package available to interested parties on a test program basis. Please contact the company for details.

More information about High Dynamic Turning and FreeTurn tools from CERATIZIT can be found at www.ceratizit.com/hdt

Product videos:

Conventional vs. HDT

The Revolution in Turning

Explanation of process and tool features

Technical Experts and Developers

Published on behalf of

CERATIZIT S.A.

101, Route de Holzem

LU-8232 Mamer, Luxembourg

Tel: +352 31 20 85-854

www.ceratizit.com

CERATIZIT USA, Inc.

Canada, United States

11355 Stephens Road

Warren, MI United States 48089-1833

Tel: +1 586 759 2280 (Toll free: +1 800 783 2280)

www.ceratizit.com

For specific requests regarding the HDT – FreeTurn technology we have a centralized email address.

FreeTurn@ceratizit.com

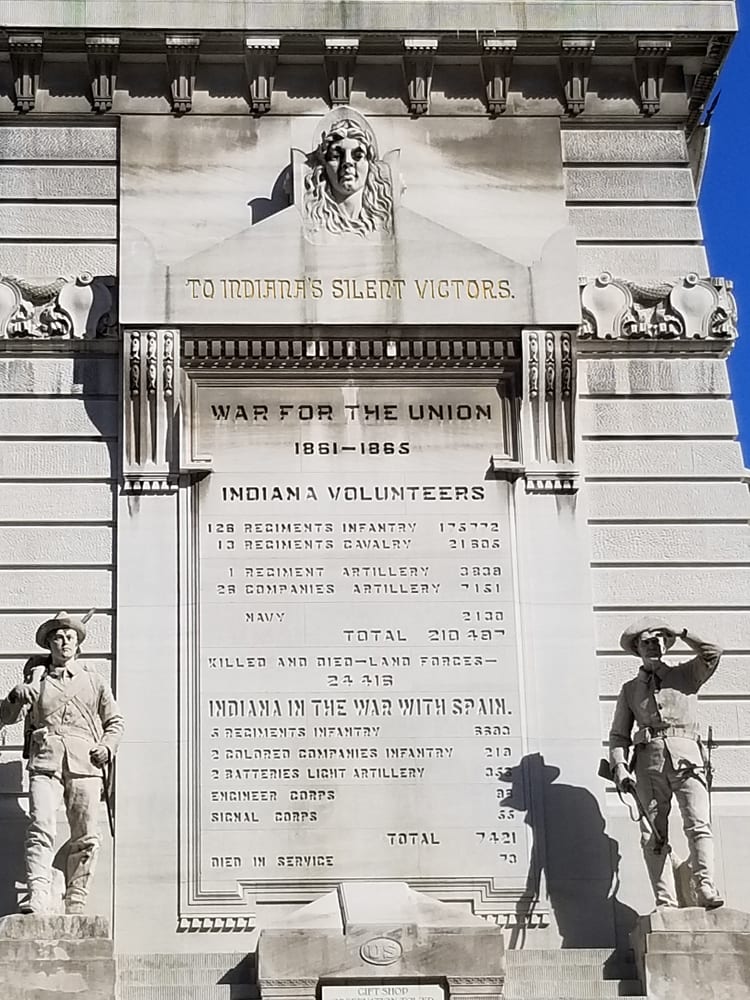

Exact Metrology Scans Monument Circle in Indianapolis

Innovative, an ad agency in Indianapolis, was contacted by Downtown Indy Inc. to create a light projection at Monument Circle for Veterans Day. Located in the heart of downtown Indianapolis, it features the Soldiers & Sailors Monument and the Colonel Eli Lilly Civil War Museum. Downtown Indy Inc., the city’s nonprofit organization, received a grant from the Lilly Endowment for the show and the goal of the ad agency was to produce a projection show that will be image mapped on two buildings in the circle’s southwest quadrant. To accomplish this, Innovative became the creative content provider for Exact Metrology.

Greg Hoeting, the application specialist at Exact Metrology, used a Leica P40 to collect point cloud data. Leica ScanStation P-Series 3D laser scanners are ideal for capturing 3D geometry of civil infrastructure, creating an as-built representation of large industry complexes, reconstructing crime scenes or generating 3D data for integration into Building Information Modeling (BIM). In addition, these laser scanners offer unsurpassed range and angular accuracy with low-range noise and survey-grade dual-axis compensation that form 3D color point clouds mapped realistically.

Next, Hoeting used Polyworks® to mesh the data and export a .stl file. The Polyworks® software suite maximizes productivity, quality and profit when integrating 3D measurement devices into the industrial manufacturing process. The software interfaces directly with major brands and technologies of single- point and point cloud 3D models through plug-in extension models. Furthermore, Polyworks® supports a wide array of native point cloud and polygonal model file formats.

Lastly, Hoeting used Leica Cyclone to align the color texture with a center point at the base of the monument. This point cloud processing software provides the widest range of options for 3D laser scanning projects in engineering, surveying, construction and related applications.

Exact Metrology scanned around the monument and several buildings such as: Novel Coworking Circle Tower, IPL, Guaranty Building, Salesforce Tower (Chase Tower portion).

Exact Metrology and Leica Close-up of monument Monument Circle

Exact Metrology is an ISO AS9100 Certified along with being FFL and ITAR Registered.

Exact Metrology, with facilities in Cincinnati, Ohio, Milwaukee, Wisconsin and Moline, Illinois and affiliated offices throughout the Midwest, is a comprehensive metrology services provider, offering customers 3D and CT scanning, reverse engineering, quality inspection, product development and 2D drawings. The company also provides turnkey metrology solutions, including equipment sales and lease/rental arrangements.

For more information, please contact:

Steve Young

Exact Metrology, Inc.

11575 Goldcoast Drive

Cincinnati, OH 45249

Toll Free: 866-722-2600

Local: 513-831-6620

www.exactmetrology.com

stevey@exactmetrology.com

Suhner Offers Economaster® Drilling Units for Value-Priced Production Use

All the features and reliability of Suhner technology at an affordable price, whether OEM or end user…MADE IN AMERICA

EconoMaster® value-priced drilling units from Suhner are suitable for medium-duty production cutting of light metal, wood, composite, foam and plastic materials

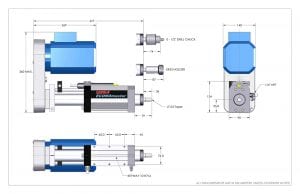

Suhner introduces the EconoMaster® line of drilling units, affordably priced at under $3000 for the basic unit, in stock for immediate delivery or customizable to suit the particular operation. This economical solution is ideal for multiple materials such as light metal, wood, composite, plastic and foam. Because these units are entirely produced at the Suhner factory in Rome, Georgia, response times for delivery and customized construction are very fast, according to Sales Manager Lee Coleman. “We recognized the need to bring our global technology to a local level, here in America, and the EconoMaster® is a key step in that process.” Suhner is based in Brugg, Switzerland with plants and distribution centers worldwide.

The EconoMaster® drilling unit features low power and air consumption, adjustable motor housing, adjustable total stroke up to 4”, hydraulic feed control cylinder, J33 taper spindle end, 0-1/2” drill chuck, electric front & rear position limit switches, belt tensioner and chrome-plated quill. Basic unit weight is 45 lbs.

EconoMaster® drilling units can be supplied with an adjustable stand, inline vertical configuration and multiple spindle heads for medium-duty production drilling, with many other spindle options and toolholders available. Please consult the factory.

For more information, please contact:

Lee Coleman, National Sales Manager-Machining Division

Suhner Industrial Products Corp.

25 Anderson Road SW

Rome, GA 30161 USA

Direct: 706-314-2927

Mobile: 706-409-1876

Fax: 706-235-8045

lee.coleman@suhner.com

www.suhner.com

Exact Metrology Set to Open New Center in Moline, Illinois

This location will serve as a training, support, contract measurement and sales center. Training will be provided on software packages such as: PolyWorks®, Geomagic and PC-DMIS. The Polyworks® software suite maximizes productivity, quality, and profit, while integrating 3D measurement technologies into an industrial manufacturing process. Geomagic is a leading provider of 3D software that creates digital models of physical objects for industries like aerospace, archeology, medical, dental, tooling and foundry. Provided by Exact Metrology through Hexagon

Commenting on the importance of this opening, Joe Wright of Exact Metrology said, “Exact Metrology can add support and service to our customers in western Illinois and Iowa. We hope to keep growing the customer base in this area.”

Exact Metrology is an ISO AS9100 Certified along with being FFL and ITAR Registered.

Exact Metrology, with facilities in Cincinnati and Milwaukee and affiliated offices throughout the Midwest, is a comprehensive metrology services provider, offering customers 3D and CT scanning, reverse engineering, quality inspection, product development and 2D drawings. The company also provides turnkey metrology solutions, including equipment sales and lease/rental arrangements.

For information, please contact:

EXACT METROLOGY, INC.

Dean Solberg

20515 Industry Avenue

Brookfield, WI 53045

Local: 262-533-0800

www.exactmetrology.com

deans@exactmetrology.com

2000°F Inert Atmosphere Heavy-Duty Box Furnace

No. 954

The unit is equipped with a roof-mounted heat-resisting alloy recirculating fan, powered by a 1-HP motor with V-belt drive, motor-operated vertical lift door, 100 lb. capacity alloy loading cart with cast alloy roller rails, 3-1/2” diameter cast alloy rollers and a roller rail loading table with 4” diameter cast iron rollers.

This Grieve furnace also features inert atmosphere construction, consisting of a continuously welded outer shell, high temperature door gasket, sealed heater terminal boxes, inert atmosphere inlet, inert atmosphere outlet and inert atmosphere flowmeter.

Controls onboard No. 954 include a digital programming temperature controller, manual reset excess temperature controller with separate contactors, plus a strip chart recorder.

For more information, please contact:

THE GRIEVE CORPORATION

500 Hart Road

Round Lake, Illinois 60073-2835

Phone: (847) 546-8225

Fax: (847) 546-9210

Web: www.grievecorp.com

Email: sales@grievecorp.com

Attention: Frank Calabrese.

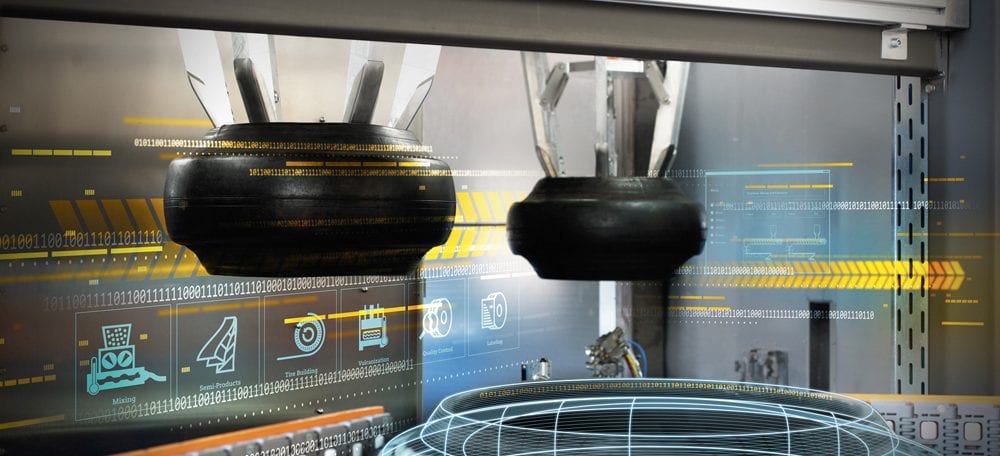

Siemens Announces Collaboration with McNeil & NRM on a Digital Twin of the AUTOLOK® Tire Curing Press

Siemens has developed a complete digital twin of the AUTOLOK® curing press with software in the loop capability (SIL) for McNeil & NRM, a leading builder of tire presses and related equipment.

While the global tire market has experienced significant growth over the years, the industry has undergone several changes lately that are driving a re-focus of the technology. These include e-Mobility and autonomous driving. Competitive tire production needs to be highly flexible and react quickly to volatile market developments, while also meeting today’s high standards of quality, safety and environmental impact issues. Digitalization helps manufacturers remain competitive, as it provides heavy machine builders significantly increased flexibility in design protocols.

In the Siemens strategy, digital twins of the product, the production process and the production facilities, as well as the product’s in-plant performance, are linked to a single integrated data model in the cloud. This creates a complete picture of the manufacturing landscape and a closed loop through the digital world. It enables continuous improvements for best possible results, based on actual production and performance data feedback. The digital twin of a tire press helps turn innovative design into a successful new machine by providing design, simulation and verification, all in the digital environment. The entire production process is planned, simulated and optimized under virtual working conditions, before the press build starts. Furthermore, prototyping efforts are reduced considerably, machines can be optimized during development and machine operators can be trained, long before a machine is actually commissioned.

Using the digital twin technology from Siemens, McNeil & NRM can predict the operation of the press and simulate its actual running. The Siemens Mechatronics Concept Designer (MCD) provides the ability to achieve virtual commissioning. Virtual commissioning based on “software in the loop” is based on the TIA Portal, PLCSIM Advanced and the Mechatronics Concept Designer. This is a crucial factor in reducing commissioning times in the real world and preventing costly machine crashes. In addition, McNeil & NRM will be working on applying NX software and Mechatronics Concept Designer tools to accelerate the sharing of information between its mechanical design and control design teams to improve the efficiency of the machine development process. Going forward, mechanical design changes and enhancements will be replicated in the virtual world to provide operational data and design feedback to bring innovations to the production of tires.

Performance and maintenance data from production equipment and entire production lines will be captured and analyzed using Mindsphere, the Siemens cloud based open IoT system. Mindsphere provides analytics and connectivity capabilities, developer tools, applications and services to evaluate and utilize all available data in a meaningful way for the machine builder and end user alike.

Ed Bailey, Vice President of Engineering & Development at McNeil & NRM, also notes, “The Siemens and McNeil & NRM collaboration to create the digital twin of our 63” curing press provides an essential foundation for our product development roadmap. This twin is a prerequisite to accelerate all dimensions of development and collaboration with our customers, including software development, virtual commissioning, training, and press optimization. Further development can enable our customers to virtualize tire production machine cells, complete lines and ultimately the entire plant.”

More information on these developments will be available at the Tire Technology Expo in Hanover, Germany, between February 25 and 27, 2020. It features the world’s most important suppliers to the tire manufacturing industry. Please visit Siemens at booth 8224 and McNeil & NRM at booth 8040 for a demonstration of these cooperative capabilities.

About McNeil & NRM

With a combined total of more than 150 years of experience and expertise, McNeil & NRM, Inc. stands at the cutting edge of the global tire industry. With its technology base in Akron, Ohio and high-quality manufacturing plant in Bucharest, Romania, McNeil & NRM, Inc. is positioned to remain a pillar in machinery supply to the industry. This can be seen in its dedication to manufacturing excellence, their commitment to engineering and aftermarket sales support and their pursuit of total customer satisfaction.

McNeil & NRM, Inc. stands to meet the future head-on by designing, manufacturing and servicing a new generation of tire production equipment to meet the most stringent processing requirements. This is backed up by its global footprint in North America and Europe which is supported by their international network in other regions.

About Siemens Industry, Inc.

The Siemens Operating Company Digital Industries (DI) is an innovation leader in automation and digitalization. Closely collaborating with partners and customers, DI drives the digital transformation in the process and discrete industries. With its Digital Enterprise portfolio, DI provides companies of all sizes with an end-to-end set of products, solutions and services to integrate and digitalize the entire value chain. Optimized for the specific needs of each industry, DI’s unique portfolio supports customers to achieve greater productivity and flexibility. DI is constantly adding innovations to its portfolio to integrate cutting-edge future technologies. Siemens Digital Industries has its global headquarters in Nuremberg, Germany, and has around 78,000 employees internationally.

Continue reading

Guill Offers Medical Machining and Fabricating Manufacturing Services

For over 55 years, Guill Tool has been providing tooling for the aerospace, extrusion, medical, consumer and commercial, defense, wind, oil and energy industries. Due to its years of experience, the company has a highly skilled team of expert machinists engineers trained in the latest CAD, CAM, CFD and FEA programs. Besides being experts in extrusion tooling, Guill is a major industrial manufacturer who can provide customers with one-stop shopping for their tooling and other select machine shop needs.

The Guill high quality standards are evidenced by the company’s many certifications, including ISO 9001:2015. Defense certifications include AS9100:2016 (aerospace manufacturing), MIL-I-45208A (inspection system), MIL-STD-45662A (calibration system), JCP Certified (government contracting), ITAR Registered (export compliant), NIST SP800-171 (cyber security) and others.

As part of this new medical machining program, Guill offers 5-axis machining centers, high precision machining, and full wire EDM capabilities with a .008” hole popper. Guill machines super alloys and exotic metals to close tolerances.

Machining capabilities range from small hole machining to .008” in diameter and machining material measuring up to 15 inches in all axes.

For more information, please contact:

Matt Christofaro

Extrusion Sales

Guill Tool & Engineering

10 Pike Street

West Warwick, RI 02893

USA

Office: 401-828-7600

https://www.guill.com/industries/medical/

Guill, a global leader in extrusion tooling, now offers its substantial machine shop capabilities as an independent service to customers.

Continue reading