Contact us today:

Author Archives: Bernard and Company

Exact Metrology Holds Tech Expo with 3Dvision Technologies on 3D Scanning & 3D Printing

Product demonstrations and technical presentations from principals impress large crowd at dual open house

On March 17, 2016, Exact Metrology held a tech event in Cincinnati, Ohio with partner company, 3DVision Technologies at both of their offices. Held on St. Patrick’s Day, the event was cleverly titled “Lunch, Learn & Luck,” and had a “March Madness” theme with basketball games playing on multiple widescreen televisions. The event was attended by over 100 people from local area industries, including automotive, aerospace and consumer goods.

Co-Hosted by Steve Young, Exact Metrology co-founder and President, and Todd Majeski, President of 3DVision Technologies, the day included presentations and product demonstrations of the newest products transforming the manufacturing industry in 3D printing and 3D scanning. The informative event provided insight and hands-on experience, while displaying the newest technology that is reshaping the traditional manufacturing process.

The day began at 3D Vision Technologies office, (a provider of engineering solutions & 3D printing for manufacturing companies), with a presentation by Todd Majeski. Majeski discussed the company’s long-term partnership with Exact Metrology, and how both companies work together to improve processes, increase quality, and get their customer’s products to market faster through 3D scanning and reverse engineering. After several presentations and a question-and-answer session, attendees were welcomed into a showcase of 3D printer demonstrations and product displays of printed samples from miniature to lifesize versions, including a skateboard, helmet, and an automotive front grill.

The second part of the tech event was held at Exact Metrology’s office, conveniently located just a short walk away. Participants walked together and, after a St. Patrick’s Day themed lunch, began the afternoon session with a presentation by Steve Young. Young discussed the newest technology in CT (Computed Tomography) scanning systems, which allows users to not only scan the outside of a part, but to actually see inside of it without taking it apart, or damaging the item. Until recently, this technology was used primarily in the medical field but is creating much excitement within a variety of industrial markets now, as it enables manufacturers to check for defects, internal contact points after assembly, porosity and dimensional accuracy, comparing actual scans to point cloud data, CAD files etc. According to Young, this type of 3D scanning has been a “huge success” for his company, which he co-founded with Dean Solberg, who runs the company’s facility in the Milwaukee area.

Products displayed at the event included the P40 Leica Scanner, a long-range scanner, which, according to presenter Jacob Wallace, Processing Engineer at Exact, can be set up and ready to scan in 30 seconds. The scanner has a 150-meter range and will show everything in the surrounding area. Wallace recently scanned an entire office to make an accurate 3D model, complete with windows, doors, ceiling and wall thickness. Other uses of these long-range scanners include collecting topography of roadways (without stopping traffic) and large buildings of 500,000 square ft. or more, to collect information inside and outside of the building, all within a reasonable timeframe.

Other products displayed and discussed at the expo were the Romer Absolute 77, an Articulated Arm with a Laser Line Scanner, the Atos Triple Scan, the Artec EVA Handheld Portable Scanner and the NDI ScanTrak Large Volume Laser Scanner.

Exact Metrology ended the afternoon with a St. Patrick’s Day raffle, with two lucky attendees winning a 48” high-def television and a MakerBot 3D printer.

Exact Metrology offers a complete line of portable scanning and measurement technologies as well as contract measurement for 3D laser scanning services, reverse engineering services, non-contact inspection, metrology services, 3D digitizing and training.

For more information on this new equipment, please contact:

EXACT METROLOGY, INC.

11575 Goldcoast Drive

Cincinnati, Ohio 45249

Phone: 513-831-6620

Toll Free: 866-722-2600

www.exactmetrology.com

stevey@exactmetrology.com

Steve Young, President

Exact Metrology is an ISO 9001:2008 Certified Company.

—

Exact Metrology, with facilities in Cincinnati and Milwaukee and affiliated offices throughout the Midwest, is a comprehensive metrology services provider, offering customers 3D scanning, reverse engineering, quality inspection, product development and 2D drawings. The company also provides turnkey metrology solutions, including equipment sales and lease/rental arrangements.

Chemcoaters Addresses EQ Controversy Directly

ASTM B117 salt spray test results, performed on HDG G235 with hexavalent chemtreat vs. HDG G40 with InterCoat® ChemGuard 315, as exposed for 1500 hours. The RoHS compliant coating applied by Chemcoaters is made with trivalent chrome vs. hexavalent chrome, a known carcinogenic.

“G40 hot dip galvanized with Intercoat® ChemGuard will substantially outperform G235 and offer a much lower overall cost,” states director of sales & marketing Mike Tieri

In a forceful announcement made today, Chemcoaters, Inc. (Gary, Indiana) directly addressed the EQ (Equivalent Coating) controversy with the statement above, attributed to Mike Tieri, Director of Sales & Marketing for the company, a leading green coil coater based in Gary, Indiana.

Elaborating, Mr. Tieri cited the following example.

“For 16 ga coil (0.056 specifically), the zinc coating to a G30 thickness is currently adding $1.90 cwt. By contrast, G235 thickness zinc coating is $11.10 cwt. To apply our Intercoat® ChemGuard to G30 is no more than $4.00 cwt, so the economics are unquestionable. Since G30 is commercially available from many more sources, it means service centers, OEM’s and processors can use a lighter and obviously less-expensive zinc coating thickness, have a metal product that is considerably easier to form and shape, reduce SKU’s, increase inventory turns, increase corrosion resistance (see graphic) and save money immediately. Doesn’t get much better,” Tieri mused. He further noted that this example is not always applicable, given the size of the coils supplied to Chemcoaters.

The InterCoat® ChemGuard product can also remain bare, be painted or welded, plus it’s RoHS compliant and can even be tinted in a spectrum of colorations, according to Tieri.

Chemcoaters, Inc. is a leading supplier of various coil coatings and cleaning services for the coiled metals market. The company’s patented InterCoat® ChemGuard 300 coating is formulated with trivalent chrome vs. hexavalent chrome, making it environmentally friendly in all building, architectural, transportation and consumer appliance applications. InterCoat® ChemGuard 300 coating has superior corrosion resistance, as well. Chemcoaters offers a presentation that evidences this fact to all interested parties.

For more information, please contact:

Mike Tieri

Director of Sales Marketing

Chemcoaters, Inc.

700 Chase Street

Gary, IN 46404

Phone: 877-411-2905

Email: miket@chemcoaters.com

Website: www.chemcoaters.com

Connect with Chemcoaters online:

2000°F Inert Atmosphere Heavy-Duty Furnace from Grieve

This Grieve inert atmosphere furnace has a roof-mounted, heat-resisting alloy circulating fan powered by a 1-HP motor with V-belt drive, water cooled bearings and inert atmosphere shaft seal. Furnace features include 9” thick insulated walls comprised of 5” of 2300°F ceramic fiber and 4” of 1900°F block insulation; 8 ½” floor insulation comprised of 4 ½” of 2300°F firebrick and 4” of 1900°F block insulation. Other features include ¼” plate exterior reinforced with structural steel, ½” steel face plate at doorway with air-operated vertical lift door. Inert atmosphere construction includes continuously welded outer shell, high-temperature door gasket, sealed heater terminal boxes, inert atmosphere inlet, inert atmosphere outlet, inert atmosphere flow meter and manual gas valve.

Controls on No. 1039 include a digital programming temperature controller, a manual reset excess temperature controller with separate contactors, paperless event recorder and SCR power controller.

For more information, please contact:

THE GRIEVE CORPORATION

500 Hart Road

Round Lake, IL 60073-2898

Phone: (847) 546-8225

Fax: (847) 546-9210

Web: www.grievecorp.com

Email: sales@grievecorp.com

Attention: Frank Calabrese, VP

Siemens Offers Compact Disconnect Switches for Sinamics G120D Drives

Siemens announces immediate availability of two new compact quick disconnect switches used with the popular Sinamics G120D distributed drives. This new disconnect switch design mounts directly onto the input power connector of the drive and locks in place to provide a tight, reliable interface, in accordance with ISO 23570-3. Many applications exist in the decentralized distributed power environments, where control cabinets are being replaced with IP65 protected products.

Two versions of the new disconnect switches are now available. A 10-amp rated switch is offered for G120D drives up to 4 kW (5 hp) and features a daisy-chain Power-Y-junction box design to enable power wiring to additional G120D drives. A 25-amp rated version is offered for the heavier-duty 5.5 kW (7.5 hp) and 7.5 kW (10 hp) drive models. This larger unit features a standard Q4/2 pin configuration.

Through the introduction of these new disconnect switches, Siemens can now offer system integrators, OEMs and field maintenance personnel immediate availability to a drive and connector package for a number of applications, according to Robert Soré, product marketing manager, Sinamics general purpose drives at Siemens. “We’ve developed this product line in tandem with our solution partner Harting and we see it expanding our presence in the distributed, decentralized control markets, which include automotive, packaging, metals processing, food and beverage, as well as general conveyorized material handling.”

For more information about these new quick disconnect switches, please visit:

www.usa.siemens.com/sinamics-g120d

For specific product information and inquiries, call (800) 879-8079 ext. Marketing Communications or send an e-mail to: SiemensMTBUMarCom.industry@siemens.com.

Exact Metrology Now AS9100 Certified at Cincinnati Location

Leader in 3D and CT scanning for industrial, commercial concerns achieves key aerospace supplier metric

As the certification notes, Exact has its recognition for “…sales and supply of 3D non-contact and contact measuring equipment for inspection and reverse engineering to the commercial, aerospace, medical, automotive and industrial manufacturing industries.”

The AS9100 is a vital certification for the work this facility performs in the aerospace sector.

Exact is a prime supplier of equipment as well as the services that utilize various portable and stationary 3D scanning devices, plus one of the first industrial-grade CT scanners, a unit that can examine the internal geometric and material composition of various substrates on molded, cast and forged products, as well as food ingredients and packaging for seal integrity and safety.

Exact Metrology is also an ISO 9001:2008 Certified Company.

For more information on this development or to arrange a demonstration, please contact:

EXACT METROLOGY, INC.

11575 Goldcoast Drive

Cincinnati, Ohio 45249

Phone: 513-831-6620

Toll Free: 866-722-2600

www.exactmetrology.com

stevey@exactmetrology.com

Steve Young, President

—

Exact Metrology, with facilities in Cincinnati and Milwaukee and affiliated offices throughout the Midwest, is a comprehensive metrology services provider, offering customers 3D scanning, reverse engineering, quality inspection, product development and 2D drawings. The company also provides turnkey metrology solutions, including equipment sales and lease/rental arrangements.

Continue reading500°F Inert Atmosphere Oven from Grieve

No. 870 is a 500°F (260°C), inert atmosphere oven from Grieve, currently used for aging rubber parts at the customer’s facility. Workspace dimensions of this oven measure 36” W x 60” D x 36” H. 12 KW are installed in lncoloy sheathed tubular heating elements, while a 600 CFM, ½ HP recirculating blower provides universal airflow to the workload.

This Grieve inert atmosphere oven has 4” insulated walls, an aluminized steel exterior and Type 430 stainless steel interior. The oven features inert atmosphere construction, including a pressure regulator, flow meter, pressure gauge, inner oven walls sealing directly against ½” thick silicone rubber door seal, air jacket on the inner oven for cooling, blower shaft seal, positive latching door hardware, adjustable offset door hinges, outlet with pressure relief, interior seams welded gas-tight and all wall penetrations fitted with compression fittings. Also onboard is a 650 CFM blower with 2-position motorized dampers to pull air through the air jacket on the inner oven for cooling.

Controls on No. 870 include a recording and programming temperature controller.

THE GRIEVE CORPORATION

500 Hart Road

Round Lake, IL 60073-2898

Phone: (847) 546-8225

Fax: (847) 546-9210

Web: www.grievecorp.com

Email: sales@grievecorp.com

Attention: Frank Calabrese

New Gear Motor Drive from Siemens

Motor-integrated drive offers onboard safety features and communications

Simogear gear motors offer high torque density, low noise and high efficiency — and now with Sinamics G110M, it becomes easier for designers and system builders to integrate gear motors into a variety of control architectures. Plug connections for onboard I/O ensure fast installation, while optional power connectors deliver even more time savings. The system is delivered pre-configured and the drive offers simple yet comprehensive onboard diagnostic features. Options such as internal braking resistors and motor brakes — operational simultaneously — and integrated features such as “Quick Stop” and the limit switch function make this system ideal for conveyor applications.

For uses requiring safety technology, the Sinamics G110M offers integrated safety functions such as “Safe Torque Off” (STO), which can be activated via a fail-safe input or via Profisafe, without needing additional safety monitoring components.

Sinamics G110M features integral USS/Modbus RTU, Profibus and Profinet / EtherNet/IP communication profiles.

To watch a video of the Sinamics G110M for the material handling industry, please visit: https://www.youtube.com/watch?v=GgDxptBqpHg

For specific product information and inquiries, call (800) 879-8079 ext. Marketing Communications or send an e-mail to: mc.us@siemens.com

Siemens Drive Selector App Enjoys Growing Polarity

Drive selector app enjoys growing polarity

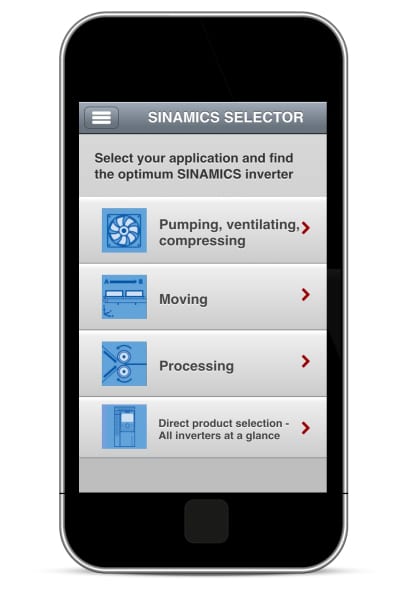

For some time, it has been apparent that mobile apps have been spreading more and more across the industrial environment and have become a popular medium among users. One special feature in this field is the variable frequency drive app for the easy selection of all necessary components from the respective corporate portfolio. The online selection is always up-to-date, available in many different language versions and saves the user time — laboriously poring over catalogs is now a thing of the past.

Due to the special requirements in some cases, selecting the right drive is not always straightforward and can often waste valuable time. After all, the fields of application and the requirements regarding operating behavior and costs are wide-ranging. Whether the drives are used to operate pumps, fans or compressors, or to drive conveyors, mixers or kneaders, it is important to find the appropriate drive for the required range of performance and voltage quickly and easily for each of these applications. And wherever possible, this must be done without the need for expert knowledge of drive technology.

The Sinamics Selector app helps you to select a suitable drive in just a few simple steps and also suggests alternative options.

Assembling components by smartphone

In order to simplify this sometimes complex process, Siemens, for example, has been offering its Sinamics Selector app free-of-charge. This is a solution that displays the entire collection of products from the portfolio of low-voltage frequency drives — Sinamics V20, G120C, G120 and G120P — on the most popular iOS and Android smartphones and can be used both online and offline. This offline capability is of particular importance in regions which do not have full cellphone coverage. Since Version 4.0, not only have brochures, product videos and application examples (Fig. 1) been available to users and electrical distributors, but also more language versions.

Everything up-to-date

Katharina Roehrlein, marketing manager for Sinamics drive systems at the Siemens Digital Factory division, explains additional innovations: “With the latest update, Version 5.0, we have adopted the second generation of the Sinamics G120 modular Frame Size D-E, as well as the Sinamics V20 Power Extension up to 30 kW, into the app. In addition, we have integrated more technical values such as resistance, peak performance and continuous power ratings into the logic of the app. And for good reason, because we want to make it as easy as possible for our customers to find the right drive in order to save valuable time.”

As a matter of principle, when assembling the appropriate components, the Sinamics Selector app offers not only a product-specific, but also an application-specific approach. In other words: either the user knows from the outset which frequency drive is required, or the app guides the user step-by-step to the right drive by asking for key parameters (Fig. 2). The information held by the Sinamics Selector app is kept up-to-date at all times by the central storage of data and continuous updates. Bob Hendrickson, applications engineer at Wesco, one of the largest distributors in the United States, regards this as an enormous advantage over conventional catalogs, especially when the app can save him a great deal of time in preparing a bid. “The Sinamics Selector app is very helpful as it lets me create a complete bill of materials for a customer offer very quickly. This option saves me a huge amount of time since I no longer have to create bills of materials by hand. The app also makes it easier for me to respond to queries arising from projects when I’m on the road and don’t have any catalogs or other documents to hand.”

Bid preparation made easy

After choosing the required type of frequency inverter, the rated output, device options and accessories can then be selected and adapted individually — if necessary, also with the support of the respective Siemens contact, whose details are also stored in the app. Once the components have been selected, the user has the option of either saving or emailing them. To make it easier for end-users to get in touch later, the headers and footers of the email can be adapted individually, for example, with personal contact information. The overview includes actual part numbers for all of the selected components. This can be used as information for the customer, but also as the basis for ordering specific components or preparing an offer at the local dealer/distributor. Kevin Young, application engineer at electrical distributor C&E Sales Inc., in the U.S., also confirms this: “I really like the Sinamics Selector app. I copy the result into my bill of materials, which enables me to immediately present a bid to my customer.” His colleague Jay Swank adds, “I use the application almost every day now.”

Over 15,000 downloads and counting…

Since the introduction of the first version, the Sinamics Selector app has been installed 17,000 times on mobile devices worldwide — and the number is still rising. Apart from Europe, China and the U.S., this trend is being led by key markets such as India, Brazil and Mexico. “It is particularly important in these countries to have a solution in the local language which also functions faultlessly offline. The email containing the results can be stored and then transmitted when sufficient network capacity is available again,” adds Ralf Weber from the Siemens Digital Factory division responsible for the app.

Think global, act local

Due to the great success of the app in all language versions offered thus far, Siemens is planning the integration of additional languages, as well as the continuous support and expansion of the product range covered. The main focus here is on Europe, particularly the eastern regions.

For more information about the Sinamics Selector app, visit:

www.usa.siemens.com/sinamics-selector-pr

Access – online and offline

Cost – Free-of-charge

Platforms – iOS, Android

Languages – English, German, French, Italian, Spanish, Portuguese, Chinese, Russian, Korean and Turkish

Quicklink to the Sinamics Selector app: http://ow.ly/WFRe5

For more information on this story, please contact:

SIEMENS INDUSTRY, INC.

DIGITAL FACTORY

MOTION CONTROL — GENERAL MOTION CONTROL

390 Kent Avenue

Elk Grove Village, IL 60007

Phone: 847-640-1595

Fax: 847-437-0784

Web: www.usa.siemens.com/motioncontrol

Email: mc.us@siemens.com

Attention: John Meyer, Manager, Marketing Communications

Siemens offers Sinamics G120C drives in new smaller frame size AA (FSAA)

New Sinamics G120C FSAA — the “Tiny Drive” in frame size AA from Siemens Industry, Inc.

Siemens announced today immediate availability of its popular Sinamics G120C drive in AA size, which replaces the previous G120C frame size A in power ratings up to 2.2 kW

(3 hp), including communication variants for USS, PROFIBUS, PROFINET and EtherNet/IP. Offering high power density in a smaller footprint, the new “tiny drive” offers fully compatible replacement for the equivalent power ratings on the previous version.

On new control cabinet designs, the G120C FSAA has significant size advantages, up to 32% less overall volume, for the OEM or integrator, but requires no re-engineering, when migrating from the G120C FSA on current jobs. Overall dimensions on the smaller unit, designed for use with PROFIBUS and USS variants are only 173mm high x 73mm wide x 155mm deep (6.8” x 2.8” x 6.1”).

Other benefits of the new G120C FSAA include use with increased motor cable lengths,

up to 50m (165 ft) for shielded and 150m (495 ft) for unshielded, plus identical voltage ratings, current ratings, load cycles and compatibility with all standard Siemens options such as operator panels, input and output chokes, as well as external Class B EMC filters.

Sinamics G120C FSAA has smaller footprint, up to 32% less volume, but delivers comparable features to previous version of this Siemens drive.

The G120C FSAA offers UL open type, IP20 protection in the 0.55–2.2 kW (0.75–3 hp) range.

Through the introduction of this new tiny drive, Siemens can now offer machine builders another economical, space-saving and easy-to-operate standard AC drive with a wide range of functions, according to Robert Soré, product marketing manager for general purpose drives at Siemens. Typical applications for this product span a broad machine and equipment range, including smaller test stands, mixers, conveyors, fans, pumps, compressors and basic production machinery.

For more information about the Sinamics G120C drive platform, please visit: www.usa.siemens.com/sinamics-g120c-pr

For specific product information and inquiries, call (800) 879-8079 ext. Marketing Communications or send an e-mail to: mc.us@siemens.com

Continue readingLaser Welding System to Weld Clear-to-Clear Plastic Without Laser Absorbing Additives

Dukane Laser Welding Workcell

Dukane Corporation, St. Charles IL introduces a new Laser Welding System that allows clear-to-clear plastic welding without the need of any laser absorbing additives. This system incorporates a recently developed 2-micron laser with a greatly increased absorption by clear polymers and enables a highly controlled melting through the thickness of optically clear parts.

New beam delivery system integrates both a programmable multi-axes servo gantry and a scan head, supported by proprietary LaserLinQTM software, which harmonizes the action of both components moving the beam. This assures highly precise and controllable beam delivery when welding mid-size and large components.

LaserLinQTM also provides users with the ability to break complex weld patterns into separate geometric segments, modify each segment independently and assign different welding parameters to each segment. The CCTV camera integrated within the machine enables a live weld preview on the HMI screen and the ability to directly monitor and record welding cycles for further analysis. All laser enclosures are Class I CDRH certified and utilize laser-safe glass viewing windows.

This Dukane flexible welding system also allows rapid changeover of a wide variety of highly specialized tooling cassettes. The tools, as a standard, incorporate binary tool ID recognition for automatic weld recipe recall. They support multi-cavity function, multiple feature detection, vision systems and independent clamping systems to compensate for part variations.

Manufacturers from various industries including medical, electronics and appliances can benefit from this clear-to-clear laser welding solution.

Dukane Corporation offers a full range of ultrasonic, vibration, spin, hot plate welders, and thermal presses, probes, tooling and software for both OEM and the commercial plastic assembly markets. Dukane is an ISO 9001:2000 certified manufacturer with 24/7 Service. For more information on Dukane’s Laser welding System, and their complete line of plastic assembly solutions, contact Jason Barton, National Sales and Marketing Manager. He can be reached at (630) 797-4902 or visit their web site www.dukane.com/us.

Continue reading