Contact us today:

(847) 934-4500

tdaro@bernardandcompany.com

Contact us today:

(847) 934-4500

tdaro@bernardandcompany.com

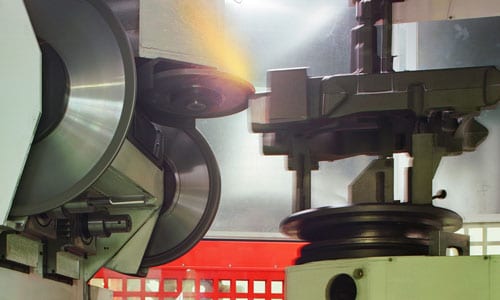

Major Indian caster anticipates dramatic improvement in surface quality and production rates from new Italian grinding/fettling center

Mr. N. Krishna Samaraj, managing director for Magna, stated it was the company’s expectation that this machining system, scheduled for start-up after July, 2011, will result in significant improvements in the surface quality and production rates at the company. Magna is a vertically integrated foundry, as it performs various machining, surface treatment and heat treating operations, in addition to its full foundry capabilities for various products sold to the valve, refrigeration, rail, hydraulics, automotive, wind turbine and other industries worldwide.

Magna runs a fully automated sand prep and mold line, as well, using equipment from its longtime supplier, Hunter Automated Machinery, who represents Maus in various world market areas. Magna currently runs a Hunter HMP20E Automatic Molding Machine (1994) and an HLH 20 Type II mold handling system (2007).

The sale of this Maus grinding/fettling machine was finalized between Mr. N. Krishna Samaraj for Magna and Mr. Ashwin Katke of Carraro, the parent company of Maus, with offices in India.

For further information on this announcement, interested parties may contact:

MAGNA ELECTRO CASTINGS LIMITED 43, Balasundaram Road Coimbatore – 641 -018 Tamilnadu, India Phone: +91 4322 2240109 Email: magnacast@vsnl.com Web: www.magnacast.com Attention: Mr. N. Krishna Samaraj, Managing Director

Or

MAUS SpA Via Caltana, 28 35011 Campodarsego Padova, Italy Phone: +39 0499299311 Sandra Selwan, Marketing Manager Sandra_Selwan@maus.it www.maus.it

Or

HUNTER AUTOMATED MACHINERY CORPORATION 2222 Hammond Drive Schaumburg, Illinois 60196-1094 USA Phone: +1 847 397 5136 Email: kpurdy@hunterauto.com Web: www.hunterauto.com Attention: Kevin Purdy, Vice President

Editor Note: Please direct all publication-generated inquiries to Kevin Purdy at Hunter. Thanks!

Agency contact for Hunter: Tim Daro Bernard & Company Palatine, Illinois (Chicago) USA +1 847 934 4500 tdaro@bernardandcompany.com

The unit has 4” insulated walls and a Type 430 stainless steel interior. A 1000 CFM, 1-HP recirculating blower provides horizontal airflow to the workload. Stainless steel pans are held by three tiers of seventeen shelf supports on a 3” vertical center.

Controls onboard No. 834 include a digital indicating temperature controller, recirculating blower airflow safety switch and a manual reset excess temperature controller with separate contactors.

For more information, please contact: THE GRIEVE CORPORATION, 500 Hart Road, Round Lake, Illinois 60073-2835 USA. Phone: (847) 546-8225. Fax: (847) 546-9210. Web: www.grievecorp.com. Email: sales@grievecorp.com. Attention: Frank Calabrese.

NEWS RELEASE: THE GRIEVE CORPORATION

Agency contact: Tim Daro 847-934-4500

Continue readingSignificantly reduces inventory, changeover time for lathe and mill/turn users

See the U-Tec video HERE.

Heimatec, a world leader in live tools, angle heads and multi-spindle drill heads, today announced immediate availability of its newest development, recently unveiled at IMTS.

U-Tec® is the company’s patented flexible tool adapter system that allows a standard ER output live tool to accept various adapters for different applications. This allows users the ability to have quick changeover of tools on almost any lathe, using a single live tool, without having to commit to a quick-change system on the initial purchase. A facemill adapter, for example, can be quickly positioned into the standard holder, without the need for a completely new base being installed. This significantly reduces inventory costs as well as changeover time, for the busy shop.

The U-Tec® system, according to Heimatec Inc. President Preben Hansen, “…represents a real improvement in lathe and mill/turn tooling design. U-Tec® allows great user flexibility, while a polygonal drive system ensures extremely high power transmission stability and faster set-up with absolutely no loss in performance or accuracy, because the live tool base remains in position and only the adapter and collet get swapped.”

He went on to explain the unique collet nuts on the U-Tec® system have internal threading for rigid mounting and that this new tool adapter system enables the actual cutting tool to be brought into closer proximity to the bearing, thus further improving performance in use. This benefit results from the short and compact tool length design. Internal coolant up to 2000 psi(140 bar) is provided standard.

Every adapter in the U-Tec® system comes complete with any necessary clamping nuts and adapters are immediately available in face mill style, ER extensions, side lock, shrink fit, hydraulic and blank.

The U-Tec® system is available for all major turning machines on the market today. Heimatec currently manufactures over 10,000 live tool types.

For further information and literature on this new product, please contact:

Preben Hansen, President

HEIMATEC INC.

16 E. Piper Lane Suite 129

Prospect Heights, IL 60070

Phone: 847-749-0633

Fax: 847-749-2445

Email: info@heimatecinc.com

Website: www.heimatecinc.com

—

Heimatec is an international tooling manufacturer, based in Renchen, Germany. Its experienced staff is dedicated to providing customers the most innovative tooling technology possible. In 2010, the company opened Heimatec Inc. in Prospect Heights, IL, near Chicago, to serve its growing North American customer base with sales and service, plus an extensive inventory of products. Heimatec serves the auto, aero, medical, off-highway, rail, energy, woodworking, composites and other industries, as well as an ever-increasing number of machine tool OEM’s worldwide.

Continue readingSinumerik MDynamics Milling Roadshow is coming to IMTS 2010.

If your company is looking for the way to more efficiently cut parts for aerospace, automotive or medical, one thing is certain — the demand for five-axis CNC machining has risen dramatically. And now there’s MDynamics: using one solid CAD/CAM/CNC process chain will get you to market faster than your five-axis competitors who will be lagging under a less integrated approach.

What is Sinumerik MDynamics?

“For users, it is extremely important to get from the blueprint to the finished part quickly, precisely and cost-effectively,” says John Meyer, marketing communications manager, Siemens Industry, Inc. “Sinumerik MDynamics combines our milling expertise together with our powerful Sinumerik CNC hardware platform, intelligent CNC functions, and our unique CAD/CAM/CNC process chain to form integrated technology packages for three- and five-axis milling.”

Seeing is believing.

According to Robert Scholz, international business development manager, Siemens Industry, Inc., Motion Control Business, “Together with leading machine tool OEMs, Siemens will demonstrate how users can benefit from accurate, high-speed machining and perfect workpiece surfaces. Every roadshow event will demonstrate part programming and simulation with NX CAM, followed by five-axis part manufacturing using MDynamics functions and Sinumerik CNC. With real applications for the automotive, aerospace and medical industry, we will prove to our customers that we are the perfect fit for every industry.”

From A-Z and everything in between, Siemens has you covered.

By providing a uniform and integrated system that ranges from programming directly at the CNC for simple parts, to a CAD/CAM system for complex workpieces, Siemens has the right solution for all CNC machining needs. With NX CAM, Siemens provides manufacturing engineers with an open and flexible 3D system that applies not only to the development of part models and drawings, but also to full NC programming and machining simulation. NX enables 3D and 2D construction in a full-, partial- and non-paramaterized form. The fully-integrated NX CAD/CAM system supports a complete part model to CNC program process and even offers 3D quality inspection programming in the same system. NX CAM provides optimized output for Siemens-controlled machines with additional programming commands and automated post-processor functions. During planning and into production, special focus is placed on the process related to the workpiece.

This process chain includes:

Product and process development using advanced CAD/CAM software

Part program generation for the most advanced machine tools

Optimized part program and post-processor output for maximum machining performance

Integrated and offline simulation for checking and optimization of manufacturing process on the PC

Optimized and highly-efficient manufacturing on the machine

See what Sinumerik MDynamics can do for your business!

Attend the Siemens Sinumerik MDynamics Milling Roadshow.

Roadshow schedule

20-minute demonstrations every day

during IMTS, September 13–18, 2010

12:30 p.m. — Milling for Medical

DMG/ Mori Seiki, booth S-8900

1:30 p.m. — Milling for Automotive

Grob Systems, booth S-9066

2:30 p.m. — Milling for Aerospace

MAG, booth S-8519

www.usa.siemens.com/cncroadshow

Continue readingGear manufacturer supplying various defense sector customers completed registration process on March 31, 2010

Roscoe, IL-Forest City Gear supplies some of the world’s leading companies with high-precision gear work. These include products for various defense sector contractors, which would be subject to the strict guidelines of the International Traffic in Arms Regulations (ITAR). This standard is designed to “establish and maintain a procedure for identifying and complying with export authorization requirements for the sale and shipment of defense articles, the performance of defense services and the transfer of technical data” by the companies involved, pursuant to the Arms Export Control Act. Applicable products include those on the United States Munitions List (USML).

Specifically, ITAR requires that Forest City Gear maintain a strict record of all manufacturing procedures and defense articles produced, as well as visitor records and the tracking of all potentially sensitive documents such as engineering data and shipping logs. Under the guidelines, only U.S. citizens may visit the facility, where no cameras or laptops are permitted and only citizens may work for the company, during the design, engineering, manufacture, production and handling of products and all relevant data related to defense projects. Exchange of data, especially via the Internet, is highly restricted, plus no non-citizen may access data in any way, without authorization from the State Department or a specially issued exemption. A non-citizen may also visit the plant, but only with a previously completed letter of authorization, stating they understand and comply with all relevant ITAR standards. And any non-citizen must be accompanied by a company official at all times.

The registration process was completed on March 31, 2010, after over a year’s effort to comply with all applicable standards, procedures and paperwork.

Overseeing the registration process and executing all documents for Forest City Gear was the company’s CEO, Fred Young. Quality Manager Joe Luy will oversee the internal process and procedure.

Forest City Gear supplies gears and gearwork for all types of military ordnance, as well as numerous military aircraft, vehicles, instrumentation and other defense devices. The company has also supplied gears on Jeep’s for decades, long before they became consumer items.

The company recently celebrated its 55th anniversary. Forest City Gear was founded in 1955 by Fred Young’s parents, Stetler and Evelyn Young, in Rockford, Illinois, near the company’s current facility in Roscoe.

ITAR is managed by the Department of Homeland Security, the Directorate of Defense Trade Controls and other government agencies, at this time. Only vendors listed on the Approved ITAR Vendor List are sent quote requests on ITAR-restricted materials and products.

For more information on the company, please contact: FOREST CITY GEAR CO., INC. 11715 Main Street Roscoe, IL 61073-0080 Phone: 815-623-2168 Fax: 815-623-6620 Web: www.forestcitygear.com Email: sales@forestcitygear.com Attention: Fred Young or Joe Luy

PR agency contact for Forest City Gear: Tim Daro Bernard & Company 847-934-4500 tdaro@bernardandcompany.com

Continue readingGear manufacturer on the grow, says President Wendy Young

Roscoe, IL-Forest City Gear (FCG), a precision gear manufacturer here, today announces the hiring of four new employees and the promotion of two longtime employees. “We’ve been growing steadily in the last two years, despite the economic conditions, and this news reflects that situation,” comments company President Wendy Young, who runs the business alongside her husband, CEO Fred Young.

Effective immediately, the following new individuals have been retained in the roles indicated:

Joe Luy-Quality Manager

Bruce Haxton-Gear Processing Engineer

Paul Lindquist-Process Engineer

Jim Cagle-Cost Estimator

Also, these longtime employees have been promoted:

Krista King-Order Processing

Andrea Bagwell-Estimating/Quoting Assistant

Briefly, Joe’s role will be the supervision of the company’s quality lab, acknowledged as one of the finest metrology centers in the gear industry. Over a third of Forest City Gear’s current customers are other gear companies around the world, who bring FCG work they cannot do themselves, either on tolerance or consistency. Joe will also manage the company’s ISO and ITAR registered programs, the latter having been secured this past March.

Bruce will be responsible for the transitions from design to manufacturing protocols at FCG. He brings an impressive background in gearmaking to the task.

Paul oversees the utilization of the companies 80+ machine tools to streamline production workflow through the shop, again considered one of the world’s leading gearmaking facilities.

Jim will help keep pace with the hundreds of RFQ’s received each week at FCG, a daunting task, to say the least.

Krista moves into an expanded role in purchasing, working with numerous vendors and the strict guidelines of the many government, aerospace and defense contractors served by FCG. Her primary role will be processing purchase orders for the company.

Andrea will be responsible for the preparation of quotes, serving the now larger department of inside sales engineers and others, including Fred Young, who continues in his longtime role of reviewing and estimating particularly challenging gearmaking jobs at the company.

The company recently celebrated its 55th anniversary. Forest City Gear was founded in 1955 by Fred Young’s parents, Stetler and Evelyn Young, in Rockford, Illinois, near the company’s current facility in Roscoe, approximately 90 miles northwest of Chicago.

For more information on the company, please contact:

FOREST CITY GEAR CO., INC. 11715 Main Street Roscoe, IL 61073-0080 Phone: 815-623-2168 Fax: 815-623-6620 Web: www.forestcitygear.com Email: sales@forestcitygear.com

Attention: Wendy Young or Fred Young

PR agency contact for Forest City Gear:

Tim Daro

Bernard & Company

847-934-4500

tdaro@bernardandcompany.com

The unit has 7” thick insulated walls, comprising 5” of 2300°F ceramic fiber and 2” of block insulation. The 7” floor insulation contains 4 1/2” of 2300°F firebrick and 2-1/2” of block insulation.

Controls onboard No. 862 include an automatic door switch to drive burners to low fire when the door is opened and an air-operated vertical lift door. All safety equipment required by the IRI, FM and the National Fire Protection Association Standard 86 for gas-heated furnaces is also included.

For more information, please contact:

THE GRIEVE CORPORATION

500 Hart Road

Round Lake, IL 60073-2898

Phone: (847) 546-8225

Fax: (847) 546-9210

Web: www.grievecorp.com

Email: sales@grievecorp.com

Attention: Frank Calabrese, VP

AerOpak® cable for myriad temperature measurement and signal-sending applications in harsh environments; wide assortment of sizes and sheath materials available for immediate shipment

ARi Industries, Inc., a longtime market leader in temperature measurement, announces immediate availability of its AerOpak mineral-insulated (MI) thermocouple cable in an expanded assortment of sizes and sheath materials. MI cable offers thermocouple fabricators, instruments designers, process engineers and various equipment builders a unique solution to the challenges of temperature measurement and electrical signal-sending in harsh, corrosive and other hazardous environments.

Offered as thermocouple and conductor cable, AerOpak products comprise thermocouple or conductor wires insulated with compacted ceramic powder, drawn and encased in a seamless metallic sheath material. Standard thermocouple or conductor cables up to 10-wire configurations are available in various stainless steel, Hastelloy and Inconel sheath materials in OD sizes ranging from 0.020” to 0.750” diameter. Cable can be supplied for temperatures up to metal melt points of 2600ºF and over 1000 ft. in length, making these products suitable for all types of process operations and very large equipment. Owing to the strict manufacturing and production standards of ARi, MI cable signal integrity is consistent over the longest length applications.

Thermocouple cables in Types K, E, J, T, N, R, S, and B are stocked in calibration tolerances to meet all applicable ASTM, IEC and ANSI standards.

MI cable from ARi can be welded, brazed or soldered in the field, relative to the application and techniques used. Please consult the manufacturer for details or installation assistance. Custom wire configurations, other sheath materials and assorted insulation ingredients are also available on request, to suit virtually all applications.

For full details and specifications on this line of products, please request Bulletin 4.0.

For more information, please contact: ARi Industries, Inc. 381 ARi Court Addison, IL 60101 Toll-Free: 800-237-6725 Phone: 630-953-9100 Fax: 630-953-0590 Web: www.ariindustries.com

Email: sales@ariindustries.com

ARi Industries, Inc. is a division of Okazaki Manufacturing Company (Japan).

ARi Industries is a manufacturer of mineral-insulated wire and cable, thermocouples, RTD’s, thermowells and temperature transmitters, as well as conductor cable assemblies, neutron detectors, electric heating elements of various types and related hardware. The company is ISO-9001-2000 Certified and performs X-ray inspection, helium leak testing, temperature calibration traceable to NIST and other analytical services. The company is a worldwide supplier to instrument, power generation, aircraft and other equipment builders, as well as all process industries, serving the most demanding environments.

Continue reading

STAMA unveils a new concept in multi-spindle machining

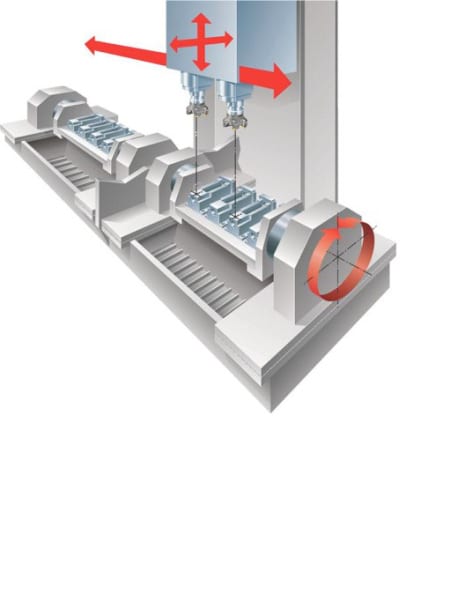

The “2 Plus 4” principle has represented the most economical and efficient means of multi-spindle machining in manufacturing. STAMA has implemented this principle, with 2 spindles and 4 clamped workpieces, in hundreds of existing projects worldwide, resulting in radically reduced cost per part scenarios for its customers. In today’s highly competitive market, however, STAMA has recently conducted discussions with its customers concerning greater factory floor utilization and “non-productive” capacity, leading to the question, are more than 2 spindles – perhaps even 4 – for the simultaneous machining of workpieces, economically more reasonable? This challenge has sparked an interesting development at STAMA, the 4-spindle TWIN2 concept that’s now being introduced to the world market for multi-spindle machining applications.

In answering this 2 vs. 4 question, a shop must first verify which productivity upsides will be realized by this concept. Figure 1 below shows the productivity benefits with a 4-spindle solution on completely different manufacturing processes with different primary machining times. Contrary to the “logical” expectations, the 4-spindle solution with 4 clamped workpieces doesn’t result in double the output, compared to a 2-spindle production with 4 clamped workpieces. In the relationship between the primary machining time and the overall cycle time of the process, the actual output will usually increase by 60% to 70% by adding 2 more spindles. Individual exceptions with short time-consuming machining operations can reflect an increase of more then 80%, according to STAMA research.

While twin spindle machining needs to double the capacity of the tool magazine, the four spindle solution requires a tool magazine to handle four times as many tools. The STAMA MC 531/TWIN² is equipped with 56 tool places in the standard version, for example, with options for magazines up to 120 tools.

One major key in four spindle machining, with short tool-to-part contact times, is the load and unload sequences of the workpieces. In such cases, as long as the machine isn’t equipped with a quick automatic loading/unloading system, pendulum machining is more advisable. This ensures parallel machining time while loading new workpieces. Time for loading and unloading can then be as long as the actual cycle time of the machine. This will also result in less time when the operator is interacting with the machine, thereby allowing the operator to run multiple stations in a work cell set-up, while keeping a constant touch time protocol on each machine.

Under these conditions, for many workpieces studied by STAMA and its customers, the “4 Plus 4” solution can result in major cost per part reduction. With over 25 years’ experience in TWIN spindle technology, the simplicity of a common Z-headstock for twin spindles from STAMA is well accepted and proven technology worldwide. The simplicity of this system is also used throughout this new TWIN² technology. Incorporating a state-of-the-art tool presetter, even single spindle manufacturing challenges with high accuracy demands can be realized with multi-spindle technology. The outstanding productivity and high workpiece quality achievable are the benchmarks by which STAMA TWIN spindle centers are known. The expansion to this 4-spindle TWIN2 machining center technology is the logical consequence of the company’s latest research and machine development strategies.

Already in full production use at a STAMA customer in one of the BRIC markets is a new four-spindle TWIN2 machining center, currently doing ABS housing manufacturing and connecting rod machining. This success for STAMA evidences the simplicity and practical application of the company’s highly productive manufacturing equipment.

Excellence in Manufacturing…the keystone of STAMA

STAMA America is the U.S. subsidiary of STAMA Maschinenfabrik GmbH in Germany.

For more information or to arrange a demonstration, please contact:

STAMA America 1063 Hawthorne Drive Itasca, IL 60143 Phone: (630) 233-8101 www.stama-america.com simon.knecht@stama-america.com

Simon Knecht, Director of Sales

PR agency contact: Tim Daro Bernard & Company 847-934-4500 tdaro@bernardandcompany.com

Continue readingCHICAGO, IMTS — At this year’s International Manufacturing Technology Show (IMTS) in Chicago, Siemens will introduce new solutions and services for machine tool manufacturers and end-users. Under the theme, “Productivity in motion,” the presentation will focus on turnkey solutions for the job shop, aerospace, automotive, mold and die and medical manufacturing industries.

For machine tool builders and end-users, Siemens will exhibit the newest innovations in CNC (computer numerical control), motor and drive technology as well as new value-added services ranging from condition monitoring and manufacturing IT to innovative solutions for CNC training and machine tool retrofit.

SOLUTIONS FOR THE JOB SHOP

For the job shop, the new Sinumerik 828D numerical control will be presented for the first time in the United States. Perfect for mid-range machine tools, the Sinumerik 828D is designed to address the needs of complex milling and turning machines in the job shop segment. It combines CNC, PLC, operator panel and axis control for six CNC measurement circuits in a single, robust operator panel.

The Sinumerik 828D is capable of full graphical, high-level language command and supports ISO programming that is customary in the United States. The new control is ideal for single-part and small-batch production. Programming time can be further reduced for small-batch production with the use of the ShopMill and ShopTurn graphical workstep programming system, while high-level language programming can be used in conjunction with programGuide to significantly reduce programming times for large-scale serial production.

With the introduction of the Sinumerik 828D, modern PC and mobile phone technology is now available to the mid-range machine tool. Extensive online help animations and a new type of input prompting system with moving picture sequences provide the basis for exceptional user convenience. USB, Compact Flash (CF) card and Ethernet ports enable high-speed data transfers onto storage media or integration of the control system into corporate networks. Through the use of its Easy Message functionality, the Sinumerik 828D offers production status monitoring by text messaging (SMS). Depending on the recipient’s profile setting, the machine will transmit information about workpiece machining status, report on the tool condition currently in use and send machine maintenance bulletins to a mobile phone, anytime and anywhere. These combined functions are designed to help keep machine downtime to a minimum.

For the aerospace market, the new Sinumerik 840D solution line is the latest in CNC technology that increases performance and user productivity. The Sinumerik 840D sl is a universal and flexible CNC system featuring the innovative Sinamics S120 drives that can be used for up to 31 axes. It is a distributed, scalable, open and inter-connecting system offering a wide range of specialized functions for milling, drilling, turning, grinding and handling technologies.

The Sinumerik 840D offers users innovative features that increase productivity on the manufacturing floor, especially the challenging segments of high-speed and five-axis aerospace machining.

SOLUTIONS FOR AUTOMOTIVE

In the automotive industry, Siemens continues to solidify its position with the Transline System Solution, the solution for automotive powertrain. This system integrates diverse metalcutting technologies such as milling, drilling, turning and grinding, and the assembly of powertrain parts, under a common system architecture. Since its implementation in 1993 at the Mercedes Benz NVM engine plant in Bad Canstatt, Germany, Transline has grown to become a recognized standard of excellence in the United States among both OEMs and end-users.

Based on the new Sinumerik 840D solution line and Simatic PLC, the Transline solution line transforms the company’s concept of “productivity in motion” into a real world application for total factory automation. By specifying Transline, machine tool users benefit from faster start-up times, better equipment serviceability and increased productivity.

SOLUTIONS FOR MANUFACTURING EXCELLENCE

Condition Monitoring and Manufacturing IT are two value-added services that are continuing their introduction to the U.S. machine tool market.

Condition Monitoring is an internet-based service from Siemens that supports maintenance processes while simultaneously forming a platform for cross-company service and support between OEMs and machine operators. Services can be configured over secure Internet connections from anywhere in the world via a standard PC, an internet connection and a web browser.

Manufacturing IT solutions from Siemens provide software tools for fast, easy integration of machines in a production network, while ensuring that production planning, scheduling and execution is always problem-free and based on the very latest data.

An entire line of powerful software modules for production machines ensures optimum integration of the machines in the IT-environment and supports a wide range of different functionalities including:

SOLUTIONS FOR CNC TRAINING

SinuTrain, the Siemens package of CNC training software on CD-ROM, provides milling and turning machine operators with a high degree of practical hands-on experience, prior to using the CNCs on their actual machines. It is designed to run on Windows XP operating systems and is the optimal solution for machine tool control-identical simulation training.

With SinuTrain, actual NC programs are developed and simulated, using a direct connection to the company’s CAD systems to further speed the program generation protocol. In this way, machine tool operators not only learn the control language commands, but they also visualize part programs on a P

C screen that are identical to the actual machine screen. As a further benefit, programs generated through SinuTrain on the PC software can then be used on the machines.

Other exhibits on display in the Siemens booth include the new 1FK7 high-inertia and 1PH8 servomotors, integrated motor spindles, linear motors and direct-drive torque motors that contribute to the increase in machine performance. The exhibition will also focus on machine tool retrofit, field service, customer service, spare parts and repair, all of which support the machine tool manufacturer and end-user.

For product information and inquiries:

SIEMENS INDUSTRY, INC.

DRIVE TECHNOLOGIES

MOTION CONTROL

MACHINE TOOL BUSINESS

390 Kent Avenue

Elk Grove Village, IL 60007

Phone: 847-640-1595

Fax: 847-437-0784

Web: www.usa.siemens.com/cnc

Email: SiemensMTBUMarCom.sea@siemens.com

Attention: John Meyer, Manager, Marketing Communication

Follow us on Facebook: www.facebook.com/SiemensCNC or Twitter: www.twitter.com/siemens_cnc_us.

—

Siemens Industry Sector is the world’s leading supplier of innovative and environmentally friendly products, solutions and services for industrial customers. With end-to-end automation technology and industrial software, solid vertical-market expertise, and technology-based services, the sector enhances its customers’ productivity, efficiency and flexibility. With a global workforce of more than 100,000 employees, the Industry Sector comprises the Industry Automation, Drive Technologies and Customer Services Divisions as well as the Metals Technologies Business Unit. For more information, visit http://www.usa.siemens.com/industry.

The Siemens Drive Technologies Division is the world’s leading supplier of products, systems, applications, solutions and services for the entire drive train, with electrical and mechanical components. Drive Technologies serves all vertical markets in the production and process industries as well as the infrastructure/energy segment. With its products and solutions, the division enables its customers to achieve productivity, energy efficiency and reliability. For more information, visit http://www.usa.siemens.com/drivetechnologies.

Continue reading