Contact us today:

(847) 934-4500

tdaro@bernardandcompany.com

Contact us today:

(847) 934-4500

tdaro@bernardandcompany.com

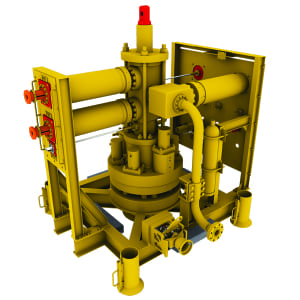

Argus Subsea uses hydraulic rod locks from AME to secure underwater oilfield trees at 5000-6000’ depths to 3000 psi and 50,000 pounds of axial holding

Argus Subsea produces its AZ-10 fully concentric, vertical mono-bore subsea tree design for rapid field development. Originally designed for low net present value (NPV), marginal and smaller fields, where the capital investment containment is critical and the need exists for off-the-shelf hardware, the AZ-10 can be run on any rig, regardless of moonpool size or accessibility through a V-door or port side. Essentially, according to Earl Broussard, the company’s director of sales & marketing, “Anywhere a rig can power a BOP, the AZ-10 can operate effectively. And, being a standard horizontal tree design with a universal tubing hanger system that runs in any 18-3/4”, 10,000 or 15,000 psi wellhead, with a concentric design for all downhole and tubing hanger-to-tree interface, it can be quickly put into service.” In fact, the company’s literature boasts a typical reduction in time to first oil of fifteen months, with lower CAPEX and OPEX costs, less drilling and wellhead completion cost, plus reduced third-party cost.

The AZ-10 is currently rated at 10,000 psi working pressure and 6000’ water depth and is designed to the standards of API 17D, API 6A, PR2, NACE MR0175 and AV1 PR-2 USV. The unit weighs approximately 50,000 pounds and is light enough to be handled safely with rig cranes and easily transported to the moonpool. The AZ-10 can be deployed through any Generation-2 semi-submersible or newer generation rig’s moon pool. A much simpler design than most horizontal or vertical trees, the AZ-10 requires only five running tools versus 20-30 typically found on comparable subsea tree systems. The units are designed for 20 years of service life in production, injection or well test operations.

AMLOK rod lock highlighted on tree. Each rod lock operates to 3000 psi and provides 50,000 pounds of axial holding force at depths of 5000-6000’. Special construction, porting and heat treatment were utilized in the manufacture of these devices.

The hanger system operates on a lock and seal system that uses mechanical and hydraulic sealing within the tubing hanger. A key component designed into the AZ-10 is the AMLOK® hydraulic rod lock, provided by Advanced Machine & Engineering (AME) of Rockford, Illinois, a designer and builder of various rod locks for both hydraulic and pneumatic holding, in the event of a power loss. AME rod locks are typically found on all types of off-highway and construction equipment, as well as materials handling devices, machine tools and elsewhere, used to secure a cylinder rod in place to prevent further motion.

For the application on the Argus Subsea trees, according to Shane Hatfield, AME sales manager, several challenges were apparent and a few were not. The obvious obstacles were the depth and the pressures involved. The maximum load was to be 3000 psi and the axial holding force approximately 50,000 pounds at typical depths in the 5000-6000’ range. To address these issues, AME engineered the rod locks from 4140 steel with electroless nickel plating and a specially formulated two-part epoxy to create a completely sealed unit. Marine grade lubricant was used. “Those were the easy parts,” muses Hatfield.

With the external sealing system of the AZ-10 and the wide variety of connections involved, the construction of the rod lock also needed to accommodate the unique challenges of force over distance in a wide window of installation conditions. Since the customer was very cost-sensitive, it was necessary for AME engineers to create a one-size-works-for-all unit and this presented considerable application engineering challenges. “This was the hard part,” recalls Hatfield.

Working with Chance Burton, the driving force behind the original engineering effort at Azura, the predecessor company to Argus, Hatfield and his team demonstrated AMLOK rod locks as the only design that worked immediately over the entire range of performance scenarios. 1500 psi release and 3000 psi compressive were needed to satisfy all conditions and the AME engineers successfully satisfied these criteria. Key factors in the success of the AMLOK design here are the special porting and autoclave treatment used.

After an initial order of 10 units (2-4 used per tree), the business has remained steady, according to Hatfield. These rod locks have been used successfully on numerous installations of the AZ-10, where the connections to numerous wellhead equipment brands have varied considerably.

As the attached diagrams demonstrate, AME rod locks are actuated by a spring/collet mechanism upon loss of hydraulic power and unclamped by the restored pressure. They are built to accomplish a mechanical locking, holding a cylinder rod or machine shaft in position, up to the rated load, until power is restored and the locking mechanism released.

For more information on the subsea trees referenced in this story, please contact:

ARGUS SUBSEA 5510 Clara Road Houston, TX 77041 Phone: 713-983-7222 Fax: 713-983-7007 Email: info@argussubsea.com Web: www.argussubsea.com Attention: Earl Broussard, Director of Sales & Marketing

For more information on the rod locks referenced in this story, please contact:

Shane Hatfield, Sales Manager

ADVANCED MACHINE & ENGINEERING CO.

2500 Latham Street Rockford, IL 61103

Toll-Free: 800-225-4263

Phone: 815-962-6076

Fax: 815-962-6483

Email: shane@ame.com

Web: www.ame.com

AME-Advanced Machine & Engineering Co., is a manufacturer located in Rockford, Ill., serving the Machine Tool Industry with precision components and accessories, including spindle interface components, workholding devices and, through our sister company, Hennig, machine enclosures, chip removal and filtration systems. The Fluid Power – Safety markets are served with cylinder rod locks and Safety Catcher devices; and the Production Saw market with our AmSaw carbide saw machines and Speedcut blade products. AME has manufacturing partners and service centers around the world and across the U.S. To learn more, visit www.ame.com.

Hennig, Inc. designs and produces custom machine protection and chip/coolant management products for state-of-the-art machine tools. Hennig products are designed to protect against corrosion, debris and common workplace contaminants. Manufacturing facilities are located in the U.S., Germany, France, Czech Republic, Brazil, India, Japan, China and South Korea. Repair centers are located in Machesney Park, IL; Chandler, OK; Livonia, MI; Blue Ash, OH; Mexico City, Mexico; and Saltillo, Mexico. To learn more, visit www.hennigworldwide.com.

Please direct all inquiries from this article to:

Tim Waterman

ADVANCED MACHINE & ENGINEERING CO.

2500 Latham St.

Rockford, IL 61103

Phone: 815-316-5277

Fax: 815-962-6483

E-mail: info@ame.com

Connect with AME online:

Global leader in carbide sawing systems acquired by leading machine tool component and carbide saw machine manufacturer

Advanced Machine & Engineering (AME), the Rockford, Illinois-based manufacturer of various machine tool components and auxiliary equipment, today announced the asset purchase of the Metalcut Carbide Saw Division of Centro-Metalcut, also of Rockford and a longtime global industry leader in the design and manufacture of heavy-duty carbide sawing systems for the metalcutting industries.

AME is also a leading global manufacturer of carbide sawing systems, under its popular AMSAW® brand name. AMSAW systems are found in forge, metalcasting, service center and primary producer operations, anywhere large or continuous sawing is performed. The acquisition of the Metalcut carbide saw line represents a substantial expansion of the company’s capabilities in the world market.

This purchase will transfer the complete sawing machine technologies, engineering data, inventory, spare parts and service operations for all Metalcut carbide saws to AME. Steve Swanson, the business unit manager for the carbide saw machine division of AME, will assume oversight responsibility for the Metalcut product line, allowing a seamless transition for all existing customers and immediate access to the Metalcut carbide saw line for all new AME accounts. AME has worldwide sales and service locations already in place to accommodate all customer requirements, according to Greg Champion, vice president of sales & marketing for the company.

Centro-Metalcut will continue to manufacture and market all other product lines in its offering, including hot and cold abrasive saws, conditioning grinders and materials handling equipment.

Dietmar Goellner, AME president and CEO, and Danny Pearse, CEO of Centro-Metalcut, agreed to the purchase terms on September 24, 2010.

For more information, please contact:

Tim Waterman

ADVANCED MACHINE & ENGINEERING CO.

2500 Latham St.

Rockford, IL 61103

Phone: 815-316-5277

Fax: 815-962-6483

E-mail: info@ame.com

Connect with AME online:

Advanced Machine & Engineering Co., is a manufacturer located in Rockford, Ill., serving the Machine Tool Industry with precision components and accessories, including spindle interface components, workholding devices, and, through our sister company, Hennig, machine enclosures, chip removal and filtration systems. The Fluid Power – Safety markets are served with cylinder rod locks and safety catcher devices; and the Production Saw market with our AmSaw carbide saw machines and Speedcut blade products. AME has manufacturing partners and customers around the world and across the U.S. To learn more, visit www.ame.com.

Hennig, Inc. designs and produces custom machine protection and chip/coolant management products for state-of-the-art machine tools. Hennig products are designed to protect against corrosion, debris and common workplace contaminants. Manufacturing facilities are located in the U.S., Germany, France, Czech Republic, Brazil, India, Japan, China and South Korea. Repair centers are located in Machesney Park, IL; Chandler, OK; Livonia, MI; Blue Ash, OH; Mexico City, Mexico; and Saltillo, Mexico. To learn more, visit www.hennigworldwide.com.

Continue reading

At a time when the media are constantly touting the imminent demise of American manufacturing, there are numerous suppliers to one of this country’s greatest and most universally sought after technological achievements who might challenge that notion. In fact, they just might debunk it with extreme prejudice. These are the suppliers to the Undulator System on the Linac Coherent Light Source (LCLS) project, recently completed at Argonne National Laboratory (ANL) and supplied as an extension of the SLAC National Accelerator Laboratory in California.

On Friday, September 3, at ANL in Lemont, Illinois, several vendors to this project were acknowledged for their roles, during a presentation made by various key individuals in the project’s start-up and ongoing development. One of these vendors is M-1 Tool Works of McHenry, Illinois, who supplied a variety of machined metal components and assemblies used in the focusing operation on the light beams that create ultra-bright, ultra-short x-ray pulses from a high-energy electron beam. These x-ray pulses are a billion times brighter than the most powerful light source known and are used to capture images of molecules and detail their actions within an atomic structure. The first beam was generated in April, 2009 and the undulator was installed and fully functioning in the Spring of 2010.

Users of this new American technology from every continent are already lining up at SLAC to apply it for the investigation of atoms on various mechanical structures, raw materials, pharmaceuticals, industrial chemicals, military ordnance, space exploration hardware and hundreds of other products. Commercial, institutional, educational, governmental and advanced research concerns are all requesting use of this technology, according to the directors of the project.

M-1 Tool Works, a longtime supplier of precision components to such diverse fields as the aerospace industry, defense, medical, high tech, close tolerance and high reliability commercial industries, had previously done work for Fermilab and Lawrence Livermore National Laboratory. They were called upon by ANL to produce 36 assemblies, each comprising a central assembly and various close tolerance components. The materials used included tool steel, stainless steel, aluminum and specially annealed oxygen-free copper for the particular densities and electrical properties required on this application.

Functionally, the highly collimated electron beam travels through the undulator, where its motion is modified by a series of alternating magnets to create radiation saturation and the coherent alignment structure of the beam. This occurs in a two-mile section of the linear accelerator. First light was generated in April, 2009, light to the instrument was achieved in August of that year and the project was completed for commercial utilization in the summer of 2010. This $415 million project was completed by ANL on time and under budget.

Overall, the undulator section measures 433’ and runs in a 600’ section of the tunnel at SLAC. All the assemblies were built and tested at ANL in Illinois, then transported for assembly and final commissioning at Stanford. A Beam Position Monitor checks the dimension and orientation of the beam to sub-micron levels of accuracy.

For further information on this story, please contact:

M-1 TOOL WORKS INC.

1419 S. Belden Ave.

McHenry, IL 60050-8399

Phone: 815-344-1275

Fax: 815-344-1950

Web: www.m1toolworks.com

Email: ray.lindberg@m1toolworks.com

Attention: Ray Lindberg, Sales Manager

Agency contact:

Tim Daro

Bernard & Company

847-934-4500

tdaro@bernardandcompany.com

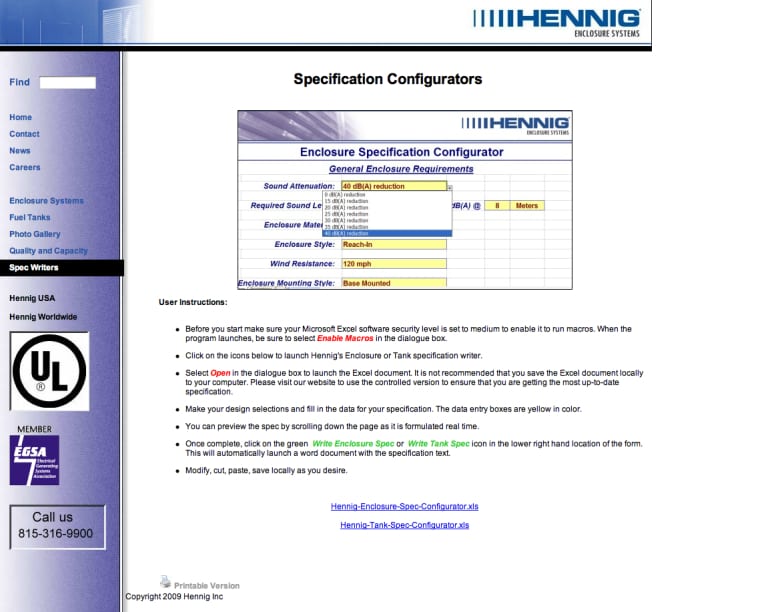

Saves time, money and engineering through series of online selections; makes spec writing much easier

All performance and dimensional requirements are menu-selected, along with all electric, HVAC, exhaust system, roof, door and materials of construction on the enclosure. Likewise, for the sub-base diesel fuel tank, all size and accessory specs are selectable on a downloadable .xls menu for easy completion. Upon completion of the selections, a .doc is generated for the enclosure spec and another for the fuel tank.

“Through this system, the Hennig enclosure and fuel tank are precisely matched to the generator and the particular conditions of the installation. No settling for less and no need to make a standard product ‘fit’ the requirement. It really is a useful time and money saving tool,” says Robin Moore, the Hennig vice-president for engineering and operations.

Hennig manufactures all enclosures and fuel tanks in its Rockford, Illinois facility, located approximately 90 miles northwest of Chicago. Here, experienced power gen engineers work in concert with the company’s vertically integrated metalworking, fabricating, finishing and test departments to ensure the highest quality and reliable construction of the enclosures and fuel tanks to suit the specification mandated by customers. Hennig then ships the finished units to the construction site, power gen subcontractor or other location with full guarantees of satisfaction, backed by the company’s service and after-sale assistance team.

Hennig currently builds enclosures and fuel tanks to be compatible with CAT, Cummins, Detroit Diesel (MTU Onsite Energy), Kohler and all other leading brands of power generators. The company also works with the power gen distributors, plus design/engineering firms, consulting engineering firms and all levels of the building contractor community. Spec writers at all these types of companies can utilize the new Hennig configurator to save time, money and engineering effort in the construction of gensets.

To learn more about Hennig Enclosure Systems, visit www.hennigenclosuresystems.com or contact:

Tim Waterman

Hennig Inc.

9900 N. Alpine Rd.

Machesney Park, IL 61115

(815) 316-5277

info@hennig.ame.com

www.hennigworldwide.com

—

Hennig, Inc., at www.hennigworldwide.com, has been designing and producing custom machine protection and chip/coolant management products for state-of-the-art machine tools for over 50 years. Hennig products are designed to protect against corrosion, debris and common workplace contaminants. Hennig has manufacturing facilities in the U.S., Germany, Czech Republic, France, Brazil, India, Japan, China and South Korea. Its North American repair centers are located in Machesney Park, Ill.; Chandler, Okla.; Livonia, Mich.; Blue Ash, Ohio; Mexico City, Mexico; and Saltillo, Mexico.

Continue reading

Han-Kwang USA announces immediate availability of its new Series PS, specifically Model PS 3015, a short gantry, 2D flying optic laser system capable of handling 60” wide x 120” long workpieces. With the short gantry arrangement, operator vision is enhanced on the machine, plus the more compact design facilitates a high degree of regulation in the cutting process.

Model PS 3015 features rapid single axis speed of 4724 ipm, simultaneous X-Y axis speed of 7900 ipm, driven by twin servos on the gantry and maximum cutting speed of 1181 ipm, all with positioning accuracies better than +/- 0.004” per 118” of travel and repeatability to 0.001”. A dual shuttle pallet system is onboard to maintain optimum productivity in processing.

This Han-Kwang laser system features a powerful Panasonic CO2 laser resonator in 2.5, 4 and 6 KW versions, as well as the builder’s patented beam radius control, which optimizes the beam diameter for various material substrates and thickness variations,

A plasma monitoring unit constantly tracks cut errors to further reduce out-of-tolerance conditions in the cutting cycle, while a built-in lens crack sensor monitors the state of lens contamination, with instant alerts through the onboard Siemens CNC to provide operators and maintenance personnel useful and immediate alarm notifications.

All machine mechanical movements and laser cutting operations are controlled by the powerful Siemens SINUMERIK 840D CNC. With its open architecture, 10GB hard drive and plain language commands, the CNC enables faster start-up and reduced time to first part for the programmers and operators alike. Further, a remote service support feature allows online communication to the CNC manufacturer for troubleshooting assistance.

For more information, the name of a local Han-Kwang dealer or to arrange a demonstration, please contact:

HAN-KWANG USA INC. 1120 Garfield Street Lombard, IL 60148 Phone: 630-916-0200 Fax: 630-916-0300 Web: www.hankwangus.com Email: salesusa@hankwang.co.kr Attention: Robert Won or Erik Kim

Editor note: Robert Won, director for North American operations, is available for interviews to discuss the company, its laser technology and other aspects of the industry. Han-Kwang is Korea’s largest laser builder and the company has embarked on an aggressive marketing effort in North America.

Continue reading

The unit has 7” thick insulated walls, comprising 5” of 2300°F ceramic fiber and 2” of block insulation. The 7” floor insulation contains 4 1/2” of 2300°F firebrick and 2-1/2” of block insulation.

Controls onboard No. 862 include an automatic door switch to drive burners to low fire when the door is opened and an air-operated vertical lift door. All safety equipment required by the IRI, FM and the National Fire Protection Association Standard 86 for gas-heated furnaces is also included.

For more information, please contact:

THE GRIEVE CORPORATION

500 Hart Road

Round Lake, IL 60073-2898

Phone: (847) 546-8225

Fax: (847) 546-9210

Web: www.grievecorp.com

Email: sales@grievecorp.com

Attention: Frank Calabrese, VP

AerOpak® cable for myriad temperature measurement and signal-sending applications in harsh environments; wide assortment of sizes and sheath materials available for immediate shipment

ARi Industries, Inc., a longtime market leader in temperature measurement, announces immediate availability of its AerOpak mineral-insulated (MI) thermocouple cable in an expanded assortment of sizes and sheath materials. MI cable offers thermocouple fabricators, instruments designers, process engineers and various equipment builders a unique solution to the challenges of temperature measurement and electrical signal-sending in harsh, corrosive and other hazardous environments.

Offered as thermocouple and conductor cable, AerOpak products comprise thermocouple or conductor wires insulated with compacted ceramic powder, drawn and encased in a seamless metallic sheath material. Standard thermocouple or conductor cables up to 10-wire configurations are available in various stainless steel, Hastelloy and Inconel sheath materials in OD sizes ranging from 0.020” to 0.750” diameter. Cable can be supplied for temperatures up to metal melt points of 2600ºF and over 1000 ft. in length, making these products suitable for all types of process operations and very large equipment. Owing to the strict manufacturing and production standards of ARi, MI cable signal integrity is consistent over the longest length applications.

Thermocouple cables in Types K, E, J, T, N, R, S, and B are stocked in calibration tolerances to meet all applicable ASTM, IEC and ANSI standards.

MI cable from ARi can be welded, brazed or soldered in the field, relative to the application and techniques used. Please consult the manufacturer for details or installation assistance. Custom wire configurations, other sheath materials and assorted insulation ingredients are also available on request, to suit virtually all applications.

For full details and specifications on this line of products, please request Bulletin 4.0.

For more information, please contact: ARi Industries, Inc. 381 ARi Court Addison, IL 60101 Toll-Free: 800-237-6725 Phone: 630-953-9100 Fax: 630-953-0590 Web: www.ariindustries.com

Email: sales@ariindustries.com

ARi Industries, Inc. is a division of Okazaki Manufacturing Company (Japan).

ARi Industries is a manufacturer of mineral-insulated wire and cable, thermocouples, RTD’s, thermowells and temperature transmitters, as well as conductor cable assemblies, neutron detectors, electric heating elements of various types and related hardware. The company is ISO-9001-2000 Certified and performs X-ray inspection, helium leak testing, temperature calibration traceable to NIST and other analytical services. The company is a worldwide supplier to instrument, power generation, aircraft and other equipment builders, as well as all process industries, serving the most demanding environments.

Continue reading

Han-Kwang USA recently attended the Fabtech Mexico show, co-located with the Metalform and Weldmex shows. Over 8000 visitors per day were in attendance to see over 400 exhibitors and hundreds visited the Han-Kwang booth to watch the company’s plate laser, Model FS3015, in action. Onsite for this exhibition were Han-Kwang’s director of North American sales, Robert Won, as well as engineer Philip Kim and the company’s distributors in Mexico.

Mr. Won commented, “The Mexican market has been excellent for Han-Kwang. We’re assisted by a very strong distributor, who has an extensive sales and service network to cover the entire region with us. Our sales recently have been quite strong, because of the quality of our machines and the quality of our representation in Mexico. I believe this will continue to be a very good market for our plate and tube lasers into the future.”

The FS3015 is a 5’ x 10’ plate laser with shuttle tables, flying optic design, fast-axial flow type Panasonic resonator, S5 high-speed cutting head, twin servos for precise gantry motion and Siemens CNC, motors and drives to power and control the machine’s total operation. This plate laser is available in 2, 2.5, 4 and 6KW models to handle any type of plate cutting with speed and precision position accuracy to +/- 0.004” per 120” of travel. The machine also has automatic focus control with multi-pulse piercing technology, unique to Han-Kwang.

This machine was specifically chosen for display at the booth during Fabtech Mexico, because of its performance and value combination for the local market.

Han-Kwang enjoyed a very successful exhibition at Fabtech Mexico, held May 11-13

For more information or to arrange a visit to Han-Kwang for a demonstration, please contact:

HAN-KWANG USA INC. 1120 Garfield Street Lombard, IL 60148 Phone: 630-916-0200 Fax: 630-916-0300 Web: www.hankwangus.com Email: salesusa@hankwang.co.kr Attention: Robert Won, Eric Kim or Jane Lee

Agency contact: Tim Daro Bernard & Company tdaro@bernardandcompany.com 847-934-4500

Continue reading

Advanced Machine & Engineering Co. (AME) Rockford, IL announces their return to IMTS 2010. As in the past, they will have two booths to showcase their products and services.

Visit Booth W-2405 to learn about precision machine components, featuring:

Visit Booth E-5708, for additional AME products such as:

Our sister company, Hennig, Inc., will have their complete line of products in Booth E-5708 and W-2405.

Visit Booth N-7216 to learn about carbide sawing systems, featuring:

Advanced Machine & Engineering Co., is a manufacturer located in Rockford, IL, serving the Machine Tool Industry with precision components and accessories, including spindle interface components, workholding devices, and, through our sister company, Hennig, machine enclosures, chip removal and filtration systems. The Fluid Power – Safety markets are served with cylinder rod locks and safety catcher devises; and the Production Saw market with our Amsaw carbide saw machines and Speedcut blade products. AME has manufacturing partners and customers around the world and across the U.S. To learn more, visit www.ame.com.

Hennig, Inc. design and produces custom machine protection and chip/coolant management products for state-of-the-art machine tools. Hennig products are designed to protect against corrosion, debris and common workplace contaminants. Manufacturing facilities located in the U.S., Germany, Brazil, India, Japan, China and South Korea. Repair centers are located in Machesney Park, IL; Chandler, OK; Livonia, MI; Blue Ash, OH; Mexico City, Mexico and Saltillo, Mexico. To learn more, visit www.hennigworldwide.com.

For more information, contact:

Tim Waterman

ADVANCED MACHINE & ENGINEERING CO.

2500 Latham St.

Rockford, IL 61103

Phone: 815-316-5277

Fax: 815-962-6483

E-mail: info@ame.com

Connect with AME online:

Advanced Machine & Engineering Co. (AME) Rockford, IL announces their participation in IMTS 2010.

Visit the pioneers of carbide sawing systems in North America at Booth N-7216, featuring: Amsaw high-speed production sawing machines for billets, tubes, rails and more Speedcut carbide saw blades.

Amsaw systems are specifically designed for faster cutting speeds, longer tool life and enhanced precision of carbide saw technology. Amsaw systems use carbide-or cermet-tipped blades to provide fast, accurate cutting for ferrous and non-ferrous materials, bars or billets, rails, profiles, pipes and tubes.

AME custom machine services include complete design and build services to go along with Amsaw sawing systems, blades and machine rebuilding services.

Speedcut sells and services saw blades with a variety of styles and tooth configurations. New carbide, cermet and thin-kerf blades are available along with complete in-house facilities for sharpening, re-tipping and repairing older blades. Virtually any size blade can be fully reconditioned, so it’s ready to cut ferrous and non-ferrous materials, bars or billets, rails profiles, pipes and tubes.

Speedcut can build and service blades as large as 80 inches in diameter, so whatever your application, you can make sure your blades are always sharp and ready for the rigors of high-speed, high-volume cutting.

See our other AME and Hennig group products in Booths E-5708 and W-2405.

Advanced Machine & Engineering Co., is a manufacturer located in Rockford, IL, serving the Machine Tool Industry with precision components and accessories, including spindle interface components, workholding devices, and, through our sister company, Hennig, machine enclosures, chip removal and filtration systems. The Fluid Power – Safety markets are served with cylinder rod locks and safety catcher devises; and the Production Saw market with our Amsaw carbide saw machines and Speedcut blade products. AME has manufacturing partners and customers around the world and across the U.S. To learn more, visit www.ame.com.

Hennig, Inc. design and produces custom machine protection and chip/coolant management products for state-of-the-art machine tools. Hennig products are designed to protect against corrosion, debris and common workplace contaminants. Manufacturing facilities located in the U.S., Germany, Brazil, India, Japan, China and South Korea. Repair centers are located in Machesney Park, IL; Chandler, OK; Livonia, MI; Blue Ash, OH; Mexico City, Mexico and Saltillo, Mexico. To learn more, visit www.hennigworldwide.com.

For more information, contact:

Tim Waterman

ADVANCED MACHINE & ENGINEERING CO.

2500 Latham St.

Rockford, IL 61103

Phone: 815-316-5277

Fax: 815-962-6483

E-mail: info@ame.com

Connect with AME online: