Contact us today:

(847) 934-4500

tdaro@bernardandcompany.com

Contact us today:

(847) 934-4500

tdaro@bernardandcompany.com

Ann Arbor, Michigan – American-Wera represents various top-quality German metalworking machine builders, including Profilator, Pittler, Praewema, Diskus, WMZ and MAE. These machines are sold for gear and spline production, as well as bar, pipe and tube straightening plus wheelset pressing. The company’s target markets include automotive, off-highway, OCTG, rail and other heavy equipment manufacturing.

-Caterpillar selects Pittler as manufacturing partner for new cylinder liner project; Peoria, IL location to use inverted spindle turning centers with 16 spindles for high production

-Linamar Mexico adds second Scudding machine from Profilator at Nuevo Laredo plant for use on Getrag Ford project; Scudding is a unique and patented form of gear and spline production from Profilator

-IMTS 2012-Our booth N6260 will include information on all our gearcutting machines and feature two MAE straightening presses in action…come and see the show!!

-We’re expanding our facility in Ann Arbor, Michigan-North American facility expands in floorspace and showroom capacity, with additional staff to be added soon; full application engineering assistance, sales, service and training offered for our customers and field sales representatives

For more information on this announcement, please contact:

GMTA (German Machine Tools of America) Formerly American Wera

4630 Freedom Drive

Ann Arbor, MI 48108

Phone: 734-973-7800

Fax: 734-973-3053

Web: www.gmtamerica.com

Email: scott@gmtamerica.com

Attention: Scott Knoy

Facebook: GMTA

Twitter: @GMTA_US

This Grieve high-temp, inert atmosphere oven features 10” insulated walls, comprising 2” of 1900ºF block and 8” of 10lb/cf density rockwool, aluminized steel exterior, Type 304, 2B finish stainless steel interior, plus inner and outer door gaskets. The inner gasket seals directly against the door plug, while the outer gasket seals directly against the front face of the oven. An integral oven leg stand is also provided.

Inert atmosphere construction on this Grieve oven includes pressure gauge, internal high-temperature gasket, all-welded construction in the doorway throat, air jacket on inner oven for cooling, ½” thick cellular silicone rubber atmosphere seal, blower shaft seal, positive latching door hardware, adjustable offset door hinges, outlet with pressure relief, interior seams welded gas-tight and all wall penetrations fitted with compression fittings. A 650 CFM stainless steel blower pulls air through the air jacket on the inner oven for cooling.

Controls on No. 966 include a digital programming temperature controller, manual reset excess temperature controller with separate contactors and recirculating blower airflow safety switch.

For more information, please contact: THE GRIEVE CORPORATION, 500 Hart

Road, Round Lake, Illinois 60073-2835 USA. Phone: (847) 546-8225. Fax: (847) 546-

9210. Web: www.grievecorp.com. Email: sales@grievecorp.com. Attention: Frank

Calabrese.

Continue readingLeading supplier of electro-chemical technologies introducing new machines for aero, auto, medical and nano markets

Farmington Hill, Michigan – EMAG L.L.C. here today announces the introduction of its ECM and PECM machines to the North American market. As a longtime European leader in these technologies, the company will sell and support these machines with application engineering, field commissioning and technical service from its Detroit-area location.

Electro-chemical machining takes many forms, but all involve the electrolytic dissolving of metal substrates. This technique is often utilized in applications involving hard-to-machine materials such as Inconel, high-nickel alloys, titanium etc.

Because ECM is a non-contact machining process with no heat input involved, the process is not subject to the variances inherent in conventional machining, such as tool wear, mechanical stress, microcracking caused by heat transfer, plus surface oxidation and recast layer present with EDM (electrical discharge machining), for example. By contrast, the ECM process is characterized by stress-free stock removal, smooth and precise transitions in machining contours with burr-free surfaces. End products from turbine blisks to dental implants and automotive industry products are ideal uses for this technology, according to Tobias Trautmann, product manager for ECM/PECM Products at EMAG ECM.

The many advantages of the EMAG ECM and PECM technologies for the end user include: low tool wear on the cathode, ideal for batch production; surface finishes to Ra 0.05, depending on the material, suitable for high precision pro

duction in nearly all machining areas; reproducible cutting depth to <20mm; extremely high-precision machining; no negative thermal or mechanical effects on the material, so no changes in microstructures; basic material properties are unaffected; hardness, magnetic and other performance properties are unchanged; nano and extremely thin-walled section contours are possible, critical in aero and medical applications, for example; high repeatability, owing to the consistency of the mechanical components and predictability of the machining conditions; minimal secondary operations; roughing, finishing and polishing in one machine. The process allows users to employ multiple fixtures and run the process simultaneously.

Standard features offered on the EMAG ECM Basic Series machines are a Siemens S7 controller with full graphics display, current relay and voltage monitor, pH control and conductance monitor, temperature control module, machining area of 1150mm x 950mm (45.27” x 37.40”) and two-handed operator safety controls. EMAG also provides ancillary equipment interfacing for work cell set-ups, including pre- and post-op cleaning stations and multiple machining units, as well as robotic workpiece handling.

Precise Electrochemical Machining (PECM) machines operate on the same basic principle of electrolytic dissolution, but include a mechanical oscillation mechanism for more intricate 2D and 3D microstructures. All standard machines include EMAG scalable generator technology up to 30,000 Amps, pulse frequencies to 100 kHz and a machine base of MINERALIT® or granite.

The Premium Series further offers precision imaging, surface finishes up to Ra 0.05 (relative to the material) and a high degree of precision in lowering speeds, essential for micromachining.

Complementing this new machine series is the EMAG test laboratory. Users can examine a variety of test cut scenarios to determine the optimum conditions for machining, fixturing, process performance and materials specification, matching the requirements to the most productive machines and systems available.

For more information:

EMAG LLC

38800 Grand River Avenue

Farmington Hills, MI 48335

Tel: (248) 875-0313

Fax: (248) 477-7784

E-mail: info@usa.emag.com

Web: www.emag.com

Attention: Peter Loetzner

Continue readingLeading supplier of machine tools partners with Oakland Community College; $200,000 agreement from Michigan New Jobs Training program to create 21 new jobs

EMAG president Peter Loetzner addresses a gathering during the Oakland County (MI) Economic Outlook Luncheon, April 26, 2012

Farmington Hills, Michigan – EMAG L.L.C. announces its receipt of a five-year, $200,000 agreement with Oakland Community College (OCC), through the Michigan New Jobs Training (MNJT) program, for the training of 21 new employees in manufacturing technology, CNC machine tools, mechanical maintenance, electrical and robotics disciplines.

Peter Loetzner, EMAG CEO, accepted the award from Dr. Timothy Meyer, chancellor of Oakland Community College, and J. Brooks Patterson, Oakland County Executive, during the Oakland County Economic Outlook Luncheon, held at the Troy Marriott on April 26, 2012.

Beginning the speeches at the event, OCC Chancellor, Dr. Timothy Meyer noted the critical importance of education and training in the creation and retention of manufacturing jobs in Southeastern Michigan, an area hard hit by the recent economic downturn in the auto industry and other manufacturing sectors of the economy. He then introduced Oakland County Executive J. Brooks Patterson, who continued this theme, citing the recent creation of 36,000 new jobs in Oakland County as well as other awards made to companies who’ve chosen to locate in the area.

Introducing Peter Loetzner, Meyer then detailed the collaboration between OCC and EMAG, noting how the study of mechatronics would raise the skill level of both engineers and the plant workforce to higher levels of technical competence and multi-functional abilities.

Oakland Community College Chancellor Tim Meyer announces the award of $200,000 in Michigan New Jobs Training to EMAG; 21 new employees will be trained in manufacturing at the EMAG facility in Farmington Hills, near Detroit

During his remarks, Loetzner recounted his own experience as a student in this now rapidly growing field of mechatronics, where mechanical engineering melds with electrical and electronic engineering to help students better understand the inter-relationship of components on a machine. Mechatronic engineers and field technicians are now highly valued individuals in many industries, Loetzner noted. He added that EMAG will have at least 20 openings in engineering throughout the next few years at his company, the result of increased sales and the EMAG commitment to serving the North American market from its expanding headquarters in the Detroit area. He further commented how such programs have the dual advantages of growing the manufacturing base in the area, as well as raising the skill level of the employees, which in turn attracts more businesses to Oakland County.

EMAG has engaged in training for its employees as well as its customers’ programming, operator and maintenance personnel throughout the company’s history, both in Germany and in America. The company sells its machines to job shops and original equipment manufacturers’ metalworking departments worldwide, with a heavy concentration in the automotive and off-highway machinery markets.

Loetzner thanked the OCC and Oakland County personnel who helped develop this program, especially Meyer, Patterson and Sharon Miller, the vice chancellor of external affairs at OCC. He concluded his remarks on a humorous note, “As we say in mechatronics, keep thinking INSIDE the box.”

L. Brooks Patterson, Oakland County (MI) Executive congratulates Peter Loetzner of EMAG on the award

Sharon Miller next spoke at the event, citing the creation of five new jobs programs in the last year, awarded to companies ranging from the start-up mode such as Oxus, a portable oxygen equipment distributor for the medical industry, to the multi-national truck parts supplier Meritor, who added 63 employees in Troy, Michigan as a result of the MNJT program.

Dr. Meyer concluded the speaking with several observations on the nature of education. He cited the need for institutions to be more proactive in redesigning their curriculum to better suit the needs of the local manufacturing base, plus the need to partner with more companies in the area, as well as community organizations. “After all,” he concluded, “community is our middle name!”

EMAG equipment covers the entire spectrum of machining processes in the metalworking industry, offering the latest technological advances in turning, drilling, milling, grinding, gear cutting, electrochemical machining and laser welding for the automotive, oil field, power generation and earth moving equipment industries. EMAG is a trendsetter in the field of vertical turning centers, multi-spindle machining centers and multi-functional production machines, and has become an important partner in the realization of complete process streams in the manufacture of automotive transmission, engine and chassis components.

Oakland Community College is the largest community college in Michigan, and the 21st largest in the nation. With five campuses throughout Oakland County, OCC offers degrees and certificates in more than 160 fields including university transfer degrees in business, science and the liberal arts, as well as workforce training and certificate programs. Approximately 750,000 students have enrolled at the college since it opened in 1965.

OCC also announced an award to Denso, one of the world’s largest suppliers of automotive components, totaling $2.6 million to support the creation of 169 jobs in e-learning, project management, leadership, quality and engineering at the company’s Southfield, Michigan facility.

For more information:

Kristal Kilgore

EMAG LLC

38800 Grand River Avenue

Farmington Hills, MI 48335

Tel: (248) 875-0313

Fax: (248) 477-7784

E-mail: kkilgore@emag.com

Web: www.emag.com

Major German supplier joins with new master distributor for North America; variety of presses to be marketed to iron & steel industry sectors

Ann Arbor, Michigan – During the upcoming AISTech show, May 7-10 in Atlanta, MAE Maschinen-und Apparatebau Götzen GmbH (Erkrath, Germany) will display its various press technologies for the iron and steel industry and related business sectors in Booth 1536. MAE recently announced its formation of a partnership with American Wera here for representation throughout North America.

Built on three pillars: The MAE product portfolio

In the last decades, MAE has developed increasingly from a manufacturer of standard hydraulic presses to specialists for select niche markets. The company has established a leading market position with innovative products in the fields of straightening machines, hydraulic presses and assembly machines, serving metals producers, rail, heavy equipment, energy and marine markets.

Straightening– MAE has the broadest portfolio of manual and automatically controlled straightening machines for handling round, profiled and complexly shaped workpieces available worldwide. Press forces from 15 to 25,000 kN make it possible to straighten workpieces with lengths from 40 mm to 30 m and weights from 5 g to 20 tons. Straightening accuracy to 0.01 mm is possible. In addition to the conventional bending-straightening method, MAE also offers peening-straightening for through-hardened workpieces and torsion-straightening for twisted section bars. The MAE straightening controller for the manual straightening presses in the S-RH and P-H RH Series guarantees precise and repeatable metalworking and does not necessitate specially trained operators. Measurement and straightening in one setting ensures optimal cycle times. The M-AH, ASV and ASRU Series enable automatic straightening of small, large and complex shaped workpieces. The software of the RICOS straightening controller is the result of decades of experience with various applications. Innovative MAE design ideas are further making the straightening process increasingly more powerful and faster. Various interlinking concepts allow continuous operation with low manpower requirements.

Hydraulic presses – The broad range of hydraulic standard presses in the S and DS Series with C- and O-frames as well as the four-column presses in the VS Series are based on a modular system. By recombining and adapting the individual modules, MAE finds an inexpensive, individually optimized solution with press forces up to 25,000 kN for customer needs. Hydraulic presses are exposed to considerable stresses in daily use. With 60 years of experience, MAE has a reputation for sturdy dimensioning on all components. Comprehensive calculation software in design, including the finite-element method, is a further guarantee of exceptionally strong machine construction.

Assembly – Whether you want to assemble gear parts, rotor shafts or wheelsets, MAE offers many suitable solutions. The MAE machine Series S and M-S with hydraulic or mechanical servo drive are robust machines tailored to customer application. The OPUS controller with flexible software that can be modified to fulfill customer-specific requirements guarantees control and documentation of the entire assembly process. Our horizontally acting wheelset presses in the RADS Series with forces up to 8,000 kN are the industry choice for mounting and dismounting wheelsets from railway vehicles. They stand out primarily for their innovative underlying concept, rational interlinking systems and extensive control functions.

Service – An innovative and high-quality machine is only the basis for high customer satisfaction. Equally important for continuous duty with high availability are quick-response service from experienced technicians and spare parts available immediately from stock. North American installation and service is provided by American Wera service technicians in Ann Arbor, Michigan and Queretaro, Mexico. Additionally, with our optimally staffed service centers at our headquarters in Erkrath, Germany and Beijing, China, we are able to respond quickly worldwide. Telephone support and remote diagnostics onboard the machines usually allow MAE to correct minor problems without complication or onsite service. In partnership with American Wera, our North American master distributor, MAE seeks to continue as a powerful force in the industry.

During AISTech, the following individuals will be present to assist visitors:

Robert Singer, MAE Sales Manager for North America

Joseph Kemple, MAE Product Manager for North American distributor American Wera

For more information, please contact:

GMTA (German Machine Tools of America) Formerly AMERICAN WERA, Inc.

4630 Freedom Drive

Ann Arbor, MI 48108

Phone: 734-973-7800

Fax: 734-973-3053

Web: www.gmtamerica.com

Email: joseph@american-wera.com

Attention: Joseph Kemple, MAE Product Manager

Facebook: GMTA

Twitter: @GMTA_US

Tooling supplier expands headquarters, offers specific machine tool brand product lines, detailed in new full-specification catalogs

Heimatec, Inc., the North American operation for a world leader in live tools, angle heads and multi-spindle drill heads, today announces it has relocated to substantially larger headquarters near Chicago.

Heimatec will display a complete line of high-quality live tools for all major turning machine brands, as well as angle heads for milling applications, during the upcoming IMTS 2012 in Chicago. The company will feature its unique HT quick-change system and patented u-tec flexible machining system.

According to company president Preben Hansen, “We made this move to increase our inventory and our staff to better serve the growing ranks of our customers, both end users and distributors alike.” The new location is in Prospect Heights, Illinois, previously home to Heimatec.

It represents a 50% increase in the office and warehouse capacity for this growing supplier to the North American machine tool market. Hansen anticipates hiring new staff for the facility soon.

In related news, Heimatec has introduced complete lines of tooling, each designed for specific brands of machine tools, including the major builders of turning machines used in the North American market, such as Haas, Okuma, Mazak, Spinner, Miyano, Nakamura and others. This full-specification literature by machine brand is immediately available from the company in print and online pdf versions. Interested parties should contact the company. Heimatec also offers its new corporate capability brochure, in which all lines are presented.

For further information on this news release, please contact:

Preben Hansen, President

HEIMATEC INC.

16 E. Piper Lane Suite 129

Prospect Heights, IL 60070

Phone: 847-749-0633

Fax: 847-749-2445

Email: info@heimatecinc.com

Website: www.heimatecinc.com

—

Heimatec is an international tooling manufacturer, based in Renchen, Germany. Its experienced staff is dedicated to providing customers the most innovative tooling technology possible. In 2010, the company opened Heimatec Inc. in Prospect Heights, IL, near Chicago, to serve its growing North American customer base with sales and service, plus an extensive inventory of products. Heimatec serves the auto, aero, medical, off-highway, rail, energy, woodworking, composites and other industries, as well as an ever-increasing number of machine tool OEM’s worldwide.

Continue readingNo. 959 is a 300ºF, electrically-heated, vertical conveyor oven from Grieve, currently used for curing electronic parts at the customer’s facility. Workspace dimensions of this oven measure 36” W x 89” D x 115” H. 40KW are installed in Incoloy-sheathed tubular elements to heat the oven chamber, while a 6000 CFM, 5-HP recirculating blower provides vertical downward airflow to the workload.

This Grieve vertical conveyor oven features 4” insulated walls, aluminized steel interior and exterior, motor-operated vertical lift door at the loading/unloading opening and two (2) independent doors for access to the workspace. Twenty-seven (27) product carrier trays, each 30” wide by 14” long, supported at each side by a heavy-duty roller chain, driven by a ½-HP drive motor, controlled by a variable frequency drive, are also included.

Controls on No. 959 include a digital temperature controller, manual reset excess temperature controller with separate contactors, recirculating blower air flow safety switch, plus a tower light to indicate machine status. The oven is built to exacting JIC/NEMA 12 electrical standards.

For more information, please contact: THE GRIEVE CORPORATION, 500 Hart

Road, Round Lake, Illinois 60073-2835 USA. Phone: (847) 546-8225. Fax: (847) 546-

9210. Web: www.grievecorp.com. Email: sales@grievecorp.com. Attention: Frank

Calabrese.

Continue reading

Advanced Machine & Engineering Co. is the pioneer in carbide sawing and sawing technology, with over 40 years of manufacturing. They will be presenting:

Hennig, Inc. design and produces custom machine protection and chip/coolant management products for state-of-the-art machine tools. Hennig products are designed to protect against corrosion, debris and common workplace contaminants. Manufacturing facilities located in the U.S., Germany, Brazil, India, Japan, France and South Korea. Repair centers are located in Machesney Park, IL; Chandler, OK; Livonia, MI; Blue Ash, OH; Mexico City, Mexico and Saltillo, Mexico. To learn more, visit www.hennigworldwide.com.

For more information, contact:

Tim Waterman

ADVANCED MACHINE & ENGINEERING CO.

2500 Latham St.

Rockford, IL 61103

Phone: 815-316-5277

Fax: 815-962-6483

E-mail: info@ame.com

Connect with AME online:

No. 855 is a 1250ºF electrically-heated, inert atmosphere cabinet oven from Grieve, currently used for heat treating at the customer’s facility. Workspace dimensions on this oven measure 38” W x 26” D x 38” H. 40KW are installed in Incoloy-sheathed tubular elements to heat the oven chamber, while a 1500 CFM, 1-1/2 HP recirculating blower provides horizontal airflow to the workload.

This Grieve cabinet oven features 10” insulated walls comprising 2” of 1900ºF block and 8” of 10 lb/cf density rockwool insulation, Type 304, 2B finish stainless steel interior with continuously backwelded seams, plus inner and outer door gaskets with the inner gasket sealing directly against the door plug while the outer gasket seals directly against the face of the oven.

Full inert atmosphere construction further includes a pressure regulator, flow meter, pressure gauge, internal high-temperature gasket, all welded expansion connection in doorway throat, air jacket on inner oven for cooling, ½” thick silicone rubber atmosphere seal, blower shaft seal, positive latching door hardware, adjustable offset door hinges, outlet with pressure relief, interior seams welded gas-tight and all wall penetrations fitted with compression fittings. A 325 CFM blower pulls air through the air jacket on the inner oven for cooling.

Controls on No. 855 include a special heating/cooling temperature controller to control heating elements for heating and modulating damper on cooling blower for cooling. The oven also has an SCR power controller and circular chart recorder onboard.

For more information, please contact: THE GRIEVE CORPORATION, 500 Hart Road, Round Lake, Illinois 60073-2835 USA. Phone: (847) 546-8225. Fax: (847)546-9210. Web: http://www.grievecorp.com. Email: sales@grievecorp.com Attention: Frank Calabrese.

Continue readingThrough the use of Siemens SINUMERIK CNC technology, plus PLC and HMI, on a combination servo-controlled cold saw cut-to-length and brush deburring system, Rattunde customer achieves triple the output on small engine exhaust components

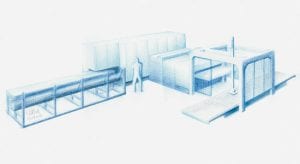

Rattunde ACS + BDM tube and bar production system at Cosmos.

Rattunde Corporation of Grand Rapids, Michigan is the five-year-old subsidiary of Germany’s Rattunde & Co. GmbH, a machine tool builder of tube, pipe and bar processing equipment. The company is already making its mark in the American manufacturing industry, as demonstrated by a recent success it had at Cosmos Manufacturing of South Chicago Heights, Illinois, a major supplier of small engine exhaust tubes to the leading outdoor power equipment manufacturers in the country.

The Rattunde system, incorporating a servo-controlled cutoff saw and brush deburring mechanism, is consistently producing up to 11,000 parts per hour at Cosmos, according to Mike Jemilo, the end user’s general manager. “This number represents triple the output production for Cosmos.” He continues, “Better still, it’s been in operation more than a year and we have not reported a single reject, with only routine maintenance and zero downtime due to machine problems. This is truly a win-win scenario for the machine tool builder and us alike.”

At the heart of the Rattunde system, according to Richard Stadler, company president, is the computer numerical control (CNC) system used by this builder. It consists of a Sinumerik 840D CNC, Simatic S7 PLC with various analog and Profibus modules, plus numerous Simotics servomotors, motor protection devices, circuit breakers and other components supplied by Siemens.

Machine performs all servo-controlled saw cut-to-length, washdown, brush deburring and packing operations on a single line, controlled by Siemens CNC and HMI.

At Cosmos, this Rattunde system is used to process mill-length tubes to customer-specified dimensions, using a fully NC-controlled cold saw. Cut-to-length parts are then automatically measured for dimensional accuracy and brush deburred. Production of these parts runs up to 11,000 units per hour, according to Cosmos’ Mike Jemilo. Because of the overall improvements in automation, speed and parts handling, plus the precision of the Sinumerik CNC system, Cosmos is further experiencing significant reductions in parts handling, secondary operations and final assembly.

The primary products being produced on this equipment at Cosmos include mountings, connectors and sections for muffler tubes in dozens of lengths, typically in 3/8-inch, 7/16-inch, 12 millimeter and 1/2-inch sizes. Products are routinely run in mild steel, aluminized steel and stainless steel on the same Rattunde system, with offline pre-programming done by the Cosmos engineering team. The final products are sold by Cosmos to leading manufacturers of chain saws, leaf blowers, lawn mowers and other small engine-powered equipment.

All machine functions and 13 axes of movement are affected by the Siemens CNC, which also provides remote monitoring capability for the builder Rattunde.

Jemilo concluded by citing the Rattunde service advantages. “From the initial contacts with their application engineering, through the build process, commissioning and on-site training, we’ve been extremely impressed with their work — very professional and responsive. Our previous system had nowhere near the production of the Rattunde solution and we are already working with this supplier on our next system.”

From the machine tool builder’s perspective, the same relationship is echoed about Siemens. Alec Banish, vice-president at Rattunde, commented, “We were asking Siemens to do some fairly complex operations in motion control, including 13 total axes with an articulating gearbox, plus the conveyor and part articulations, spindles and servomotors.” He further noted the scalloped motion of the ID/OD brushing with disc transfers all presented unique motion challenges for the control hardware and software alike. “The Siemens servo technology automated our entire process in a totally controlled, high-precision manner, allowing customers such as Cosmos to process a wide variety of materials, dimensions, shapes and lengths with easy-to-manage presets.” Banish concluded by saying, “The Siemens support is greatly enhanced by the remote monitoring capability of the Sinumerik CNC. About 70 percent of our issues are resolved remotely, working between us and Siemens or directly with the customer’s plant personnel.”

Prior to the implementation of the Rattunde system, all the piece part work done at Cosmos required two or three saws, with the attendant fixturing, parts handling, logistics and labor costs. These bottlenecks in production were eliminated by the fully automated and single operation processing of the tubes provided by the Rattunde system. Four tubes are processed per cycle, with servo control of the entire bundle, as it moves through the saw, brush and loading zones on this fully integrated machine line.

Rattunde builds various production systems for tube and bar product manufacturers.

From a factory utilization perspective, the prior system at Cosmos ran in three shifts for six days, each week. Today, with the Rattunde system on the floor, occupying a far smaller footprint, one shift per day working just five days produces the same output with far superior quality and virtually no rework, according to company sources.

Rattunde President Richard Stadler further comments on the power of the Siemens CNC and related motion control products. “We’re using all ten channels and pushing the axis capability to some extreme limits, but have seen absolutely no problems in signal degradation or processing speeds.” Stadler also observed the Sinumerik CNC program storage capabilities were quite impressive. “All the operator needs to do is provide a size range indication onscreen and all the relevant programs appear for easy selection. Repeatability is obviously critical for our customer, who often process dozens of shapes and sizes per shift.”

He recalled meeting the Cosmos team at FABTECH in 2009. “They approached us with their scenario and it was right in our wheelhouse. We did some test cuts and time/motion studies for them and the results were quite impressive, both to them and to us,” Stadler muses.

Rattunde operates facilities in Grand Rapids, Michigan as well as a service center in Burlington, Ontario to better serve their North American customer base.

Rattunde markets its tube and bar production systems to makers of precision parts. Currently selling 60 percent automotive, the company’s systems produce airbag canisters, cam shaft cylinders, steering components, rack mounts, driveshafts, frame components, seating parts, headrests, shock absorber parts, door impact devices, luggage racks and a variety of axles. In addition to the cut-off and brush deburring system detailed here, the company also supplies production systems to perform various types of secondary machining operations, including threading, facing, chamfering and ID turning.

For further information on this story, please contact:

RATTUNDE CORPORATION

4980 Kendrick St. SE

Grand Rapids, MI 49512

Phone: 616-940-3340

Web: www.rattunde-corp.com

Email: r.stadler@rattunde-corp.com

Attention: Richard Stadler, president or Alec Banish, vice-president

OR

SIEMENS INDUSTRY, INC.

DRIVE TECHNOLOGIES

MOTION CONTROL

MACHINE TOOL BUSINESS

390 Kent Avenue

Elk Grove Village, IL 60007

Phone: 847-640-1595

Fax: 847-437-0784

Web: www.usa.siemens.com/cnc

Email: SiemensMTBUMarCom.sea@siemens.com

Attention: John Meyer, Manager, Marketing Communication

Follow us on Facebook: www.facebook.com/SiemensCNC or Twitter: www.twitter.com/siemens_cnc_us.

—

Siemens Industry Sector is the world’s leading supplier of innovative and environmentally friendly products, solutions and services for industrial customers. With end-to-end automation technology and industrial software, solid vertical-market expertise, and technology-based services, the sector enhances its customers’ productivity, efficiency and flexibility. With a global workforce of more than 100,000 employees, the Industry Sector comprises the Industry Automation, Drive Technologies and Customer Services Divisions as well as the Metals Technologies Business Unit. For more information, visit http://www.usa.siemens.com/industry.

The Siemens Drive Technologies Division is the world’s leading supplier of products, systems, applications, solutions and services for the entire drive train, with electrical and mechanical components. Drive Technologies serves all vertical markets in the production and process industries as well as the infrastructure/energy segment. With its products and solutions, the division enables its customers to achieve productivity, energy efficiency and reliability. For more information, visit http://www.usa.siemens.com/drivetechnologies.

Continue reading