Contact us today:

(847) 934-4500

tdaro@bernardandcompany.com

Contact us today:

(847) 934-4500

tdaro@bernardandcompany.com

Permanent corrosion protection is more effective and less expensive than standard heavy-zinc galvanize

G235 treated with Hexavalent Chemtreat (top) vs. G40 treated with InterCoat® ChemGuard (bottom).Test: ASTM B117 salt spray test on hot dipped galvanized.

A leading coil coater and manufacturer of proprietary coating chemistries has recently introduced InterCoat®ChemGuard, a new type of corrosion protection for galvanized steel.

InterCoat®ChemGuard uses a new type of coating technology that utilizes covalent bonds and enhances the effectiveness of zinc and substantially improves corrosion protection on galvanized steel. Standard practice to protect metal from corrosion for approximately the last 70 years has been to coat it with zinc. Heavier zinc coatings have normally been applied to provide longer protection. This was the industry standard practice, until now.

InterCoat®ChemGuard, instead, reacts with the zinc to form a permanent, covalent bond on the surface of the metal. The product is applied over a light layer of zinc, which reacts with the zinc to dramatically improve its corrosion protection properties. The bond which is formed at the molecular level cannot be washed or worn off. This is different and more effective than the typical barrier coating. This revolutionary process allows bending, stamping, post-painting and even shearing, while providing self-healing characteristics that help protect newly exposed zinc that naturally occurs during secondary processing.

InterCoat®ChemGuard is a major development for any user looking to extend the corrosion resistance of galvanized steel. The product is RoHS compliant and continues to protect during stamping, roll forming, shearing and is weldable. With a low coefficient of friction, it actually enhances these processes. InterCoat®ChemGuard is designed to be applied on the galvanize line or, for custom formulas, by the original coil coater and developer of this unique compound.

G40 bare (left) after 144 hours and G40 with InterCoat® ChemGuard (right) after 2520 hours. Test: ASTM B117 salt spray.

InterCoat®ChemGuard offers significant cost savings because it allows for lighter zinc to form the bond. It is not necessary to apply heavy zinc; it reduces the need for zinc coatings heavier than G30, in many applications on the market today. The product also eliminates the need for temporary corrosion protection coatings, often used in shipping and materials storage, including hexavalent chrome, a known carcinogen, making it more environmentally friendly for all building, architectural, transportation and consumer appliance applications.

It is applicable to many industries, including automotive, aerospace, construction, electrical conduit, wall studs, furniture, fixtures, appliances, outdoor and highway railing, agricultural, lawn and garden and other products using galvanize.

For more information on this product, please visit the website at: www.lowerzinc.com

To discuss, or arrange a trial, please contact:

Bill Capizzano, President

Chemcoaters, Inc.

700 Chase Street

Gary, IN 46404

Email: BillC@chemcoaters.com

Phone: 219-977-1929

or

Mike Tieri, Vice President, Sales & Marketing

Email: MikeT@chemcoaters.com

Phone: 708-715-7759

This Grieve cabinet oven has 4” insulated walls and an aluminized steel interior and exterior. Features also include safety equipment for handling flammable solvents, including explosion venting door hardware.

Controls on No. 994 include all applicable NEMA 12 electrical standards and a tower light to indicate machine status.

For more information, please contact:

THE GRIEVE CORPORATION

500 Hart Road

Round Lake, Illinois 60073-2835

Phone: (847) 546-8225

Fax: (847) 546-9210

Web: www.grievecorp.com

Email: sales@grievecorp.com

Attention: Frank Calabrese.

Long-established technology of Coordinate Measuring Machines (CMM) is today being challenged in myriad markets by fast-emerging, highly advanced science of blue light scanning

For over 50 years, the benchmark for accuracy in measuring solid objects, whether machined, molded, die cast, welded or forged, was the coordinate measuring machine. Using a solid granite base table typically, along with a vertical, horizontal, gantry or bridge-mounted arm and touch probe, measurements would be taken and compared in blocks to an engineering file, first as 2D drawings and today as CAD files hosted in the cloud.

During the last two decades, however, a “new kid in town” has arrived on the scene, with power, size, point capability and price value that are rapidly leaving the CMM technology in the dust.

3D laser scanning, plus the latest trend of industrial CT scanning, which is based on the same technology used for medical MRI, permit an array of points to be read, both external and now internal, on a wide variety of substrates and manufacturing techniques. 3D scans are made on many types of metals, composite, thermoplastic, elastomeric, wood, fiber and fabric materials, while CT scanning permits internal exploration of a thick aluminum casting, injection molded plastic or rubber part, even prepared foods, packaging, archaeological finds and fine art. The old joke is, with CT scanning, we would have known about Venus de Milo’s arm problems, long before they occurred. CT scanning can produce results for porosity, dimensional, failure analysis, volume and fiber orientation, all while leaving the part undamaged.

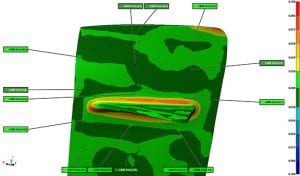

3D laser scan can capture millions of points, instantly comparing them to a CAD file or cloud-resident data

In contrast to conventional tactile CMM techniques, laser and especially CT scanning captures all surface points simultaneously, on even the most complex, convoluted surface areas. As an example, where a typical touch probe might capture 300 points of reference for comparison to a CAD overlay, the laser or CT will capture millions of points. Typical systems today can offer measurement accuracies to 4+L/100µm referring to the VDI 2630 metrology guideline.

A customer recently came to us with the following scenario. An engineer at his company was boasting of having produced the “perfect part,” based on CMM deviation points. Our contact had used our scanning services in the past. We performed a quick blue light 3D scan on the object and quickly determined the part was out of spec on several faces, as certain critical points had been missed in the CMM protocol. Our millions of scan data points were fit to the deviation map and the problem was tracked backed to the production source and rectified. Today, this company is a regular customer.

CT scan enables the internal examination of a die cast, molded or other solid part, even food and packaging, to detect issues of porosity or void analysis without destruction of the object, as well as seal integrity

The above example does not indicate CMM technology has outlived its usefulness, by any means. We continue to use it in our operations for certain measurements in many applications.

One important point to note is that the same software that manipulates the data from the CMM can be used with 3D scanners and CT equipment alike. As there are substantial cost savings to be realized in the purchase of a 3D scanning device or the new generation of table top CT scanners, depending on the parts being examined, the transition from CMM to 3D or CT is more feasible today, economically. The driving factors for a company, when evaluating the service vs. purchase issue are two.

The easier factor is raw cost, where a 3D scanner is typically half the cost of a CMM for measuring comparable part sizes. The other is more complex, namely the talent of the personnel doing the work. Experienced technicians have the ability to scan and process large data sets on a wide variety of substrates, geometries and part sizes effectively. Coupled with the part volumes being processed and other factors, it is often more practical and profitable for a company to use a scanning service on an as-needed basis.

3D printing allows quick sampling of modified designs, as well as finished prototypes, producing parts directly from the scanned data

An additional point to note in evaluating CMM vs. scanning is the time involved. To derive those 300 touch points referenced above might take four hours, while the 2.5 million points derived from a 3D scan would take 30 minutes. Since Polyworks software can be used on a CMM or 3D laser scanner, the time and money savings quickly accumulate. Plus, in this manner, companies can develop something of a “universal metrology” scenario at their companies by augmenting the existing CMM technologies with 3D and even CT scanning capabilities, making their QC department more powerful from the outset. One practical note: We can train QC, R&D and production department personnel usually in three days or less to expand their capability from CMM to include 3D and CT scanning.

In terms of the data created, the 3D scanning produces color maps, inspections, first article inspections or other outputs. What you do with the data after completing the scanning is endless.

On the topic of substrates, it should be noted that CT scanning today offers the ability to evaluate a wide variety of dual thickness and dual density materials, with disparate examples ranging from an automotive firewall that might have differing thermoplastics or rubber and TPE materials co-molded to a candy bar with chocolate and nuts.

NOTE: The author welcomes all contact and questions regarding this article. In full disclosure, Exact Metrology performs 3D laser and CT scanning, plus sells, rents or leases the equipment to perform such scanning procedures.

For more information on this article, please contact the author:

Matthew Martin

Exact Metrology, Inc.

www.exactmetrology.com

11575 Goldcoast Drive

Cincinnati, OH 45249

513-831-6620

matthewm@exactmetrology.com

Exact Metrology is an ISO 9001:2008, AS9100 Certified and ITAR Registered Company.

Exact Metrology, with facilities in Cincinnati and Milwaukee and affiliated offices throughout the Midwest, is a comprehensive metrology services provider, offering customers 3D laser and CT scanning, reverse engineering, quality inspection, product development, 3D printing and 2D drawings. The company also provides turnkey metrology solutions, including equipment sales and lease/rental arrangements.

Continue reading

This Grieve oven has 6” insulated walls, an aluminized steel exterior and Type 430 stainless steel interior. The oven features a 12”wide x 8” high door installed in main door. Additional safety features include those required by IRI, FM and National Fire Protection Association Standard 86 for gas heated equipment, including a 325 CFM, ½-HP powered forced exhauster.

Controls on the No. 843 include a digital indicating temperature controller.

For more information, please contact: THE GRIEVE CORPORATION, 500 Hart Road, Round Lake, Illinois 60073-2835 USA. Phone: (847) 546-8225. Fax: (847) 546-9210. Web: www.grievecorp.com. Email: sales@grievecorp.com. Attention: Frank Calabrese.

Continue readingPomona, California – NOARK Electric, a low-voltage electrical product manufacturer, announces its UL 489 B1NQ miniature circuit breaker is now a direct replacement for the common MCB when paired with the optional surface mount. This recyclable, quick-connect breaker is available in three curves (B, C and D), ranges from 0.5 to 63 A and is compliant with UL/CSA/IEC standards for branch circuit protection in commercial and residential applications.

While designed and engineered for the HVAC market, the HACR compatible MCB is also suited for a host of industrial applications and other component sub-assembly designs. The current-limiting B1NQ is thermal-magnetic and protects against short circuit and overload conditions. The 1- and 2-pole breaker, offered at 120/240 Vac provides optimum and efficient protection for branch and control circuits. NOARK offers exceptional value with local support and inventory for a wide range of UL 508A panel designs, all backed by the industry’s first 5-year limited warranty.

The B1NQ and surface mount attachment saves customers substantial time and money in both upfront cost and installation time. The surface mount is an exact match to the existing bolt hole pattern of the common, competing MCB and requires no additional drilling. With the surface mount in place, the B1NQ can be removed in as little as 7 seconds – over 300% faster than the common MCB. Installation takes seconds and simply requires placing the B1NQ onto the surface mount and clicking into place. Quick removal is possible by pulling down the clips with a standard screwdriver. The removable terminal shrouds offer the installer unmatched access to the terminals. This feature saves users valuable time during installation and helps reduce the chance of wiring errors. With more space available, technicians in the field and factories are able to work quickly and accurately. Additional accessories are available including Comb Bus Bars and Rotary Handles.

NOARK Electric (North America), located in Pomona, CA, is a global electrical component and intelligent control system supplier. The company is establishing a representative and distribution network to serve its primary markets, which include the building trades and electric panel board builders in various industries. As a global supplier, NOARK currently operates four R&D centers, three distribution centers, 15 office locations and employs over 1,000 associates. Sales currently exceed $2 billion worldwide.

For more information on this product, consult your local sales representative or email: nasales@noark-electric.com

Continue reading

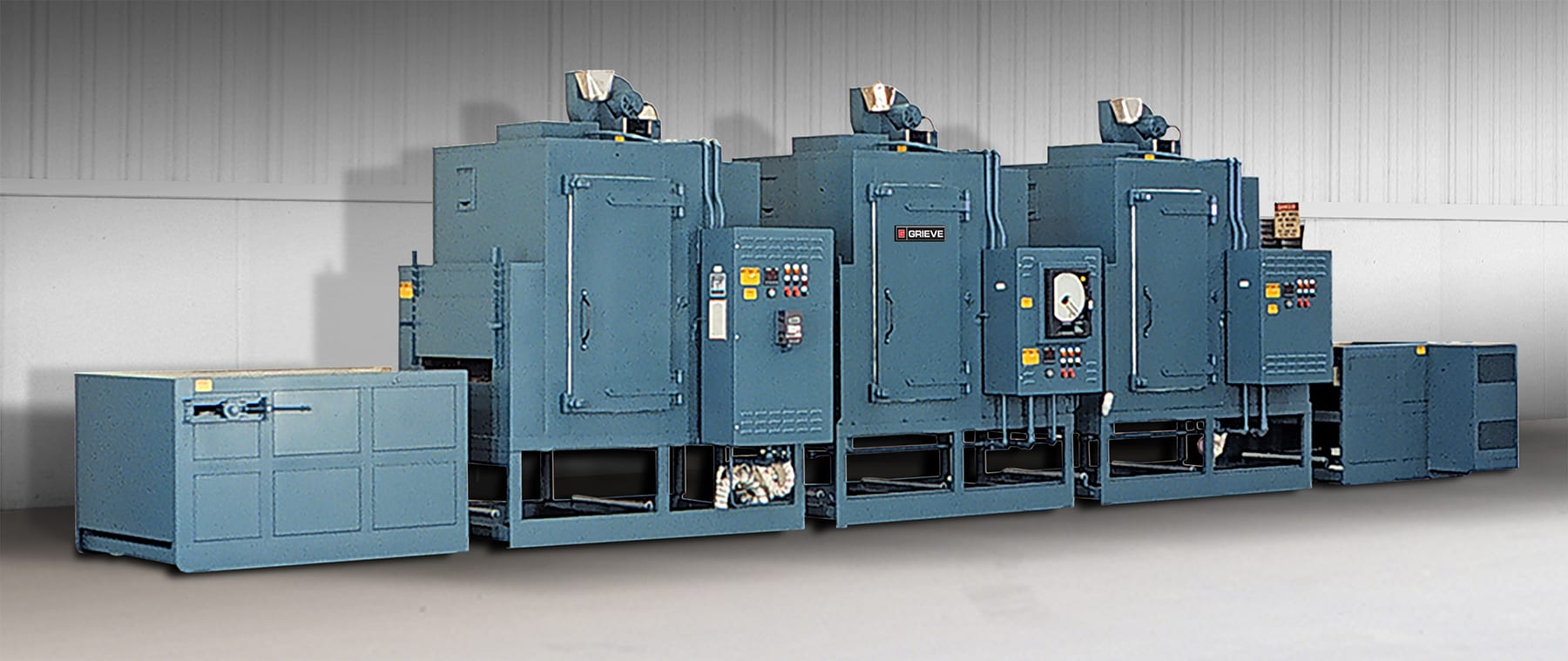

This Grieve conveyor oven has a 4’ long open belt loading zone and 4’ long open unloading zone. Features include three 6’ long insulated heat zones with independent recirculated airflow and temperature control, 6” insulated walls and aluminized steel exterior. Type 304, 2B finish stainless steel interior with continuously backwelded seams. Additional features include 24” wide, 1” x 1” 304 stainless steel flat wire conveyor belt with ½ HP motor drive, variable from 0.1 to 2 feet per minute. The oven is sectioned into five pieces for shipping. The oven has safety equipment for handling flammable solvents, including explosion venting door hardware.

Controls on the No. 865 include digital indicating temperature controllers and a 3-pen circular chart recorder.

For more information, please contact: THE GRIEVE CORPORATION, 500 Hart Road, Round Lake, Illinois 60073-2835 USA. Phone: (847) 546-8225. Fax: (847) 546-9210. Web: www.grievecorp.com. Email: sales@grievecorp.com. Attention: Frank Calabrese.

Continue readingLow-cost kits allow easy-to-install, direct mounting of G120C Compact and G120 PM240-2 modular drive

Available in power ranges from ½ to 200 hp and voltages from 230V to 690V, the kits offer streamlined, compact design for use with all drive frame sizes of the corresponding Siemens drive units. Each kit provides best-in-class space-savings and direct access to the drive-mounted operator panel for simple commissioning, condition monitoring and even troubleshooting.

The new kits accommodate all G120C, PM240-2 and PM240P-2 power modules, control units and operator panels in the Sinamics drive family. Standardized designs permit efficient side-by-side mounting with minimal clearance, while multiple conduit knockout holes allow separate power, motor, I/O and network cabling.

Seven kits are currently available to fit all drive units from AA to F frame sizes.

Siemens offers seven sizes of NEMA 1/UL Type 1 wall-mounting kits for its popular G120C and PM240-2 modular drives. The kits feature space-savings plus multiple knockouts for separate power, motor, I/O and network cabling.

For specific product information, please visit: www.usa.siemens.com/sinamics-g120

Siemens Digital Factory (DF) offers a comprehensive portfolio of seamlessly integrated hardware, software and technology-based services in order to support manufacturing companies worldwide in enhancing the flexibility and efficiency of their manufacturing processes and reducing the time to market of their products.

Siemens Corporation is a U.S. subsidiary of Siemens AG, a global powerhouse focusing on the areas of electrification, automation and digitalization. One of the world’s largest producers of energy-efficient, resource-saving technologies, Siemens is a leading supplier of systems for power generation and transmission as well as medical diagnosis. With approximately 351,000 employees in 190 countries, Siemens reported worldwide revenue of $88.1 billion in fiscal 2016. Siemens in the USA reported revenue of $23.7 billion, including $5.4 billion in exports, and employs approximately 50,000 people throughout all 50 states and Puerto Rico.

Continue reading

Product demonstrations and technical presentations from principals impress large crowds; 3D/CT scanners and NEW 3D printer line highlighted

Services on display at the Cincinnati open house included 3D scanning, reverse engineering, quality inspection, instant scan-to-CAD comparison and a full suite of PolyWorks software solutions. Equipment shown at the event included Aicon 3D systems, Breuckmann 3D scanners, Leica Geosystems, Romer and Hexagon brands of scanning devices and related hardware, all of which were available for hands-on use by event attendees. Company representatives from the various equipment lines, as well as Exact Metrology’s team of application engineering and testing specialists, were present for demonstrations and technical presentations, throughout the event.

The EnvisionTEC line drew particular attention and Steve Young commented, “This new partner was a natural extension of our service work. We do 3D scanning and were using a 3D printer, so we had that light bulb moment and decided to connect with a 3D printer builder to expand our equipment offerings.” Exact represents EnvisionTEC throughout the Midwest. EnvisionTEC is a Detroit-based builder of various 3D printers for the medical, dental, jewelry and various industrial sectors, offering machines to produce parts up to 18” cube.

As Steve Young further noted commented, “We constantly seek to find the optimum combination of equipment and services to suit the applications and challenges presented by our customers. In some cases, it’s a matter of matching the right standard equipment to the job, while at other times we bring custom solutions and services to our customers, whether they buy, lease or rent equipment or use our services to achieve the desired results on their metrology projects.” Young credited his staff of metrology engineers, technicians and customer service personnel for their hard work, dedication and adaptability in seeking the correct solution to all customer challenges.

During the day, two big screen TV’s were raffled off to attendees, who also enjoyed a tasty pig roast luncheon.

Exact serves both industrial and commercial concerns, ranging from heavy equipment, automotive and appliance companies to nuclear test facilities and even museums, who routinely use metrology to examine artwork such as paintings and sculpture.

Cincinnati Photos:

Subsequently, on May 25, Exact held an open house at its Brookfield, Wisconsin (outside Milwaukee) location.

Attended by 70 companies in the area, the event was hosted by Exact Metrology co-president Dean Solberg in conjunction with Exact partners EnvisionTEC, Hexagon Metrology, PolyWorks, 3DSystems and ETI.

A variety of scanning equipment was demonstrated throughout two rooms in the facility. One highlight of the open house was the new Leica BLK360 Imaging Laser Scanner, a 360-degree scanner that allows high resolution scans for a full-dome in less than three minutes. Other devices showcased included the Hexagon Metrology Romer Absolute Arm, several Artec3D scanners, the Surphaser 100HSX, several Leica long range scanners and the ProCon CT scanner. While demonstration pieces were available to scan, attendees were able to bring in their own parts to show live 3D scanning on the screen.

Also present at the open house was Exact Metrology’s new 3D printer partner, EnvisionTEC, Inc. High-precision, high-detailed models illustrated the 3D printing capabilities of the Detroit-based manufacturer.

The Brookfield open house’s agenda consisted of four breakout sessions with experts in 3D metrology and scanning technology demonstrating their wealth of knowledge on the industry. The breakout sessions happened simultaneously during the day. During one presentation, Jason Reno of PolyWorks talked about what to expect in the industry for 2017. Another session was given by Dave Meyers, a Professor affiliated with Effective Training Inc. He instructed the audience on the use of GD&T Training (Geometric Dimensioning and Tolerancing). Greg George, Corey Mayeda and Mike Tsand from 3DSystems gave a discussion on 3DSystems Software: DesignX and Geomagic.

The guests enjoyed a full spread of delicious food for lunch and were given keepsakes such as mouse pads, pens, coffee mugs, and m&m’s, all with the Exact Metrology logo on them.

Wisconsin Photos:

Exact Metrology is an ISO 9001:2008 and AS9100 Certified Company and is also ITAR Registered.

Exact Metrology, with facilities in Cincinnati and Milwaukee and affiliated offices throughout the Midwest, is a comprehensive metrology services provider, offering customers 3D and CT scanning, reverse engineering, quality inspection, product development and 2D drawings. The company also provides turnkey metrology solutions, including equipment sales and lease/rental arrangements.

For more information on this event or to arrange a demonstration, please contact:

EXACT METROLOGY, INC.

Steve Young

11575 Goldcoast Drive

Cincinnati, OH 45249

Phone: 513-831-6620

www.exactmetrology.com

stevey@exactmetrology.com

Continue reading

My name is Ioana and I’ve been a part of the Bernard & Company team for almost three years. My activities as a marketing information specialist help our clients increase their profits and become better-known within their industries.

One of my primary duties is to read magazines for our clients’ PR. Once identified, the appearances are scanned and archived online. When one of our clients meets with us to talk about the results of their PR campaign, they are presented with magazine clippings and online access to PR that appeared both online and in print. This benefits our clients in two ways. First, clients like Grieve and Suhner, who sell their products in many markets, see which magazines are most responsive to their PR. Secondly, it is very helpful for them to see their ROI. Some clients consistently realize ROI in the 15-20:1 range, depending on the quantity of releases, the occasion of success stories, and the breadth of their master media list. We have clients who sell to very limited markets such as forge, foundry, tire and rubber molding, while others sell power tools, electric motors and industrial heat processing equipment to almost every industry.

Continue reading

This Grieve oven has 8” insulated walls and a 4” insulated floor. Additional features include an aluminized steel interior and exterior and safety equipment for handling flammable solvents, including explosion venting door hardware.

Controls on the No. 852 include a digital indicating temperature controller & manual reset excess temperature controller with separate contactors.

For more information, please contact: THE GRIEVE CORPORATION, 500 Hart Road, Round Lake, Illinois 60073-2835 USA. Phone: (847) 546-8225. Fax: (847) 546-9210. Web: www.grievecorp.com. Email: sales@grievecorp.com. Attention: Frank Calabrese.

Continue reading