Contact us today:

(847) 934-4500

tdaro@bernardandcompany.com

Contact us today:

(847) 934-4500

tdaro@bernardandcompany.com

Contact us to receive this whitepaper as a WordDoc.

Why an Interest in EQ Coatings?

The Steel Industry is a highly competitive world market. The industry is always in search of innovative and fresh manufacturing methods to improve quality and lower costs. One wouldn’t automatically think the metal stud industry utilizes cutting edge technology to create their products, since studs are well hidden and only visible during construction, but this is a common misconception. Progression in the engineering of stud design and stud manufacturing processes has followed a challenging path similar to that of the more well-known automotive industry. Throughout the years, the automotive industry has seen the approval of countless regulatory guidelines, pressuring automotive manufacturers to become innovative in their processing, leading to the creation of better operational processes, new metallurgical steels, new technology development in roll forming and stamping methods, plus the creation of new coatings to provide better corrosion resistance and impart specific characteristics, such as weldability and improved formability. Just as these regulatory guidelines pushed automotive manufacturers to innovate, the metal stud manufacturers were driven by the need to remain competitive against alternative building materials (eg. wood and concrete). Metal studs are sold and priced by the pound, so the need to be market competitive added pressure for stud manufacturers to engineer innovative designs and processes that drive out costs while creating products that are equal to or superior to the products already available. These innovations can be seen through many advancements; one such example being the creation of special tooling that imparts specifically designed shapes and ridges which work to improve strength (yields) while reducing both gauge and weight.

When the discussion turns to materials, metal stud manufacturers primarily utilize galvanized substrates. These materials have worked well for manufacturers as zinc premiums have been stable over the past several years. However, in 2014 and 2015, experts project that zinc premiums will drastically increase. As the gauges of the metal studs are reduced, a correlation can be observed where the percentage of reduction in the thickness of the metal studs increases the percentage of zinc to the overall metal stud thickness and therefore increases the zinc premiums. These higher zinc premiums have also contributed to pressuring stud manufacturers to innovate, leading to some metal stud manufacturers taking advantage of purchasing excess automotive, high quality Galvanneal substrates and subjecting those substrates through the process of cold-reduction in order to drive yields up while obtaining equal strength from light gauges. The creation of new processing techniques such as this one led to the design and creation of coatings that were specifically formulated for the metal stud industry and are best known as EQ Coatings. EQ Coatings have been shown to significantly outperform standard metallic coatings such as:

EQ Coatings were developed to provide equivalent or superior corrosion protection, compared to approved metallic coatings that are listed in the ASTM A1003 standard for metal studs. While the “EQ” stands for Equivalent, EQ Coating manufacturers and test data insist that EQ Coatings are nothing short of being superior coatings.

Interior Drywall Steel Stud Framing – Codes and Standards

Over the past several years, there have been countless discussions between metal stud manufacturers and metal stud industry associations over the acceptance of EQ studs and whether or not EQ Coatings conform to industry standards. Some regulating bodies have dealt with these discussions for several years, mostly due to the confusion caused by the distribution of misinformation in the marketplace. The SFIA (Steel Framing Industry Association) Technical Director Pat Ford explained in a recent Webinar, co-sponsored by the SFIA and AWCI associations, that EQ Coatings conform to the many codes within IBC, ASTM, AISI and ICC. Though there are many ASTM standards associated with manufacturing and specifying Cold Formed Members (metal studs), the key standards that are applicable to EQ Coatings are:

Members shall have a protective coating conforming to Specification A653 – G 40 minimum or have a protective coating with an equivalent corrosion resistance.

(Note that this “equivalent” provision has been in the standard for over 20 years.)

9.1.3.1; No more than 10% loss of coating… at the end of the prescribed test duration.

9.1.3.2; Minimum exposure for type NS steels is 75 h.

6.2.1: Use Practice ASTM B-117 (Accelerated Salt Spray Test) to evaluate corrosion conformance…

These standards and requirements have been adopted into the SFIA QC program and serve as the basis for performance requirements for this program. In short, this program states, the requirements for a metallic G40 EQ (Equivalent) coating are:

In summary, for drywall framing, the IBC Code refers to ASTM standard C645 for guidelines. Relative to EQ Coatings, the other standards that reference guidelines for the performance are ASTM A1003, ASTM A1004 and ASTM B117.

How do EQ Coatings Work?

EQ Coatings are primarily (or entirely) composed of metallic compounds and are highly conductive. Due to their unique chemical nature, EQ Coatings require zinc, zinc alloy or zinc-iron alloy metallic coated base substrate to effectively work. EQ Coatings are Not Barrier Coatings, unlike more common coatings such as pretreatments, sealers, TFA’s (Thin-Film-Acrylics), primers and/or prepaints. EQ Coatings permanently (chemically and covalently) bond and integrate into the zinc, zinc alloy or zinc-iron alloy metallic coated substrate and become a singular composite coating system. It is this characteristic that provides the tremendous corrosion resistance properties. In some EQ Coating systems, cut edge and scratch resistance are so enhanced, compared to traditional standard metallic coated systems, that some EQ Coatings can provide self-healing characteristics.

Typical G40 HDG or A40 Galvanneal metallic coated substrates are manufactured according to the ASTM A653 Standard for Galvanized Sheet Steel and are expected to have .40 oz./ft² (total for both sides) of coating weight (mass). The standard (A653) allows for a range in the galvanized coating weights but must have a minimum coating weight of .30 oz./ft² (total both sides). In closer review of the standard, the actual coating weight can be as low as .12 oz./ft² on a single side. The photo below shows the full coating weight range of a typical G40 HDG metallic coating that can be purchased from a steel mill and still be within the approved specification range. In review, the coating weights at the lower end of the G40 specification do not perform very well in an ASTM B177 salt spray test. Even coating weights at the high end of the G40 standard show 100% white rust at 48 – 75 hours.

The galvanizing process can create vast valleys, fractures, pits and porosity in the zinc metallic surface. EQ Coatings are applied via a reverse roll coating application on a coil coating line and then cured with an IR or conventional oven. The combination of the coating and the process allows the EQ Coating to penetrate deep into the fractures and valleys within the zinc metallic coating, where it proceeds to chemically react with the zinc, sealing it off from the environment. It is this unique process and reaction that provides the tremendous corrosion protection associated with EQ Coatings. EQ Coating and a zinc metallic coating are more than just a basic coating. When combined, they become a singular permanent integrated composite coating. The unique level of corrosion protection provided by an EQ Coating allows metal stud manufacturers to utilize substrates that do not meet minimum metallic coating weight (mass) requirements of ASTM A1003 but when enhanced with a singular composite integrated EQ Coating system, they can provide extensive corrosion protection that meets or exceeds the corrosion expectations associated with the metallic coating weight ranges referenced above.

Superior Performance of EQ Coatings

As mentioned earlier, EQ Coatings were specifically designed and created for the metal stud industry. They were designed to be applied to excess automotive Galvanneal, HDG or Electro-Galvanized, be cold-reduced by 20% to 50% after coating, slit down and then roll-formed into finished metal studs. EQ Coatings have been shown to outperform other mill applied or other post applied coatings. Some EQ Coatings are formulated to provide superior cut-edge and scratch protection. In the photo, the flat test panels on the top show cut edge and scribe performance, as compared to the G40 control pictured at the bottom.

EQ Coating formulations can be modified to meet the needs of many specialized requirements or applications, such as:

Other Advantages of EQ Coatings

In accordance with the ASTM A1003 Standard; 9.1.1 Not all coatings will react the same under a given set of environmental conditions. These minimum coating designations assume normal exposure conditions and construction practices. When more severe exposure conditions are probable (for example: in coastal areas), consideration should be given to specify heavier coating weights (mass).”

In this section of the ASTM A1003, the standard recommends specifying substrates with better corrosion performance when in severe environments, such as G60 or G90 HDG. EQ Coatings can easily accommodate this requirement at a fraction of the cost, compared to zinc premiums on substrates above G40.

Since September of 2011, when Eco-Green Coatings, a division of Chemcoaters, developed their EQ Coating known by the trade name as InterCoat®ChemGuard, there have been over 500 million linear feet of EQ coated studs sold in the marketplace without a single claim for corrosion in the field.

Other steel product industry segments have found an interest and have accepted the EQ coatings due to their field performance, as depicted in the data above, and the tremendous corrosion resistance. Some of these applications include:

Innovation and Change

It is important for steel driven industries to continue to innovate and stay ahead of the competition provided by alternative materials. The Automotive industry is faced with aluminum and carbon composites competition. The Appliance and HVAC industries are utilizing more plastics. The Building & Construction industry has wood, concrete and composite products to compete against. Many of the EQ Coating manufacturers and applicators service all of the various steel industries. The synergies that exist between all of these steel markets produce unique opportunities for technology advancements, such as EQ Coatings, to service multiple industries rather than a single market. It is advancements like this that will ultimately lead to driving down costs and allow steel products to remain competitive among these vast and diverse marketplaces. Despite some resistance to change, the quality and performance of these innovative coatings are clearly defined in the ASTM standards that have been in place for over a decade and that is because these standards were written to accommodate innovation in coating technologies and provide defined test methods to insure adequate levels of performance for the application.

William R. Capizzano, is President and board member of Eco-Green Coatings, LLC and Chemcoaters, LLC in Gary, IN and has been employed in the coil coating industry since 1978.

|

| Website

—

Webinar Originally Presented on Oct. 15 and 17, 2013 by:

Bill Capizzano, President

Chemcoaters, LLC & Eco-Green Coatings, LLC

Input from Patrick Ford, P.E. Matsen Ford Design, Technical Director, SFIA

Presentation converted to paper by Bill Capizzano on June 13, 2014

Now for iOS and Android!

You asked and we listened. Our popular Easy CNC app is now available for Android devices. Easy CNC contains all the current training manuals for Siemens Sinumerik CNCs and will ensure that you always have the latest updates.

With no more heavy manuals to carry, you have access to over 4,000 pages of vital CNC instruction and content. In addition, a handy G-code compatibility tool lets you quickly find compatible codes for Siemens and ISO G-codes. The glossary feature is your reference guide to CNC terminology, and web-links to service, support and CNC social media feeds open the door to our online user community. Don’t wait – download the Easy CNC app for iPhone, iPad and Android devices for free.

To download Easy CNC to your mobile device, visit: http://www.usa.siemens.com/cnc-apps

—

For specific product information and inquiries, call (800) 879-8079 ext. Marketing Communications or send an e-mail to: SiemensMTBUMarCom.industry@siemens.com.

Follow us on Social Media:

Twitter: www.twitter.com/siemens_cnc_us

Facebook: www.facebook.com/SiemensCNC

The Siemens Industry Sector is the world’s leading supplier of innovative and environmentally friendly automation and drive technology, industrial software and technology-based services. The Sector’s comprehensive portfolio covers the entire industrial value chain, from product design, engineering and production to services. Siemens enhances its customers’ productivity, efficiency, and flexibility in a wide variety of different industries. With a global workforce of more than 100,000 employees, the Industry Sector comprises the Divisions Industry Automation, Drive Technologies and Customer Services as well as the Business Unit Metals Technologies.

Continue reading

This Grieve cabinet oven features 4” insulated walls, aluminized steel exterior and interior, three integral metal shelves, plus all safety equipment required by NFPA Standard 86 for handling flammable solvents, including a powered forced exhauster, airflow safety switch and purge timer.

Other controls on No. 814 include a fused disconnect switch, digital temperature controller and manual reset excess temperature controller.

For more information, please contact:

THE GRIEVE CORPORATION

500 Hart Road

Round Lake, IL 60073-2898

Phone: (847) 546-8225

Fax: (847) 546-9210

Web: www.grievecorp.com

Email: sales@grievecorp.com

Attention: Frank Calabrese, VP

Siemens has added new applications to its “Sinumerik Integrate for production” software

suite for networking machine tools with production-level IT systems.

Siemens has added new applications to its “Sinumerik Integrate for production” software suite for networking machine tools with production-level IT systems. The new release now includes Manage MyMaintenance (MMM), an effective maintenance-tasks management system, and Access MyData (AMD), a set of open interfaces that now allows direct access to machine and process data.

Access MyData offers an interface to access machine and process data of machine tools controlled by the Sinumerik 840D sl CNC. To allow data communication, the machine tool is directly connected to the Sinumerik Integrate server at the customer’s site.

AMD Basic is available free-of-charge and enables the direct reading and writing of NC and PLC data from the Integrate application server. Purchasing extensions to AMD Basic allows machine tool data to be processed and NC part programs transferred via a file transfer interface.

Manage MyMaintenance enables small and medium-sized companies to enter the world of maintenance management without any additional investment. MMM automatically instructs the user, as soon as a new maintenance date is scheduled for a machine. The time and tasks to be performed are presented in a clearly laid out list.

Self-explanatory color-coding indicates which measure is overdue and which has

not yet reached its deadline. A number of maintenance tasks can be defined and intervals specified. The software is easily installed via the Sinumerik Operate graphical user interface without any programming effort.

Background information:

The Sinumerik Integrate for production software suite includes applications for simple management of machine tools and part programs, transparent recording of machine states and production data, as well as the remote maintenance of machines installed

all over the world.

—

For specific product information and inquiries, call (800) 879-8079 ext. Marketing Communications or send an e-mail to: SiemensMTBUMarCom.industry@siemens.com.

Follow us on Social Media:

Twitter: www.twitter.com/siemens_cnc_us

Facebook: www.facebook.com/SiemensCNC

The Siemens Industry Sector is the world’s leading supplier of innovative and environmentally friendly automation and drive technology, industrial software and technology-based services. The Sector’s comprehensive portfolio covers the entire industrial value chain, from product design, engineering and production to services. Siemens enhances its customers’ productivity, efficiency, and flexibility in a wide variety of different industries. With a global workforce of more than 100,000 employees, the Industry Sector comprises the Divisions Industry Automation, Drive Technologies and Customer Services as well as the Business Unit Metals Technologies.

Continue readingSiemens has put together a scalable package of coordinated automation and drive components specifically for tapping centers. It consists of the Sinumerik 828D compact CNC with new panel processing units PPU2xx.3 of various performance classes as control hardware and the new variant of the Sinamics S120 Combi drive with triple overload capability. The package is completed with the new Simotics M-1PH8 Premium Performance main motor, which can achieve high speeds.

The productivity of tapping centers can be increased considerably due to the specially coordinated components, the powerful control system hardware, the converter with enhanced overload resilience and the high-speed main motor from Siemens. For example, the spindle can be started up from 0 to 24,000 revolutions per minute in less than one second. This saves considerable time, particularly with tapping center applications featuring frequent tool changes.

The Siemens range is also especially suitable for the increasing number of applications with freeform surfaces and high surface quality, for example cell phone components, which are manufactured with small high-speed cutting (HSC) tools and have short machining times. The tapping center’s maximum machine dynamics can be utilized to the fullest extent with the scalable performance spectrum, for example the different control hardware variants PPU 260.3 or 280.3 for the Sinumerik 828D compact CNC.

Background information

Tapping centers are designed as machine tools with small work spaces for milling, drilling and thread machining, and are frequently used to manufacture hard disk and mobile phone housings, for example. These are made out of lightweight materials using small tools and at high speeds.

—

For specific product information and inquiries, call (800) 879-8079 ext. Marketing Communications or send an e-mail to: SiemensMTBUMarCom.industry@siemens.com.

Follow us on Social Media:

Twitter: www.twitter.com/siemens_cnc_us

Facebook: www.facebook.com/SiemensCNC

The Siemens Industry Sector is the world’s leading supplier of innovative and environmentally friendly automation and drive technology, industrial software and technology-based services. The Sector’s comprehensive portfolio covers the entire industrial value chain, from product design, engineering and production to services. Siemens enhances its customers’ productivity, efficiency, and flexibility in a wide variety of different industries. With a global workforce of more than 100,000 employees, the Industry Sector comprises the Divisions Industry Automation, Drive Technologies and Customer Services as well as the Business Unit Metals Technologies.

Continue reading

We did it for Mother’s Day, and now it’s dad’s turn. They’ll make you laugh, they’ll make you cry, they’ll make you appreciate dad more than ever before!

Here’s a collection of the best commercials/videos celebrating dads:

American Greetings – The Dad Life Rap

And here’s a little extra:

25 Absolute Greatest Dad Jokes of All Time

** Happy Father’s Day!! **

Do you have must-see commercial to add?? Share the link in the comments below!

Continue readingIs there a better way to celebrate and honour Mother’s Day than to make you weep uncontrollably at your office desk?

Olympics P&G – Pick Them Back Up

Publix – Mother’s Day Commercial

Video – Parents Announce New Baby; Daughter Has Best Reaction. Ever.

And then there’s this one. Disclaimer: this commercial is incredibly creepy. But also hilarious.

** Happy Mother’s Day!! **

Do you have must-see commercial to add?? Share the link in the comments below!

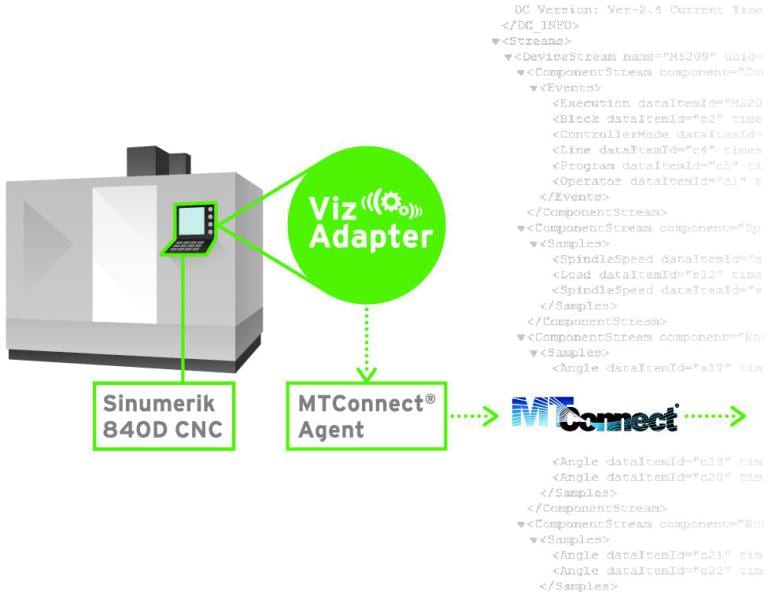

Continue readingDuring this year’s [MC]2 2014 MTConnect: Connecting Manufacturing Conference, Siemens announced today the appointment of TechSolve (Cincinnati) as a Solution Partner to offer solutions to customers with Sinumerik CNCs who are interested in or have already implemented MTConnect into their factories. Through this development, Siemens proactively responds to the growing demand in the market for MTConnect solutions among the end-user and machine builder sectors. TechSolve was a Founding Sponsor of the Institute and is a major supplier of MTConnect Adapters, translation products as well as support software and services that enable shops and production departments alike to more efficiently gather and analyze machine tool performance data, using the open-source communication standard of MTConnect.

This schematic illustrates the typical scenario for a machine tool control modification at an end-user, where the Siemens CNC is modified with TechSolve Adapter software, allowing machine data to be sent through an agent in MTConnect compatible language. This facilitates a significantly greater degree of information gathering and analysis by the customer, across the open-source standard of MTConnect for greater interoperability between devices and software applications. Machine builders can also make such modifications to their controls, to suit customer needs or respond to market conditions.

In a typical machine tool end-user scenario, TechSolve applies its Adapter software to an existing machine’s CNC, such as the Siemens Sinumerik 840D, which enables data transfer through an MTConnect Agent. For older controls and legacy devices that do not have native communication output, TechSolve can also supply additional hardware and communication software to facilitate this process. The data can then be stored locally or cloud-based for further access and evaluation in an overall equipment effectiveness (OEE) strategy.

Likewise, TechSolve provides Adapter software to machine tool builders for integration into their control schemes to suit particular applications or customer-mandated specifications for MTConnect compatibility.

Ryan Legg, product manager, Sinumerik CNC, Siemens Industry, Inc., explains, “In the U.S. market especially, we are seeing growing demand for MTConnect. This appointment of TechSolve as a Solution Partner to support requests for MTConnect represents our company’s commitment to bring practical solutions to our customers through an experienced and reliable source of both products and services. When MTConnect is written into the specification on any job, we now have an ideal resource to complement our capabilities.”

Noting the open architecture of the Siemens CNC allows easy integration of the TechSolve solutions; Legg further explained the cross-platform advantages of this new relationship. “TechSolve has written their MTConnect Adapter for the Sinumerik CNC

in a way which allows complete flexibility regardless if the system architecture of the Sinumerik employs a PCU or if it is running in an embedded architecture without a PCU. Ultimately, this allows for more customers to take advantage of this offering.”

Ron Pieper, manager, VizProducts™ Group at TechSolve, observes, “To be affiliated with Siemens is a compliment to both of our products and services as well as our engineering talents. We believe this relationship will be mutually beneficial, as it will further promote the acceptance of MTConnect in the machine tool market, plus being a Solution Partner to Siemens will open new doors for our company.”

Pieper further comments on the market need for these solutions. “When all the data from the shop or factory floor is available as it occurs, the customer learns the reality of their situation, then can make confident steps to improve their game, so to speak.

They see where the inefficiencies are, where and why the downtime is occurring and how they might improve or streamline production. All of these factors are crucial in today’s competitive machining market.”

More information on the above-mentioned solutions will be available at the upcoming MTConnect Conference in Orlando, April 8-10, 2014, organized by the MTConnect Institute.

For more information about this announcement, please visit: www.usa.siemens.com/techsolve-pr.

For specific product information and inquiries, call (800) 879-8079 ext. Marketing Communications or send an e-mail to: SiemensMTBUMarCom.industry@siemens.com.

Follow us on Facebook: www.facebook.com/SiemensCNC or Twitter: www.twitter.com/siemens_cnc_us.

—

Siemens Industry Sector is the world’s leading supplier of innovative and environmentally friendly products, solutions and services for industrial customers. With end-to-end automation technology and industrial software, solid vertical-market expertise, and technology-based services, the sector enhances its customers’ productivity, efficiency and flexibility. With a global workforce of more than 100,000 employees, the Industry Sector comprises the Industry Automation, Drive Technologies and Customer Services Divisions as well as the Metals Technologies Business Unit. For more information, visit http://www.usa.siemens.com/industry.

The Siemens Drive Technologies Division is the world’s leading supplier of products, systems, applications, solutions and services for the entire drive train, with electrical and mechanical components. Drive Technologies serves all vertical markets in the production and process industries as well as the infrastructure/energy segment. With its products and solutions, the division enables its customers to achieve productivity, energy efficiency and reliability. For more information, visit http://www.usa.siemens.com/drivetechnologies.

TechSolve is a consulting firm that has helped organizations of all sizes leverage process improvement, machining expertise and innovation to enhance their competitive edge across ever-changing markets. We understand engineering and manufacturing, so we developed an array of machine monitoring software under the umbrella of VizProductsTM.

Our custom-tailored machine-monitoring and data-gathering solutions enable shops and production departments alike to more efficiently gather and analyze machine tool performance data, TechSolve can help manufacturers eliminate extraneous costs, increase productivity, and maximize profits. For more information please visit www.techsolve.org.

Ann Arbor, Michigan – GMTA (German Machine Tools of America) represents various top-quality German metalworking machine builders, including Wera Profilator, Pittler, Praewema and WMZ. These machines are sold to the North American market by GMTA primarily for gear and spline production, as well as other power transmission applications. The company’s target markets include automotive, off-highway, energy and other heavy equipment manufacturing. Machines are provided for gear honing, gear grinding, the patented Scudding® process for gearmaking, polygon milling, turning, gear tooth pointing and multi-task machining operations. This newsletter is provided to our friends in the media to keep you and your readers updated on News of Note at GMTA.

In the news…

– GMTA proudly announces the addition of Stefan Kloos as Product Manager. Stefan will handle the Pittler vertical turning lathes and WMZ centerdrive lathes. He will be based in Ann Arbor, Michigan, North American Headquarters for GMTA.

– German Language and International Careers (LIC) students from Eastern Michigan University visited GMTA on March 12, 2014. Students were given a tour of GMTA facilities and a presentation in German by GMTA President, Walter Friedrich. As EMU Department of World Languages Professor Margrit Zinggeler Ph.D. pointed out, “Eastern Michigan was one of the first universities to combine foreign language with a practical business component. The EMU major in language and international careers (LIC) is designed to integrate the study of modern foreign languages and cultures with preparation for an international business career. The major objective of the program is to provide students with the skills, knowledge and understanding needed to function in a foreign environment and in professional dealings with people and clients who speak a foreign language. It is a very useful course of study in today’s global economy, especially with so many foreign companies setting up shop in the U.S.” After the presentation and questions, students were invited to a typical German “Brotzeit” (evening meal of German bread and coldcuts) and, of course, ample quantities of German beer Reissdorf Koelsch! GMTA is proud to support young people in the community and help provide them with (German) language opportunities in a business environment.

Students from Eastern Michigan University’s Language and International Careers (LIC) program visited GMTA for a detailed explanation in German from the company president, Walter Friedrich, right. Leading the group was Professor Margrit Zinggeler, Ph.D., third from the right

– A definitive explanation on the trademarked Profilator Scudding® process for advanced gearmaking is now available from GMTA. Please contact Scott Knoy below for details.

– GMTA supports the Judson Center, a charity that serves the needs of individuals with life challenges such as autism. Every year, the Center tries to provide the youngsters served with a life-changing event. This year, the Center is providing 150 bicycles. GMTA is part of a group of companies supplying the bikes, along with GM Warren Transmission and local radio station, 95.5 WYCD Detroit Country. Claudia Hambleton coordinated the effort for GMTA.

For more information on this announcement, please contact:

GMTA (GERMAN MACHINE TOOLS OF AMERICA)

4630 Freedom Drive

Ann Arbor, MI 48108

Phone: 734-973-7800

Fax: 734-973-3053

Web: www.gmtamerica.com

Email: scott@gmtamerica.com

Attention: Scott Knoy

Connect with GMTA online:

Siemens Industry, Inc. presents its new Sinumerik 808D Advanced CNC with compatible motors, drives and cabling, in vertical or horizontal variants for basic milling and turning machines

Siemens Industry, Inc. announced today its new Sinumerik 808D Advanced CNC, designed for basic milling and turning machines. Affordably priced for the machine builder (OEM), this new addition from Siemens offers a suite of design features to improve the accuracy, surface finish, safety and communication of the control. This new CNC is available now to the North American machine tool market.

The Sinumerik 808D Advanced offers up to five axes / spindle motion control on a single machine channel, with drive bus communication between the CNC and drive for better position control, data transfer over standard Ethernet protocol, plus Auto Servo Tuning (AST) for superior surface quality and repeatable part accuracy in mold and die applications. These include incremental encoder with 2,500 parts per revolution (ppr) or absolute encoder with 20-bit resolution.

Motor speeds up to 4,000 rpm are offered with Safe Torque Off (STO) and IP65 enclosure protection. Vertical and horizontal configurations of the Sinumerik 808D are available to suit all standard control panels.

The Sinumerik 808D Advanced T is the ideal choice for basic turning machines or turning centers without a Y-axis, with the option of driven tools, while the Sinumerik 808D Advanced M offers advanced surface finish and the SINAMICS V70 drive platform from Siemens, all with an attractive price-to-performance ratio.

Additional features of the Sinumerik 808D Advanced CNC include an RJ45 Ethernet port, 7.5” LCD color display with 640 x 480 resolution for easy viewing, machine technology-specific keyboards with hard keys shielded with protective membrane, a robust enclosure with no fan or hard disk, maintenance-friendly power with no battery, continuous data buffering with NV-RAM technology, LED tool number display and a master control panel with rotary switch for feed and spindle override. The rated torque is 1.9-40 Nm with drive line input of 400V and overload rating of 300 percent.

Part programs can be managed on an external PC, then fed to the control over an Ethernet cable or input via the USB port. Simple program sub-folders can be stored on the control, just like on the PC. Other standard features of the Siemens CNC for machine operators and programmers include intelligent jog, precise tool data handling with easy-to-recognize on-screen icons, tool wear data logging to ensure consistent high workpiece quality and startGUIDE engineering support, complete with the graphical user interface wizard for easier machine commissioning and startup and troubleshooting.

Siemens provides full training, on-site support and service plus a three-year warranty on parts and service. Proper machine registration is required.

For more information about the new Sinumerik 808D Advanced, please visit:

www.usa.siemens.com/808D-PR.

For more information on Siemens SINUMERIK CNC, visit www.usa.siemens.com/cnc.

For specific product information and inquiries, call (800) 879-8079 ext. Marketing Communications or send an e-mail to: SiemensMTBUMarCom.industry@siemens.com.

Follow us on Facebook: www.facebook.com/SiemensCNC or Twitter: www.twitter.com/siemens_cnc_us.

—

Siemens Industry Sector is the world’s leading supplier of innovative and environmentally friendly products, solutions and services for industrial customers. With end-to-end automation technology and industrial software, solid vertical-market expertise, and technology-based services, the sector enhances its customers’ productivity, efficiency and flexibility. With a global workforce of more than 100,000 employees, the Industry Sector comprises the Industry Automation, Drive Technologies and Customer Services Divisions as well as the Metals Technologies Business Unit. For more information, visit http://www.usa.siemens.com/industry.

The Siemens Drive Technologies Division is the world’s leading supplier of products, systems, applications, solutions and services for the entire drive train, with electrical and mechanical components. Drive Technologies serves all vertical markets in the production and process industries as well as the infrastructure/energy segment. With its products and solutions, the division enables its customers to achieve productivity, energy efficiency and reliability. For more information, visit http://www.usa.siemens.com/drivetechnologies.

Continue reading