Contact us today:

(847) 934-4500

tdaro@bernardandcompany.com

Contact us today:

(847) 934-4500

tdaro@bernardandcompany.com

Rome, Georgia – Suhner introduces the Rotomax flexible shaft machine, a unique unit with interchangeable hand pieces that allow a user the freedom to perform a wide variety of machining operations with a single machine. The Suhner Rotomax functions as an angle grinder, straight grinder, drum polisher, belt sander, tube polisher or die grinder, simply by changing the hand piece. This new machine has myriad applications in industrial steel fabrication, polishing operations, sheetmetal assembly, food processing and foodservice equipment builds, appliance manufacturing, various stainless steel fabrications including medical and more.

The Suhner Rotomax offers users a range of power from 2.0-4.7HP and features electronically-controlled speeds ranging from 500-15,000 RPM in increments of 100 RPM at the touch of a button. The combination of an industrial grade motor and solid-state electronic control ensure constant speed and torque during any application. With no gearing, the Rotomax operates very quietly. Other features include soft start, integrated braking and an LED-displayed speed gauge.

The Rotomax is offered as a hanging model, for the user wishing to keep the power flex shaft above the work; on the basic stand, which can be mounted wherever the user desires; or on a specially-designed stable trolley (STM) for portability around the work shop or production line.

For more information, please contact:

SUHNER Industrial Products, LLC

43 Anderson Road SW

P.O. Box 1234

Rome, GA 30161

Phone 706/235-8046

Fax 706/235-8045

info.usa@suhner.com

www.suhner-abrasive-expert.com

Attention: Aaron Beck, National Sales Manager, Abrasives & Power Tools

New extrusion head from market leader features Mechanically Assisted Gum Space (MAGS) adjustment

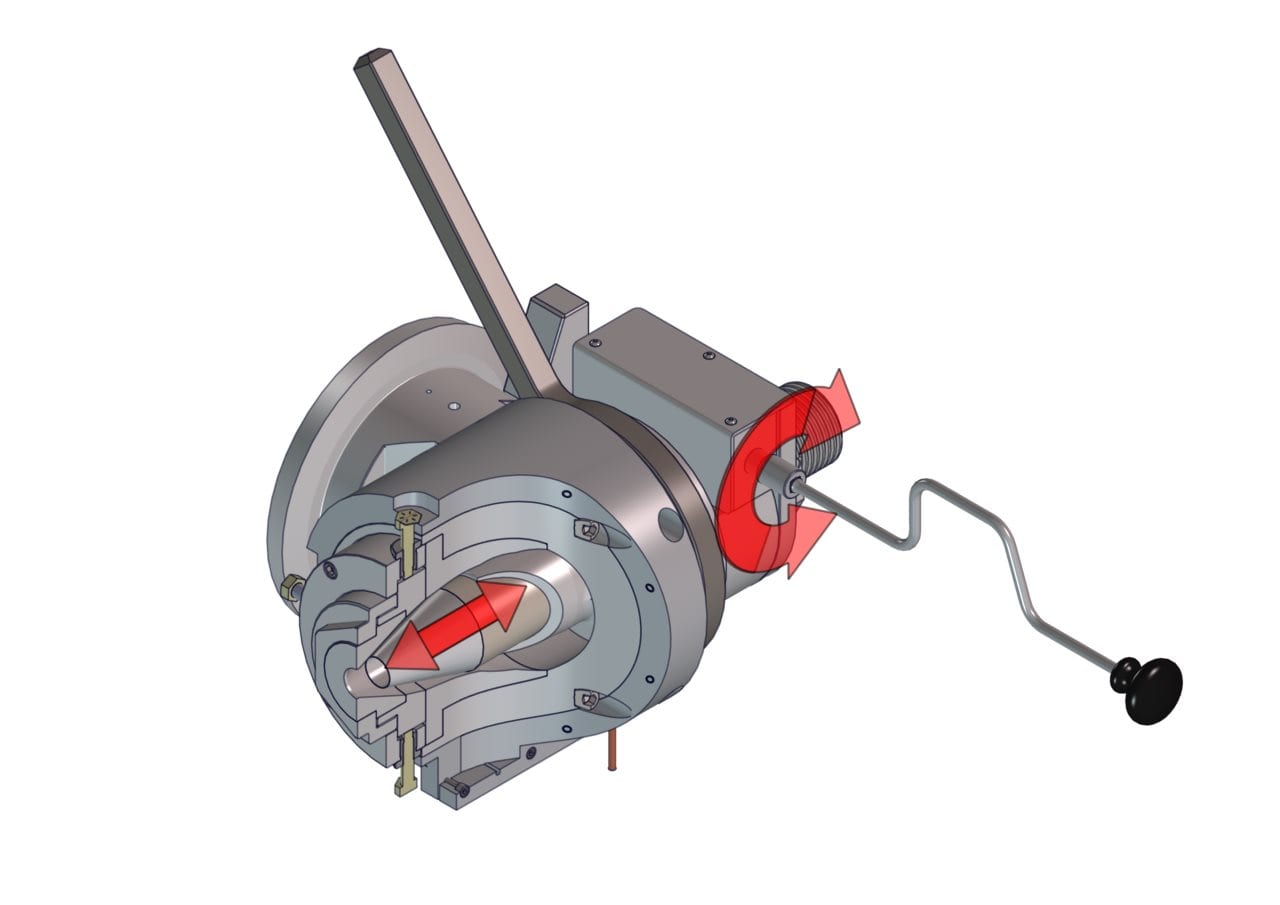

Guill Series 500 crosshead with Mechanically Assisted Gum Space (MAGS) adjustment…specially designed for the flow characteristics of elastomeric compounds

Guill Tool introduces the NEW 500 Series crosshead with MAGS gum space adjustment. The 500 Series is designed specifically for the flow characteristics and unique processing challenges of elastomeric compounds. One of the key features engineered by Guill on this new crosshead design is the mechanically assisted gum space (MAGS) adjustment system. This new method of gum space adjustment allows the operator to make an effortless adjustment from a single point using a common socket wrench. No more need to struggle with multiple nuts and bolts in order to adjust gum space, which leads to faster adjustments. The visual indicator on the core tube allows the operator to see how far the gum space has been moved, making those adjustments much more accurate and repeatable.

The hardware-free and patented cam lock design of the NEW 500 Series from Guill means no time is wasted unbolting and re-securing fasteners for disassembly and re-assembly. Only half of a rotation of the cam nut is required to loosen and automatically extract the deflector from the head body, which is another time saver. Also, with no undercuts on the deflector, there are no material hang-ups when extracting the deflector, allowing for faster and easier cleaning and changeover.

The NEW 500 Series also features the latest Center-Stage concentricity adjustment system that significantly reduces pressure on the tooling, allowing easier and more precise concentricity adjustments without loosening the face bolts. Easy-Out inserts for the adjusting bolts also allow simple replacement of locked or damaged adjusting bolts, which further saves on repair and downtime.

Another innovative feature of this new rubber/silicone crosshead is a cast aluminum liquid-fed cooling sleeve that allows the user to switch out the cooling jacket in the event of a line obstruction, again reducing downtime compared to traditional integrated cooling systems.

The NEW 500 Series crosshead with MAGS gum space adjustment is a drop-in replacement on most existing NRM lines, however this crosshead design can also be adapted to fit any extruder design or line layout.

The addition of a newly designed flow inlet channel reduces the shear and heat that is generated as the materials are being processed. This leads to lower head pressures allowing the material to move through the head in a much more balanced and even flow.

All crossheads supplied by Guill are furnished with a tool kit for assembly and disassembly as well as a detailed operator’s instruction manual. The engineering team at Guill will gladly assist users in the implementation and operation of the NEW 500 series crosshead.

For a video of the NEW Guill 500 Series crosshead with MAGS gum space adjustment, please go to:

For more information, please contact:

Bill Conley, Sales Manager

Guill Tool & Engineering

10 Pike Street

West Warwick, RI 02893

USA

Phone: 401-828-7600

www.guill.com

sales@guill.com

Continue reading

New catalogs for Mori Seiki, TSUGAMI and Miyano machines offer standard tools from live tooling leader

Heimatec, a market leader in live tooling for the North American machine tool industry, has released a series of four new catalogs showcasing the company’s lines of machine brand specific tooling.

Already offering the most complete line of live tools available in the industry, with over 40,000 designs in its database, Heimatec machine brand specific tooling includes products for the following popular brands:

Heimatec sets the standard for the highest precision and most advanced technology in the machine tool accessory market. The company is acknowledged as a world leader in live tools, angle heads and multi-spindle drill heads.

In addition to its standard tooling and machine brand specific line, Heimatec also offers custom designed tooling. Heimatec tooling experts work directly with customers to design solutions to suit specific requirements for all CNC lathes, helping to solve the most challenging applications in multiple markets served by the company, ranging from orthopedic devices to oil & gas drilling equipment.

Heimatec North American distribution headquarters are located in Prospect Heights, Illinois (Chicago) with world headquarters plus all manufacturing based in Germany. A team of manufacturers’ representatives covers the North American market for Heimatec.

Visit Heimatec at IMTS 2016, Booth # W-2054 in Chicago.

For more information or to receive a PDF copy of the new dedicated tool catalogs, please contact:

Preben Hansen, President

Heimatec Inc.

16 East Piper Lane, Suite 129

Prospect Heights, IL 60070

847-749-0633

www.heimatecinc.com

phansen@heimatecinc.com

Standard and custom styles available for Hyundai, Miyano and Nakamura machine tools; offered for all tapers, including HSK and BT30; fixed and adjustable models; many in stock for immediate delivery

Heimatec live tooling is now available in stock for all the popular models in the Nakamura, Hyundai and Miyano lines.

Heimatec, a world leader in live tools and multi-spindle drill heads, today announces immediate availability of live tooling for all popular models in the Hyundai, Miyano and Nakamura turning center lines. According to Preben Hansen, Heimatec president, “We’re carrying a substantial inventory of live tools for our customers’ machines now and it represents a substantial financial and warehouse space commitment we’ve made to support them in the North American market.”

Hansen added that the company will be announcing its in-stock arrangement for many other lines of machine tools, moving forward, as the company commits a major investment to the market. Heimatec Inc. serves its North American customers with a full team of manufacturers’ rep firms, plus its Chicagoland facility offers stocking, repair, application engineering and service for the company’s line of live tools, multi-spindle tool, adapters, UTEC® right angle heads and other items offered.

Literature detailing all the Heimatec products now available in stock for Hyundai, Miyano and Nakamura machining centers is offered at the company’s website, www.heimatecinc.com. Interested parties may also contact the company directly with inquiries.

CAT 40, BT 40, BT 30, HSK 63A, CAT 50, BT 50, HSK 100A and many other taper styles are available, as well as custom modifications such at 18” extension shafts. Offset, Slim, Dual and Adjustable styles. Heimatec offers a full one-year warranty on all parts and labor.

For further information and brand-specific literature, or to arrange a demo on any Heimatec tools, please contact:

Preben Hansen, President

HEIMATEC INC.

16 E. Piper Lane

Suite 129

Prospect Heights, IL 60070

Phone: 847-749-0633

Fax: 847-749-2445

Email: phansen@heimatecinc.com

Heimatec is an international tooling manufacturer, based in Renchen, Germany. Its experienced staff is dedicated to providing customers the most innovative tooling technology possible. In 2010, the company opened Heimatec Inc. in Prospect Heights, IL, near Chicago, to serve its growing North American customer base with sales and service, plus an extensive inventory of products. Heimatec serves the auto, aero, medical, off-highway, rail, energy, woodworking, composites and other industries, as well as an ever-increasing number of machine tool OEM’s worldwide.

Continue reading

SUHNER Flexible Shafts

Handle speeds up to 50,000 rpm with high accuracy; from printing presses and remote control valve control to speedometers and power seat actuation

Suhner Standard Flexible Shafts offer a plug and play solution. Equipped with standard female couplings with set screws, available for left hand, right hand or bi-directional application in a wide range of lengths and torque ratings, flexible shafts are easy, efficient and virtually maintenance free flexible drive shafts allowing for maximum design freedom in a wide variety of OEM applications in myriad industries.

Our K and Ka type plastic casing flex shafts are used throughout the automotive OEM, for engine control and power transmission, as well as interior controls on power seats and steering wheel adjustments.

Interested parties can review the online catalog for power transmission products from Suhner and use the handy math tools and other selection guides provided.

For more information, please contact SUHNER Mfg., Inc. at info.usa@suhner.com or visit our website at www.suhner.com.

Contact info:

Suhner Manufacturing, Inc.

43 Anderson Road SW

Rome, GA 30161

Phone: 706-235-8046

www.suhner.com

Attention: Michael Boehm, Director of Marketing & Sales

Michael.boehm@suhner.com

Continue reading

Ann Arbor, Michigan – GMTA (German Machine Tools of America) represents various top-quality German metalworking machine builders companies, including Wera Profilator, K + G, Pittler, Praewema and WMZ, as well as Arnold lasers. These machines are sold to the North American market by GMTA, primarily for gear and spline production, as well as other power transmission and various metalworking applications. The company’s target markets include automotive, off-highway, energy and other heavy equipment manufacturing. Machines are provided for gear honing, gear grinding, the patented Scudding® process for gearmaking, polygon milling, turning, gear tooth pointing and multi-task machining operations, as well as various laser operations or laser line integration. This newsletter is provided to our friends in the media to keep you and your readers updated on News of Note at GMTA.

In the news…

-GMTA will exhibit at several shows upcoming, including EMO in Milan and Gear Expo in Detroit. At the latter, the company will show its latest development for gearmaking, namely, the Hard Scudding process. Just a few years ago, the concept of Scudding®, developed by GMTA and its partner company Wera in Germany, left the traditional skiving method in the dust, so to speak, for internal gear production used primarily in the powertrain buildup. This process, 5-10 times faster than gear shaping, formed the surface of the workpiece through several, small enveloping cuts, providing a surface finish and part quality level that was far superior to hobbing, shaping or broaching. Scudding is a continuous generating process, meaning no idle strokes on the machine tool, as when shaping gears. Ring gears, sliding sleeves and annulus gearing, whether internal helical or spur, external helical or spur or blind spline, synchronizer parts with block tooth features and synchronizer hubs remain among the popular products in the market, made with Scudding technology.

Today, this continuous gear cutting process is widely used in production environments for internal, external, helical and spur gears, as well as splines and other components in the powertrain world. The machining can be done without the need for an undercut or groove (clearance) and lead of the gear can be manipulated via axial motions (crown/taper). It is a demonstrably superior technology and automotive suppliers have embraced its advantages for many years now.

Impressive a technology as it is, the industry took another step forward recently with our new process known as Hard Scudding™. The conventional Scudding process provides excellent results on green or soft gears, while this new advancement enables the re-machining of hardened gears with a tooth-to-tooth composite error and total composite error in the AGMA 12, DIN 5 range and a surface finish better than 1.5 Ra.

The capital investment is minimal for shops and production departments already doing Scudding, because the same gear can be run on the same CNC machine, using a solid carbide tool to do the work. Recent testing done on various internal automotive powertrain and agricultural machinery ring gears is showing extremely positive results. Stock division calculations on the tooth position are standard technology for GMTA and Profilator, so re-cutting is quick and easy. Using the latest CNC technology to control the machine kinematics, users are able to transfer this technology to Scudding machinery that is already deployed in the field. Thus, the same part can be cut on different machines at different times, allowing for more flexibility in scheduling. With today’s portable programming, onscreen or offline tool path and cutting condition simulation, plus the immediacy of call-up onscreen for all values and tolerances in real time, the busy machine shop or large production department stays flexible and demand responsive, using this Hard Scudding technology. In some cases, this new technology is applicable on near net, pre-hardened gear blanks, allowing significant step reductions in the manufacturing process.

In operation, cutting 60-100 thousandths per flank on a tooth, the Hard Scudding process can be used on a carburized or through-hardened parts; nitriding generally does not provide enough case depth to ensure sufficient stock for “clean-up”. An automotive ring gear, for example, which requires 40-50 seconds for Scudding can be produced with Hard Scudding in 25-30 seconds. This process development stands as a viable and very cost-effective alternative to conventional grind-and-hone operations, yielding a highly attractive cost per piece and extended tool life scenario. The added benefits of reduced capital outlay and a significantly more consistent end product bode well for the automotive powertrain and other gear market segments.

STOP BY BOOTH 2109 IN DETROIT, OCTOBER 20-22 TO LEARN MORE OR CALL SCOTT KNOY TODAY!

-GMTA management will be attending EMO in Milan with its partners, then exhibiting at Gear Expo, being held this year in Detroit, October 20-22.

-GMTA is running at “light speed” with their new Arnold laser work cells. Available as single or double work cells, the Arnold systems are offered as CO2 or fiber lasers, with full integration into a machining line, either by means of robotic part articulation or other automated transfer mechanisms, most of which are being supplied to customers by GMTA engineering. Leads from the last IMTS and the company’s aggressive ad program are already being developed into serious opportunities for the company, often in tandem with other machine tool lines and auxiliary equipment now offered by GMTA, according to company President Walter Friedrich. The most recent development is laser cladding, a process of simultaneous metal deposition and fusion, with an extremely high degree of control on the geometry. This technology has considerable application in the aerospace, medical, power gen and oil & gas market segments, in addition to the GMTA home base of automotive.

-The new Mexican office of GMTA, located in Queretaro, is reporting brisk activity, owing to the substantial procurement authority in-country now. According to VP Scott Knoy, “This contrasts with bygone days, when the decision-making and purchasing were largely centered in America and specifically in Detroit. It’s a whole new ballgame with the Mexican market today and we believe our new location (Queretaro) there is well positioned to serve this dynamic manufacturing environment.” GMTA already has a substantial installed base of machines in Mexico from all their partner companies. At the new facility, machines are in place for demo and test runs, plus the facility is fully staffed with application engineering, technical support, after-sale service and parts inventory.

-Sales continue to be brisk on the 9- and 10-speed transmission projects in the automotive market. Scott Knoy, GMTA VP, comments, “We’re seeing a lot of activity here in the States and in Mexico, so we know our timing was right with the opening of our new facility there.”

-As part of the company’s ongoing commitment to education, GMTA Corporate Treasurer Claudia Hambleton volunteers for the Junior Achievement program in Saline, Michigan for educating K-12 students about jobs, entrepreneurship, financial literacy and work readiness in today’s competitive and changing market. She is active in the recruitment of local business people in the area to assist the program.

-The alliance with Star SU, through which GMTA is sourcing tooling locally, continues to prosper and mutually benefit both companies.

– We are proud to announce a business transaction between the Profilator Group and the Dr. Dieter Murmann Beteiligungsgesellschaft, in which Dr. Dieter Murmann Beteiligungsgesellschaft has acquired all shares of the Profilator Group, consisting of Profilator GmbH & Co. KG and the U.S. affiliate company GMTA (German Machine Tools of America Inc.). The Murmann family has long term plans with the Profilator Group to act as an autonomous business, striving for future success and ongoing technical developments. The current management team of the entire Profilator Group will remain the same, including Thomas Buchholz as Managing Director of Profilator in Wuppertal, Germany and Walter Friedrich as President of GMTA.

-GMTA is a corporate sponsor of the Smart Factory Industry Forum, being sponsored by the German American Chamber of Commerce and held at the Digital Manufacturing & Design Innovation Institute in Chicago on October 9.

For more information on this announcement, please contact:

GMTA (German Machine Tools of America)

4630 Freedom Drive

Ann Arbor, MI 48108

Phone: 734-973-7800

Fax: 734-973-3053

Web: www.gmtamerica.com

Email: scott@gmtamerica.com

Attention: Scott Knoy, VP

Connect with GMTA online:

New low-volume spiral flow ABA crosshead with 2-stage clamping for easy concentricity adjustment

Guill Tool introduces Series 824, a co-extrusion crosshead designed for irrigation tubing with an emitter tool. Manufactured from stainless steel, this new crosshead features balanced flow design with spiral technology that improves flow characteristics at all extruder speeds. Dual feed ports provide concentric compound flow, while the splits flow from one extruder to feed the inside and outside layers via a manifold assembly. Series 824 is adaptable to all popular extruders on the market currently.

Capacities include a max. die ID of 1.875”, max. core OD of 1.250”, max. tip OD of 1.500” and max. emitter tool OD of 30mm (1.18”). The Series 824 design allows the emitter insertion tool to pass completely through the crosshead ID. Gum space adjustment is performed with die nut rotation, while the Guill 2-stage clamping mechanism allows easier concentricity adjustment. Quick-change tooling and a tool kit for disassembly and re-assembly are provided with the unit.

Bill Conley, sales manager for Guill, comments, “On this project, the customer challenged us with an application that required precise placement and bonding of preformed emitters within the extruded tubing without melting them in the crosshead. It was also necessary to process either a low-cost ABA layer construction or single-layer construction within the same unit.”

With the Series 824, the customer realized cost reductions, better quality, less scrap and more uptime in their process. The Guill cool-tube design prevented the emitter from melting in the head and the overall unit mechanics allowed more rapid and easier changeover from a co-extrusion to a single layer.

On this project, Guill also supplied the customer the company’s extrusion tool cart, which facilitates easy alignment and tool changes. The removable cart swing gates stay free from accumulated process fluids, while the adjustable height means the cart is compatible with virtually any extruder model. Thermal isolation in the design keeps heat in the head, not the cart.

For further information, please contact:

GUILL TOOL & ENGINEERING CO., INC.

10 Pike Street

West Warwick, RI 02893

Phone: 401-828-7600

Web: www.guill.com

Email: sales@guill.com

Attention: Bill Conley

Connect with Guill Tool online:

No. 980 is a 500ºF (260ºC), electrically-heated universal style oven from Grieve, currently used for post curing fabric-coated silicone rubber gaskets at the customer’s facility. Workspace dimensions of this oven measure 30” W x 144” D x 30” H. 24 kW are installed in Nichrome wire elements to heat the oven chamber, while a 4200 CFM, 3-HP recirculating blower provides front-to-rear universal airflow to the workload.

This Grieve universal oven features 4” thick insulated walls, aluminized steel exterior, Type 304, 2B finish stainless steel interior, plus an integral oven leg stand and one pair of truck wheel guide tracks installed on the top of the floor to accept the customer’s wheeled fixture.

No. 980 includes all safety equipment required for flammable solvent processing, including explosion-venting door hardware and powered forced exhauster.

Controls on this oven include a digital indicating temperature controller.

For more information, please contact:

THE GRIEVE CORPORATION

500 Hart Road

Round Lake, IL 60073-2898

Phone: (847) 546-8225

Fax: (847) 546-9210

Web: www.grievecorp.com

Email: sales@grievecorp.com

Attention: Frank Calabrese, VP

New extrusion head from market leader features NO hardware, for easy cleaning, plus quick-change tooling, as tips removes from the back, die from the front

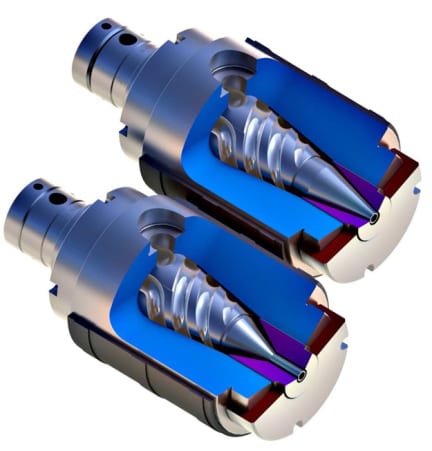

The Bullet, showing the absence of hardware, i.e. nuts and bolts, so disassembly, cleaning and restart are made easier

Guill Tool introduces The Bullet™, a new extrusion head with fixed center design, multi-port spiral flow design and gum space adjustment, plus the added feature of no fastening hardware, so cleaning and restart are easier and faster than any conventional head on the market currently, according to company sources.

The Bullet allows quick tooling changes, as the tips remove from the back and the die removes from the front of the unit. The absence of fastening hardware eliminates leaking, as does the taper body and deflector design pioneered by Guill.

High- and low-volume applications are suitable for this head and are accommodated with the simple, easy changing of just one component. A family of crosshead designs is available and users can specify the “caliber”, that is, the max. die ID.

A vacuum chamber and kit for assembly and disassembly are included with the unit. Optional keyed tooling capability offers machine designers and end users quick orientation, so the overall unit design enables faster disassembly, proper cleaning and restart, allowing the line to become more profitable.

For further information, please contact:

GUILL TOOL & ENGINEERING CO., INC.

10 Pike Street

West Warwick, RI 02893

Phone: 401-828-7600

Web: www.guill.com

Email: sales@guill.com

Attention: Bill Conley

Connect with Guill Tool online:

This Grieve universal oven features 6” insulated walls, aluminized steel exterior, Type 304 stainless steel interior with 2B finish plus two 24” wide x 24” long shelves supported by rollers and each rated at 300 lb. load capacity. An integral oven leg stand is also provided.

No. 1034 controls include a digital indicating temperature controller, manual reset excess temperature controller with separate contactors and recirculating airflow safety switch.

For more information, please contact:

THE GRIEVE CORPORATION

500 Hart Road

Round Lake, IL 60073-2898

Phone: (847) 546-8225

Fax: (847) 546-9210

Web: www.grievecorp.com

Email: sales@grievecorp.com

Attention: Frank Calabrese, VP