Contact us today:

(847) 934-4500

tdaro@bernardandcompany.com

Contact us today:

(847) 934-4500

tdaro@bernardandcompany.com

No. 1021 is a 1250ºF high-temperature belt conveyor oven from Grieve, currently used for drying steel nesh (sieve) materials at the customer’s facility. Workspace dimensions of this oven measure 21” W x 38” D x 3” H. 40 KW are installed in Incoloy-sheathed tubular elements to heat the oven chamber, while a 1600 CFM, 1-1/2 HP recirculating blower provides vertical downward airflow to the workload.

This Grieve packaged conveyor oven features 10” thick insulated walls made from 8” of 1900ºF block and 2” of 10 lb/cf density rockwool insulation, aluminized steel exterior, Type 304, 2B finish stainless steel interior and an 18” wide, 1” x 1” stainless steel flat wire conveyor belt with 1/3 HP motor drive, variable from 0.05 to 1.20 feet per minute. The oven travel comprises a 30” long open belt loading zone, 38” long insulated heat zone with recirculated airflow and 30” long open unloading zone. 10” x 10” stainless steel mesh screens above the return ductwork below the conveyor are provided to collect debris from the workload.

Controls onboard No. 1021 include a digital indicating temperature controller, SCR power controller and wall mounted remote control panel (shown detached in photo).

For more information, please contact:

THE GRIEVE CORPORATION

500 Hart Road

Round Lake, IL 60073-2898

Phone: (847) 546-8225

Fax: (847) 546-9210

Web: www.grievecorp.com

Email: sales@grievecorp.com

Attention: Frank Calabrese, VP

Corbas – REP international, leader in the rubber injection molding machine with the head office being located in Lyon-Corbas, France, has just concluded the acquisition of the patented HSM devulcanization technology on an exclusive right basis, as well as the devulcanization center Watson-Brown HSM-Berlin. This center is equipped with an operational devulcanization line and a test laboratory operated by a team of 6 persons.

Bruno Tabar, CEO of the REP group announces that “REP International will carry on with the development of the HSM technology, its implementation in the center of Berlin and promote a sales offer of devulcanization machines and a devulcanization service on the international market with compounders and processors“.

A resolutely promising eco-process

Watson Brown HSM Berlin becomes so far the 7th subsidiary of the REP group, the 6 others being involved in the sales and after-sales of REP presses throughout the world. This take-over confirms REP’s readiness to extend their offer, as accentuated through their new corporate baseline “Rubber in motion”. Aiming to work beyond the injection of rubber and devoted to the tradition of innovation at customers’ service, REP has developed a technical and commercial partnership with Watson Brown HSM the purpose of which is to devulcanize rubber production scraps and reintroduce them into the production chain.

After a series of validation tests conducted in REP’s customer plants it was established that the process is technically performing and economically efficient. That’s when REP decided after many years of collaboration to integrate Watson Brown HSM in their group.

But what is the HSM devulcanization process?

This patented process applies to any kind of uncontaminated rubber production waste. Once the compound is devulcanized, it is reintegrated into the basic compound. This results in significant savings on both compound and waste disposal costs.

Watson Brown has developed a patent for devulcanizing cured rubber. Controlling the strain applied to the compound by the HSM machine causes the rubber to be devulcanized by preserving properties which are very close to the initial compound.

This is a 100% thermo-mechanical process without adding any further substances or chemical agents and is performed at low temperature, in order to prevent the characteristics of the devulcanized rubber from being altered.

From the devulcanization service to the series machine

REP relies on their industrialization capacities, their experience and geographical international presence to develop the commercialization of HSM machines. The HSM structure and its components being very close to those of a press, REP has the capacities to industrialize and manufacture these machines.

With the acquisition of the intellectual property and the plant of Watson Brown in Berlin, REP is developing a devulcanization machine offer intended for compounders and rubber processors in addition to the existing devulcanization service.

What do the activities of Berlin’s center consist in?

Berlin’s devulcanization center is equipped with a laboratory to run tests on samples intended for customers who are willing to test the process based on their own compound, so as to validate the properties before running industrial HSM tests. The existing capacities grant the center the ability to service all customers who want to devulcanize and reintegrate their scraps back into production, in order to substitute them for one part of the basic compound, resulting in a drop in operating cost.

For companies interested in implementing the tests, a few kilograms of scraps will be sufficient to conduct the lab tests resulting in data on the elongation, tensile strength and rheology of the samples. After the test, the customer receives back the processed compound for assessment. It is then possible to conduct production tests to test the final parts on an industrial scale.

Rendezvous at the K2013, Hall 14, Booth B57, October 16-23!

For more information on this announcement, please contact:

REP Corporation

8N740 Tameling Court

Bartlett, IL 60103-8146

Phone: 847-697-7210

Fax: 847-697-6829

Web: www.repinjection.com

Email: tgraham@repcorp.com

Attention: Tim Graham, President

Integrated operation, programming, and diagnostics of KUKA robots via the Sinumerik Operate user interface from Siemens

Automation of machine tools will immediately become more flexible: with Sinumerik Integrate Run MyRobot, Siemens Drive Technologies Division and KUKA Roboter GmbH presented a solution for integrated operation, programming, and diagnostics of a KUKA robot in Sinumerik at EMO 2013. For example, in conjunction with the new “Run myRobot” technology, the CNC control Sinumerik 840D sl package can optimally enable KUKA robots to perform handling tasks on machine tools, in particular, loading and unloading of machining cells. Interaction, such as operation, tool retraction, teach-in, and diagnostics of robots, can be performed through just one operator panel with the Sinumerik 840D sl, thus increasing the efficiency and flexibility of the machine tools. Customer can order this technology package with immediate effect from Siemens.

As part of the dynamic automation solution, functions for handling are one hundred percent available at the Sinumerik Operate user interface. The execution of the machine tool and robot program can be tracked and controlled on screen on parallel channels. This gives the operator a quick overview of the current status of the machine tool and robot. The Sinumerik hand-held terminal HT8 and the user interface can be used to “teach” not only machine tool-related setup actions but, as part of the same operating philosophy, also the path points and functions of the robot.

Execution of the robot movements, provision of robot safety functions, and other robot-specific functions are still performed by the KUKA robot control KR C4. The Sinumerik 840D sl is connected to the KUKA control via a command interface.

With the mxAutomation function block library from KUKA, the motion sequence of the robot can be programmed completely in the Sinumerik control 840D sl. In this way, the robot program can be created completely without any knowledge of Step 7, the Siemens tool for PLC programming.

This press release and further press material are available at http://www.siemens.com/press/emo2013

For more information on this story, contact:

Siemens AG, Media Relations

Franz-Ferdinand Friese, phone: +49 911 895 7946

E-mail: franz.friese@siemens.com

KUKA Roboter GmbH, Corporate Communications

Wolfgang Meisen, phone.: +49 821 4533 1981

E-Mail: WolfgangMeisen@kuka-roboter.de

—

The Siemens Drive Technologies Division (Nuremberg, Germany) is the world’s leading supplier of products, systems, applications, solutions and services for the entire drive train, with electrical and mechanical components (Integrated Drive Systems). Drive Technologies serves all vertical markets in the production and process industries as well as the infrastructure/energy segment. With its products and solutions, the Division fulfills the key requirements of its customers for productivity, energy efficiency, and reliability. For more information, visit http://www.siemens.com/drivetechnologies

The KUKA Roboter GmbH, with its headquarters in Augsburg, is a member of the KUKA Aktiengesellschaft and ranks among the world’s leading suppliers of industrial robots. Core competencies are development, production and sale of industrial robots, controllers and software. The company is the market leader in Germany and Europe and the number three in the world. KUKA Roboter GmbH employs about 3180 people worldwide. In 2012, sales totaled 742,6 million Euro. 25 subsidiaries provide a presence in the major markets of Europe, America and Asia.

Continue readingSiemens and KUKA held a press conference at the EMO Hannover 2013. Manfred Gundel, CEO of the KUKA Roboter GmbH, and Dr. Robert Neuhauser, CEO of the Motion Control Systems (MC) Business Unit of the Siemens Drive Technologies Division, has informed about an enhanced cooperation.

· Joint solutions offered: integrated, operator-friendly loading of machine tools using robots

· Integration of robotics and CNC solutions for machining workpieces with robots

· Strengthening the fundamental idea of integrated production processes

· Development of new applications in lightweight construction

Siemens Drive Technologies Division and KUKA Roboter GmbH have announced comprehensive cooperation at EMO in Hanover. The central pillar of the cooperation is integration of KUKA robots and Siemens CNC solutions for loading machine tools. “With this joint approach, the two companies are strengthening the fundamental idea of integrated production and can, for example, develop new markets by close intermeshing of machine tool tasks and loading tasks,” says Manfred Gundel, CEO of KUKA Roboter GmbH. “The CNC control from Siemens and the robot controls from KUKA are ideal for integrating robot and CNC technology. With this cooperation, we are deepening our many years of cooperation and together advancing intelligent automation solutions as outlined by the Industrie 4.0 project for the benefit of both partners and to expand business,” says Dr. Robert Neuhauser, CEO of Business Unit Motion Control Systems at Siemens.

Highly flexible and fully automated production today demands complete integration of robots into the production flow and into the automation environment. In this area, in particular, applications for robots and machine tools are growing together steadily as a result of new requirements and technological progress. Given these developments, Siemens and KUKA are strengthening their cooperation in automation and industrial robots. The aim is to be better able to serve industries with high automation requirements in loading and machining. With the shared development, customers will have access to new products and solutions that are coordinated optimally over their entire life cycle, from design, to production simulation, to engineering and the production shop level. Moreover, in the long term, the two companies will be including aspects of robot automation in their activities as outlined in the Industrie 4.0 project.

With this close partnership, Siemens and KUKA can offer end customers integrated solutions with a high technological demand and level of maturity and position themselves still better on global markets. At the center of the joint development and the closely meshed marketing activities is seamless, operator-friendly integration of the robot for loading the machine tool. The companies will also develop scalable, integrated solutions for machining workpieces with robots, especially for lightweight construction. In this field, in particular, new materials such as composites require innovative machining concepts that the two companies will be intensively advancing as part of the cooperation.

KUKA will provide robot systems that make use of proven solutions in the field of CNC with Sinumerik from Siemens for integration with machine tools. The standard implementation of the concept includes loading by a KUKA robot, which is integrated in Sinumerik. A scaled offer is also planned ranging from a robot with additional CNC machining functionality to a robot as a pure CNC machining unit. Here, too, the aim is complete integration of the robot into the PLM processes.

At EMO 2011, both partners have already presented the integration of the robot into the Sinumerik user interface as an application, for programming, teach-in, and diagnostics. The next step will now be the connection to CNC tasks.

Click here to view the slide presentation from the press conference.

For more information on the story above, contact:

Siemens AG, Media Relations

Franz-Ferdinand Friese, phone: +49 911 895 7946

E-mail: franz.friese@siemens.com

KUKA Roboter GmbH, Corporate Communications

Wolfgang Meisen, phone.: +49 821 4533 1981

E-Mail: WolfgangMeisen@kuka-roboter.de

—

The Siemens Drive Technologies Division (Nuremberg, Germany) is the world’s leading supplier of products, systems, applications, solutions and services for the entire drive train, with electrical and mechanical components (Integrated Drive Systems). Drive Technologies serves all vertical markets in the production and process industries as well as the infrastructure/energy segment. With its products and solutions, the Division fulfills the key requirements of its customers for productivity, energy efficiency, and reliability. For more information, visit http://www.siemens.com/drivetechnologies

The KUKA Roboter GmbH, with its headquarters in Augsburg, is a member of the KUKA Aktiengesellschaft and ranks among the world’s leading suppliers of industrial robots. Core competencies are development, production and sale of industrial robots, controllers and software. The company is the market leader in Germany and Europe and the number three in the world. KUKA Roboter GmbH employs about 3180 people worldwide. In 2012, sales totaled 742,6 million Euro. 25 subsidiaries provide a presence in the major markets of Europe, America and Asia.

Continue readingResponding to growth in sales and expanded market opportunities, industry leader in rubber injection presses adds to staff

Bartlett, IL – REP Corporation announces the appointment of John “JR” Mohl to the position of regional sales manager, effective immediately. JR will cover select regions of the country, representing the full line of rubber/TPE injection presses and other processing equipment built by REP, the longtime world leader in rubber molding technology.

Commenting on the appointment, REP Corporation President Tim Graham observed, “We have been experiencing considerable growth in our business, with new machine orders from many of our longtime customers and also the acquisition of new customers who’ve come our way as the result of the new equipment offerings in our suite. We know JR will be a real asset to our efforts in the field. He also obviously has the right genes for the job,” Graham joked in reference to the new employee’s father, John Mohl, also a REP regional sales manager and an acknowledged expert in rubber molding technology. John will be speaking at the upcoming International Elastomer Conference in Cleveland on various aspects of the molding and curing process.

A resident of Kalamazoo, Michigan, JR Mohl comes to REP with 15 years experience in various customer service and sales roles. He holds a degree in Aviation Flight Science from Western Michigan University, where he is currently enrolled in the MBA program.

For more information on this announcement, please contact:

8N740 Tameling Court

Bartlett, IL 60103-8146

Phone: 847-697-7210

Fax: 847-697-6829

Web: www.repinjection.com

Email: tgraham@repcorp.com

Attention: Tim Graham, President

Milwaukee-based commercial heat treater now a formidable player in the Midwest

Milwaukee, Wisconsin – Complete Heat Treating, LLC today announces the completion of its acquisition of all assets and equipment of the former Wisconsin Steel Industries, Inc. Complete co-owners Jake and TJ Dolhun made the announcement from the company headquarters here. By this acquisition, Complete becomes a formidable player in the commercial heat treating market in the Midwest, as the combined companies boast 75 years of service to the metalworking industry, with substantial heat treating and related capabilities. The purchase of Wisconsin Steel was made by Complete in 2011, with the relocation of all equipment and key personnel having now concluded.

All equipment from both companies has been consolidated at the 65,000 square foot Complete facility in Milwaukee, where the highlight is a gas-fired car bottom furnace with a 53’ x 22’ x 14’ workspace, powered by 40,000,000 BTU’s with a 1,000,000-pound load capacity and operating temperatures to 2150ºF max.

The equipment and services now offered here include five car bottom furnaces, five box furnaces, heavy-duty polymer and water quench tanks, stress relieving, sand blasting, prime and finish painting, annealing, normalizing, BHN inspection, straightening, saw cutting of test specimens, tractor/trailer fleet and full compliance with ISO 9001 certification standards. Workpieces to 50 tons are routinely processed here, using existing and new crane equipment recently installed.

Customers for this commercial heat treater include many of the Midwest’s leading builders of farm equipment, mining equipment, materials handling equipment, rail systems, construction equipment, power generation, oil/gas and other machinery.

Wisconsin Steel was established in 1939 by Ted Dolhun, Sr., grandfather to the current owners of Complete.

For more information on this story, interested parties should contact:

COMPLETE HEAT TREATING, LLC.

125 East Greenfield Avenue

Milwaukee, Wisconsin 53204-2937

Phone: 414-643-5161

Fax: 414-383-8766

Web: www.completeht.com or www.wisconsinsteel.us

Email: rfq@completeht.com or jake@completeht.com

Attention: Jake Dolhun, TJ Dolhun or Catherine Mercuri

To guarantee perfect workmanship and the highest possible product quality, BMW uses five-axis machining centers equipped with Sinumerik 840D sl and a range of new user interfaces for machining operations in its Berlin motorcycle plant.

The horizontal design of the Grob five-axis G550 guarantees the highest levels of rigidity, which keeps axial deviations below 10 µm.

Thanks to previous positive experience with Siemens, the BMW manufacturing specialists in Berlin already employ technology from Europe’s market leader for 90 percent of their controllers. This allows both operators and tool setters the flexibility to work on almost all the machines in the plant. Other key requirements noted in the specification were adequate space for manufacturing all relevant components, the highest levels of precision and surface finish, compliance with pre-defined cycle times, and the ability to reuse all current tools and equipment.

The highest levels of precision on even the hardest material

Before committing to the new investment, the responsible BMW production engineer worked with a colleague from process engineering to investigate the effectiveness of the Grob machines in cylinder head production. Initially, it was the G550’s near-identical sibling, the G350, that was under consideration. As a first traditional single-workplace machine tool, it already met almost all the main criteria, but the space available inside was deemed too small to accommodate all the required processing tasks. However, the G550 satisfied this requirement as well. Among other factors, the horizontal design of this five-axis machine, which has both rotary axes in the work area, contributes significantly to its outstanding rigidity. As a result, axial deviation remains process-compliant at values under 10 µm. The level of precision that can be achieved is correspondingly high, even when processing extremely hard materials, as with valve seat inserts, for example.

The machine also produces a high-quality surface finish, with roughness (Rz) of up to 2 µm. Christian Heiß, applications engineer at Grob, explains a further benefit of the horizontal design: “Tool life can be increased by approximately 30 percent compared with that of vertical machining centers. And the problem of jammed slivers is almost completely eliminated because they are not able to fall onto the workpiece in the first place, but instead fall right through to the ground.”

One of the G550’s strengths is its compact size, at only 3800 mm x 6300 mm. However, despite its size, it still features an extremely long z-axis stroke of 1020 mm, meaning that tools up to 500 mm long can be retracted completely out of the work area and into the so-called spindle tunnel. The swivel-mounted shuttle table is another feature that helps deliver high levels of productivity. While one workpiece is being processed, the next can be clamped and set, thus minimizing costly downtime.

Programmed and set in no time at all

Employees find the new Sinumerik 840D sl CNC especially easy to operate because, in the production of BMW cylinder heads, only Siemens controllers are used. Despite this, the user interface presented on the Grob machines looks completely different from the others. Until now, operators and setters have been used to the DIN-based HMI Advanced user interface, but the new CNC on the G550 features the Sinumerik Operate animated graphical display. Siemens has integrated a new operation and programming structure, with practical functions such as copy and paste that are well known to users from their daily use of PCs. This allowed BMW employees to quickly adapt and master the new Sinumerik user interface in no time at all.

Thanks to its excellent usability and intuitive operation through various technology cycles, measurement cycles, and setting functionality, the new G550 machines can be set up for new batches much more quickly than before. As Heiß explains: “This means our customers are much faster than before. Previously, it might have taken several hours to set up the machine and the workpiece, now it can be done in just a few minutes.”

Highly trained employees and specialist suppliers help BMW motorcycles maintain their excellent reputation for reliability, quality, and safety.

Quick and reliable with remote maintenance

Along with the tools and equipment from the current machines, the German motorcycle manufacturer was able to reuse all its existing programs as well. It took a single employee only two days to upgrade these programs to be compatible with the latest software, which can be loaded onto the relevant machine as required either over the network or from a USB stick. The modern Windows Explorer-style program manager means that complex programs can be managed either on the CF (Compact Flash) card or directly on the CNC.

If problems arise while the machine is operational, BMW production engineer Taner Ögretmen and his colleagues use the network-based remote maintenance functionality provided by Grob. This has rarely been required so far – but when it has, it proved to be extremely smooth and efficient, stresses Ögretmen. Grob can also perform minor optimizations together with Siemens using the teleservice. This is usually done automatically and without any disruption to ongoing production. The Sinumerik-controlled Grob machines have met every expectation in full, which is why BMW has already ordered an additional four G550s.

Programming and operation using Sinumerik Operate

be clear and self-explanatory, so that even operators with no programming experience can learn the basics in no time at all. To write programs in programGUIDE, the operator will need some knowledge of G-code. The highlights here include new cycle support functionality and animated elements that can be used to represent the cycle graphically. Tooltip support is also provided.

For more information on this story:

SIEMENS INDUSTRY, INC.

MOTION CONTROL

MACHINE TOOL BUSINESS

390 Kent Avenue

Elk Grove Village, IL 60007

Phone: 847-640-1595

Fax: 847-437-0784

Web: www.usa.siemens.com/cnc

Email: SiemensMTBUMarCom.sea@siemens.com

Attention: John Meyer, Manager, Marketing Communications

Follow us on Facebook: www.facebook.com/SiemensCNC or Twitter: www.twitter.com/siemens_cnc_us.

Continue readingAnn Arbor, Michigan – GMTA (German Machine Tools of America) represents various top-quality German metalworking machine builders, including Profilator, Pittler, Praewema and WMZ. These machines are sold to the North American market by GMTA primarily for gear and spline production, as well as other power transmission applications. The company’s target markets include automotive, off-highway, OCTG and other heavy equipment manufacturing. Machines are provided for gear honing, gear grinding, Scudding®, polygon milling, turning, gear tooth pointing and multiple machining operations.

In the news…

– The renovation of the GMTA facility in Ann Arbor, Michigan is now complete with plans in the works for future expansion of the campus. Additional floorspace, showroom capacity and training facilities, plus more personnel, are planned, according to company VP Scott Knoy. In that regard, two personnel announcements were made by GMTA company President Walter Friedrich on August 1. Doug VanDeven is now GMTA Parts Manager and Shawn Wilkin is now GMTA Service Manager. As Friedrich remarked, “These two positions are essential parts of our business, as they reflect our company’s image to our customers.”

– GMTA will be exhibiting at Gear Expo in Indianapolis in September.

– All the member groups of GMTA will be exhibiting at EMO in Hannover, Germany in September. GMTA representatives Walter Friedrich and Scott Knoy will attend.

– A major sale was recently secured on the Chrysler nine-speed transmission program.

– GMTA will now represent K+G (Kristen + Goermann) carbide inserts, toolholders and cutters, plus offer a new line of GMTA Scudding® tools. An agreement negotiation to represent Naxos grinding wheels and hone rings is underway at this time, as well.

For more information on this announcement, please contact:

GMTA (German Machine Tools of America)

4630 Freedom Drive

Ann Arbor, MI 48108

Phone: 734-973-7800

Fax: 734-973-3053

Web: www.gmtamerica.com

Email: sales@gmtamerica.com

Attention: Scott Knoy, VP

Connect with GMTA online:

This Grieve bench oven features 5” insulated walls, stainless steel exterior with #4 brushed finish, Type 304, 3B finish stainless steel interior, integral oven stand and an 8” x 10” double-pane Pyrex/Vycor viewing window.

Controls onboard No. 1017 include a digital programming temperature controller and manual reset excess temperature controller with separate control contactors.

For more information, please contact:

THE GRIEVE CORPORATION

500 Hart Road

Round Lake, IL 60073-2835 USA

Phone: (847) 546-8225

Fax: (847) 546-9210

Web: www.grievecorp.com

Email: sales@grievecorp.com

Attention: Frank Calabrese

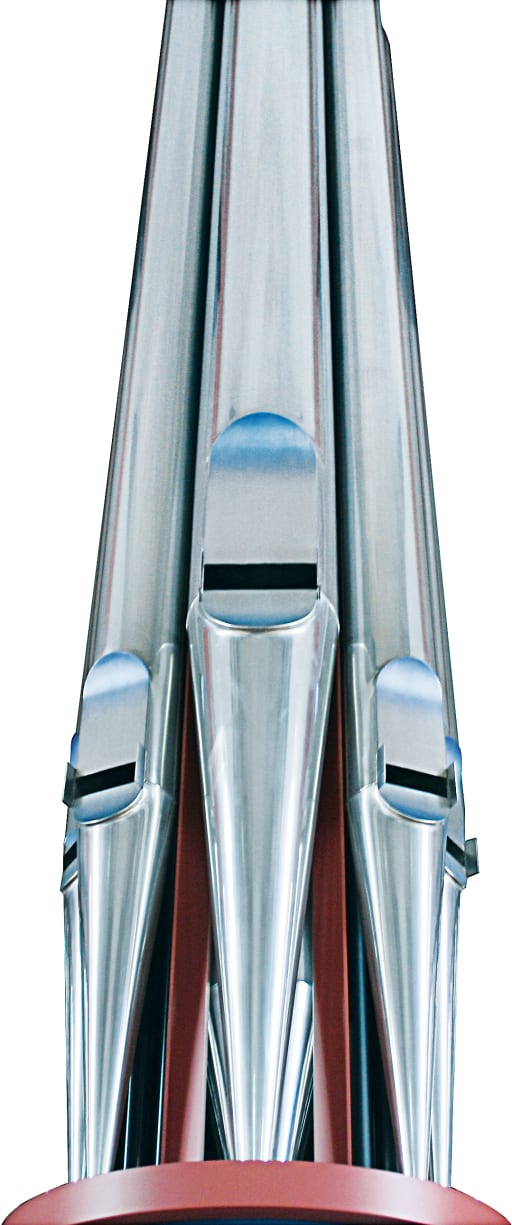

The art of organ building at the highest level with modern CNC techniques…

Laukhuff relies on five-axis milling center from Spinner with Sinumerik 840D sl for small-series production

At Laukhuff in Weikersheim, Germany, tradition and modernity merge together in a way that can not merely be seen, but also heard. The family-run company, with almost 200 years of history, is the international leader in organ building – as a supplier to the best-known organ builders and a provider of its own complete instrument developments. The company operates on a global level with 150 employees, considering itself an artistic crafting enterprise rather than an industrial company. Company CEO Hans-Erich Laukhuff emphasizes, “In our carpenter’s workshop and when manufacturing organ pipes, we are hardly able to use any machines because 90 percent of the work must be done by hand. When it comes to cutting, however, this is a different matter. Here, we can use modern milling and turning machines with innovative CNC equipment, so that we can keep productivity levels as high as possible.”

If required, these masters of organ building will supply everything from a single source. Laukhff further explains, “If requested, we will take on all the tasks involved in the design, the manufacture of individual parts and the installation onsite. We even make the bench seat and the key lights ourselves, as there are no usable, satisfying solutions in the market today.”

The high level of perfection shown by this organ builder is reflected in the optics, in the haptics (touch and feel) and naturally in the sound of the instruments. It also has a positive effect on their reliability. After all – quite unusual in these fast-moving times – it is typically not necessary to plan the replacement of a Laukhuff organ for more than 100 years. However, a few spare parts will still be required.

Despite the fact their high quality is globally recognized, this family-run company is still facing constant cost pressure. To achieve a high throughput in cutting applications, the company uses five CNC turning machines and three CNC milling machines – together with their latest acquisition, a five-axis CNC center (3+2) from Spinner’s U-series, with a state-of-the-industry Siemens Sinumerik 840D sl CNC onboard.

Impressive price-performance ratio

With the Sinumerik-controlled Spinner U5-620, Laukhuff uses new options for the more productive manufacturing of organ components, such as chimes

Company owner and CEO Hans-Erich Laukhuff and Production Manager Walter Rhein already had positive experiences with the CNC. However, since mid-2009, they have been relying on the Spinner machine tool factory in Sauerlach, Germany for the first time and using the U5. According to the production manager, this decision was based on the price-performance ratio and the small space required by the machine in contrast to comparable machines from other manufacturers. The U5-620 only needs 2000 x 2400 millimeters of surface area, but achieves travel distances of 620/520/460 millimeters in the X/Y/Z-axis direction.

The new Spinner machining center has high-quality individual components, including 32 tools as standard, a double arm for rapid tool changes and linear axes on roller bearing guides. Michael Schulz, Spinner sales representative at Hollenbach GmbH, confirmed, “This enables us to achieve rapid feed speeds of 48 meters per minute in all directions. Even in terms of accuracy and surface quality, our U-series sets a very high standard.”

In terms of the productivity and quality increases that can be achieved, as well, the organ builder expects the acquisition of the Spinner machine to be amortized within a relatively short period of time. Ultimately, an organ builder will often manage without time-consuming retooling, as Rhein noted, “In the cutting applications for our organ pipe tuners, we previously had to retool three times and needed around 13 minutes just for clamping – which doesn’t even take into account the downtime while retooling. The five axes mean that production is now possible in a single clamping, within about eight minutes per piece. All in all, we are at least twice as fast as a result.”

Graphically-animated user interface

Like many medium-sized contract manufacturers, this organ builder’s employees also program directly at the machine. CNC specialist Kurt Stüdlein is totally convinced about the Sinumerik 840D sl because, “…it is powerful, safe to operate, user-friendly and reliable. But the CNC user interface, tailored to shopfloor programming, also scores highly, being graphically-animated and logically-structured. ShopMill, the resident software suite, is great, particularly for beginners. Production Manager Rhein further explains, “Even a fitter who has only just finished his training, without any extensive programming experience, can work with it, after some brief instructions.”

CNC professional Stüdlein adds, “Even on complex components using the 3+2 axis machining, I can create lots of programming steps with ShopMill. If I reach the limits when entering certain contours, or if I am quicker with DIN, then I can switch from the graphic to the text-oriented DIN interface at the touch of a button.” For additional employee safety, the Safety Integrated software solution is also built into the control. This means that it is possible for the user to safely track his program’s production process in setup mode with the machine doors open.

Laukhuff is certain, based on the experience gained, that he has made the right decision with the Spinner-Siemens CNC combination. The technology and the continuously fast service from both companies have convinced him, “If there is a problem, we are helped very quickly – which is not always a given with other manufacturers in this particular industry.”

For more information on Siemens SINUMERIK CNC, visit www.usa.siemens.com/cnc.

For specific product information and inquiries, call (800) 879-8079 ext. Marketing Communications or send an e-mail to: SiemensMTBUMarCom.industry@siemens.com.

Follow us on Facebook: www.facebook.com/SiemensCNC or Twitter: www.twitter.com/siemens_cnc_us.

—

Siemens Industry Sector is the world’s leading supplier of innovative and environmentally friendly products, solutions and services for industrial customers. With end-to-end automation technology and industrial software, solid vertical-market expertise, and technology-based services, the sector enhances its customers’ productivity, efficiency and flexibility. With a global workforce of more than 100,000 employees, the Industry Sector comprises the Industry Automation, Drive Technologies and Customer Services Divisions as well as the Metals Technologies Business Unit.

The Siemens Drive Technologies Division is the world’s leading supplier of products, systems, applications, solutions and services for the entire drive train, with electrical and mechanical components. Drive Technologies serves all vertical markets in the production and process industries as well as the infrastructure/energy segment. With its products and solutions, the division enables its customers to achieve productivity, energy efficiency and reliability.

Continue reading