Contact us today:

(847) 934-4500

tdaro@bernardandcompany.com

Contact us today:

(847) 934-4500

tdaro@bernardandcompany.com

No. 845 is a 150oF electrically-heated drawer oven from Grieve, currently used for curing printing plates at a customer’s facility.

This Grieve drawer oven features 4” insulated walls, aluminized steel interior and exterior, plus an access door to the heat chamber for maintenance. Eight drawers, 84” wide x 54” long x 1” high, are each rated for 50 lb. loading. Explosion venting panels are built into the oven roof.

Safety equipment is on-board this Grieve oven to handle 1.34 gallons of flammable solvents, including a manual reset excess temperature controller, back-up heating element relay, separately powered forced exhauster, exhauster airflow safety switch, recirculating blower airflow safety switch and purge timer.

The drawers on the No. 845 open to extend 40” in front of the oven to accommodate the large workpieces involved in this particular application.

For more information, please contact:

THE GRIEVE CORPORATION

500 Hart Road

Round Lake, IL 60073-2898

Phone: (847) 546-8225

Fax: (847) 546-9210

Web: www.grievecorp.com

Email: sales@grievecorp.com

Attention: Frank Calabrese, VP

Workspace dimensions of this oven measure 30” wide x 96” deep x 24” high. A 2’ long open belt loading zone, 8’ long insulated heat zone with recirculated airflow and 2 ½’ long open belt unloading zone constitute the full heat processing system. 48KW installed in Nichrome wire heating elements provide the heat, while a 4200 CFM, 3-HP recirculating blower furnishes vertical downward airflow to the load.

This Grieve oven features 4” insulated walls, a Type 304, 2B finish stainless steel interior, stainless steel exterior with #4 brush finish, as well as a 24” wide, 1” x1” Type 304 stainless steel flat wire conveyor belt with ¼-HP motor drive, variable speed from 0.9 to 17.6 ipm. A side door allows access to the unit’s workspace.

Safety and control equipment on-board No. 853 include PVC electrical conduit, a remote control panel, 325 CFM stainless steel powered forced exhauster, six-point thermocouple jack panel through the oven wall, digital indicating temperature controller, manual reset excess temperature controller with separate contactors, and recirculating blower airflow safety switch.

For more information, please contact:

THE GRIEVE CORPORATION

500 Hart Road

Round Lake, IL 60073-2898

Phone: (847) 546-8225

Fax: (847) 546-9210

Web: www.grievecorp.com

Email: sales@grievecorp.com

Attention: Frank Calabrese, VP

This specially modified Grieve lab oven features 1” insulated walls throughout, aluminized steel interior, stainless steel exterior with #4 brushed finish, heavy duty door latch, reinforced door hinge, shelf supports bolted through the oven walls to support the load at a double shelf height and an adjustable fresh air inlet damper at the oven bottom to control the amount of fresh air entering the chamber.

An added feature for accuracy, the temperature control shaft onboard No. 969 is recessed and slotted to avoid a set point change.

For more information, please contact:

THE GRIEVE CORPORATION

500 Hart Road

Round Lake, IL 60073-2898

Phone: (847) 546-8225

Fax: (847) 546-9210

Web: www.grievecorp.com

Email: sales@grievecorp.com

Attention: Frank Calabrese, VP

TCT Stainless Steel, Inc., a Lebanon, Tennessee metal service center, is proud to announce the commissioning of a new 64” wide heavy gauge EMAG slitter. This line is capable of slitting .035 to .3125 gauges. Maximum coil weight is 40,000 lbs. with a maximum 72” outside diameter uncoiler/recoiler. The line is complemented with an Alcos (8) position carousel packing line.

This new line is in addition to the existing 20” Stanat light gauge slitter commissioned by TCT in late 2012, which slits .005 gauge.

The addition of this line complements the other (4) slitters, rolling mill, edger and cut-to-length capabilities that TCT currently offers to customers. With these additions, TCT now offers more in-house capabilities and services than any service center in the Southern United States, according to a company spokesperson.

TCT invites all interested parties to visit the company at 711 Maddox Simpson Parkway, Lebanon, TN for a personal tour or visit www.tctstainless.com for a virtual tour. Let TCT show you what these new lines can do to benefit your operation.

For more information, please contact:

TCT STAINLESS STEEL, INC.

711 Maddox Simpson Parkway

Lebanon, TN 37090

1-800-877-8366

Phone: 615-443-4657

Fax: 615-449-6079

Web: www.tctstainless.com

Email: tcttn@tctstainless.com

Attention: Sherry Shaub, General Manager

TCT Stainless Steel, Inc. is one of the steel industry’s leading service centers. Our vast, in-house capabilities include virtually every facet of coil processing. Our capabilities include slitting, tempering, gauge reduction, cut-to-length, edging, buffing and tension leveling. TCT currently serves the aerospace, medical, electronic, telecommunication, automotive, lift equipment, building trade and other markets.

The combined inventory of our Michigan and Tennessee service centers include annealed and tempered stainless, aluminum, carbon and coated steels. Our dedication to providing high-quality products, short lead times and reliable delivery has always been the key to our success. We are constantly improving our facilities to include state-of-the-art technology, SPC and quality control standards.

Customer satisfaction is our specialty. Whether it be heavy or light gauges, narrow or wide widths, small or large quantities – TCT guarantees satisfaction and dependability at competitive prices. Our outstanding reputation for product quality is backed by our dedicated, customer-oriented team. Our sales staff welcomes all orders and inquiries and will respond quickly with reliable service and industry leading lead times.

Using the process-oriented approach of SIGMASOFT® makes it possible to consider all of the molding times present in an actual injection molding cycle. In the injection molding simulation of elastomeric applications, SIGMASOFT® not only considers the filling and curing times, but also the non-productive times between each production cycle while the mold is opened and closed. If the simulated process considers the influence of multiple consecutive molding cycles, the accuracy of the simulation is dramatically improved.

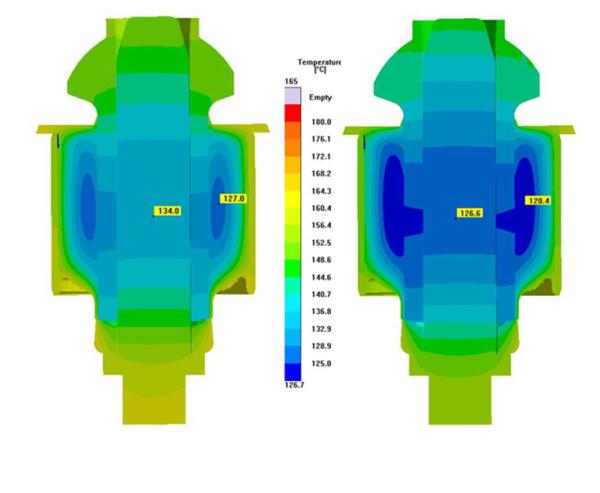

Figure 1 – Temperature distribution in a metallic component over-molded with rubber. Left: without consideration of the mold opening time; right: considering a mold opening time of 60 seconds, where significantly lower temperatures and long curing times are observed.

Even though it is not necessary to include them to complete an injection molding simulation, the “non-productive” times have a major influence on the mold temperature and thus on the process and on the part quality. With the Process Simulation Software SIGMASOFT®, from SIGMA Plastic Services, Inc. (Schaumburg, Illinois), all the non-productive times can also be included into the simulation of multiple consecutive production cycles and a substantial improvement in the accuracy of the results predicted can be achieved.

Considering the times in which the mold opens and closes, the times in which the mold is heated or cleaned, as well as handling times in which the inserts are placed or the parts removed, makes it possible to exactly describe the real multi-cycle production process. The interaction between all components present in the mold is considered with the local temperature dependent material properties, along with the heat that escapes the mold into the environment while it is both opened and closed and the exact timing of each event are coupled together inside of SIGMASOFT® to provide a comprehensive understanding of a very complex system. In this way, even factors that influence the part quality, such as the mold temperature and curing degree, can be predicted before the mold is ever built.

An example is presented in Figure 1. In this case, the mold temperature drops significantly while it is in the open position because heat radiates from both heated mold surfaces. If this time and open condition are not considered in the simulation, the mold temperature calculation will be higher than actual; resulting in a faster curing reaction and a shorter cycle time than what is actually possible. Other events will also be incorrectly calculated such as curing degree during filling and required injection pressure.

In SIGMASOFT®, non-productive times can be defined and individually modified in the simulation. For this reason, it is also possible to optimize the entire production process or mold design simultaneously. Through this simulation, it is possible to decide if changes in the process definition will solve production problems, or if the mold has to be modified to achieve the desired quality and productivity goals.

For more information:

Matt Proske

SIGMA Plastic Services, Inc.

10 N. Martingale Road, Suite 425

Schaumburg, IL 60173

Phone: 847-558-5600

Email: contact@3dsigma.com

Web: www.3dsigma.com

—

SIGMA® (www.3dsigma.com) is 100% owned by MAGMA® (www.magmasoft.com), the world market leader in casting process simulation technology based in Aachen, Germany. Our SIGMASOFT® process simulation solution optimizes the manufacturing process for injection molded plastic, thermoset, rubber, and MIM/CIM components. SIGMASOFT® combines the 3D geometry of the parts and runners with the complete mold assembly and temperature control system and incorporates the actual production process to develop a turnkey injection mold with an optimized process.

At SIGMA® and MAGMA®, our goal is to help our customers achieve required part quality during the first trial. The two product lines – injection molded polymers and metal castings – share the same 3D simulation technologies focused on the simultaneous optimization of design and process. SIGMASOFT® thus includes a variety of process-specific models and 3D simulation methods developed, validated and constantly improved for over 25 years. A process-driven simulation tool, SIGMASOFT®, with its comprehensive simulation approach, provides a tremendous benefit to production facilities. Imagine your business when every mold you build produces required quality the first time, every time. That is our goal. This technology cannot be compared to any other conventional “design” simulation approach employed in plastics injection molding.

New product success requires a different communication between designs, materials, and processes that design simulation is not meant for. SIGMASOFT® provides this communication. SIGMA® support engineers, with 450 years of combined technical education and practical experience, can support your engineering goals with applications specific solutions. SIGMA® offers direct sales, engineering, training, implementation, and support, by plastics engineers worldwide.

Continue readingWith the process-oriented approach of SIGMASOFT®, the injection molding simulation for elastomers is no longer limited to predicting the cavity filling while designing the part, or to answering questions regarding balanced filling. Based on an accurate simulation of the curing reaction (vulcanization), it can be used for designing the mold, identifying process windows and troubleshooting during production.

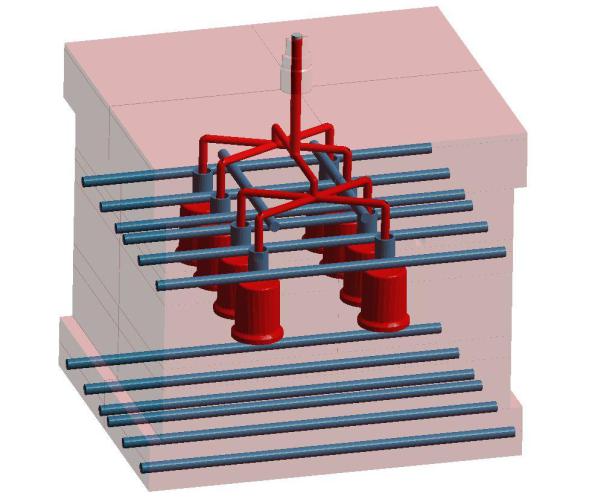

Figure 1 – The process-oriented approach of the Injection Molding Simulation Software SIGMASOFT® allows all relevant information (Part, Insert, Venting, Material, Mold, Heaters, Thermocouples, Process, etc.) to be used in the calculations.

SIGMA Plastic Services, Inc., Schaumburg, IL presents the latest functionality of its 3D Injection Molding Simulation Software SIGMASOFT®. The focus is on reduction of development and production costs using these new developments in process simulation.

Many factors in elastomer injection molding have an influence on product quality and costs. Here it is of little help to solely focus on a single aspect; part design, material, mold design, or molding process. To ensure a competitive advantage, the entire system must be considered simultaneously. Only when everything is optimized during the design phase, before the mold is shipped, can the largest cost savings be achieved.

By means of process simulation, molding feasibility and initial process parameters can be evaluated. Parting line and venting channels can be developed, as well as the optimal type and position of the injection point. Where are weld-lines acceptable, where must they be avoided? How much injection pressure will be required? Ultimately, the complete mold and process must be optimized. What wattage and heater design is most beneficial? Where is the best thermocouple location for each heater? Do inserts need pre-heating and how will they influence the curing? How long is the curing cycle, what areas of the part cure late and why? These questions are all related to the mold design and the production process and they are all important factors regarding part quality.

The simulation results provide answers to all of these questions in a clear and meaningful way, allowing injection molders a way to virtually test the mold before it is built. Costs can be reduced significantly during development, and existing processes can continuously be improved, while substantially reducing material waste and improving quality.

The latest developments in the thermal solver allow for the integration of all mold components and their individual temperature dependent material properties. In this way, an accurate reproduction of the real temperature profile in the mold is possible, even over several consecutive injection molding cycles. The simulation set-up is optimized for the requirements of process engineers. This allows production-minded engineers to use this technology without a simulation background. For example, a process engineer can determine how heating cartridges influence mold temperature and part quality, simulating them with their respective electric power and thermocouple control.

For more information:

Christof Heisser or Matt Proske

SIGMA Plastic Services, Inc.

10 N. Martingale Road, Suite 425

Schaumburg, IL 60173

Phone: 847-558-5600

Email: contact@3dsigma.com

Web: www.3dsigma.com

—

SIGMA® (www.3dsigma.com) is 100% owned by MAGMA® (www.magmasoft.com), the world market leader in casting process simulation technology based in Aachen, Germany. Our SIGMASOFT® process simulation solution optimizes the manufacturing process for injection molded plastic, thermoset, rubber, and MIM/CIM components. SIGMASOFT® combines the 3D geometry of the parts and runners with the complete mold assembly and temperature control system and incorporates the actual production process to develop a turnkey injection mold with an optimized process.

At SIGMA® and MAGMA®, our goal is to help our customers achieve required part quality during the first trial. The two product lines – injection molded polymers and metal castings – share the same 3D simulation technologies focused on the simultaneous optimization of design and process. SIGMASOFT® thus includes a variety of process-specific models and 3D simulation methods developed, validated and constantly improved for over 25 years. A process-driven simulation tool, SIGMASOFT®, with its comprehensive simulation approach, provides a tremendous benefit to production facilities. Imagine your business when every mold you build produces required quality the first time, every time. That is our goal. This technology cannot be compared to any other conventional “design” simulation approach employed in plastics injection molding.

New product success requires a different communication between designs, materials, and processes that design simulation is not meant for. SIGMASOFT® provides this communication. SIGMA® support engineers, with 450 years of combined technical education and practical experience, can support your engineering goals with applications specific solutions. SIGMA® offers direct sales, engineering, training, implementation, and support, by plastics engineers worldwide.

Continue readingDuring EASTEC 2013, Siemens will present its newest solution for the job shopfloor, the Sinumerik 808D, an attractively-priced CNC for entry-level milling and turning machines.

Over 50 years of Siemens CNC experience have been brought to the development of this control, which is specially designed for the highly competitive, high-volume 230V, three-phase and economy machine tool market. With up to three-axis plus spindle control capability in milling or turning applications, the 808D is offered as a package with Siemens Sinamics drives and Simotics motor solutions. The Sinumerik 808D will be immediately available for OEM machine tool builders and in-the-field retrofit installation by Siemens business partners worldwide.

Start with an IP 65 enclosure, easy-to-load USB port, mechanical, hot and soft keys for easy, intuitive operation, clamp-mounted front panel and a modular design that allows customizing by machine model or with out-of-the-box operation. Plus, the machine control panel is connected using plug-and-play technology using a simple USB interface. On a turning machine, the Sinumerik 808D provides high contour accuracy and maximum machine productivity on high-volume production runs. On a milling machine, likewise, the Sinumerik 808D offers machine builders of vertical machining centers all the benefits of the Siemens MDynamics velocity control for mold and die section work.

A 7.5-inch LCD color display with 640 x 480 resolution for easy reading, selectable function keyboard, rotary dials for speed and spindle override, LED tool number display, durable buffer battery and rear connection ports for USB, RS232 C, distributed and onboard I/O, setpoint to feed axes and spindle, spindle encoder, fast I/O, e.g., for probes and handwheel operation are all standard on the Sinumerik 808D.

With 80-bit nano floating point accuracy and intelligent jerk limitation for smoother path cutting and less mechanical stress on the machine structures, workpiece accuracy and repeatability are improved. Whether turning with a C-axis changeover or milling mold sections where path control is paramount, the Sinumerik 808D has been designed to significant heighten the performance level of basic machine tools.

With programGuide Basic, a wide range of pre-determined technology cycles are available, in addition to the standard G-code and coordinate transformation language. Standard ISO codes can also be intermixed with high-level Sinumerik CNC commands on the 808D. The onboard contour computer further allows complex programs to be created and modified at the CNC without the need for a CAD/CAM system.

For routine or even online help with maintenance or troubleshooting issues, a simple push of a button is the only requirement, as the complete library of system parameters is accessible onscreen.

Commissioning is made easier with a ready-to-run PLC program. Customizing the PLC is simpler, as well, with function and data blocks for program testing and debugging built-in. The Sinumerik 808D further allows easy connection to the PLC I/O of other machine devices, whether proximate or remote. The open architecture of Siemens CNC has not been sacrificed on the 808D, so customized HMI screens and menu trees are easily defined and created.

Finally, with Manual Machine Plus (MM+) function on this new CNC enables transition from conventional machining to CNC programming. A machine equipped with MM+ can be operated using handwheels but with all the benefits of CNC-assisted technology cycles.

The Sinumerik 808D is offered with full THREE-YEAR WARRANTY on parts and labor.

FOR END-USERS

In addition to the above features and benefits for the machine builder, shop operators and programmers alike will appreciate the Sinumerik 808D for its many end-user advantages, including simplified keyboard entry of all program values, named part programs in subfolders just like a PC, convenient shortcut keys to access tool offset lists or the Program Manager, intelligent jog features easily identified and graphically-supported, precise tool handling and tool wear data readily available onscreen and a powerful simulation routine. An operator can access all system information and obtain online help, whenever needed.

The multimedia training materials include on-screen tutorial video and full step-by-step procedures to go from the blueprint to the finished part. For offline training, a fully operable software machine control panel on a PC is available to end users.

For more information about Siemens CNC solutions for the machine tool industry, visit our website: www.usa.siemens.com/cnc.

For more information on the this story, contact:

SIEMENS INDUSTRY, INC.

DRIVE TECHNOLOGIES

MOTION CONTROL

MACHINE TOOL BUSINESS

390 Kent Avenue

Elk Grove Village, IL 60007

Phone: 847-640-1595

Fax: 847-437-0784

Web: www.usa.siemens.com/cnc

Email: SiemensMTBUMarCom.sea@siemens.com

Attention: John Meyer, Manager, Marketing Communication

Follow us on Facebook: www.facebook.com/SiemensCNC or Twitter: www.twitter.com/siemens_cnc_us.

—

Siemens Industry Sector is the world’s leading supplier of innovative and environmentally friendly products, solutions and services for industrial customers. With end-to-end automation technology and industrial software, solid vertical-market expertise, and technology-based services, the sector enhances its customers’ productivity, efficiency and flexibility. With a global workforce of more than 100,000 employees, the Industry Sector comprises the Industry Automation, Drive Technologies and Customer Services Divisions as well as the Metals Technologies Business Unit.

The Siemens Drive Technologies Division is the world’s leading supplier of products, systems, applications, solutions and services for the entire drive train, with electrical and mechanical components. Drive Technologies serves all vertical markets in the production and process industries as well as the infrastructure/energy segment. With its products and solutions, the division enables its customers to achieve productivity, energy efficiency and reliability.

Continue reading

At this year’s EASTEC Show in West Springfield, MA, Siemens will demonstrate new versions of its popular, compact CNC for the job shop, the Sinumerik 828D.

The Sinumerik 828D BASIC T is designed to address the needs of shopfloor turning machines.

It combines CNC, PLC, operator panel and axis control for five axes/spindles, including live tooling. Milling and drilling operations on a turning machine, both for face and peripheral surfacing, are therefore possible. In tandem with the new Sinamics S120 Combi drives package, the 828D BASIC T represents a new level of efficiency and virtually maintenance-free operation, as the fans, hard disks and batteries of past CNC generations have been eliminated.

With rugged diecast magnesium front panel on an IP65 enclosure, the BASIC T enables an Ethernet connection, USB or Compact Flash (CF) card program loading. An 8.4-inch color display for easy readability and simple QWERTY keyboard provide fast ramp-up for the operator. Various communication ports in USB, Ethernet, Drive-CLiQ, PLC I/O interface, RS232 C and NC inputs/outputs are standard.

In operation, reliable 80-bit nano accuracy means contour control precision and a better workpiece, every time, while Siemens intelligent kinematic transformations provide the proper orientation of machining plane to work surface.

Though simple command language is provided for operator ease, the BASIC T functions with the highest level of ISO programming language. Established cutting cycles can be utilized with fully Animated Elements for the faster visualization of part production on various levels with combinations of Sinumerik CNC and ISO programming languages possible, as well.

SINUMERIK 828D BASIC M

Similarly, the new Sinumerik 828D BASIC M class features the same quality performance as the T class, but for use on milling machines. Even in complex moldmaking operations, mirror-smooth surfacing and reduced machining times are enabled. Again, in tandem with the Sinamics S120 Combi drives package and Simotics feed and spindle motors, the 828D BASIC T will operate a milling machine at the highest level of performance possible. Superior axis and spindle dynamics within a broad speed bandwith yield quality workpieces, every time.

All the other benefits of the Siemens CNC family, including the Sinumerik Operate graphical user interface platform as well as ShopMill and ShopTurn easy programming are offered in these new 828D CNCs.

SINUMERIK 828D

The Sinumerik 828D is capable of full graphical, high-level language command and supports ISO programming that is customary in the United States. This control family is ideal for single-part and small-batch production. Programming time can be further reduced for small-batch production with the use of the ShopMill and ShopTurn graphical workstep programming systems, while high-level language programming can be used in conjunction with programGuide to significantly reduce programming times for large-scale serial production.

Also included with this expansion of the Sinumerik 828D family of CNC, modern PC and mobile phone technology are also available for the mid-range machine tool. Extensive online help animations and a new type of input prompting system with moving picture sequences provide the basis for exceptional user convenience. USB, Compact Flash (CF) card and Ethernet ports enable high-speed data transfers onto storage media or integration of the control system into corporate data networks.

Through the use of its Easy Message functionality, the Sinumerik 828D family offers production status monitoring by text messaging (SMS). Depending on the recipient’s profile settings, the machine tool can transmit information about workpiece machining status, report on the tool condition currently

in use and send machine maintenance bulletins to a mobile phone, anytime and anywhere. These combined functions are designed to help keep machine downtime to a minimum.

For more information about Siemens CNC solutions for the machine tool industry, visit our website: www.usa.siemens.com/cnc.

For more information on this story, please contact:

SIEMENS INDUSTRY, INC.

DRIVE TECHNOLOGIES

MOTION CONTROL

MACHINE TOOL BUSINESS

390 Kent Avenue

Elk Grove Village, IL 60007

Phone: 847-640-1595

Fax: 847-437-0784

Web: www.usa.siemens.com/cnc

Email: SiemensMTBUMarCom.sea@siemens.com

Attention: John Meyer, Manager, Marketing Communication

Follow us on Facebook: www.facebook.com/SiemensCNC or Twitter: www.twitter.com/siemens_cnc_us.

—

Siemens Industry Sector is the world’s leading supplier of innovative and environmentally friendly products, solutions and services for industrial customers. With end-to-end automation technology and industrial software, solid vertical-market expertise, and technology-based services, the sector enhances its customers’ productivity, efficiency and flexibility. With a global workforce of more than 100,000 employees, the Industry Sector comprises the Industry Automation, Drive Technologies and Customer Services Divisions as well as the Metals Technologies Business Unit.

The Siemens Drive Technologies Division is the world’s leading supplier of products, systems, applications, solutions and services for the entire drive train, with electrical and mechanical components. Drive Technologies serves all vertical markets in the production and process industries as well as the infrastructure/energy segment. With its products and solutions, the division enables its customers to achieve productivity, energy efficiency and reliability.

Continue reading

This Grieve cabinet oven features 8” insulated walls, removable top-mounted heat chamber, aluminized steel interior and exterior, plus two tiers of four 300 lb. capacity shelves supported by rollers to extend 14” in front of the oven for easy access.

Controls onboard No. 1028 include a digital indicating temperature controller, manual reset excess temperature controller with separate contactors, recirculating blower air flow safety switch, SCR power controller and circuit breaker disconnect switch.

For more information, please contact:

THE GRIEVE CORPORATION

500 Hart Road

Round Lake, Illinois 60073-2835

Phone: (847) 546-8225

Fax: (847) 546-9210

Web: www.grievecorp.com

Email: sales@grievecorp.com

Attention: Frank Calabrese

Turning-milling centers with coordinated drive and CNC engineering achieve superior accuracy and repeatability

Hamuel CEO Dr. Markus Stanik (right) and his sales manager Jochen Schaede agree: “The Sinumerik 840D sl CNC complements perfectly the capabilities of our five-axis turning-milling centers in the HSTM Series. Because of this fact, we can usually convince leading turbine manufacturers from the aerospace and automotive industries about the dynamics, high-performance and precision of these machines.”

The complete machining of turbine blades requires striking a balance between powerful roughing and ultra-precise finishing, a task for which the modern five-axis turning-milling centers are ideal, when robust machine construction is combined with high-quality drive and control engineering. Experience is the solid basis on which the Hamuel Maschinenbau GmbH & Co. KG, Meeder, Germany, can offer a great deal: with 85 years of machine tool manufacturing, 35 years of CNC machining, 25 years of five-axis simultaneous machining and over 10 years in the construction of five-axis turning-milling centers. CEO Dr. Markus Stanik knows that experience by itself cannot be any yardstick for the quality of machine tools, noting, “It certainly helps us, together with the right partner companies, to design and build the machines so that our customers can be successful in the marketplace.” This machine builder and its many customers have developed correspondingly positive accomplishments together. Today, Hamuel stands on three standards:

The latter, as evidenced by Hamuel’s HSTM (high-speed turning-milling) series, has been marketed since 1999 and makes a decisive contribution to the sales and success of the company. Leading turbine manufacturers from the aerospace and power-generating industries have been particularly impressed by the dynamic response, capability and precision of these machines. Even the smallest faults are unacceptable on turbine blades

Form deviations are unacceptable for products such as turbine blades and blisks because even the smallest error would significantly reduce the efficiency of the power plant or aircraft turbine.

The HSTM that runs on the Sinumerik 840D sl CNC controllers is used mainly to manufacture turbine blades and blisks (turbine disks) deployed in stationary steam and gas turbines as well as in mobile turbines for aircraft jet engines and large turbochargers. These products always consist of high-strength materials, such as titanium or high-alloyed steels. Form deviations are taboo in such applications, because even the smallest error would significantly reduce the efficiency of the turbines. Correspondingly high and comprehensive are the requirements placed on the machine tools. Hamuel sales manager, Dipl.-Ing. Jochen Schaede, explains: “Our customers normally manufacture large turbine blades longer than approximately 1000 mm from forging blanks. In contrast, shorter workpieces are milled from a solid piece of material with a stock-removal ratio of approximately 80 percent. This makes it obvious that our machines must not only rough-cut very productively but also finish with high precision.” Whereas productivity takes precedence for rough-cutting, accuracy is more important for the subsequent finishing of the spatial free-form surfaces. “With regard to accuracy, our high-performance machining centers achieve a precision in the micrometer range coupled with excellent surface quality,” added Schaede.

Form deviations are unacceptable for products such as turbine blades and blisks because even the smallest error would significantly reduce the efficiency of the power plant or aircraft turbine.

Key to this capability is the combination of compact machine construction together with perfectly matched drive and control engineering. The basis is the robust machine design with a one-piece machine base – either as welded construction cast with special concrete or latterly directly as polymer-concrete made from a single piece of material. The careful distribution of the masses ensures the best dynamic rigidity. The experience of the developers at Hamuel paired with the knowledge of the Siemens mechatronic experts make such results possible, as Jochen Schaede confirmed: “Thanks to various simulation tools, the Siemens engineers could provide us with very exact data to which we could add or remove masses. It was certainly advantageous that we could procure all components required for the dynamics from Siemens starting with the spindle, including the axis drives, and ending with the CNC. This means we needed only a few iteration loops in order to obtain a perfect dynamic rigidity in the machines.” It is also important that all components are arranged so that the horizontally clamped turbine blades and blisks can be machined optimally. This is also facilitated by the 45°-inclined orientation of the axes that ensures a favorable swarf removal further augmented by the permanent rinsing of the machine internal area. The accessibility has also been enhanced by this inclined axis orientation. Such designed and built HSTM machines equipped with precise direct drives from Siemens achieve a maximum positioning accuracy of 5 µm with traversal speeds exceeding 40 m/min in all linear axes. Indeed, the extremely fast rotary axes have a positioning accuracy of 3 µm. This allows the user to achieve maximum productivity, accuracy and surface finishes in the range of Ra = 0.8 µm, and so fully meet the industry requirements placed on the blade machining. CNC ensures optimized surface transitions at the inlet and outlet edges One of the biggest challenges for the turbine-blade manufacturing industry concerns the critical surface transitions (leading and trailing edges) of the turbine blades. To achieve a high quality, the milling paths described with curve interpolation points must have a constant machining speed. As a consequence, the leading and trailing edges demand extreme angular accelerations. The number of curve interpolation points to be described is correspondingly quite high.

The manufacturing of precise free-form surfaces for turbine blades demands the highest performance from the CNC. The excellent block-cycle times of the Sinumerik 840D sl and its look-ahead function improved as part of the new “Advanced Surface” motion control, which play a significant role here.

The controller now faces the challenge to reliably process the generated NC steps that are supported by the fast block cycle times and the look-ahead function of the CNC. “Hardly any other controller can supply the drive information for all five axes in the required short time as reliably as the Sinumerik 840D sl controller,” confirmed Jochen Schaede, who added, “The new Advanced Surface motion control that includes among other things an optimized look-ahead function is also excellent. And I would also like to mention the five-axis high-speed turning-milling of free-form surfaces requires a continuous spatial reorientation of the geometry vectors.” This leads to the use of the Traori (transformation orientation) principle in the Sinumerik 840D sl. Hamuel’s customers can therefore achieve reproducible results with the best-possible surface finish, exact contour accuracy and with the maximum possible machining speed.

Despite being a high-end controller that offers many modern features, the Sinumerik 840D sl CNC is easy-to-use.

In addition to the primary properties of precision, productivity and reliability, Hamuel also appreciates other properties of the Siemens drive and control engineering – an example: the DRIVE-CLiQ interface. When this digital connection is used, all appropriately equipped drive components are detected automatically. Only a cable for the connection is required to achieve this result. Equivalent circuit diagram data for the motors and the characteristic values of the installed encoder systems are all stored. This avoids the need for manual data input during the commissioning and so makes this task more reliable and much faster, according to Hamuel engineers. Sales manager Schaede is also impressed with the “know-how” protection onboard the control. With the help of innovative software, his customers can protect all their programs and their application know-how, using individual passwords and so largely prevent unauthorized access. According to Hamuel, the Teleservice offered by Siemens has proven to be an important advantage for its machine users who often operate globally. It allows not only software problems to be rectified but also updates to be installed fast and reliably without needing to be present onsite. Manufacturing operations save time and money and they always remain up-to-date with the latest software releases, via this service. Powerful motor spindle with Hirth gearing

Leading turbine manufacturers are particularly impressed by the dynamics and high-performance of the HSTM machines. The perfect interaction of the robust Hamuel machine construction and the high-quality Siemens drive and control engineering provide the basis for this satisfaction.

The capability of the turning-milling center also depends greatly on the 54-kW motor spindle made by Weiss Spindeltechnologie GmbH (a Siemens subsidiary). Equipped with a HSK A63 tool holder, it is able to provide the high torque required for roughing plus speeds as high as 16,000 rpm for finishing. This means an optimum cutting speed is always guaranteed. As a practical detail, the Hamuel engineers also emphasize the integrated Hirth gearing that makes it possible to clamp the spindle and relieve load on the bearings during the turning process. The machine sizes in the HSTM Series are oriented to the length of the workpieces to be produced in standard ranges from ≤ 500 mm (HSTM 300) to 1750 mm (HSTM 1500). On special request, Hamuel also builds larger machines. A project for machining blades as large as 2500 mm in length is currently running in the field. CEO Markus Stanik explains, “Thanks to our modular machine construction, we are able to satisfy special requests and build turning-milling centers in these dimensions.”

The manufacturing of precise free-form surfaces for turbine blades demands the highest performance from the CNC. The excellent block-cycle times of the Sinumerik 840D sl and its look-ahead function improved as part of the new “Advanced Surface” motion control, which play a significant role here.

New developments already in the introductory phase are also evolving at Hamuel. For example, in the near future, a special gas will be able to be used to cool the tool in the HSTM machines. A machine base made of mineral casting is also now offered. One of the first machines of this type has already been presented at EMO. “This material not only exhibits excellent properties with regard to vibration suppression but we have also been able to reduce somewhat our dependency on steel suppliers,” noted Markus Stanik. For the machine user, this makes itself apparent directly in improved surface quality and a significantly longer tool service life. CNC gantry milling machines of the HSM (high-speed milling) series In addition to the component production and the construction of the HSTM series, the company’s HMS Series machines are another mainstay for Hamuel. These simultaneous five-axis machining centers are designed for high-speed cutting (HSC). They feature not only the modern Siemens drive and CNC control engineering, but also the optimized milling-head systems and the high-performance high-speed spindles, providing this capability. HSM machines allow high-performance roughing and ultra-precise finishing. With regard to the size of the HSM machines, the manufacturer adapts the designs specifically based on the customer requirements. As a component producer, Hamuel also has its own machines in constant use at its factory.

For more information about Siemens CNC solutions for the machine tool industry, visit our website: www.usa.siemens.com/cnc.

For more information on the this story, contact:

SIEMENS INDUSTRY, INC.

DRIVE TECHNOLOGIES

MOTION CONTROL

MACHINE TOOL BUSINESS

390 Kent Avenue

Elk Grove Village, IL 60007

Phone: 847-640-1595

Fax: 847-437-0784

Web: www.usa.siemens.com/cnc

Email: SiemensMTBUMarCom.sea@siemens.com

Attention: John Meyer, Manager, Marketing Communication

Follow us on Facebook: www.facebook.com/SiemensCNC or Twitter: www.twitter.com/siemens_cnc_us.

—

Siemens Industry Sector is the world’s leading supplier of innovative and environmentally friendly products, solutions and services for industrial customers. With end-to-end automation technology and industrial software, solid vertical-market expertise, and technology-based services, the sector enhances its customers’ productivity, efficiency and flexibility. With a global workforce of more than 100,000 employees, the Industry Sector comprises the Industry Automation, Drive Technologies and Customer Services Divisions as well as the Metals Technologies Business Unit.

The Siemens Drive Technologies Division is the world’s leading supplier of products, systems, applications, solutions and services for the entire drive train, with electrical and mechanical components. Drive Technologies serves all vertical markets in the production and process industries as well as the infrastructure/energy segment. With its products and solutions, the division enables its customers to achieve productivity, energy efficiency and reliability.

About Hamuel Maschinenbau GmbH & Co. KG, Meeder, Germany

Hamuel was founded in 1927 and is now part of the Hamuel Reichenbacher company group. More than 2000 CNC machines from this enterprise group are currently in use globally for the machining of a wide range of materials. The focus of Hamuel Maschinenbau comprises three areas: the production of machine-tool components, CNC gantry milling machines (HSM) and five-axis CNC turning-milling centers (HSTM).

Continue reading