Contact us today:

(847) 934-4500

tdaro@bernardandcompany.com

Contact us today:

(847) 934-4500

tdaro@bernardandcompany.com

SUHNER introduces a new and re-designed version of its BEX15 machining unit, capable of a spindle speed increase from 18,000 rpm to 23,000 rpm

This improvement is the result of a complete redesign of drive and spindle bearing components. A new style timing belt drive multiplies the motor speed up to 13,050rpm spindle speed. An AC-inverter drive is used to increase the spindle speed up to 23,000rpm at 87Hz.

The machining unit BEX15 can be applied in axial and radial orientation, directly mounted to a SUHNER slide assembly type UA15-PH or UA15-CNC. In this combination, numerous machining operations such as milling or demanding drilling cycles, including jump or peck feed, can be accomplished very easily.

Four optional tool holder systems (Collet ER25, ISO30, HSK50 and Weldon) , standard air purge connections for spindle and belt housing including a number of additional options (for example: coolant through the spindle or automated tool change features), make this machining unit type BEX15 highly adaptable and an optimal choice for demanding and specific machining requirements.

SUHNER INDUSTRIAL PRODUCTS, CORP.

Hwy 411 S./Suhner Drive

P.O. Box 1234

Rome, GA 30162

Phone: 706-235-8046

Fax: 706-235-8045

Attention: Lee Coleman, Automation Division

www.suhner.com

automation.usa@suhner.com

Text and pictures files can be found and down loaded at:

www.suhner-press.com

Bartlett, IL (Chicago) – REP Corporation, longtime leader in injection and other molding presses for rubber and TPE, announces the appointment of Jim Wirtz as Service Manager for the company, effective immediately. The announcement was made at company headquarters by REP Corporation President Tim Graham.

Wirtz brings nearly a lifetime of experience in the rubber molding industry to REP, as his family owns and operates Wirtz Manufacturing, likewise a longtime leader in injection molding, based in Michigan, where Jim learned the business from all aspects of mold design and contract production. When the family business redirected itself into battery manufacturing in the mid-1990’s, Jim’s passion for the rubber molding industry continued, as he helped design and construct various manufacturing facilities across the United States, in the rubber industry. “My entire working life has been centered around the rubber injection and extrusion business. It is an honor to be part of REP Corporation and the REP International global network, staying in the industry where my grandfather, father and I have all spent our careers. It’s where I belong,” Jim notes.

Jim will be responsible for the service department and field technician network of REP, a leading supplier of injection, compression, transfer molding, plus tiremaking and devulcanization machinery.

For more information, please contact:

REP CORPORATION

8N750 Tameling Court

Bartlett, IL 60104

Phone: 847-697-7210

Web: www.repinjection.com

Attention: Tim Graham, President

This Grieve universal oven features 6” insulated walls, aluminized steel exterior, Type 304, 2B finish stainless steel interior, single front door with five 3” diameter ports and two 6” diameter ports equipped with slide dampers, plus an 8” x 10” Pyrex/Vycor viewing window and interior oven light.

Controls on No. 985 include a digital programming temperature controller, manual reset excess temperature controller with separate contactors and recirculating airflow safety switch.

For more information, please contact: THE GRIEVE CORPORATION, 500 Hart

Road, Round Lake, Illinois 60073-2835 USA. Phone: (847) 546-8225. Fax: (847) 546-

9210. Web: www.grievecorp.com. Email: sales@grievecorp.com. Attention: Frank

Calabrese.

Continue reading

For more information: http://www.industry.usa.siemens.com/drives/us/en/events/imts-show/pages/imts-show.aspx

For additional photos of the event: http://ow.ly/BH12k

Download the Siemens Customer Booklet: IMTS 2014 Siemens Customer Booklet

Please forward all inquiries to:

SIEMENS INDUSTRY, INC.

DRIVE TECHNOLOGIES

MOTION CONTROL

MACHINE TOOL BUSINESS

390 Kent Avenue

Elk Grove Village, IL 60007

Phone: 847-640-1595

Fax: 847-437-0784

Web: www.usa.siemens.com/cnc

Email: SiemensMTBUMarCom.sea@siemens.com

Attention: John Meyer, Manager, Marketing Communication

Follow us on Facebook: www.facebook.com/SiemensCNC or Twitter: www.twitter.com/siemens_cnc_us.

–

Siemens Industry Sector is the world’s leading supplier of innovative and environmentally friendly products, solutions and services for industrial customers. With end-to-end automation technology and industrial software, solid vertical-market expertise, and technology-based services, the sector enhances its customers’ productivity, efficiency and flexibility. With a global workforce of more than 100,000 employees, the Industry Sector comprises the Industry Automation, Drive Technologies and Customer Services Divisions as well as the Metals Technologies Business Unit. For more information, visit http://www.usa.siemens.com/industry.

The Siemens Drive Technologies Division is the world’s leading supplier of products, systems, applications, solutions and services for the entire drive train, with electrical and mechanical components. Drive Technologies serves all vertical markets in the production and process industries as well as the infrastructure/energy segment. With its products and solutions, the division enables its customers to achieve productivity, energy efficiency and reliability. For more information, visit http://www.usa.siemens.com/drivetechnologies.

Continue reading

The unit features an aluminized steel interior and exterior with 4” thick insulated walls, a reinforced 1/4” steel plate workspace floor to hold a 5,000 lb. Distributed load, a motor-operated rear-hinged door and a front flush-mounted control panel. The oven is supported on eight swivel casters with swivel locks and brakes for mobility.

No. 882 also includes a digital indicating temperature controller, a manual reset excess temperature controller with separate heating element control contactors and a recirculating blower airflow safety switch.

For more information, please contact:

THE GRIEVE CORPORATION

500 Hart Road

Round Lake, IL 60073-2898

Phone: (847) 546-8225

Fax: (847) 546-9210

Web: www.grievecorp.com

Email: sales@grievecorp.com

Attention: Frank Calabrese, VP

Gehring showcases their latest modular honing machines of the Lifehone and Powertrainhone series, complete portfolio and latest technologies at the IMTS!

FARMINGTON HILLS, MI – At IMTS 2014, Gehring will feature its new line of modular honing machines for precision metal components. Several machines from its new modular standard product families will be on display. These modular standard machines offer a systematic approach that is advantageous in establishing a highly efficient manufacturing process.

Integrating the technologies of the Gehring Group into these new modular product standards, the lifehone and powertrainhone will make their debut at the McCormick Center.

Small bore diameters often place different demands on the production technology than large ones. Due to customer requests and feedback from the market, we are showcasing our new lifehone machine with market proven components in a modular design. This new machine with inner column construction combines modern design with optimized accessibility. The rotary table is placed around the inner column so we can guarantee a quick access to the process stations, a good overview and a quick and easy changeover.

Alternatively equipped with a six or eight sided inner column you can fix up to 7 honing spindles. With this we can assure short cycle times and multistep processes. Pre and post gauging stations are fixed on the opposite side to optimize the interior space the best way possible. The compact design is resulting low space requirement in your facility. The Gehring Operator Panel can be led around the machine so that it is easily visible from any location, thus ensuring optimum flexibility and ease of use.

All of our lifehone machines are characterized by ease of use and high performance. The lifehone can be constructed as a multi-spindle transfer solution for mass production, or as a single-spindle design for small production batches as well. You will find the right solution for your requirements and process conditions in our portfolio.

The powertrainhone is also part of a new machine generation with a unique modular concept. The innovative modular design system is comprised of standardized functional components which can be combined with tailor-made honing centers. This groundbreaking configuration enables new freedom and flexibility in production compared to modern hone systems with a conventional layout.

Gehring will also present its entire portfolio of honing technologies and services, from position and form honing, laser structuring to contract honing, displays of our tooling and abrasives, as well as a technical presentation titled “Honing of Thermal Coated Cylinder Bores” scheduled for Tuesday September 9, 2014 at 11.00am -11.55am by Mr. Gerhard Flores at the IMTS technical conference.

Gehring Honing Technologies invites manufacturers to visit them at booth N-6740 to meet with technology experts to discuss production honing solutions for the automotive and commercial vehicle, aerospace & defense, oilfield, job shop and other metal working industries. For more information on the Gehring product line and portfolio of honing solutions, please visit our website www.gehring.de.

Contact for press and publishers:

Rita Conroy-Martin

Gehring L.P.

24800 Drake Road

Farmington Hills, MI 48335

USA

Tel +1 (734) 395 2514

Cell +1 734 926 7538

Fax+1 (248) 478 9787

E: rconroy@gehringlp.com

No. 797 is a 260ºF (127ºC), electrically-heated, Class 100 cleanroom cabinet oven from Grieve, currently used for drying coatings onto printed circuit boards at the customer’s facility. Workspace dimensions of this oven measure 36” W x 36” D x 39” H. 20 kW are installed in Incoloy-sheathed tubular elements to heat the oven chamber, while a 1000 CFM, 1-1/2-HP recirculating blower provides horizontal airflow to the workload.

This Grieve cleanroom cabinet oven features 4” insulated walls, Type 304, 2B finish stainless steel interior with continuously back-welded seams, exterior finished with white epoxy paint, #4 brushed stainless steel door cover and control panel face, 30” x 24” x 6” thick stainless steel high-temperature HEPA recirculating filter, plus all safety equipment for handling flammable solvents, including explosion-venting door hardware.

Controls on No. 797 include a digital indicating, programming temperature controller and SCR power controller.

For more information, please contact:

THE GRIEVE CORPORATION

500 Hart Road

Round Lake, IL 60073-2898

Phone: (847) 546-8225

Fax: (847) 546-9210

Web: www.grievecorp.com

Email: sales@grievecorp.com

Attention: Frank Calabrese, VP

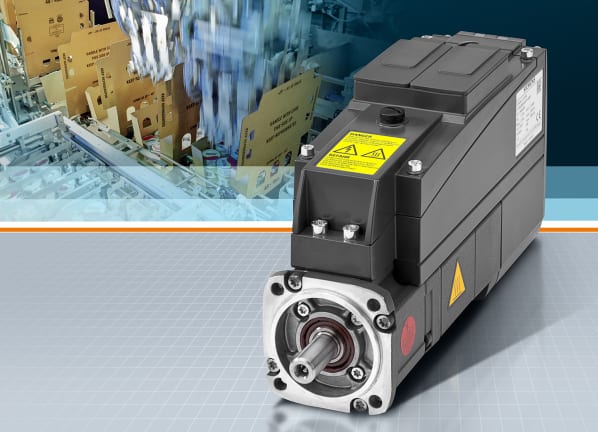

The new Sinamics S120M distributed servo drive system enables decentralized configuration of the drive and integration of the inverter power unit directly onto the driven axis of the motor. Less cabinet space, less cooling energy and shorter cable runs result for the machine builder or production line end-user.

Expanding on its popular Sinamics S120 multi-axis drive system, Siemens introduces the new Sinamics S120M, a compact, ready-to-connect motor with integrated drive that offers users the option of moving the motor inverter outside the control cabinet and directly onto the motor, thereby reducing both cabinet space and required cooling.

The addition of the Sinamics S120M distributed format into the S120 offering adds a high degree of flexibility for new and existing machines, as well as introducing innovative production line setups that can now be achieved.

Typical applications for the Sinamics S120M include packaging, printing, glass, textile and other processes, where machinery and production lines require multiple servo axes in a space-restricted environment.

The decentralized S120M axes are connected back to the central S120 components in the cabinet via a hybrid cable and the AM600 adapter module. The pre-assembled hybrid cable contains all encoder and power cables and serves multiple S120M axes through a daisy chain connection. This single-cable solution drastically reduces the number and length of cables and is easily expanded for additional axes.

As a fully integrated format of the Sinamics S120 drive system, all existing Safety Integrated functions and communication options are available, and the benefits of power sharing between axes across the DC bus are completely realized. Additional design features of the S120M include a synchronous servomotor with multi-turn absolute encoder, optional holding brake and an integrated power unit (motor module) available in three shaft heights covering the power range of 0.25–1.5 kW.

For more information about the new Sinamics S120M distributed servo drive system, please visit: www.usa.siemens.com/S120M-PR.

For specific product information and inquiries, call (800) 879-8079 ext. Marketing Communications or send an e-mail to: SiemensMTBUMarCom.industry@siemens.com.

Continue reading

Corbas, France – On the occasion of the preview of its new V510 machine and the anniversary of its partnership with the Taiwanese company Tung Yu, Rep International hosted an Open House on June 17, 2014 at its headquarters in Corbas, near Lyon, France, resulting in a large number of customers coming together for the celebration.

REP, the world leader in molding machinery for rubber and TPEs, has successfully demonstrated its ability to adapt to different markets and serve all the needs of their customers, bringing many of them together at the world headquarters here to present the company’s latest achievements and investments. Synthesizing the strategic choices made by REP in recent years, REP President Bruno Tabar observed, “Each market has its own needs, sometimes even opposing. Our goal is to adapt our offering to each segment by providing innovative solutions, neglecting none of the individual market needs.” This includes further developing the range of high-tech molding machines ( REP Series G10) and modernizing production in Corbas to cope with a substantial increase of activity in the company’s core business, launching new product lines such as the micro-molding machine and the devulcanization equipment and developing industrial partnerships to access emerging markets, thanks to a complementary line of machines from our global partner, Tung Yu, the leading Taiwan builder of rubber molding and tiremaking machinery.

Visitors could see firsthand that the REP Group continues modernizing its production process at a steady pace by making major investments. The overall investment in the modernization of the plant in Corbas and in the product developments initiated represents almost EUR 4 million ($5.5 million). REP has invested in high-speed machining equipment: 2 flexible machining centers, compatible with each other in terms of tooling and programming to complement the existing capabilities. As a result, gains in responsiveness, productivity and operating costs are expected. It is worth repeating that REP G9 and G10 presses, which make up the overwhelming bulk of sales, are entirely “made in France” as was shown on the product documentation of each molding machine exhibited at the Open House.

Visitors were shown the entire range of REP molding machines in the G9/G10 high-tech range, as REP continues to actively renew their product range with the development of the V510/300T injection press, which is the second G10 model (the first one, the V710 /500T, was unveiled at K2013 in Düsseldorf). New technologies are embedded on the G10 machines with a goal to improve performance and yield, production data communication (predictive maintenance, 3G link and auto-tuning for optimization of settings) and human-machine ergonomics. This further includes the low working height, especially for the V710, the improved visibility of the molding area and a double screen on the operator interface. Energy efficiency has also been emphasized and was the subject of a technical presentation during the event. REP has improved each of the energy consumption sources on the machine: mold heating, injection unit heating and hydraulic power, while noting that cycle time is a major key directly linked to the energy required to produce one part.

Concerning the V510, which replaces the V59, it is important to note the increase of the clamping tonnage from 255 to 300T. The distance between columns is increased, as well, so that an operator can not only mount V59 molds, but may also fit larger square molds of 630x630mm into the press. A large number of specific custom-application machines developed for customers were also shown: dual-compound machines, stripping kits saving time by allowing hidden time demolding and rotary CMS machines with stations for operations including insert loading, molding, stripping etc.

In addition to launching the V510, the event gave REP the opportunity to explain to its customers its partnership approach with Tung Yu and to celebrate their 10-year collaboration. This partnership is built on two main principles: On one hand, REP ensures sales and after-sales service for Tung Yu compression presses, while on the other hand, shares manufacturing (partly in France, partly in Taiwan) of the RT9 basic molding machines. Shortly after the year 2000, as the industrial relocation to emerging countries accelerated sharply, REP chose the pursuit of this partnership. For a medium-sized capital-goods-producing firm in such a fluctuating business field, this was the best way to rapidly and safely set up a new offering, best-suited to local market conditions. This was achieved through the cooperation of a few close customers for Tung Yu, who as a leading manufacturer of compression presses with a strong presence in the Asian market was highly complementary to REP. As pointed out by Tung Yu’s President Chen Pin Yang in his speech on the evening of June 17th, “It was a real challenge for both our companies. Looking back through the history of us working together, it was nice but not always smooth sailing. A lot of dialogue and negotiations occurred between us and also internally in both our own companies, a natural situation. However, though our hard work, diligence and mutual understanding, we continue to move forward and achieve results beyond our expectations.”

Now, ten years later, the partnership has sold more than 1,000 machines, including over 400 RT9 injection molding machines. The overall result has been very positive and justifies the continuation of this type of global partnership.

The evening was highlighted with live music in a festive and convivial atmosphere. Undoubtedly, this interesting and productive Open House will benefit both companies.

For more information on this event, please contact:

Tim Graham

REP CORPORATION

8N470 Tameling Court

Bartlett, IL 60103

Phone: 847-697-721

Web: repinjection.com

E-mail: tgraham@repcorp.com

A new line of PM240-2 power modules is now available from Siemens, extending the use of the popular Sinamics G120 drives family. A significant change is the addition of 230V single- and three-phase line supply units featuring quick-connect pull-off terminals on the motor, line supply and braking resistor connections allowing the new PM240-2 to offer an even more simplified installation and maintenance. In addition, these new power modules can be mounted side-by-side without derating.

PM240-2 power modules are now available from Siemens for use with Sinamics G120 drives. Various mounting, frame and power rating sizes now offered from stock.

All versions of the new PM240-2 power modules are rated IP20. However, an optional push-through version is available allowing the heat sink to extend out the backside of the cabinet. The seal for the push-through heat-sink will maintain and enclosure rating of IP55 (NEMA 12). As a result, the new PM240-2 power modules will reduce the overall required cabinet size and cabinet cooling requirements.

Among the unique, new features of the PM240-2 power modules is the variable speed cooling fan, controllable to run based upon actual conditions vs. simple on / off operation, thereby reducing both the noise generated and the power required when

in use.

The PM240-2 power modules are suitable for use with general-purpose and servo-drive styles. Options on these PM240-2 power modules include braking resistors, input reactors and output reactors.

For more information about this new line of power modules, please visit: www.usa.siemens.com/sinamics-g120.

For specific product information and inquiries, call (800) 879-8079 ext. Marketing Communications or send an e-mail to: SiemensMTBUMarCom.industry@siemens.com.

Continue reading