Contact us today:

(847) 934-4500

tdaro@bernardandcompany.com

Contact us today:

(847) 934-4500

tdaro@bernardandcompany.com

Suhner Industrial Products Corp. (Rome, Georgia) is proud to introduce machining units with special guards that protect mechanical and electrical components against contamination from fiberglass dust and fibers, as well as dust from composite and 3D printed products. Suhner offers automated drilling, boring, tapping, threading and other tools for high-production environments on these products throughout North America.

When drilling high quality holes into sheet metal composites and dissimilar material stacks of resin bonded fibers or 3D printed polymer substrates, for example, these dust-protected machining units are an ideal solution. They are universal and can be positioned everywhere alongside the workpiece for precision, automatic machining. Regardless of the complexity of the workpiece or the number of operations that need to be performed, all machining units work at the same time and only the longest operation defines the total cycle time, when the units are used in multiple setups.

Any number of Suhner machining units can be applied from different directions and perform all necessary operations at the same time. Additionally, more operations in a smaller footprint lead to greater time savings, while standard and customized solutions are offered through an optimized modular component system from Suhner. These robust machining units have myriad applications in the automotive, RV, building, appliance, aerospace and electrical industries.

For more information, please contact:

Suhner Industrial Products Corp.

Machining Division

25 Anderson Road SW

Rome, GA 30161 USA

Phone: 706-235-8046

Fax: 706-235-8045

machining.us@suhner.com

Exact Metrology, a comprehensive metrology service provider, recently released the Hexagon RS6 laser scanner, designed for high-speed and accuracy scanning. It scans up to 1.2 million points/sec with a scan rate of 300 Hz. The RS6 also has a wider laser stripe of 150 mm at mid-range and a visual guide that provides real time feedback for stand-off distance.

Built using SHINE technology (Systematic High-Intelligence Noise Elimination), the RS6 laser scanner always delivers full scanning performance, even on the most challenging surfaces. Whether it’s a glossy black plastic automotive body part or a molded carbon-fiber component, this scanner scans without any reduction in quality or productivity. Furthermore, SHINE allows users to scan 99% of parts without touching the scanner exposure. With repeatable mounting (using the Absolute Arm 7 Axis), the scanner can be removed if necessary and replaced without need for calibration. The Hexagon RS6 laser scanner is certified ISO 10360 8on all 7 axis RA8 Absolute Arms.

When compared to other scanners, the RS6 has 3x faster frame rate, 30% wider laser stripe and excellent scanning performance on difficult surfaces with SHINE. With the arm mounted scanner, it is easier to measure due to less preparation, less set up, less settings and scans with full frame, with full line width, all the time.

Exact Metrology is an ISO 9001:2008 and AS9100 Certified Company

Exact Metrology, with facilities in Cincinnati, OH, Moline, IL and Milwaukee, WI and affiliated offices throughout the country, is a comprehensive metrology services provider, offering customers 3D and CT scanning, reverse engineering, quality inspection, product development and 2D drawings. The company also provides turnkey metrology solutions, including equipment sales and lease/rental arrangements.

Exact Metrology offers a complete line of portable scanning and measurement technologies as well as contract measurement for 3D laser scanning services, reverse engineering services, non-contact inspection, metrology services, and 3D digitizing. The company’s newest equipment includes a CT Scanner, the first in America being used for metrology rather than medical testing. Exact sells and rents metrology equipment solutions, in addition to providing testing as a service and application software training.

For information, please contact:

EXACT METROLOGY, INC.

Dean Solberg

20515 Industry Avenue

Brookfield, WI 53045

Local: 262-533-0800

www.exactmetrology.com

deans@exactmetrology.com

EXACT METROLOGY, INC.

Steve Young

11575 Goldcoast Drive

Cincinnati, OH 45249

Local: 513.831.6620

Toll Free: 866.722.2600

www.exactmetrology.com

stevey@exactmetrology.com

NOARK Electric is a global manufacturer of low-voltage electrical components for industrial manufacturing applications. We specialize in motor controls and protection for original equipment manufacturers. Our mission is to provide customers with the highest quality products at an exceptional value and back them with world-class service and support. Every NOARK product is tested and certified to the highest standards and covered by our exclusive five-year limited warranty.

Source:

NOARK Electric

2188 Pomona Blvd.

Pomona, CA 91768

626.330.7007

na.noark-electric.com

For more information, please contact:

Mark Mathews, Marcom Manager

Phone: 626.330.7007 x. 103 • Email: mark.mathews@noark-electric.com

This Grieve oven is a 1250°F (667°C) inert atmosphere oven, currently used for heat treating firearms components at the customer’s facility. Workspace dimensions of this oven measure 48” W x 48” D x 36” H. 30 KW are installed in Incoloy sheathed tubular heating elements, while a 1400 CFM, 1-1/2 HP recirculating blower provides horizontal airflow to the workload. Inert atmosphere ovens protect parts from oxidation using any non-flammable gas such as nitrogen, argon or carbon dioxide.

This Grieve inert atmosphere oven features 12” insulated walls, all interior seams welded gas-tight, an air jacket on the inner oven for cooling, 16” high integral oven stand, 16-gauge 304 stainless steel interior and enamel-painted aluminized steel exterior. The oven is reinforced for 2000 lb. loads, allowing the customer’s part rack to sit on the oven work space floor.

The oven meets all requirements for inert atmosphere construction, including those in NFPA 86, FM and OSHA standards.

Controls on this Grieve oven include a programmable temperature controller with data logging, capability, 975 CFM cooling blower with air flow safety switch and automatic purge solenoid. An inert atmosphere inlet (1/2” NPT) with pressure regulator maintains positive pressure within the oven.

For more information, please contact:

THE GRIEVE CORPORATION

500 Hart Road

Round Lake, Illinois 60073-2835

Phone: (847) 546-8225

Fax: (847) 546-9210

Web: www.grievecorp.com

Email: sales@grievecorp.com

Attention: Frank Calabrese.

Platinum Tooling Technologies, Inc., the exclusive North American importer of Heimatec Live Tools and Angle Heads, Tecnicrafts Swiss Collets and Guide Bushings, Henninger Spindle Speeders and AMF Cleaning and Marking tools, recently created a video highlighting the products they would have shown in their booth at IMTS this year.

Preben Hansen, company president, presented the various product lines Platinum Tooling offers and highlights the areas of expansion since the last IMTS show in 2018. Platinum Tooling Technologies, Inc. has a wide selection of machine tool accessories for most machine brands.

Hansen demonstrated the u-tec® flexible changing system for Live Tools offered from their flagship brand, Heimatec. The tool featured was an ER 32 output cross-working tool for a BMT style turret. While standard ER 32 collets can be used in this tool, Hansen explained the beauty of the built-in changing system designed to receive a variety of adapters for different applications. With this system, the customer realizes both flexibility and cost savings.

Due to the budgetary restraints caused by COVID-19, Hansen commented that many buyers are interested in buying tools that can help them do more with their existing machines, rather than investing in new equipment. One example shown was a twin spindle tool which creates a second output from a single turret position. Another tool featured was an adjustable angle tool that allows users to produce a feature on the workpiece with a compound angle without having to re-fixture the part.

In addition, Heimatec offers a wide range of Static Tools to complement their Live Tools. This includes boring bar holders, facing holders, standard and half index turning tools as presented. Other new developments from the company include CAPTO output tooling and Live and Static Tools for Citizen machines. Platinum Tooling stocks many of these tools at their headquarters in Prospect Heights, Illinois.

The last tool highlighted from the Heimatec line was a Machining Center Angle Head weighing 12 pounds with an ER 25 output that can hold a 5/8” cutter. At this weight, the tool can be used with almost any Automatic Tool Changers on the market. This is just one of many Angle Head styles offered by Platinum Tooling. As with Live Tools, most Angle Heads are designed with the u-tec® flexible changing system.

The Tecnicrafts line is another area of expansion featured by Platinum Tooling. Collets and Guide Bushings for Swiss type CNC Lathes, specialty collets for CNC cutter grinders as well as 5C & 16C Collets are included in their selection. These high-quality workholding tools are offered in a wide variety of styles and sizes. Many popular items in inch and metric sizes are stocked at Platinum Tooling.

Speed Increasers and Custom Angle Heads from Henninger are also offered through Platinum Tooling. Speeder types include mechanical, air, and motor driven. Mechanical driven speed increasers provide rpm up to 50,000, while air and high frequency speeders offer rpm up to 80,000.

Lastly, Hansen introduced the Cleaning and part Marking tools supplied by AMF. Typically used in toolholders utilizing ER Collets or Weldon clamping systems, these tools can be used independently or in conjunction with each other during the machining process. The high-speed marking tool will permanently mark the workpiece while the cleaning tool washes away unwanted chips. New for Platinum Tooling this year is the AMF gripper. This product is operated pneumatically by compressed air or hydraulically with coolant via the machine spindle for repositioning the workpiece.

Platinum Tooling prides itself on representing the highest quality machine tool accessories in the marketplace. They offer standard and custom tools throughout their product lines to help with the most challenging applications.

A new Platinum Tooling Image Catalog is now available upon request featuring all of the products lines shown in the video.

For more information, please contact:

Preben Hansen, President

Platinum Tooling Technologies, Inc.

16 East Piper Lane, Suite 128

Prospect Heights, IL 60070

847-749-0633

www.platinumtooling.com

phansen@platinumtooling.com

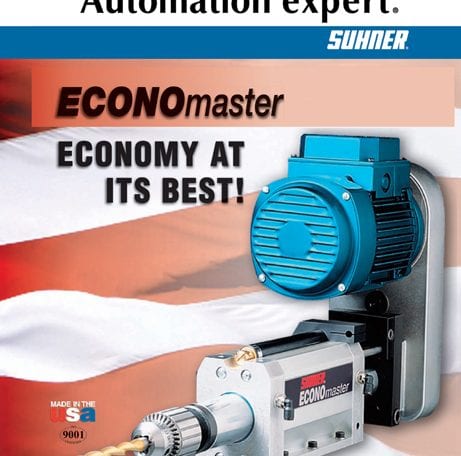

Brochure Provides Technical Data and Feature Details on Popular, Economically Priced Unit

The revised brochure offers detailed information, including technical data, product features, specifications and mechanical drawings. It features speed & feed charts as well as a full range of collet sizes available. Optional mounting stand and details for 2 spindle multi-head & adapters are also shown. The final page includes a part numbering matrix that is easy to understand and helps the customer order the perfect unit.

The ECONOmaster® drilling unit is affordably priced at just over $3,000 for the basic unit. It is in stock for immediate delivery or customizable to suit the customers application.

For more information, please contact:

Suhner Industrial Products Corporation – Machining Division

25 Anderson Road SW

Rome, GA 30161 USA

Phone: 706-235-8046

Fax: 706-235-8045

Machining.us@suhner.com

www.suhner.com

User benefits include seamless network integration, integrated drive safety, versatility, easy commissioning and servicing

Siemens is extending its drive portfolio in the safety extra-low-voltage range for 24-48V EC motors by introducing a new servo drive system named Simatic Micro-Drive. The new system with UL and CE marked components consists of the PDC (Profidrive Control) servo drive in conjunction with a flexible range of motors and connecting cables from product partners.

Simple connectivity to Simatic programmable logic controllers (PLCs) helps significantly reduce the engineering workload, while integration into Siemens automation technology via its TIA Portal makes for simple commissioning and servicing. Attributes such as smart encoders and one-button tuning add to its plug-and-play startup. Communication takes place over Profinet using Profisafe and Profidrive profiles. The new Safety Integrated function SLT (Safely Limited Torque) limits torque by monitoring motor current in running operation.

The Simatic Micro-Drive will offer units from 100 watts to 1 kilowatt and allow side-by-side rail mounting. The Micro-Drive PDC is available in a standard (only hardwired Safe Torque Off (STO)) and fail-safe version. STO, SS1, SLT, SLS, and SSM Safety Integrated functions are included with the Micro-Drive F variant. TIA Portal can be used to activate the safety functions with a Fail-safe PLC via PROFIsafe. Operating data can be transmitted directly to the controller from the Micro-Drive and transferred to Cloud-based platforms such as MindSphere over MindConnect.

To address its customers’ requirements with maximum flexibility, Siemens utilizes product partnerships with companies such as Dunkermotoren, ebm-pabst, Harting and KnorrTec when it comes to the motors and cables used with Micro-Drive. The servo drive system is suited to a wide range of diverse applications such as precise positioning, shuttles for storage and retrieval machines or warehousing systems, automatic guided vehicle systems (AGVs) and medical technology.

Siemens expands its drive portfolio with a new extra-low-voltage drive for 24–48V EC motors. The new Micro-Drive system brings industrial networking and integrated safety to a wide range of applications including battery operated equipment.

Website: http://usa.siemens.com/micro-drive

Siemens Digital Industries (DI) is an innovation leader in automation and digitalization. Closely collaborating with partners and customers, DI drives the digital transformation in the process and discrete industries. With its Digital Enterprise portfolio, DI provides companies of all sizes with an end-to-end set of products, solutions and services to integrate and digitalize the entire value chain. Optimized for the specific needs of each industry, DI’s unique portfolio supports customers to achieve greater productivity and flexibility. DI is constantly adding innovations to its portfolio to integrate cutting-edge future technologies. Siemens Digital Industries has its global headquarters in Nuremberg, Germany, and has around 75,000 employees internationally.

Siemens Corporation is a U.S. subsidiary of Siemens AG, a global powerhouse focusing on the areas of power generation and distribution, intelligent infrastructure for buildings and distributed energy systems, and automation and digitalization in the process and manufacturing industries. Through the separately managed company Siemens Mobility, a leading supplier of smart mobility solutions for rail and road transport, Siemens is shaping the world market for passenger and freight services. Due to its majority stakes in the publicly listed companies Siemens Healthineers AG and Siemens Gamesa Renewable Energy, Siemens is also a world-leading supplier of medical technology and digital healthcare services as well as environmentally friendly solutions for onshore and offshore wind power generation. For more than 160 years, the company has innovated and invented technologies to support American industry spanning manufacturing, energy, healthcare and infrastructure. In fiscal 2018, Siemens USA reported revenue of $23.7 billion, including $5.0 billion in exports, and employs approximately 50,000 people throughout all 50 states and Puerto Rico.

Continue reading

From October 11, 2019 to April 26, 2020, the Ellis Island National Museum of Immigration in New York exhibited “Sisters in Liberty: From Florence, Italy to New York, New York.” The exhibit was a collaboration between Kent State University in Kent, Ohio and the Opera di Santa Croce, a nonprofit organization in charge of the Franciscan Cathedral Santa Croce. Through art and multimedia presentations, the exhibit looked to start an international conversation about the meaning of liberty and how the concept had evolved.

The exhibit featured an 80% to scale replica of Pio Fedi’s “Liberty of Poetry,” housed at the church. It is said to have served as the basis for the Statue of Liberty. “Liberty of Poetry” honors Giovanni Battista Niccolini, a poet who inspired and supported the Resorgimento the Italian struggle for self-determination.

With permission from the Vatican, Kent neuroscientist Robert Clements and Josh Talbott, both of whom have a background in 3D imaging, traveled to Florence to scan the statue over a three-day period using technology provided by Exact Metrology.

Kent State University rented the Artec Eva scanner and Artec Studio software. Chris Lafferty at Exact Metrology provided the university with equipment, training and support. The Artec Eva, provided by Artec 3D, is used for making a quick, textured and accurate 3D model of medium sized objects. It scans quickly, capturing precise measurements in high resolution. Not only does it capture almost any type of object (including black and shiny surfaces), but it is used in numerous industries including quality control, heritage preservation, forensics, automotive, medical, aerospace and prosthetics. Artec Studio makes it easy to obtain accurate 3D models. It features an advanced smart mode that guides users through post-processing, automatically selecting the most effective settings for the data and producing a high precision 3D model. It offers best in class texture and geometry tracking, thus eliminating the need for targets on objects. Whether using Autopilot or manual mode, the software never compromises on precision. Furthermore, powerful algorithms process data in seconds and Artec Studio features a full range of advanced settings. Users can scan and process data on a tablet.

After scanning the statue, Clements and Talbott returned to Kent State to process 30 to 40 gigabytes of data and create a blueprint for a 3D printer.

Freshmade3D, a Youngstown-based start-up company, printed the replica in three sections, so the statues could be transported easily to New York. The statue was painted by a team of students at Kent State and combines sand and resin to replicate the original.

Commenting on this project, Chris Lafferty said, “This was a great experience for us as we got to see the finished product and how Exact Metrology contributed to this. We look forward to more collaborations like this in the future.”

Exact Metrology is an ISO 9001:2008 and AS9100 Certified Company

Exact Metrology, with facilities in Cincinnati, OH, Moline, IL and Milwaukee, WI and affiliated offices throughout the country, is a comprehensive metrology services provider, offering customers 3D and CT scanning, reverse engineering, quality inspection, product development and 2D drawings. The company also provides turnkey metrology solutions, including equipment sales and lease/rental arrangements.

Exact Metrology offers a complete line of portable scanning and measurement technologies as well as contract measurement for 3D laser scanning services, reverse engineering services, non-contact inspection, metrology services, and 3D digitizing. The company’s newest equipment includes a CT Scanner, the first in America being used for metrology rather than medical testing. Exact sells and rents metrology equipment solutions, in addition to providing testing as a service and application software training.

For information, please contact:

Steve Young

Exact Metrology, Inc.

11575 Goldcoast Drive

Cincinnati, OH 45249

Local: 513-831-6620

Toll free: 855-476-1431

www.exactmetrology.com

stevey@exactmetrology.com

Effective immediately, Chris Blaine will oversee all sales activities related to four Platinum Tooling rep groups across the country. This includes Machine Tool Accessory Sales which covers the states of Alabama, Georgia, North Carolina, South Carolina, Tennessee, Virginia, and West Virginia. Additionally, the territory includes Evergreen Tool Group Tool in Michigan, McGill Sales in Ohio and Western Pennsylvania, and lastly, CMI covering the states of Indiana and Kentucky.

Chris has strong technical knowledge of machine tools and machine tool accessories. Before joining Platinum Tooling, Chris worked for 3 years at Morris Group, Inc./Velocity Products headquartered in Windsor, Connecticut. As sales manager, he was responsible for managing their Live Tool sales for many states in the Midwest. In addition to his vast knowledge of Live Tools, Chris also held the position of project manager for machining center products including rotary tables. He also has experience with new product development and all levels of product and sales management.

Chris has gained experience through working with complex parts used in the aerospace, medical, defense, diesel fuel systems, automotive, oil and gas, and down hole industries. Chris has a vast understanding of metals which allows him to make recommendation for the appropriate tooling given a specific application.

Blaine studied Manufacturing Technologies at Ivy Tech Community College in Fort Wayne, Indiana. He looks forward to his work at Platinum Tooling saying, “I am excited to apply and expand my technical expertise and sales ability as a member of Platinum Tooling.”

Platinum Tooling Technologies, Inc., is located in Prospect Heights, Illinois (just outside of Chicago). They recently expanded their facility to provide increased inventory to better serve the marketplace.

For more information, please contact:

Preben Hansen, President

Platinum Tooling Technologies, Inc.

16 East Piper Lane, Suite 128

Prospect Heights, IL 60070

847-749-0633

www.platinumtooling.com

phansen@platinumtooling.com