Contact us today:

(847) 934-4500

tdaro@bernardandcompany.com

Contact us today:

(847) 934-4500

tdaro@bernardandcompany.com

Established in 1986 Mictu’s core business is the eyewear industry. As the company has grown they expanded into aerospace, automotive, dental, and mechanical. Boasting a team of 15 people and producing more than 200,000 tools per year, Mictu exports tools to China, Hong Kong, North and South America, Switzerland and Germany, as well as servicing their local Italian market.

Andrea Colavo, the son of the founder of Mictu said, “There has been significant growth in our company since its beginning. We have a big body of knowledge as the eyewear industry gave us the opportunity to test our tools in many different materials giving experience in working with many kinds of plastics and metals.”

Servicing the changeable eyewear industry

The eyewear industry is different from other kinds of industries, mostly because it’s fashion. Eyewear trends are constantly changing and customers require different tools to machine different shapes.

The industry also uses very small tools and Mictu have produced tools with a 0.2 millimeter diameter mill. For example, a hinge requires very tight tolerance — in fact drawings often specify plus or minus one hundredth of a millimeter.

Understanding different materials is fundamental

Andrea continues, “We are a curious team who understand the value of trying new approaches and materials. If a customer is asking to use a material we have no experience in, we ask them how this material reacts to machining and describe the chips of this material. This helps us build a picture of how the material reacts to cutting. We make a sample tool and analyze its performance — is the tool working correctly or does it require adjustments? In the ANCA 3D simulator we can make these adjustments to produce a second batch and try again at the customers.”

Mictu has developed many different tools for many different materials. The most common plastics are nylon or polycarbonate and metals are titanium, stainless steel or cast iron.

Designing the best tool takes trial and error

“I think that anyone can make a tool, especially now that we have more intuitive software. However experience is still key. Cutting tool makers should consider the dynamics of the grinding wheels and need to know the right speed that will not cook your material as otherwise it will break like glass.”

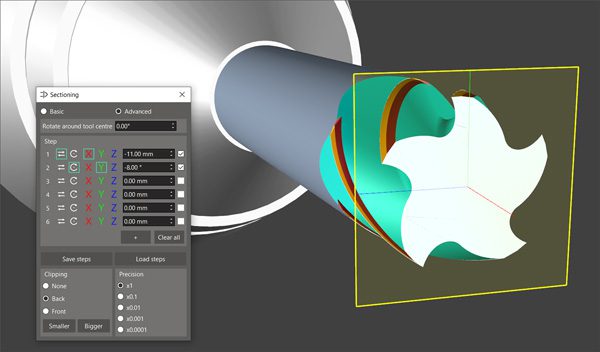

“Generally we start from a drawing of the finished part and ask our customer how he wants to machine their component. Next we use our ANCA 3D simulator software program to simulate the tool to evaluate the best performing shape for that tool.”

“We start using 3D simulation with an ANCA MGX that we bought in 2002. The 3D simulator has changed the way we make tools, mostly because using this software means we are making less errors.”

“The characteristics that make a tool perform best is choosing the right material.

“A cutting edge must be appropriate for the material you have to machine for example, sometimes a very sharp cutting edge is not the best choice. Very sharp edges are weaker than a rounded edge and can vibrate more. So for soft materials you need a very sharp edge, but for hard to cut materials, you need a stronger cutting edge. “

“I have found it is important to make mistakes. This means you can learn what is not working and that helps you next time you are designing a tool.”

Technology matters – ANCA’s MGX has produced more than 350,000 pieces and is still running

Mictu invested in an MGX in 2002. Andrea recalls, “It’s our first ANCA and is still performing with more than 350,000 pieces manufactured over the years. We found the MGX is a very good machine for producing small to medium batches of very small tools.”

“More recently we purchased two new FX7 Linears because of their flexibility. They are excellent machines for producing tool batches of varied sizes. So far, we have been running them all week, overnight and on the weekend with big batches. During the day we use them to produce smaller batches. On the FX7 we mainly produce drills, step drills and mills and sometimes even end mills with a profile.”

“The FX7 can produce very different tools in the same batch making the machines extremely efficient. Another big advantage of these machines is that we can measure the tool without looking at it. The machine has a laser that measures, and if necessary, corrects during the grinding process. Even if no one is looking at the machine, we know the machine is automatically taking care of the tolerance of our tools and that the end quality will be high. I sleep much better because I know the laser is doing its job checking the diameter of every mill you are producing.”

“We use the iBalance to ensure our wheel packs are balanced, reducing the vibration on our tools. This is fundamental when you’re making very small tools. If you have even a very small vibration, your cutting edge will be hammered and cheap. If you have it balanced well, it will work much more smoothly and have a nicer cutting edge.”

“Personally I also liked the appearance of the machine, I would even say it is good looking! With the new Linear models, we expect a longer machine lifespan and improved surface finish. The small footprint is welcome and its many features help with the repeatability of our tools. In summary, we choose the ANCA FX7 Linear because it is a complete package with a wheel changer, large loader, laser measurement technology and has 3D Simulator software.”

Professional facilities build trust with customers

Mictu recently moved to a new facility and are reaping the benefits of investing in custom design. Andrea continues “The biggest benefits we’ve seen moving to a new facility was starting from a blank sheet. We decided to put all the pipes needed for the oil for the grinders underground to make a clear surface with less stuff that can leak on the floor. The measuring machines have been installed in a separate environment to keep them on a steady temperature. Since moving we have seen improved production, better quality control and overall we are more efficient and have a better environment for our people because it’s clean and fresh.”

“I think it’s really important for a customer to visit your facility so they can assess the working environment. Fortunately, customers are very impressed which helps us build trust in our products and services. Customers choose to work with us because we are very lean and listen to their needs. We have a skilled and experienced team who are able to solve problems.”

For further information, please contact:

Johanna Boland

Group PR and Communications Manager, ANCA

M: +61 407799779

Johanna.Boland@anca.com

ANCA is a market leading manufacturer of CNC grinding machines. It was founded in 1974 in Melbourne, Australia where the company still has its global headquarters. ANCA has offices in the UK, Germany, China, Thailand, India, Japan, Brazil and the USA as well as a comprehensive network of representatives and agents worldwide.

ANCA CNC grinders are used for manufacturing precision cutting tools and components across a diverse range of competitive industries including cutting tool manufacture, automotive, aerospace, electronics and medical.

Continue reading

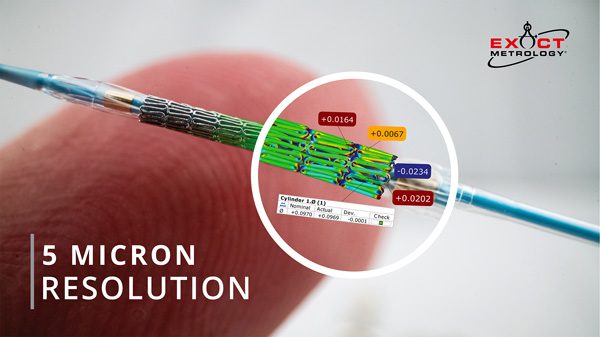

Exact Metrology, a comprehensive 3D metrology service provider and hardware sales company, has recently installed a ZEISS METROTOM 6 scout, formally known as a GOM CT, scanner at their facility in Brookfield, Wisconsin.

Considered the powerhouse of resolution for CT inspection and metrology, the METROTOM 6 scout digitizes complex parts including the internal geometries at the finest level of detail. Users obtain a complete 3D image for GD&T analysis or nominal-actual comparisons. The metrology CT excels in digitizing small plastic parts.

The combination of a 3k detector and 225 kV X-ray enables ZEISS METROTOM 6 scout to provide high contrast, high-resolution measurement results and exceptional sharpness of detail. As a result, even the smallest defects in the part become visible and can be analyzed to the last detail.

To showcase the ability of Exact Metrology’s CT scanning services, powered by the METROTOM 6 scout, a scan was done on a medical stent. This medical stent, with a diameter of only 1 millimeter, was measured within a 5 Micron resolution. Thus, Exact Metrology inspectors were able to evaluate critical features with amazing precision.

CT scanning provides several benefits including being the only way to get 3D views inside a part and the only way to obtain accurate dimensional data without cutting up and destroying an object. In addition, CT scanning requires very little time to capture data and troubleshoot parts and also offers multiple uses with one scan (void analysis, inspection, volume, porosity, reverse engineering, etc.). In contrast to conventional tactile coordinate measurement techniques, a CT acquires all surface points simultaneously —on even the most complex objects. This includes all hidden features like undercuts which are not accessible using other non-destructive measurement methods.

Due to its ability to see data layer by layer, CT scanning permitted Exact Metrology inspectors the ability to see any possible defects/details on the stent. This is crucial for any medical device, especially something as small and essential as a stent that goes into the human body.

Exact Metrology is ISO, AS9100 Certified as well as FFL and ITAR Registered.

Exact Metrology, with facilities in Cincinnati, Ohio, Moline, Illinois and Milwaukee, Wisconsin, plus affiliated offices throughout the country, is a comprehensive metrology services provider, offering customers 3D and CT scanning, reverse engineering, quality inspection, product development and 2D drawings. The company also provides turnkey metrology solutions, including equipment sales and lease/rental arrangements.

For more information, please contact:

EXACT METROLOGY, INC.

Dean Solberg

20515 Industry Avenue

Brookfield, WI 53045

Local: 262-533-0800

www.exactmetrology.com

deans@exactmetrology.com

To see optimized part positioning with ZEISS Metrology, please visit https://www.youtube.com/watch?v=Ch3JuozfqYU&list=PLvaO705pqbydFVDs_K_f0qrZgm1tQ8F9b

Continue reading

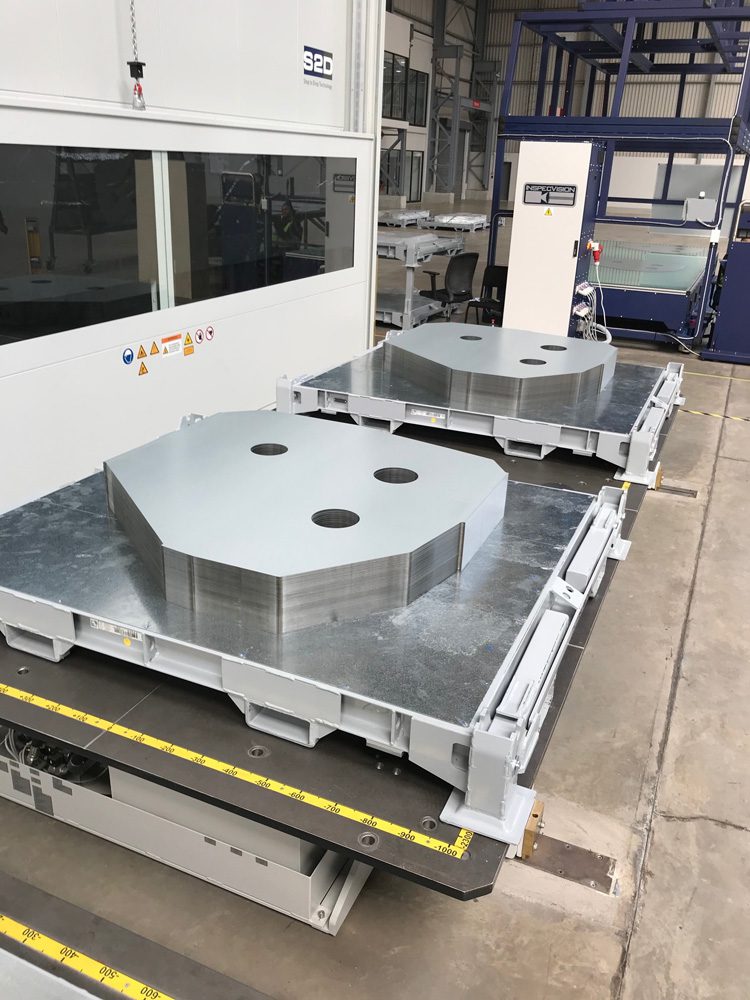

First Zimmermann portal milling machine of the newly designed FZP machine family with thermosymmetrical design offers significant user benefits

Model, tool and die makers must deliver perfect quality at competitive prices under increasing deadline pressure in order to prevail against strong global competition. Zimmermann is responding to this market condition with the newly developed FZP machine line. These 5-axis portal milling machines are customizable, space-saving and extremely thermostable. These features are ensured by the new thermosymmetrical design with a center-guided Z-slide. Daniel Demlang, technical director at Zimmermann, explains the advantages for the user.

“An evolution is a progressive process. A revolution, by contrast, is a fundamental and lasting structural change of a system – this is exactly what we have done with the development of our new FZP machine line,” reports Zimmermann Technical Director Daniel Demlang. The demands that model, tool and die makers need to meet today have grown steadily. Their customers demand workpieces with near-perfect surfaces and consistently high dimensional accuracy. The key to achieving this goal is manufacturing equipment that minimizes rework to ensure fast delivery times. “Our customers are burdened by increasing cost pressure and the demand for ever higher quality, while simultaneously increasing delivery deadline pressure for components. Reducing throughput times for workpieces was one of our main goals with the newly developed FZP series in terms of design,” explains Demlang. “Stable process control and high machining quality are decisive factors for the cost-effectiveness of our systems.” However, the customizability of our milling machines was not allowed to decline. Machines of the FZP Series are therefore even more flexible, in terms of set-up and design, with a comprehensive range of additional options.

Customizable – not only in length and width

“With our new FZP line, we primarily want to empower customers to compete successfully in the market for the long term,” says Demlang. The developers have placed particular emphasis on the customizability of the machines. Their structure can be varied in length and width with different vertical slides and gantries, thus adapting to a wide range of workpiece sizes. The “lightest” machine in the FZP line is the new FZP32 with a working range of up to X = 10, Y = 4 and Z = 2.5 meters (393” x 157” x 98”). The user can machine block materials, plastics, as well as CFRP, GFRP and aluminum, among other materials. Due to the large working area, it is also possible to mill components completely without reclamping. “The modular design of the machine offers the possibility to consider different options. Automation solutions, such as a pallet changing system, a positionable rotary table, dust extraction bells and an individualized tool clamping system are all possible,” explains the technical director.

Thermosymmetrically constructed

It was important to the developers to build the FZP line for maximum dimensional accuracy during workpiece machining. This is because changing temperatures in the user’s facility, as well as long machine running times, inevitably influence the machining quality. For this reason, the Zimmermann developers designed these new portal milling machines thermosymmetrically – a concept that was used successfully for the first time at Zimmermann in 2017 in the compact FZU portal milling machine line and was enthusiastically received by customers.

“The idea of the thermosymmetrical design is based on the fact that inevitable thermal influences can be absorbed to a considerable extent by the design of the machine structure,” explains Demlang. In the portal milling machines of the FZP line, Zimmermann has arranged the milling spindle, guides and other accuracy-determining components in such a way that their heating is either absorbed or can expand in non-critical directions. The gantry’s center-guided Z-slide in double-bridge design, for example, has an octagonal cross-section that makes it particularly stable. “With this design, we achieve very high thermosymmetric stability,” says Demlang. Comparable systems usually use complex cooling or software-based compensation for this purpose.

“Our concept is future-proof, especially when the demands on quality and surface continue to rise,” promises Demlang. Companies that do not have an air-conditioned machining facility and are therefore particularly exposed to temperature fluctuations in their production will also benefit from this concept. And this is where the new design further scores points, according to Demlang. The design of the structure alone reduces the effects of the influencing variables to a minimum.

VH10: milling head with extraction

The Zimmermann VH10 milling head is used on this new machine line. The fork head is designed in monoblock versions made of cast iron. It is compactly built, has only minimal interference contours, achieves high clamping forces and thus enables stable component machining. Zimmermann optionally equips the VH10 milling head with process cooling via cooling lubricants and minimum quantity lubrication. To reduce throughput times, a powerful spindle with 34 kilowatts (45 HP) at a maximum speed of 24,000 rpm is used as standard in the milling head. “We have now also equipped the VH10 with a dust extraction bell around the milling tool,” Demlang notes. This makes it suitable for abrasive and harmful materials such as GRP or CFRP, which are used in aircraft construction. The dust extraction system captures the dust directly at the point of origin, which greatly reduces contamination of the interior.

Great flexibility by design

Facility conditions are often a challenge for the installation of large milling machines. Free installation space is usually scarce and machine concepts must offer a high degree of flexibility in installation. The Zimmermann developers have applied symmetry not only to the basic structure of the gantry, but also to the complete machine concept. This allows the customer to individually determine specific connections or peripheral attachments. “We can then simply position the peripherals as required by the individual situation without making any major design changes to the new FZP32,” says Demlang. Overall, the ratio of floor space to workspace has been optimized with this new development.

Zimmermann equips the new machine line with larger tool magazines or even pallet changers on request. This allows users to reduce non-productive time and make their production more automated. Another feature: “Milling-turning applications are increasing, especially in aircraft construction, for example in turbine production,” says Demlang. “For this purpose, we also equip our milling machines with carousel rotary tables on request.” Regardless of the task the customer needs to perform, Zimmermann’s experts can supply the machines in a customer-specific, optimized way with their modular plant construction kit (MAB).

What’s next?

“We already have the first orders for the FZP32, our ‘light’ entry-level model in the new series,” says Demlang. “Based on the new double-bridge gantry, we will soon launch the new FZP37, a machine in the medium segment, and the FZP42, one in the heavy segment for the mold and die industry.” The heavy-duty FZP42 machine will be in the 1,000 newton-meter (737 ft lb) torque range. “We have taken a forward-looking path with this new machine line,” concludes Daniel Demlang.

About the company

F. Zimmermann GmbH from Neuhausen a.d.F. in Swabia is a leading global high-tech supplier of portal milling machines. These are characterized by huge workspaces, enormous dynamics and cutting performance. The company, founded in 1933 by Friedrich Zimmermann, now has over 200 employees worldwide. With its product range, the innovative company has one goal above all: to offer the right solution for its customers and thus to be able to guarantee high economic efficiency. “Quality made in Germany”. The special machines are used worldwide in the automotive, aerospace and mechanical engineering sectors. The company has its North America headquarters in Wixom, Michigan, near Detroit, where it operates a full tech center offering engineering assistance, commissioning, parts and retrofit services, as well as multiple machines for demonstration purposes.

For more information, please contact:

ZIMMERMANN INC.

30587 Century Drive

Wixom, MI 48393

Phone: 248-956-8511

www.zimmermann-inc.com

Ms. Lena Kiesel, Marketing Manager

lena@zimmermann-inc.com

Maintenance tips and assembly procedures on automated tools explained by Division Manager Lee Coleman

Suhner Machining recently filmed a series of maintenance tip and unit assembly videos at the company’s North American Service Center, housed on the campus of corporate headquarters in Rome, Georgia. The presentation of the procedures was done by Division Manager and longtime Suhner team leader, Lee Coleman. These “hands on” demonstrations would interest any customer or maintenance personnel currently using or planning to employ Suhner automated tools in their shop or production facility. According to Coleman, “We made these videos as the first in a series. Our goal is to help customers and trainers impart the proper procedures for maintenance and assembly of our automated drills, taps and other tools, which are used extensively in automotive and other high-volume production facilities, contract job shops and elsewhere.”

The company is planning a number of videos to assist operators and especially maintenance personnel in the proper care and handling of these high-precision automated tools, many of which typically perform thousands of operations in a single shift on the production line.

These first four new videos cover the following topics on the SPINDLEmaster Max 100:

Proximity Switch Adjustment

Spring Adjustment

General Maintenance

Flag Nut Adjustment

For more information, please contact:

Lee Coleman, Division Manager-Machining

Suhner Industrial Products Corp.

25 Anderson Road SW

Rome, GA 30161 USA

Phone: 706-235-8046

Fax: 706-235-8045

machining.us@suhner.com

…for one is silver but the other is gold. That was a song they sang in my mother’s Girl Scout Days. She rose up the ranks in Chicago to District Chairman, when I was a kid. Pioneered Operation Co-Ed, the first joint effort of Girl Scouts and Boy Scouts, here in Chicago. I can recall her out in a boat with a megaphone at night, chastizing the two camps who’d sneaked off to the island in the middle of the lake, where the sexes were housed on opposite shores. Pretty radical for the late 50’s. And my sister was one of the ring leaders of the secret meet-up! The event caused controversy but it worked. A life lesson I learned in my single-digit years.

Change is integral to life, and in our case, to the progress of manufacturing technology and its marketing messages and methods.

In this issue, you’ll read a column from our new social media director, Amie, who lives in Flint, MI and is the first employee I hired sight unseen. That took some adjustment, but not much, as she’s proving her worth every day. Social media has gone from a couple hours a week to full-time jobs at our agency. Another of the seven ways engineers get info to do their jobs and engage their colleagues and the supply chain.

Likewise, you’ll see Stiefelmayer lasers, with their line of machines dedicated solely to the production of motor laminations for the electric vehicle (EV) market, which is changing the landscape of an entire industry rapidly. We’ve handled several laser manufacturers in the past as clients, so we were a perfect fit for this company, who’s being represented by our “old” friends at GMTA in Ann Arbor. Get the picture?

New business is the lifeblood of any ad or PR agency (we’re both for most clients) and that’s a given. In this day of Covid, that’s also a tougher challenge than ever. One new client reached out to the media covering their world for agency recommendations and our name came up on all the lists. Kinda proud of that fact and it witnesses our expertise and 46 years as a strictly industrial agency.

We speak your language, that’s a fact.

From all of us at Bernard & Company, thanks to our old friends. Be a new one?

The bottom line, as we said back in the day…what we do works and we can prove it. That’s also a fact.

Keep the rally going,

Tim

p.s. Thanks, mom, for showing me that you can change the way two things get done and make them both better. Later on, I learned the word synergy, something our clients and we have, to the benefit of both!

All the features and reliability of Suhner technology at an affordable price,

For the OEM or end user…MADE IN AMERICA

Suhner introduces the ECONOmaster® line of drilling units, affordably priced at under $3000 for the basic unit, in stock for immediate delivery or customizable to suit the particular operation. This economical solution is ideal for multiple materials such as light metal, wood, composite, plastic and foam. Because these units are entirely produced at the Suhner factory in Rome, Georgia, response times for delivery and customized construction are minimal, according to Division Manager Lee Coleman. “We recognized the need to bring our global technology to a local level, here in America, and the ECONOmaster® is a key step in that process.” Suhner is based in Brugg, Switzerland, with plants and distribution centers worldwide.

The ECONOmaster® drilling unit features low power and air consumption, adjustable motor housing, adjustable total stroke up to 4”, hydraulic feed control cylinder, J33 taper spindle end, 0-1/2” drill chuck, electric front & rear position limit switches, belt tensioner and chrome-plated quill. Basic unit weight is 45 lbs.

Other key features include adjustable feed stroke of ½-3”, 400 lb. thrust at 85 psi, operating pressures to 110 psi, TEFC/IP56 protection, standard 230V/460V, concentricity of .002” TIR, speed ranges to 9600 RPM and an air connection retract/advance of ¼” to 27 NPT.

ECONOmaster® drilling units can be supplied with an adjustable stand, inline vertical configuration and multiple spindle heads for medium-duty production drilling, with many other spindle options and toolholders available. Please consult the factory in Rome, Georgia.

For more information, please contact:

Lee Coleman, Division Manager-Machining

Suhner Industrial Products Corp.

25 Anderson Road SW

Rome, GA 30161 USA

Direct: 706-314-2927

Mobile: 706-409-1876

Fax: 706-235-8045

lee.coleman@suhner.com

Fast flexibility for custom tooling, easy access through cloud technology and automation are driving tool production processes

ANCA North American President Russell Riddiford recently participated in an award ceremony at ARCH Cutting Tools in Latrobe, Pennsylvania to celebrate the company’s win in the 2020 ANCA Tool of the Year competition. During this time, Russell sat down with ARCH Cutting Tools President Jeff Cederstrom to discuss the successful collaboration between both companies, as well as future trends that they see on the horizon; and how best to maximize the opportunities of these trends.

Offline and in-process solutions help to deliver speedy custom profiles and get the “first tool right”

Jeff identified the growing trend towards custom tooling. While he described ARCH as a “full-service, one-stop shop with a broad portfolio of standard tools,” he acknowledged that the company sets itself apart in the market, thanks to the breadth of their custom tooling capabilities. Many customers work with ARCH Cutting Tools, looking for custom solutions to reduce their manufacturing costs. This leads to combination tools with complex geometries. Jeff said the combination of skilled machinists, designers and technology that ANCA provides enables the process to flourish.

Recognizing the market need for adaptability to produce custom tools Russell highlighted the range of processes offered by ANCA that are targeted to increasing the “speed to get to the grinding point.” ANCA’s 3D simulation software generates a special profile offline, while the machine is still running and completing the previous jobs. The program is then downloaded to the machine, allowing ARCH to obtain better production of the first tool. ANCA offers ARCH the option to inspect their tool on the machine, using the LaserPlus System. The system measures the profile tool, automatically compensating the machine to correct any errors in geometry. Another option is to take the tool to a ZOLLER presetter, as ZOLLER is integrated with the ANCA machines on the floor. A full contour scan is performed using the ZOLLER »genius3« to identify any imperfections in the tool.

Russell sees the importance of having the “first tool right” as a critical point for production. After the pre-grind process through simulation to perfect the tool before it even gets to the machine, ANCA as the only company with a full linear motor product line, offers customers maximum accuracy, surface finish and stability throughout the grinding process. Another new technology is spindle temperature control, a software function that maintains consistent spindle temperature. Providing this stability again allows the first tool in production to be right.

ARCH Cutting Tool’s winning tool offers five separate functions demonstrating the kind of complexity that is in demand. Jeff commented that custom tooling is becoming more challenging and ANCA’s solutions offer significant benefits. Jeff noted: “Having the software so that it is user-friendly, and we can adapt to a request quickly and having not only the software but the machining technology to support it … is critical to us.”

Jeff’s company recently launched a program called “Hot Shop” to showcase their speed from production to delivery. If a customer needs a custom tool quickly, ARCH can produce any geometry of a solid carbide round tool and have it delivered within one week. Jeff explained: “Having equipment that is nimble and fast on the floor enables (this speed)”.

Connected machines and integrated automation

ARCH has developed a web portal called “ARCH Specials.” Customers can download drawings, a DFX file or use pulldown menus on the company website, or talk to engineers to generate a fast RFQ for application specific custom tools.

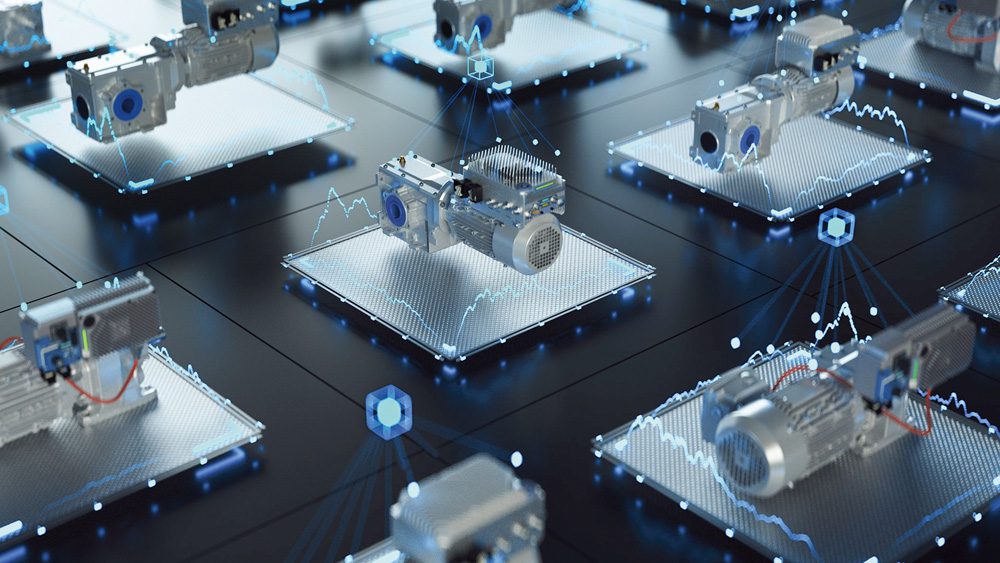

Online capabilities and cloud technology are a growing trend. ANCA can network all machines through their Management Suite software, allowing users to replicate and download files from anywhere in the country, such as across ARCH’s multiple facilities. Additionally, users can monitor real-time performance of their machines to schedule and maintain the machines, as well as predict maintenance requirements to minimize downtime.

Both Cederstrom and Riddiford identified automation as another rising trend. From customers looking for more output, better quality and more productivity, to the social distancing requirements of COVID, to the gap in skilled labor; increased automation provides a solution to these challenges. To this end ANCA has developed AIMS (ANCA Integrated Manufacturing System). Russell explains: “This is the ability to bring a stock piece of carbide at the front end and at the back end have a finished tool…without manual or operator input throughout the process. This allows end-to-end grinding.” Adding to ANCA’s product range is automated laser etching with the AutoMarkX, which fits with AIMS to complete the process. Russell added: “Some people might think of it as the future, but AIMS is here today.”

To see the discussion between Russell and Jeff, please see the video below:

For further information, please contact:

Johanna Boland

Group PR and Communications Manager, ANCA

M: +61 407799779

Johanna.Boland@anca.com

ANCA is a market leading manufacturer of CNC grinding machines. It was founded in 1974 in Melbourne, Australia where the company still has its global headquarters. ANCA has offices in the UK, Germany, China, Thailand, India, Japan, Brazil and the USA as well as a comprehensive network of representatives and agents worldwide.

ANCA CNC grinders are used for manufacturing precision cutting tools and components across a diverse range of competitive industries including cutting tool manufacture, automotive, aerospace, electronics and medical.

Continue reading

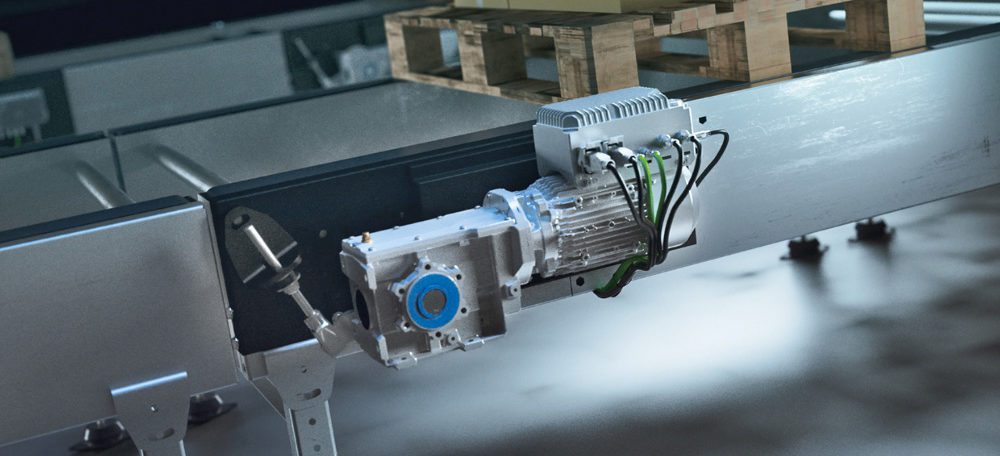

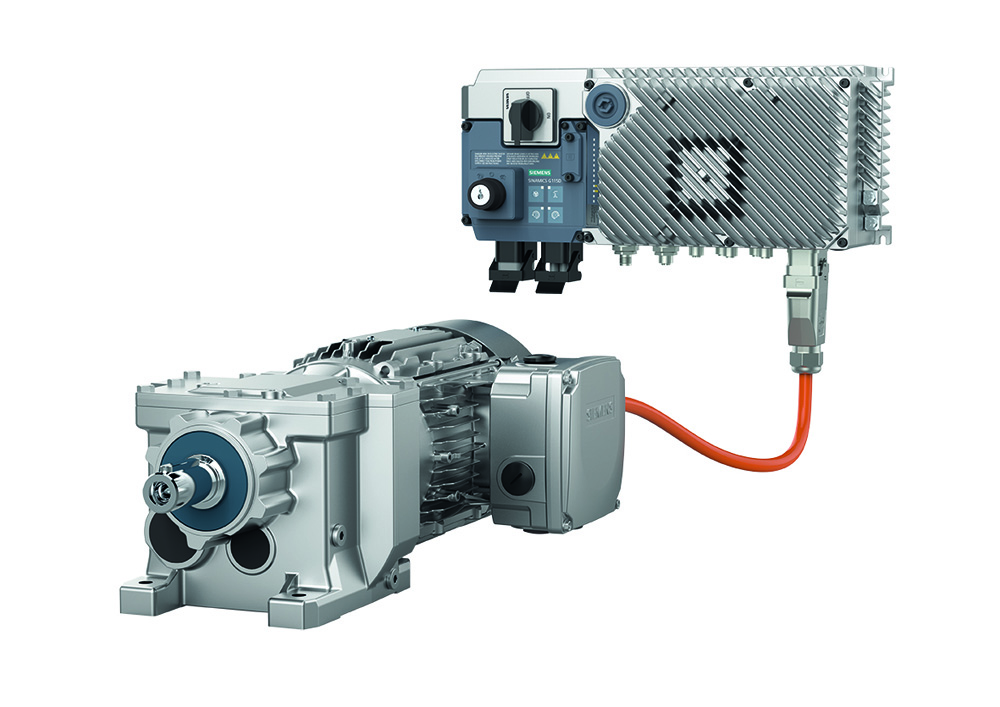

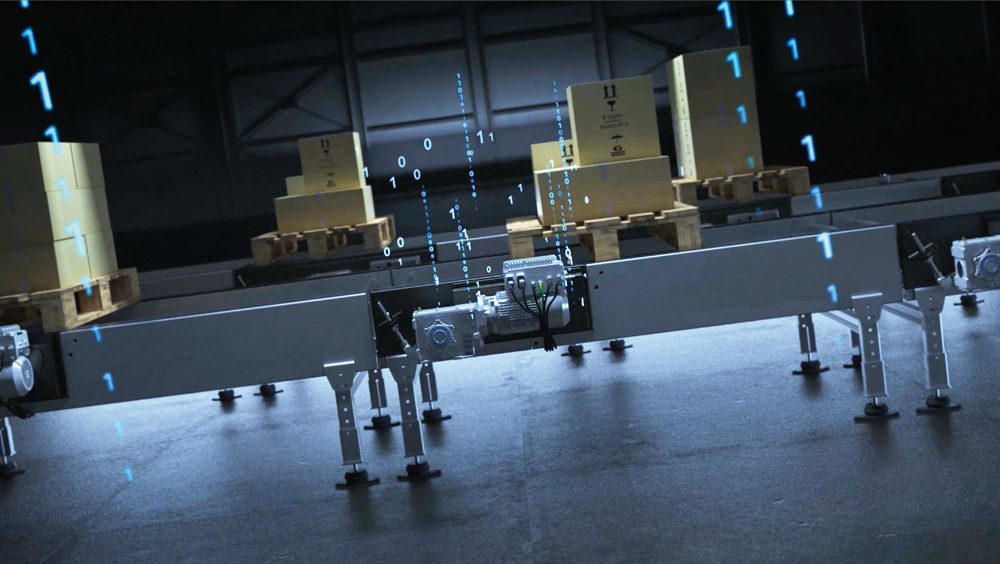

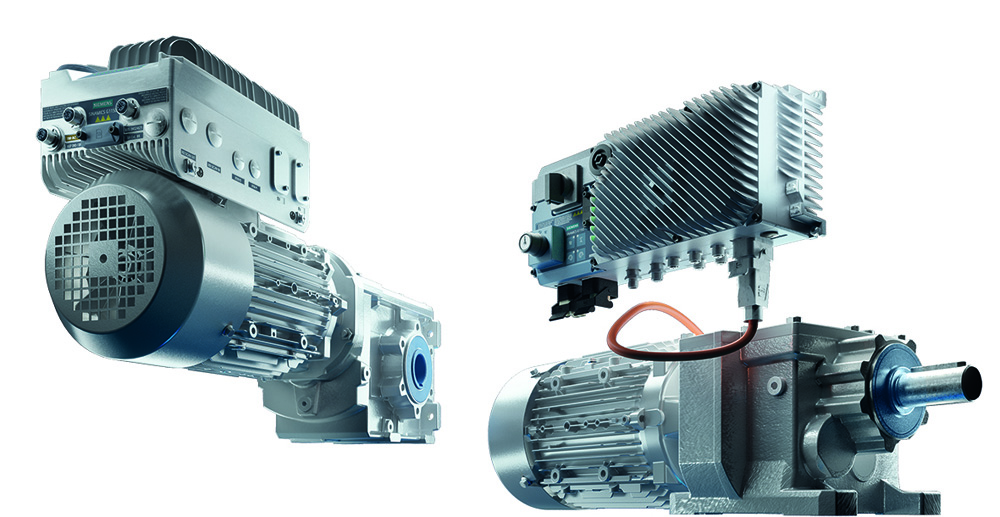

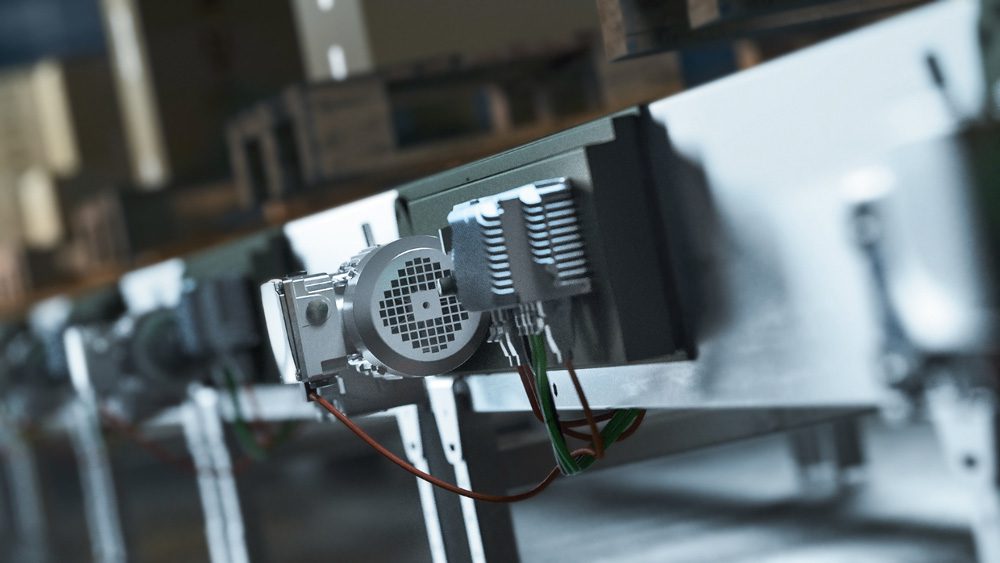

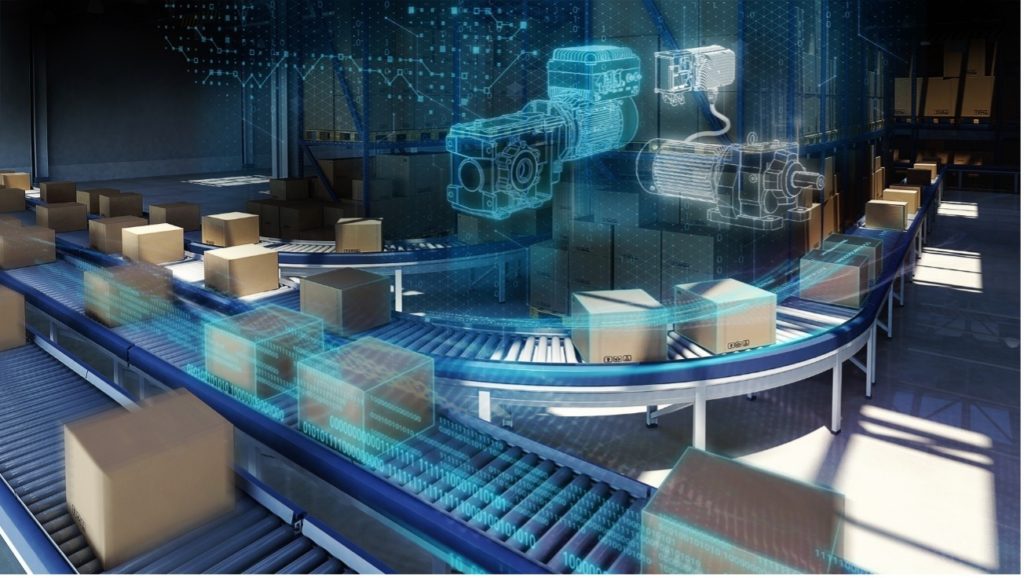

Comprised of the drive, motor and gear box, this new distributed drive system is available as a complete solution for motor-mounted and wall-mounted horizontal motion control conveyor applications.

With its new Sinamics G115D, Siemens is introducing a new, compact and powerful drive system specifically designed for horizontal conveyor applications. The drive system comprises the motor, drive and gearbox in one unit and is offered in two versions — wall-mounted and motor-mounted.

The Sinamics G115D drive system is characterized by a robust design with a high IP protection class (up to IP66 / UL Type 4X) and is suitable for use in harsh environments. Thanks to its compact dimensions, the Sinamics G115D can be easily installed in confined areas. The drive system can also be operated reliably over a wide temperature range of -30 to 55 degrees Celsius (-22 to 131 degrees Fahrenheit), enabling operation in deep freezing applications.

Sinamics G115D is suitable for applications in intra-logistics and airports, as well as in the automotive and food and beverage industries. Its power ranges from 0.37 to 7.5 kilowatts

(1/2 to 10 hp) for wall-mount applications and 0.37 to 4 kilowatts (1/2 to 5 hp) for motor-mounted applications. The drive system can be put into operation quickly and easily with comprehensive integration into the Totally Integrated Automation (TIA) portal including Startdrive commissioning software or the Sinamics Smart Access Module (SAM) web-server for Wi-Fi setup and diagnostics.

To be prepared for digital transformation and to enable cloud-based analysis, Sinamics G115D is integrated into the entire MindConnect portfolio and is compatible with MindSphere applications such as Analyze MyDrives.

Thanks to Profisafe, the Sinamics G115D has Safety Integrated in the form of STO (Safe Torque Off) SIL2, which standardizes and facilitates the certification process. For flexibility in terms of installation, service and maintenance, the solution is equipped with a plug-in connector and flexible connection possibilities. The device is particularly suitable for interaction with Simatic controllers such as the Simatic S7-1200 or Simatic ET200 for motion control.

Siemens offers warranty extensions for Sinamics G115D through its Service Protect package. As part of this service package, an additional one or two-year warranty extension may be purchased for failure coverage. The package offers simplified processing under normal warranty conditions for the extended period.

For more information regarding Sinamics G115D, please visit:

usa.siemens.com/sinamics-g115d

For specific product information and inquiries, send an e-mail to: mc.us@siemens.com

Siemens Digital Industries (DI) is an innovation leader in automation and digitalization. Closely collaborating with partners and customers, DI drives the digital transformation in the process and discrete industries. With its Digital Enterprise portfolio, DI provides companies of all sizes with an end-to-end set of products, solutions and services to integrate and digitalize the entire value chain. Optimized for the specific needs of each industry, DI’s unique portfolio supports customers to achieve greater productivity and flexibility. DI is constantly adding innovations to its portfolio to integrate cutting-edge future technologies. Siemens Digital Industries has its global headquarters in Nuremberg, Germany, and has around 75,000 employees internationally.

Siemens Corporation is a U.S. subsidiary of Siemens AG, a global powerhouse focusing on the areas of power generation and distribution, intelligent infrastructure for buildings and distributed energy systems, and automation and digitalization in the process and manufacturing industries. Through the separately managed company Siemens Mobility, a leading supplier of smart mobility solutions for rail and road transport, Siemens is shaping the world market for passenger and freight services. Due to its majority stakes in the publicly listed companies Siemens Healthineers AG and Siemens Gamesa Renewable Energy, Siemens is also a world-leading supplier of medical technology and digital healthcare services as well as environmentally friendly solutions for onshore and offshore wind power generation. For more than 160 years, the company has innovated and invented technologies to support American industry spanning manufacturing, energy, healthcare and infrastructure. In fiscal 2018, Siemens USA reported revenue of $23.7 billion, including $5.0 billion in exports, and employs approximately 50,000 people throughout all 50 states and Puerto Rico.

Continue reading

The German press manufacturer Schuler has numerous manufacturing and service locations worldwide. This ensures that customers can receive fast and efficient support from local Schuler employees. In the Americas, for example, there are sites in the USA, Mexico, and Brazil, ready to support one of the company’s latest innovations: the Laser Blanking Line.

Laser blanking makes it possible to manufacture blanks completely without dies. Instead of using presses or shears, the geometries are cut by two or three high-precision laser heads. This has several advantages: no dies, die change, die storage or die maintenance, but also no costly press foundation and no loop pit. The technological development of laser performance, combined with intelligent line automation, enables Schuler to achieve cutting speeds of up to 100 meters per minute (approx. 328 ft/min).

The design of a Laser Blanking Line is very similar to a conventional press cutting line. “Simply said, the press is only replaced by a laser cell,” explains Oswald Schoenberger, Product Manager for Laser Blanking Lines. “Operators who already have experience with conventional blanking lines can learn to handle the system very quickly, but even the ones without blanking experience the system can be operated intuitively and reliably after completing our training program,” he continues.

Programming the lasers also requires no process know-how thanks to LBL Studio. The offline program is so intelligent that cutting contours for new parts are automatically created based on CAD files. The optimal cutting distribution of the lasers is taken into account and reliable predictions about the output can be calculated in advance. Of course, changes can be made manually at any time.

With several lines around the world and production experience since 2012, Schuler is by far the leader in terms of laser blanking lines. “This is also related to our strong local service,” explains Telvi Zanin, Vice President of Service. In addition to Europe and Asia, Schuler also has long established service and manufacturing locations in North America. Schuler Inc. was founded in 1978 in Columbus, Ohio, and now has its headquarters close to Detroit in Canton, Michigan.

“With our team of 80 qualified service employees we are ready to provide high quality technical support to all our customers in North America”, says Telvi. A team from the U.S. has been sent to the product centers in Europe to join the in-house assembly where they can learn firsthand the laser blanking technology. “Our trained employees can thus react quickly and provide optimal on-site service”, says Telvi. “In addition, remote service like with Schuler Connect offers the possibility of immediate assistance from our headquarters in Canton, Michigan or from our experts in Germany if required – for established products as well as for innovations such as the Laser Blanking Line.”

www.schulergroup.com/laserblanking

About the Schuler Group – www.schulergroup.com

Schuler offers customized cutting-edge technology in all areas of forming—from the networked press to press shop planning. In addition to presses, our products include automation and software solutions, dies, process know-how and service for the entire metalworking industry. Our customers include automobile manufacturers and automotive suppliers, as well as companies in the forging, household appliance and electrical engineering industries. Presses from the Schuler Group mint coins for more than 180 countries. When it comes to the digital transformation of forming technology, we support our customers worldwide as a supplier of innovative system solutions. Founded in 1839 at our headquarters in Göppingen, Germany, Schuler AG has approx. 5,000 employees at production sites in Europe, China and the Americas, as well as service companies in more than 40 countries. The company is majority-owned by the Austrian ANDRITZ Group.

For further information on Schuler Inc., North America, please contact:

Guido Broder, Vice President of Sales & Marketing

Schuler Incorporated

7145 Commerce Blvd.

Canton, MI 48187 USA

734-207-7200

Guido.Broder@schulergroup.com

Exact Metrology, a comprehensive 3D metrology service provider and hardware sales company, is proud to be a part of the restoration of Cincinnati Music Hall’s sandstone ornaments in Cincinnati, Ohio. The restoration includes ten finials atop gables and a sandstone lyre.

This project was undertaken by Friends of Music Hall, a volunteer-driven organization whose mission is to preserve, improve, promote and provide education about Cincinnati Music Hall, a National Historic Landmark. Thea Tjepkema, board member and historic preservationist is leading this restoration project on behalf of the Friends of Music Hall.

When the architect Samuel Hannaford designed Cincinnati Music Hall in the High Victorian Gothic style, he included a Gothic fleuron, or finial, on each of the eleven gables. Over the past 140 years, the original carved sandstone has deteriorated to the point that only portions of these important decorative elements remain.

Exact Metrology scanned the extant ornament pieces using the Artec 3D Leo scanner in HD mode. Produced by Artec 3D, a world-renowned developer and manufacturer of professional 3D scanners and software, Artec 3D LEO has a 3D reconstruction rate of 80 frames per second. This makes it the fastest professional scanner on the market. With its large field of view, Artec LEO can scan and process large objects and scenes quickly and accurately. In addition, the scanner features data acquisition up to 4 million points/second, with a working range of .35-1.2 m. The 3D resolution on this scanner is up to .5 mm and 3D point accuracy up to .1mm. Artec LEO can scan in sunlight, as well as capture dark and shiny objects. It uses advanced hybrid technology and texture tracking, so users can point at an object and shoot without needing to stick targets. With no need to connect to a computer or to plug in to a main power source, users can hold the scanner and walk around freely, scanning without the worry of wires or additional equipment.

Arya Design, a Cincinnati based custom casting company, specializing in historic restoration and architectural products, used Exact Metrology’s scanned images to create complete 3D models of the finials and lyre.

The company focuses on custom mold making with exact parameters to meet the design and color that was once there. Their proprietary formulas increase overall compression strength, while replicating the look and feel of historic carved stone. Arya also makes additional architectural cast pieces for new construction for the exterior and interior of commercial and residential buildings.

Chris Lafferty of Exact Metrology commented on this project saying, “Exact Metrology used a handheld Artec LEO 3D scanner with high definition software to capture images of Cincinnati Music Hall’s sandstone ornamentation. Pointing the scanner at the existing finials and lyre, it used a grid of structured light technology to document their shape. Light bounced back at three million points per second, documenting even the chisel marks.”

Chris Rose of Arya Design concluded, “We are proud to partner with the Friends of Music Hall in creating the pieces needed as the literal “crown jewels” of an amazing historic preservation project.”

Exact Metrology is ISO, AS9100 Certified as well as FFL and ITAR Registered.

Exact Metrology, with facilities in Cincinnati, Ohio, Moline, Illinois and Milwaukee, Wisconsin, plus affiliated offices throughout the country, is a comprehensive metrology services provider, offering customers 3D and CT scanning, reverse engineering, quality inspection, product development and 2D drawings. The company also provides turnkey metrology solutions, including equipment sales and lease/rental arrangements.

For more information, please contact:

EXACT METROLOGY, INC.

Steve Young

11575 Goldcoast Drive

Cincinnati, OH 45249

Local: 513.831.6620

Toll Free: 866.722.2600

www.exactmetrology.com

stevey@exactmetrology.com