Contact us today:

(847) 934-4500

tdaro@bernardandcompany.com

Contact us today:

(847) 934-4500

tdaro@bernardandcompany.com

Maximize Productivity with Speeder Accessories from Platinum Tooling

Platinum Tooling Technologies, Inc., the exclusive importer of Heimatec live tools and angle heads, offers a variety of products designed to enhance the rpm capabilities of your machine from the largest turning centers to the smallest Swiss-type CNC lathe.

Heimatec speed increasers are now available in a complete range designed for popular live tool lathes and Swiss-style machines, offering gear ratios of 1:2, 1:3 and 1:4 with maximum speeds of 48,000 rpm. Design configurations include straight, offset, 90 degree and universal adjustable, while tools can be produced with external or internal coolant. Mounting options include BMT, Swiss-style machine and VDI interfaces to suit a wide range of machine tool setups.

With the growth of medical and other high-precision, high-volume manufacturing and the use of Swiss-style machines, speed increasers have become vital to the machine tool industry. As components get smaller, the cutting tools required also get smaller, necessitating higher rpm to provide maximum performance. Heimatec speeders for Citizen, Tsugami and Star machines are in stock at Platinum Tooling.

Speed increasers for BMT turrets including Nakamura, Miyano, DN Solutions and Haas are also in stock. Additional models are available from factory inventory with short lead times. Engineered for efficiency and precision with the highest quality components, these tools deliver increased productivity, long service life and cost savings for the busy machine shop or OEM production department.

To learn more about the speeder accessories available through Platinum Tooling, as well as other precision machine tool accessories, please contact:

Preben Hansen, President

PLATINUM TOOLING TECHNOLOGIES, INC.

16 E. Piper Lane

Suite 128

Prospect Heights, IL 60070

Phone: 847-749-0633

Fax: 847-749-2445

Platinum Tooling Technologies, Inc. in Prospect Heights, IL, near Chicago, serves its growing North American customer base with an extensive inventory of machine tool accessories. Its experienced staff provides the most innovative tooling and technology. Platinum Tooling Technologies, Inc. serves the auto, aero, medical, woodworking, composites and other industries, as well as an ever-increasing number of machine tool OEMs, through its network of manufacturers’ representatives. Platinum Tooling is the importer of Heimatec live tools and angle heads, Henninger speeders for milling, Tecnicrafts Swiss-type collets and guide bushings, Hommel + Keller QUICK knurling and marking tools and REV broaching tools in North America.

E-Z LOK, a leading manufacturer and master distributor of threaded inserts for metal, plastic and wood, has launched a multiple length coil assortment kit.

E-Z Coil ™ thread repair kits include all the essential items you need to install, and repair tapped holes in softer metal materials such as mild steel and aluminum.

Although economy and standard E-Z Coil™ installation kits were already available, the new multiple length kit allows customers to have a variety of different length inserts on hand along with the tools to install them.

The multiple length repair kits include three different length coil inserts with the same thread size (1D, 1.5D and 2D), as well as the drill, STI tap, installation tool and tang break tool.

Each of these new coil kits are offered in metric and inch threads.

For more information, please contact:

Kyle Lindsly-Roach, Director of Sales & Marketing

E-Z LOK

240 E. Rosecrans Ave

Gardena, CA 90248

USA

Phone: 310-323-5613 x221

klindsly@ezlok.com

www.ezlok.com

E-Z LOK is a leading manufacturer and master distributor of threaded inserts for metal, plastic and wood. Inserts for metal include solid wall and helical wire-thread inserts, while inserts for plastic feature press-in and ultrasonic/heat stake designs. Those for wood are die-cast zinc alloy in hex drives for softwood and brass knife threads for hardwood. A variety of kits are available and feature installation tools, drill bits etc.

E-Z LOK is a third-generation family owned and operated company. Founded in 1956, it primarily sells North American OEM’s, end users and the DIY market through local, regional and national industrial distributors.

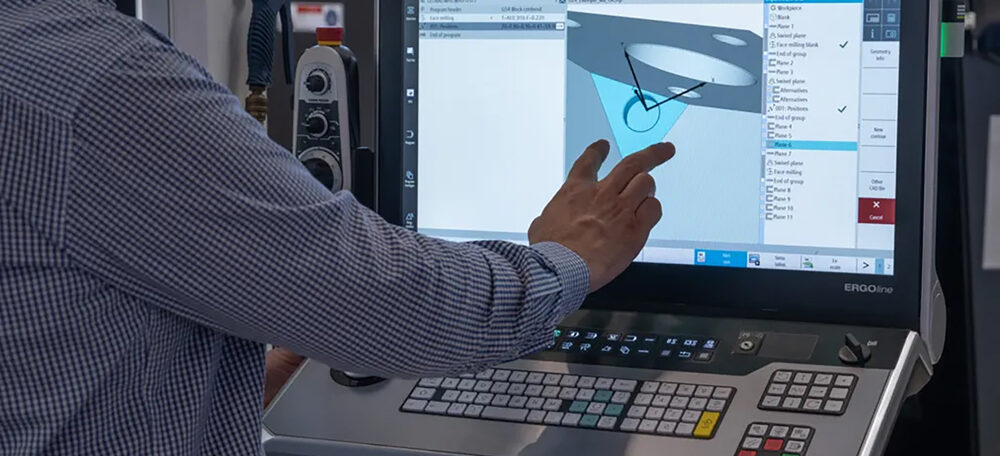

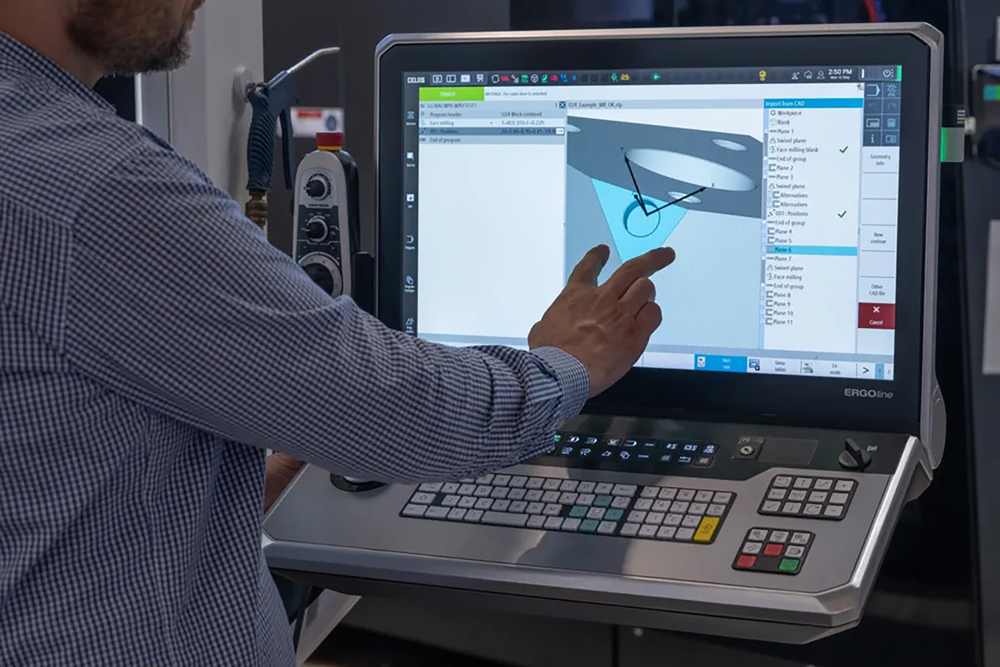

Siemens expands its SINUMERIK Run MyRobot platform with the CNC allowing cost-effective KUKA robot part handling and articulation functions directly on the control screen of a SYIL machine tool

Automation for every shop size

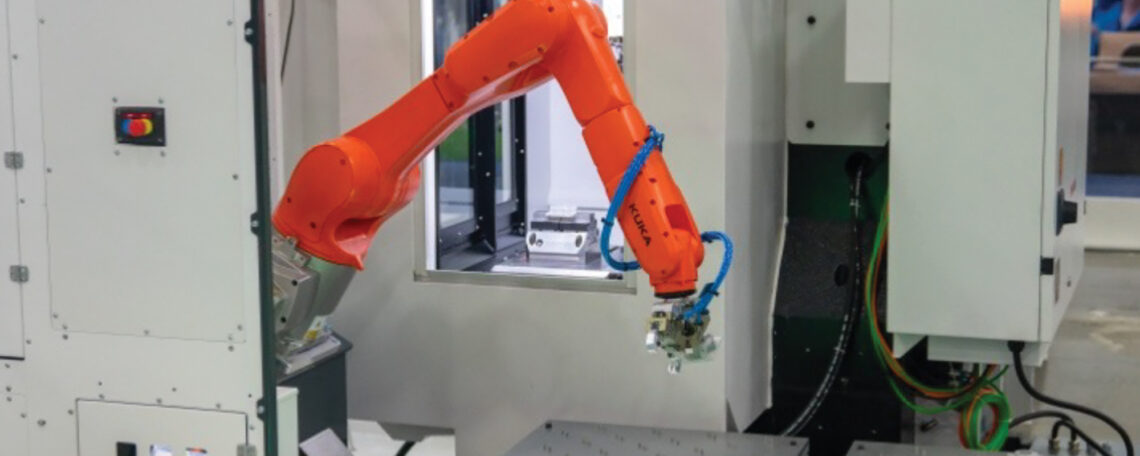

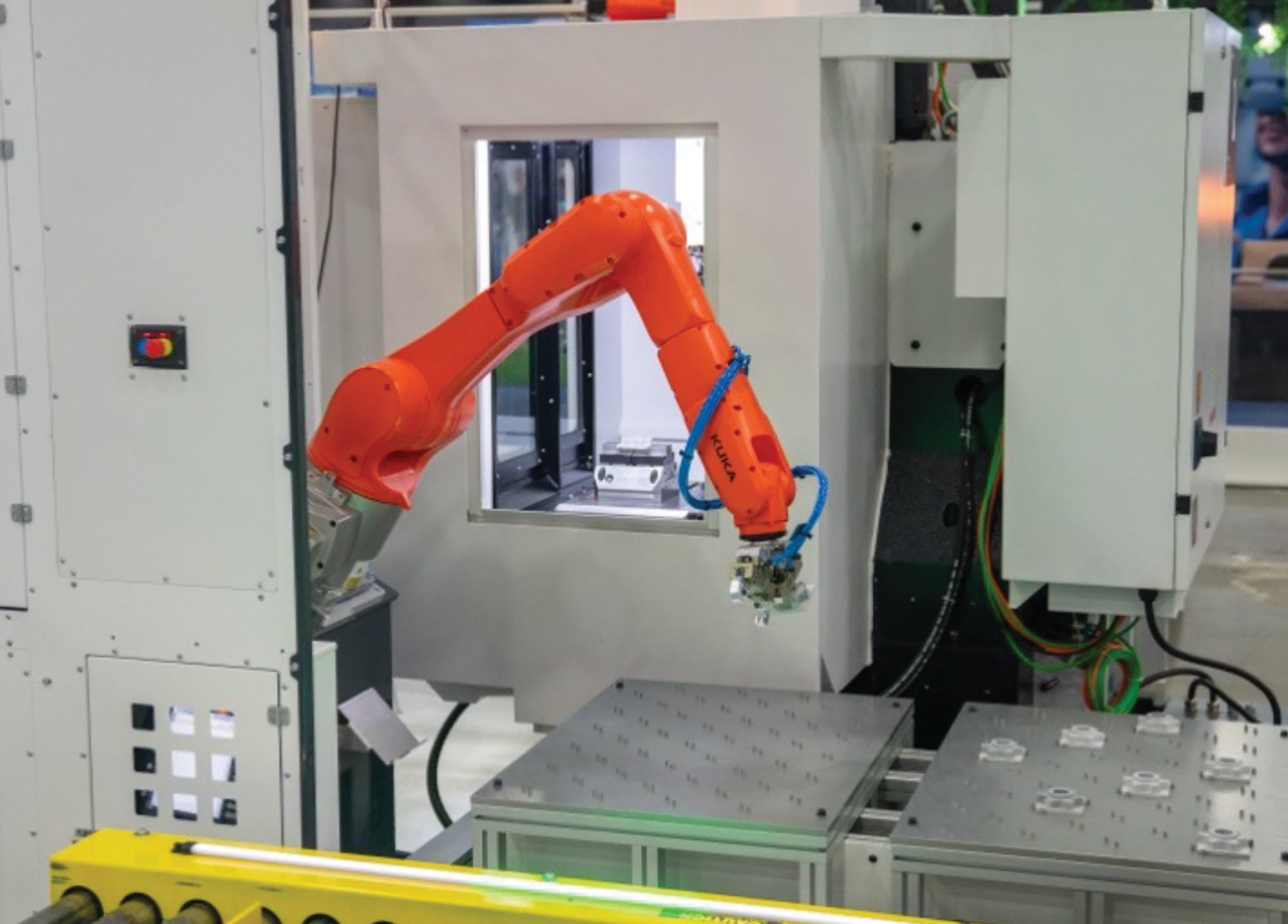

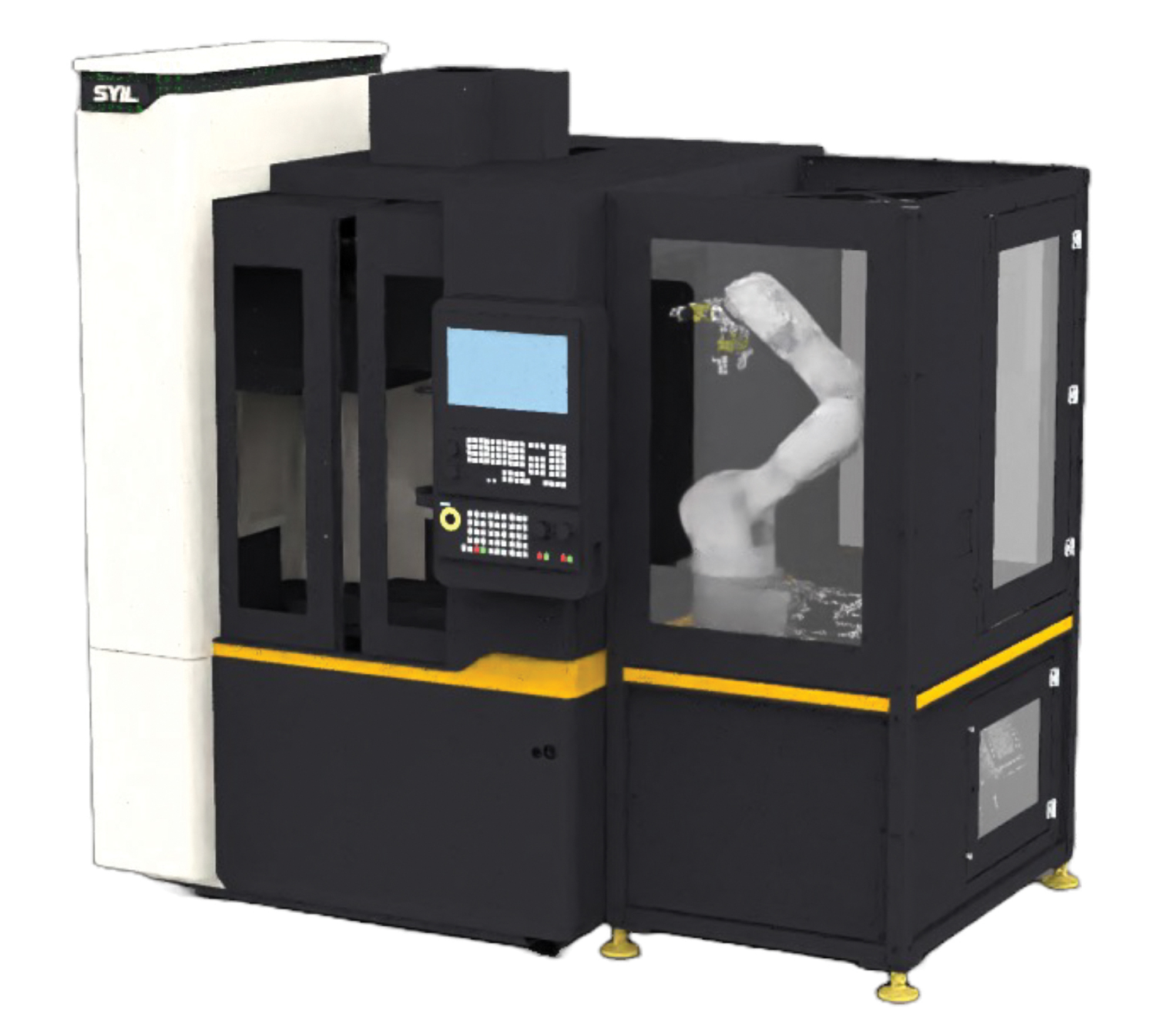

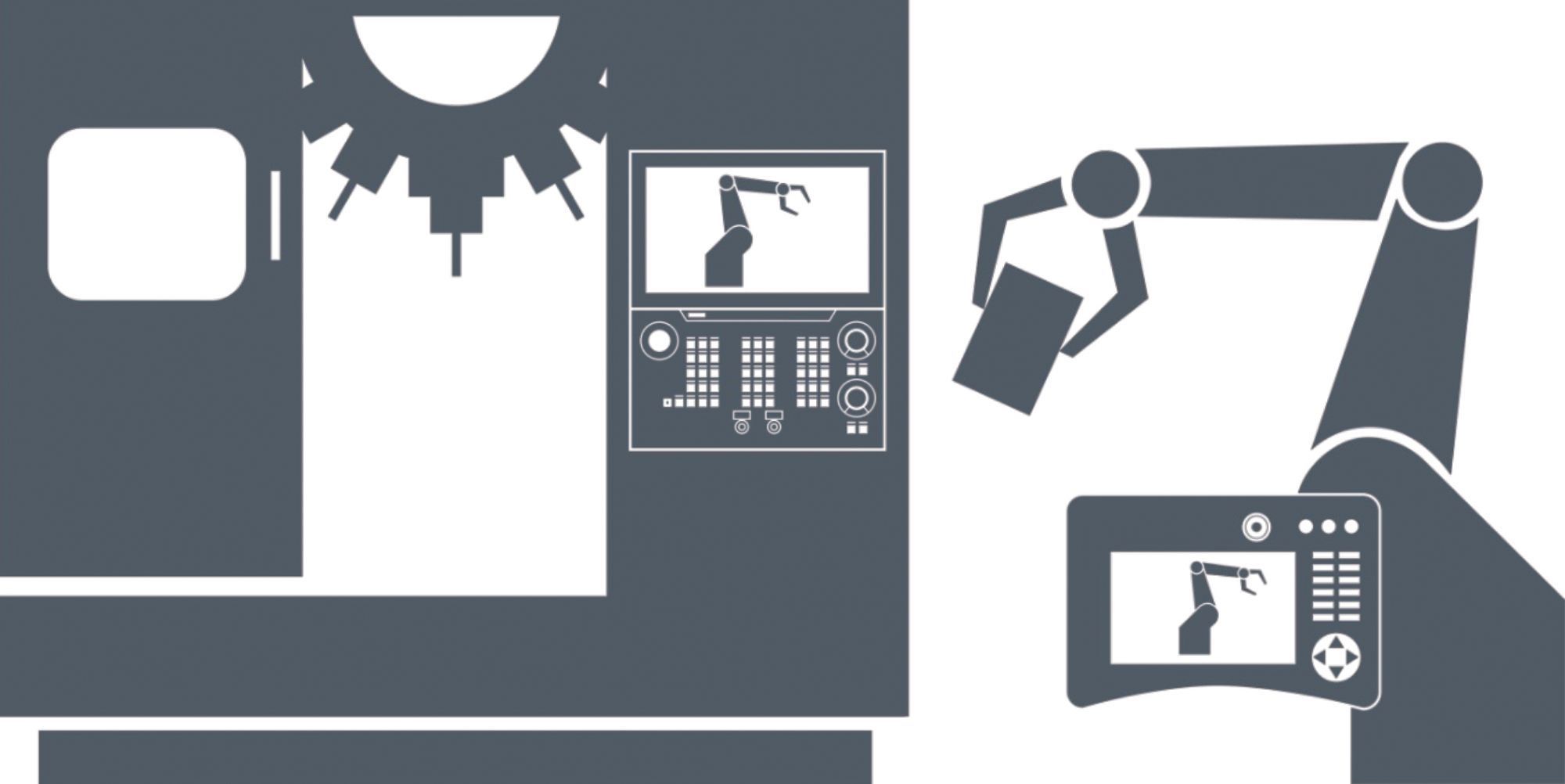

Through a technology partnership that breaks new ground in the machine tool industry, Siemens presents an automation solution for the busy, multi-tasking, small to mid-sized machine shop, as it combines a digital twin of the software and programming of its popular SINUMERIK 828 CNC, working in tandem with a KUKA robot, to simplify the operation and programming in part handling for the machine tool operator. Bringing the concept to life during a recent tradeshow, KUKA Robotics Corporation demonstrated the same control and its robot working in tandem with a SYIL vertical milling machine. The machine featured the SYIL R1 machine-tending automation package, developed with one of KUKA’s System Partners, Waybo, which seamlessly integrates the pick-and-place, part articulation and communications with the CNC onboard, all at a very attractive price point.

The goal of the program, according to Frans Buikema, Chief Marketing Officer at SYIL, is to offer the small and mid-sized shops an entry point into automation without major capital investment. Likewise, as Ron Bergamin, Key Technology Manager for Machine Tool Automation at KUKA, adds, the ROI can be very short, as this automation advancement allows the addition of a lights-out second or third shift at job shops of almost any size. Automation is the key and this cooperative engineering venture has opened a new chapter for small to mid-sized machine shops.

Simplifying robotics through the CNC

A bit of history. Only a decade ago, the integration of a robot with a machine tool required a separate learning curve for the shop, as robotics required special programming and teach-in communications, a separate pendant for operation and other challenges that often required outside consultants to implement. For small and mid-sized machine shops, this barrier, combined with the cost involved, resulted in today’s market condition, where less than a quarter of the smaller job shops in America today utilize automation and especially robotics in their workday.

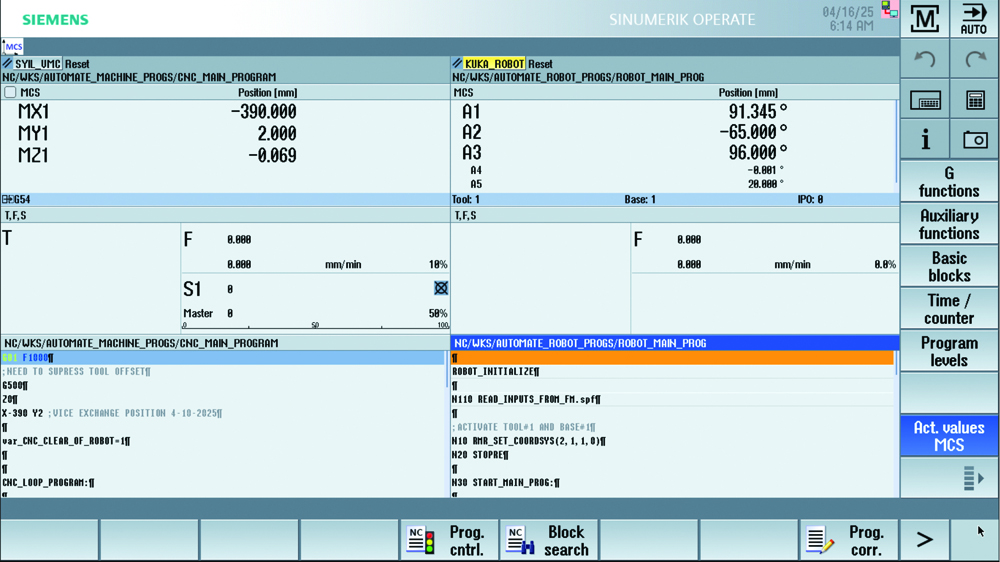

History has advanced. As Tiansu Jing, Product Manager, SINUMERIK CNC systems, explains, “The benefits of this development for the busy job shop are many. Setup, programming, operator interface and diagnostics are all improved with the SINUMERIK Run MyRobot /Handling application, as it easily incorporates the KUKA robot with the SYIL machine tool.” The teach-in functions are implemented through the SINUMERIK Operate HMI system on the control, while the proprietary SINUMERIK Run MyRobot /Handling capability of the CNC seamlessly integrates with the KUKA robot control. Jing further noted that, since there is no need to learn robotic programming, start-up time is reduced and the robot’s separate control pendant is eliminated, simplifying the operator’s task. The SINUMERIK control’s HMI is used to operate both the machine tool and the robot tender, with all commands and operating conditions displayed on a single screen. He also added that the greatest value for the busy job shop comprised the system’s ability to integrate robots on all its machines, while economizing the learning curve for all the operators. This entire cooperative venture between Siemens, KUKA and SYIL made this advancement possible, Jing noted.

From complexity to clarity

The SINUMERIK 828D CNC utilized in this application is designed for the job shop market’s use of turning centers, milling machines and Vertical Machining Centers (VMCs), but it also offers machine builders and end-users the flexibility to enhance the productivity of those machines with this new robotic automation, integrated directly into the control. As Jing points out, “The 828 is scaled to the functionality of the standard machines sold to the smaller job shops. With Run MyRobot /Handling included, programmers can use the same G-code for the robot and the machine tool.”

Designed for the job shop including affordable lights-out manufacturing

As Ron Bergamin of KUKA notes, “Machine builders can now offer robotics from KUKA PLC mxAutomation, a universal PLCopen-certified PLC interface. It allows the user to program and operate all important robot functions directly in a busy shop’s familiar control environment.”

Jing further adds that the Run MyRobot /Handling application allows the machine builder to offer robotics as another option, at a far more affordable price than in the past, as all the engineering effort has been substantially reduced. With the connection of Ethernet and safety cables to the robot, the SYIL customer finds it’s much easier to connect the robot. Bergamin adds that the robot can be up and running in a day, in most cases. “With the addition of a lights-out second or third shift at the shop, the spindles keep turning and the shop makes more money. Plus, the ROI is very fast with this setup.”

Jing concludes, “The machine builder can easily add their own robot specific screens to display the robot tasks and improve the usability. This solves long-time challenges for both the machine builder and end-user alike. Machine tool builders like SYIL can now offer robotic packages to their customers with less price pain and more advantages in the shop.”

Philip Peloso, Business Development Manager for Machine Tool Automation at KUKA, expands, “We saw a resident robotic talent gap as well as price resistance in the smaller machine shop sector and decided we needed to pursue a solution. We turned to our Official System Partner, Waybo, presenting them with the facts. This solution would be an entry-level venture, addressing the 75% of the job shops who currently have no robotic automation on their floors. We sought to present them an easy-to-use, robust system that allowed quick changeover for the busy shop doing multiple jobs or families of parts during the day.”

As KUKA has a longtime relationship with Siemens, their combined support in the field would bring a further benefit to the solution. Once developed, this new system was presented to SYIL, who adopted it as their SYIL R1 solution for the job shop market. Peloso cites the key value proposition. “All meaningful controls and diagnostics were to be displayed on the CNC, thereby reducing or eliminating all the previous roadblocks for the shop personnel.” All the motion control of the grippers, pick-and-place functionality and communications with the CNC on workholding are seamlessly transmitted from an application layer on the KUKA robot, so all commands are configured and programmed to take instructions directly from the CNC.

Ron Bergamin further notes, “Working with Waybo, we developed the automation around the robot. A new interface layer, run through our standard mxAutomation software, allowed the robot control from the Siemens CNC, so a single pendant is all that’s required to run the SYIL machine tool and the robot package. All diagnostics are under the hood,” Bergamin muses.

A new benchmark for machine tool builders

On the tactical business level, Siemens had been providing CNC technology to SYIL globally and brought the concept of robotic integration to KUKA, who worked closely with their partner Waybo to design and implement the package that became SYIL R1 automation.

Frans Buikema of SYIL details this development from the machine builder perspective.

“We’ve long had automation in our company’s vision and road map for the future. As we focus on the small and mid-sized machine shop world, we constantly encounter the lack of skilled labor, the price resistance and the shortage of robotic knowledge in this sector of the machine tool market.”

Wesley Wang, Managing Director for SYIL in North America, adds, “We have recently partnered with Titans of CNC to market our machines here and we feature the SINUMERIK 828D CNC on most of our equipment, as it offers great motion control, monitoring and communications capability, plus the onboard capacity to engage machine tending robotics, which opens the 24/7 running option to our customers in ways they have not imagined in the past.

Real results on the shopfloor

Buikema cites some hard numbers. “We believe we can tell our customers that automation is accessible today in new and exciting ways. It is decidedly not too complicated nor is it a major capital investment. For a $60,000 package, they can be looking at a payback period of a year or less.” Wang adds, “It’s all about knowing your options today and how different they are from the not-too-distant past in the machine tool world.”

Expanding the vision

SYIL currently designs and builds CNC milling machines, CNC turning centers and CNC Swiss type lathes. According to Buikema, “This development with Siemens and KUKA represents our own entry into robotics and we plan to expand the use of such packages onto all our machine offerings very soon.” He calls the implementation of the SINUMERIK 828D CNC with Run MyRobot/Handling “… a real game changer, because it enables us to start creating more automation packages and make them accessible to our audience, the small to mid-sized machine shops.” The SYIL R1 automation package utilizes the same technology integration shown by Siemens and KUKA during recent tradeshows in the industry.

Commenting on the relationship between SYIL and Siemens, Buikema observes, “It grew from supplier to strategic partner very quickly. The engineering support at Siemens collaborates with our own machine tool engineers at SYIL on virtually all new machine developments at our company. This enables us to expand our machine range much faster and better than we could do on our own. That’s true synergy.”

Of equal importance, Buikema cites the support his company gets from Siemens in the North American market. “The help they provide to our dealers in Canada, the United States and Mexico is invaluable. It allows our dealers not only the ability to sell a higher level of machine and automation, but also the software support to fulfill the needs of all our end-users.”

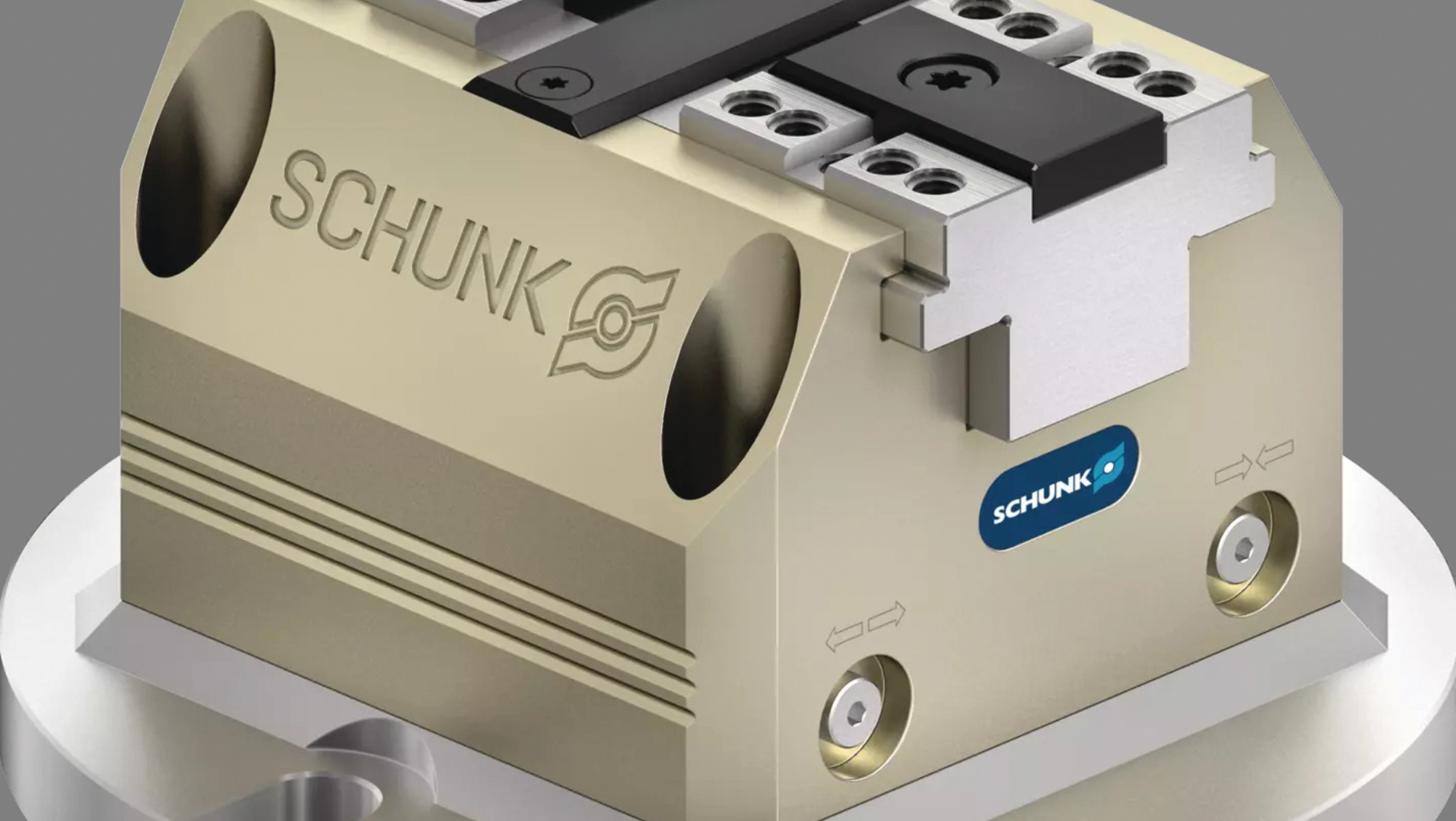

The SYIL R1 machine tending system, incorporating the KUKA robotic technology, is currently offered as a standard package by the machine builder, for parts up to 3kg (6.61 lbs.), a payload of 6.7kg (14.77 lbs.) and a reach of 901 mm (35.47 in). It offers an IP65/67 rating for harsh operating environments. It facilitates the loading and unloading of metal parts from the cutting zone and workholding devices being utilized, plus it is quick to install and easy to operate from the SINUMERIK 828D control. The R1 system from SYIL removes the manual and repetitive tasks for a CNC machine operator by automating the load/unload process. It is an ideal solution for high-mix, low-volume tasks and can be fully integrated with parts conveying systems, bins and pallets. The R1 system is offered with a standard workholding package, featuring pneumatic clamping force block design, as well as a dual gripper option when the finished part has a differing final shape from the blank.

In addition, the SYIL R1 system features an “everything on one screen” format, integrating the robot’s programming and operation in the SINUMERIK 828D control, using NC G-code and robot teach-in function for programming. This makes it very easy for machine tool operators to learn and use. All the robot diagnostic data is shown on the same HMI as the machine, allowing the entire automation cell to be monitored without the need for a second pendant.

According to Buikema, the SYIL R1 automation package can be installed and fully operational in less than one day. The system is expandable with custom solutions and various pallet drawers provided.

The future of shopfloor automation

Increasingly more job shops and machine operators are seeing that automation is an important asset when striving to achieve consistent workpiece quality and more flexibility on the shopfloor. Digitalization facilitates the higher level of automation needed and the networking

of the components involved. With this new development, Siemens is offering a cost-effective solution that incorporates the KUKA robot functionality with a line of affordable machine tools, in this case, the SYIL brand of machining centers and lathes for small to medium job shops.

From the KUKA perspective, Ron Bergamin comments, “KUKA offers machine tool builders and end-users alike the ability to incorporate advanced robotics into their equipment and onto their shopfloors, with the goal of optimizing productivity and reducing operator workload. Our partnership with Siemens has resulted in the synergy that brought this development to life.

It substantially expands the ability of the small and mid-sized shops to utilize robotics in their work environment.”

To watch a video of this system in action, please visit:

http://usa.siemens.com/kuka-syil

For more information on this technology story, please contact:

Siemens

Tiansu Jing or John Meyer

tiansu.jing@siemens.com

john.meyer@siemens.com

KUKA

Ron Bergamin or Philip Peloso

ron.bergamin@kuka.com

philip.peloso@kuka.com

SYIL

Frans Buikema or Wesley Wang

frans@syil.com

wesley@syil.com

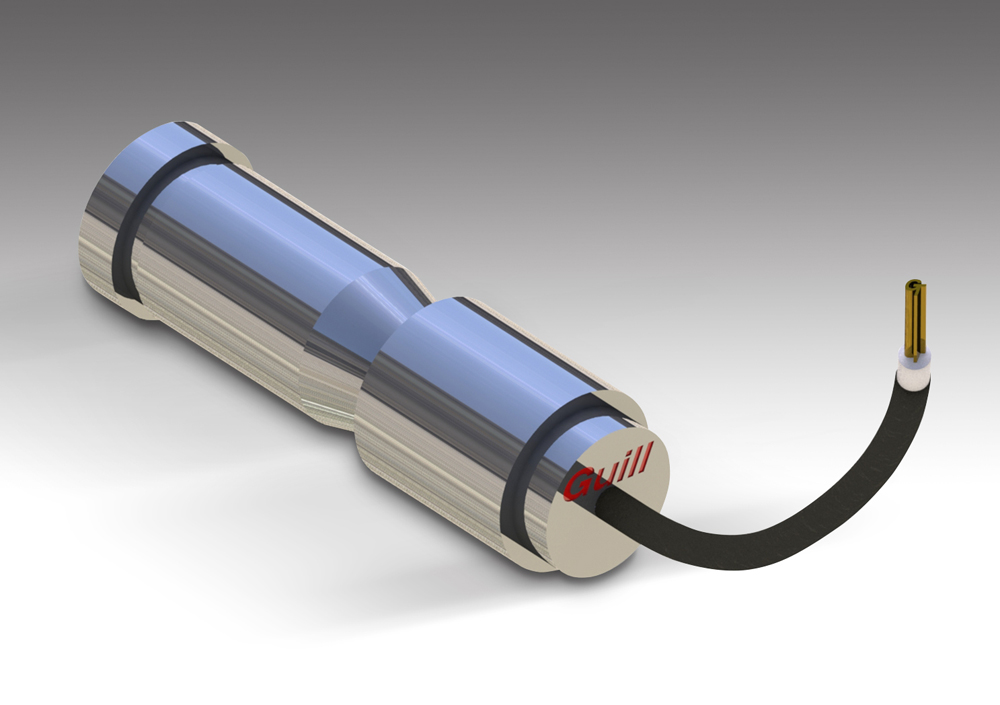

Guill Tool & Engineering, the global leader in extrusion tooling, attended the K Show in Dusseldorf, Germany from October 8th to the 15th. Guill’s technical sales engineer shared his thoughts on the companies they met at the show, the international extruders they’ve partnered with, intriguing applications as well as what caught his attention. Additionally, the company’s European sales manager discussed the role of Guill Tool Europe.

Known as the world’s premier plastics trade fair, K brings together global pioneers from the plastics and rubber industry. Located in Hall 1, booth C90, Guill Tool & Engineering’s team included Peter Leary, Technical Sales Engineer, Extrusion Division, Jacob Marcure, Design Engineer and Gerjan ter Wal, Sales Manager in Europe.

Commenting on the companies met at the show Leary said, “We met a wide range of companies across the extrusion and plastics industry including wire and cable manufacturers, medical tubing producers, compounding specialists and machinery OEMs. There was also a strong representation from raw material suppliers, large pipe extrusion and automation/controls providers, which gave us valuable insights into emerging technologies and potential partnerships.”

Guill interacted with extruders and processers from all over the world, including Europe, Asia and the Americas. Leary added, “A handful were existing customers stopping by to discuss current projects, but we also met a large number of new potential partners interested in Guill’s precision crosshead and tooling capabilities.” The company has contacts in China, Mexico, India, Greece, Turkey, Thailand, the UK, Australia and Algeria. Additional countries include Sweden, Japan, France, Finland, Chile, Poland, Singapore, the Netherlands, New Zealand, Egypt, Indonesia, Ireland, Brazil, Kenya and Switzerland.

Several applications stood out to Leary, notably multilayer medical tubing and advanced materials for sustainable production. He observed notable interest in tools that handle recycled or bio-based polymers while maintaining tight tolerances and flow balance.

Leary was impressed with the scale and diversity of the K Show. “One highlight was seeing the increasing integration of digital process monitoring and AI-driven control systems.”

Regarding Guill Tool Europe, ter Wal said that one of the goals expressed by visitors was to optimize their extrusion process and that the European office can help ensure smooth communication and planning for new production solutions.

For more information, please contact:

Tom Baldock, Sales Manager, Extrusion

Guill Tool & Engineering

10 Pike Street

West Warwick, RI 02893

USA

Phone: 401-465-5526

tbaldock@guill.com

E-Z LOK, a leading manufacturer and master distributor of threaded inserts for metal, plastic and wood has expanded their E-Z Fin™ brass threaded inserts for soft wood, thermoplastics and thermoset plastics.

Also known as Finserts, they offer a blend of strength and precision for thermoset plastics. Designed with one, two or three OD fins that distribute stress over a greater surface area to minimize the possibility of cracking and protect against thread erosion, Finserts are available with internal thread sizes ranging from #6 to 5/16.

Finserts for thermoplastics are specifically designed to integrate seamlessly with thermoplastic components, ensuring a reliable bond that can withstand the demands of various applications.

Installation in thermoset plastics requires nothing more than a straightforward press-in action. The design ensures a smooth insertion process, making them ideal for a variety of applications.

Installing Finserts into thermoplastics is a straightforward process that ensures components benefit from enhanced durability and thread integrity. Designed to be installed “cold”, the brass threaded inserts are pressed into placing using anything from a simple hand tool to an arbor press.

When used for thermoset plastics, their innovative design significantly reduces the risk of damage like splintering, a common issue. They are synonymous with durability, providing a firm, lasting connection that enhances the longevity of the plastic products they are used in. Easy installation saves time and effort. These inserts are suitable for a wide range of applications within the thermoset plastic industry, from small-scale projects to large industrial uses.

The brass threaded inserts for thermoplastics ensure a secure, tight fit that significantly reduces the risk of thread stripping. In addition, Finserts are engineered to distribute load evenly, minimizing stress on the base material and extending the lifespan of the component. Their compatibility with a wide range of thermoplastics enhances design flexibility, enabling the use of lighter, more cost-effective materials without compromising strength.

For more information, please contact:

Kyle Lindsly-Roach, Director of Sales & Marketing

E-Z LOK

240 E. Rosecrans Ave

Gardena, CA 90248

USA

Phone: 310-323-5613 x221

klindsly@ezlok.com

www.ezlok.com

E-Z LOK is a leading manufacturer and master distributor of threaded inserts for metal, plastic and wood. Inserts for metal include solid wall and helical wire-thread inserts, while inserts for plastic feature press-in and ultrasonic/heat stake designs. Those for wood are die-cast zinc alloy in hex drives for softwood and

brass knife threads for hardwood. A variety of kits are available and feature installation tools, drill bits etc.

E-Z LOK is a third-generation family owned and operated company. Founded in 1956, it primarily sells North American OEM’s, end users and the DIY market through local, regional and national industrial distributors.

Powered by the SINUMERIK ONE CNC platform and Ingersoll’s MasterPrint® industrial 3D printer, a new generation of deployable machines is bringing additive and subtractive manufacturing directly to the point of use.

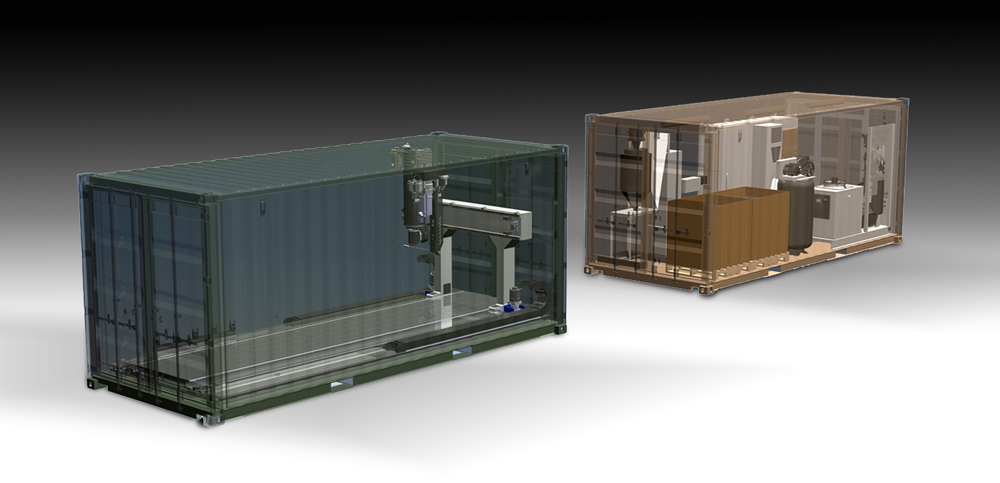

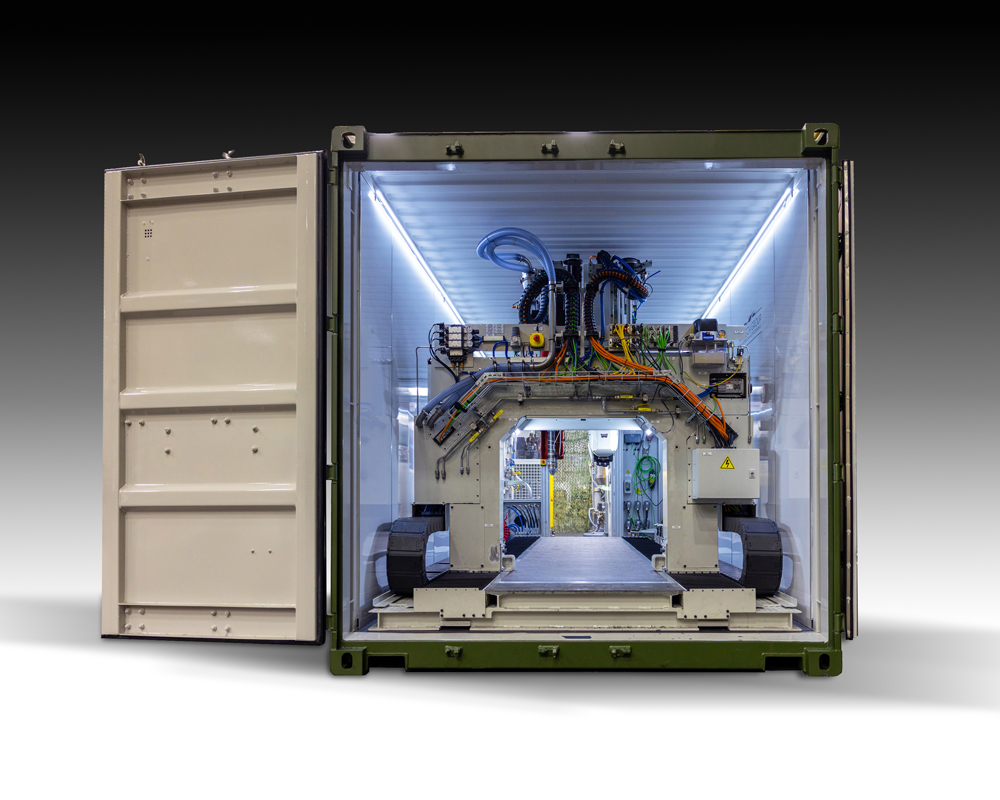

Siemens and Ingersoll, a 133-year-old Rockford, Illinois builder of high-quality, large-format machine tool solutions, have enjoyed a long-standing relationship of business cooperation, engineering dynamism and executed achievements in automated machine technology. That tradition continues today with Ingersoll’s new generation of its “machine in a box” concept, the MasterPrint® Deployable, designed to be an application-specific, portable machine tool, featuring the company’s unique combination of high-speed additive manufacturing and precise 5-axis milling. MasterPrint® Deployable is compactly housed in two 20-foot containers and allows Ingersoll’s customer to send the unit to its point of use as a free-standing manufacturing entity, with all the necessary hardware, software and tools onboard to complete a specific function.

Powered by the digital-native SINUMERIK ONE CNC, MasterPrint® Deployable “opens the possible,” as Zach Gray, Additive Business Development Manager at Siemens, notes. “We were challenged by Ingersoll, as we always are, to think outside the box and yes, that’s a pun, in this case, given the nature of the final machine.” For the initial project, the machine needed to incorporate an additive material extruder, designed by a third party, with full environmental and motion control, plus a gantry and milling head for material removal and finishing, with full capability for onsite adaptation to various conditions and climates.

As Jason Melcher, Vice President and Sales Director of Composite and Additive Technology at Ingersoll, comments, “On the first project, we knew very little about the application, as it was confidential, so we had the empty space of a Conex box as our starting point.” The Conex box is a commercially available item, heavily altered by Ingersoll. The innovation comes with the alterations to make this structure and space a plausible environment capable of carrying a large industrial 3D printer, CNC milling machine, controls and power supply to the point of use. Melcher continues, “Cooperation with our key suppliers was vital on this project and we knew we could rely on our years of experience with Siemens to assist us. As usual, our Siemens partners had less concern about the end-product and put greater emphasis on the process. This gave us confidence that we could journey together in the creation of this unique machine.”

In future applications, the same MasterPrint® Deployable technology might be used with thermoplastic or metal additive materials, applied through cold spray, Directed Energy Deposition (DED), blown powder, Wire Arc Additive Manufacturing (WAAM), friction stir or other technologies, then milled on the same machine to produce the final part. A Deployable Automated Composite solution is also possible. Applications could range from aerospace and defense to energy, R&D and even disaster relief uses in very hostile environments. Also, through the power of the CNC, robotics can also be integrated and controlled. Keeping the machine technically competent under all such circumstances is a challenge for both the Ingersoll and Siemens teams. That’s where the “future ready” technology of SINUMERIK ONE really shine. With its high-fidelity digital twin technology, the entire process can be programmed and visualized with real time operation virtually, before the machine is built. This provides Ingersoll the ability to offer the MasterPrint® Deployable solution for various applications, across a wide range of industries, including the marine industry and residential construction.

Andrew Ramirez, Siemens Account Manager for Ingersoll, adds, “Our relationship with this customer presents us new and exciting challenges all the time, and that’s very rewarding … and fun, because we can leverage our technical knowledge and collaborate with our engineering teams to address the job at hand. When it works as well as it does on MasterPrint® Deployable, that’s very satisfying as an account manager who gets to see innovative solutions come to life.”

Melcher echoes that thought, “We know Siemens has decades of experience in CNC, software development and problem-solving in the machine tool world. They bring a very open-ended attitude to our needs and, together, we produce solutions that benefit our Ingersoll customers in many ways.” In this case, it was necessary to have modifications made to the process and the combination of Ingersoll machine technology and engineering, with the Siemens control environment helps to produce a functional and flexible ecosystem for manufacturing in the field. The Siemens SINUMERIK ONE CNC, Melcher notes, incorporates all the variables and can work up solutions, prove them out virtually, then produce a functioning machine, with the added benefit of accepting variables onsite and adapting the control parameters to manage them.

A further testament to the Siemens value at Ingersoll, is training, according to Jason Melcher. “We’ve worked with all the major CNC control manufacturers and we’ve seen Siemens expand its technology, but also its training mindset. Today, they provide us training both on the operation of the control and the integration of it into the manufacturing process, something we can then share with our customers to get them running more efficiently from the start.”

On the MasterPrint® Deployable application, Zach Gray cites three key concerns.

SINUMERIK ONE plays a central role in the transformation of machine tools in the age of Industry 4.0, outperforming previous generations of controllers in terms of PLC and CNC machine operation, cutting speed, data capture and processing power. With its integrated SIMATIC S7-1500F PLC, the SINUMERIK ONE control offers up to 10 times faster PLC cycle times. Thanks to the PLC, SINUMERIK ONE is now fully integrated into the Siemens TIA Portal engineering framework, enabling standardization of all engineering tasks for operators of larger format machines. This generation of Siemens CNC is fully compatible with the previous SINUMERIK 840D sl controller generation in terms of programming and operation. This made the changeover to SINUMERIK ONE more seamless for Ingersoll and, as Jason Melcher notes, the training supplied by Siemens made the process faster and easier for Ingersoll and its first customer for MasterPrint® Deployable.

With SINUMERIK ONE, Siemens offers CNC technology that easily creates and works with digital twins of machine tools. Work preparation teams and engineering departments can also benefit from the digital twin. Siemens offers a comprehensive user interface for SINUMERIK ONE that enables convenient, flexible and efficient operation of machine tools across all machining technologies, including additive, subtractive and, in this case, both, as well as composites with chopped carbon fibers.

While under development at Ingersoll, the unit was powered by standard factory 480V power. The transformer supplied “in the box” connected to the customer’s on-site generator in the field for immediate startup, according to Jason Melcher.

On the topic of the overall benefits of the relationship with Siemens, Jason Melcher says, “We wanted to produce the largest possible workspace in the footprint provided by our customer. Siemens was very helpful, as they always are, in not letting us overreach the capabilities of the control and its processes. That’s the optimum contribution a partner can make and, combined with their technology and training, we are confident we derived the best solution for the customer’s application and their logistics.”

From the Siemens side, Zach Gray concludes, “This MasterPrint® Deployable application was an exciting challenge for Andrew (Ramirez) and me. With all the other technologies we know we can incorporate into this Ingersoll concept, including robotics, it really does open the possible up for our customer and us.”

Website:

usa.siemens.com/ingersoll

Guill Tool, the global leader in extrusion tooling, announces its 10-Day Program. This program applies to eligible tips and dies that will be shipped within 10 business days of receiving the purchase order from the customer.

Guill high-quality precision tips and dies have been manufactured in the U.S. for over 65 years. All Guill extrusion tools are produced using certified and documented quality steel material, specifically qualified for the polymer to be extruded. Furthermore, Guill designs tips and dies for any application the customer requires. These feature multi-lumen, stripe, multiple stripe, wire and cable, hose, pipe, tube, fiber optic, blown film, corrugated tube and profile. Dies include face seal, shouldered, snap-together, floating, die plate, interchangeable die plate and custom dies. Available tips include single and multi-lumen, threaded style, snap-together, fixed-center shoulder, profile, tapered style and custom.

To learn which tools are eligible for the program, check with the company or local Guill sales representative. For all other parts, company personnel will review the customer’s drawing to determine eligibility for the program.

Eligible tips and dies for this program must have a diameter less than 1.5” and a length less than 4.75.”

Guill proudly manufactures its products in the U.S. under the quality standards of ISO 9001:2015 and AS9100:2016.

For more information, please contact:

Tom Baldock, Sales Manager, Extrusion

Guill Tool & Engineering

10 Pike Street

West Warwick, RI 02893

USA

Phone: 401-465-5526

tbaldock@guill.com

Kyle Lindsly-Roach, Director of Sales & Marketing, recently shared his thoughts on several topics pertaining to the fastener industry, including current trends, new designs, additive manufacturing, the manufacturer and distributor relationship, as well as the company’s most innovative product.

Discussing insert trends, he noted that there is an increased demand specifically for inserts used in plastics and additive materials. This is attributed to the rise of 3D printing/prototyping and the movement towards lightweight materials.

While new designs may be needed today, Lindsly-Roach believes that “…many times existing designs and products are able to work in new materials.” This is true for carbon fiber and composite materials, as thread cutting type inserts traditionally used in plastic/wood can work.

The impact of additive manufacturing on E-Z LOK can’t be overstated, as it’s lead to continued expansion of inserts for plastics/additive materials as well as creating new ones.

Regarding the nature of the manufacturer and distributor relationship, he stated that the relationship hasn’t changed much and that E-Z LOK and many other manufacturers rely heavily on distribution partners to ensure their products get to market.

Lastly, Lindsly-Roach commented that the company’s most important product remains the one that E-Z LOK was founded on nearly 70 years ago: the threaded solid wall inserts for metal, also known as E-Z LOK inserts. “This product is easier to install, and higher performance than the helical coil type inserts. It also presents a good middle ground of price versus performance when looking at it compared to key locking inserts for metal.”

For more information, please contact:

Kyle Lindsly-Roach, Director of Sales & Marketing

E-Z LOK

240 E. Rosecrans Ave

Gardena, CA 90248

USA

Phone: 310-323-5613 x221

klindsly@ezlok.com

www.ezlok.com

E-Z LOK is a leading manufacturer and master distributor of threaded inserts for metal, plastic and wood. Inserts for metal include solid wall and helical wire-thread inserts, while inserts for plastic feature press-in and ultrasonic/heat stake designs. Those for wood are die-cast zinc alloy in hex drives for softwood and brass knife threads for hardwood. A variety of kits are available and feature installation tools, drill bits etc.

E-Z LOK is a third-generation family owned and operated company. Founded in 1956, it primarily sells North American OEM’s, end users and the DIY market through local, regional and national industrial distributors.

At EMO 2025, Siemens will introduce Optimize MyProgramming /3D Scanner, a groundbreaking software solution that will fundamentally transform shop floor-oriented CNC programming. This innovative software combines cutting-edge 3D analysis technologies with programming right on the CNC control, maximizing efficiency, precision, and quality in production. Optimize MyProgramming /3D Scanner is part of the Siemens Xcelerator portfolio and enhances it with advanced technologies for process optimization in manufacturing.

Programming right on the control

The solution is distinguished by its direct integration into Sinumerik Operate, which allows users to create and optimize programs on the control. Seamlessly transferring geometric information from 3D CAD models into programs eliminates the need for cumbersome and error-prone manual input. This function saves significant time and costs while minimizing sources of error.

Efficiency and quality thanks to automatic data transfer

The 3D Scanner offers customized suggestions for manufacturing strategies based on geometric features. This function not only leads to enormous time and cost savings, but it also allows better parameterization of machining cycles. This prevents programming errors, which means consistently high quality in production. By integrating Optimize MyProgramming /3D Scanner, machine manufacturers can increase the attractiveness of their products in a competitive market and convince customers through measurable efficiency and quality advantages in production.

Collaboration with DMG MORI

The software’s successful pilot with machine manufacturer DMG MORI demonstrated that the 3D Scanner is a powerful complement for optimizing manufacturing processes and can be seamlessly integrated into existing systems. Optimize MyProgramming /3D Scanner is integrated as a standard option in all DMG MORI machines equipped with Sinumerik One. The software will be available for purchase starting in autumn.

Availability and support

Optimize MyProgramming /3D Scanner is offered as a perpetual license for real machine tools and also as an option for their digital twin based on Run MyVirtual Machine. Experienced service providers offer support with comprehensive consulting as well as implementation. This ensures seamless integration of the software into modern production environments.

With Optimize MyProgramming /3D Scanner, Siemens reinforces its commitment to shaping the future of the manufacturing industry with advanced technologies and efficient solutions. The software sets new standards in CNC programming and enables manufacturing companies to make higher-quality products with more efficient production processes.

Follow us on social media

X: www.x.com/siemens_press and https://x.com/siemensindustry

Blog: https://blog.siemens.com/

Siemens Digital Industries (DI) empowers companies of all sizes within the process and discrete manufacturing industries to accelerate their digital and sustainability transformation across the entire value chain. Siemens’ cutting-edge automation and software portfolio revolutionizes the design, realization and optimization of products and production. And with Siemens Xcelerator – the open digital business platform – this process is made even easier, faster, and scalable. Together with our partners and ecosystem, Siemens Digital Industries enables customers to become a sustainable Digital Enterprise. Siemens Digital Industries has a workforce of around 70,000 people worldwide.

Siemens AG (Berlin and Munich) is a leading technology company focused on industry, infrastructure, mobility, and healthcare. The company’s purpose is to create technology to transform the everyday, for everyone. By combining the real and the digital worlds, Siemens empowers customers to accelerate their digital and sustainability transformations, making factories more efficient, cities more livable, and transportation more sustainable. A leader in industrial AI, Siemens leverages its deep domain know-how to apply AI – including generative AI – to real-world applications, making AI accessible and impactful for customers across diverse industries. Siemens also owns a majority stake in the publicly listed company Siemens Healthineers, a leading global medical technology provider pioneering breakthroughs in healthcare. For everyone. Everywhere. Sustainably.

In fiscal 2024, which ended on September 30, 2024, the Siemens Group generated revenue of €75.9 billion and net income of €9.0 billion. As of September 30, 2024, the company employed around 312,000 people worldwide on the basis of continuing operations. Further information is available on the Internet at www.siemens.com.

Continue readingGuill Tool, global leader in extrusion tooling, has expanded its lab capabilities to better serve the global extrusion market with the creation of Guill Labs. The labs include the company’s state-of-the-art rheology lab and a facility focused entirely on the extrusion process.

Guill’s existing rheology lab measures the flow characteristics of plastics and rubber to predict how a customer’s material will flow through the company’s extrusion dies before production. Tooling geometry is virtually optimized, and the project can be viewed in 3D CAD. Machines used include a rotational rheometer, scanning calorimeter, thermal conductivity meter and a new CT scanner.

The rotational rheometer quickly generates visco-elastic data for polymer melts, precisely capturing polymer melt properties. Test temperature ranges between ambient and 300°C. The lab’s scanning calorimeter characterizes the thermal properties of a polymer sample, such as crystallization temperature, glass transition temperature and head capacity of the sample. Knowing these thermal properties permits the simulation of shear heating and hot and cold spots in the flow area. The thermal conductivity meter is used to determine the thermal conductivity of the polymer sample across a range of temperatures.

This in-house lab provides faster turnaround on test results, reducing delays during the design process and offering better control over the testing parameters. The result is a high-quality part delivered on time.

The new test extrusion facility features various pieces of equipment including two Killion 1.25″ extruders, an RDN 2.0 PVS vacuum tank, one Keyence LS9000 dual axis laser gauge, two Dri Air ARID-X 10 30lb capacity driers, a custom-built tubing puller and an Accurate Thermal Systems FTBLL47 fluidized bath. In addition, the test lab permits single and co-extrusion capabilities with its tried-and-true die designs. Access to exotic extrusion processes such as rotary die extrusion of filament and tubular end-products are also available.

Supporting extrusion trials, the test lab also offers extrusion training, die cleaning services, sample inspection, and end-product testing. Guill’s fluidized bath has a 50°C-605°C temperature range and a working volume of 15.7” x 47.”

Customers can test materials, dies and actual extrusion run time… all on Guill premises.

For more information, please contact:

Tom Baldock, Sales Manager, Extrusion

Guill Tool & Engineering

10 Pike Street

West Warwick, RI 02893

USA

Phone: 401-465-5526

tbaldock@guill.com