Contact us today:

(847) 934-4500

tdaro@bernardandcompany.com

Contact us today:

(847) 934-4500

tdaro@bernardandcompany.com

Tooling supplier expands headquarters, offers specific machine tool brand product lines, detailed in new full-specification catalogs

Heimatec, Inc., the North American operation for a world leader in live tools, angle heads and multi-spindle drill heads, today announces it has relocated to substantially larger headquarters near Chicago.

Heimatec will display a complete line of high-quality live tools for all major turning machine brands, as well as angle heads for milling applications, during the upcoming IMTS 2012 in Chicago. The company will feature its unique HT quick-change system and patented u-tec flexible machining system.

According to company president Preben Hansen, “We made this move to increase our inventory and our staff to better serve the growing ranks of our customers, both end users and distributors alike.” The new location is in Prospect Heights, Illinois, previously home to Heimatec.

It represents a 50% increase in the office and warehouse capacity for this growing supplier to the North American machine tool market. Hansen anticipates hiring new staff for the facility soon.

In related news, Heimatec has introduced complete lines of tooling, each designed for specific brands of machine tools, including the major builders of turning machines used in the North American market, such as Haas, Okuma, Mazak, Spinner, Miyano, Nakamura and others. This full-specification literature by machine brand is immediately available from the company in print and online pdf versions. Interested parties should contact the company. Heimatec also offers its new corporate capability brochure, in which all lines are presented.

For further information on this news release, please contact:

Preben Hansen, President

HEIMATEC INC.

16 E. Piper Lane Suite 129

Prospect Heights, IL 60070

Phone: 847-749-0633

Fax: 847-749-2445

Email: info@heimatecinc.com

Website: www.heimatecinc.com

—

Heimatec is an international tooling manufacturer, based in Renchen, Germany. Its experienced staff is dedicated to providing customers the most innovative tooling technology possible. In 2010, the company opened Heimatec Inc. in Prospect Heights, IL, near Chicago, to serve its growing North American customer base with sales and service, plus an extensive inventory of products. Heimatec serves the auto, aero, medical, off-highway, rail, energy, woodworking, composites and other industries, as well as an ever-increasing number of machine tool OEM’s worldwide.

Continue readingNo. 959 is a 300ºF, electrically-heated, vertical conveyor oven from Grieve, currently used for curing electronic parts at the customer’s facility. Workspace dimensions of this oven measure 36” W x 89” D x 115” H. 40KW are installed in Incoloy-sheathed tubular elements to heat the oven chamber, while a 6000 CFM, 5-HP recirculating blower provides vertical downward airflow to the workload.

This Grieve vertical conveyor oven features 4” insulated walls, aluminized steel interior and exterior, motor-operated vertical lift door at the loading/unloading opening and two (2) independent doors for access to the workspace. Twenty-seven (27) product carrier trays, each 30” wide by 14” long, supported at each side by a heavy-duty roller chain, driven by a ½-HP drive motor, controlled by a variable frequency drive, are also included.

Controls on No. 959 include a digital temperature controller, manual reset excess temperature controller with separate contactors, recirculating blower air flow safety switch, plus a tower light to indicate machine status. The oven is built to exacting JIC/NEMA 12 electrical standards.

For more information, please contact: THE GRIEVE CORPORATION, 500 Hart

Road, Round Lake, Illinois 60073-2835 USA. Phone: (847) 546-8225. Fax: (847) 546-

9210. Web: www.grievecorp.com. Email: sales@grievecorp.com. Attention: Frank

Calabrese.

Continue reading

Advanced Machine & Engineering Co. is the pioneer in carbide sawing and sawing technology, with over 40 years of manufacturing. They will be presenting:

Hennig, Inc. design and produces custom machine protection and chip/coolant management products for state-of-the-art machine tools. Hennig products are designed to protect against corrosion, debris and common workplace contaminants. Manufacturing facilities located in the U.S., Germany, Brazil, India, Japan, France and South Korea. Repair centers are located in Machesney Park, IL; Chandler, OK; Livonia, MI; Blue Ash, OH; Mexico City, Mexico and Saltillo, Mexico. To learn more, visit www.hennigworldwide.com.

For more information, contact:

Tim Waterman

ADVANCED MACHINE & ENGINEERING CO.

2500 Latham St.

Rockford, IL 61103

Phone: 815-316-5277

Fax: 815-962-6483

E-mail: info@ame.com

Connect with AME online:

This Grieve walk-in oven features 4” insulated walls, aluminized steel interior and exterior, plus 2” insulated floor with integral truck wheel guide tracks for easier loading and unloading. All safety equipment is included for processing flammable solvents in the oven, including explosion-venting door hardware.

Controls on No. 850 include a digital programming temperature controller, manual reset excess temperature controller with separate contactors, recirculating blower air flow safety switch and 10” diameter circular chart event recorder.

For more information, please contact: THE GRIEVE CORPORATION, 500 Hart

Road, Round Lake, Illinois 60073-2835 USA. Phone: (847) 546-8225. Fax: (847) 546-

9210. Web: www.grievecorp.com. Email: sales@grievecorp.com. Attention: Frank

Calabrese.

Continue readingNo. 855 is a 1250ºF electrically-heated, inert atmosphere cabinet oven from Grieve, currently used for heat treating at the customer’s facility. Workspace dimensions on this oven measure 38” W x 26” D x 38” H. 40KW are installed in Incoloy-sheathed tubular elements to heat the oven chamber, while a 1500 CFM, 1-1/2 HP recirculating blower provides horizontal airflow to the workload.

This Grieve cabinet oven features 10” insulated walls comprising 2” of 1900ºF block and 8” of 10 lb/cf density rockwool insulation, Type 304, 2B finish stainless steel interior with continuously backwelded seams, plus inner and outer door gaskets with the inner gasket sealing directly against the door plug while the outer gasket seals directly against the face of the oven.

Full inert atmosphere construction further includes a pressure regulator, flow meter, pressure gauge, internal high-temperature gasket, all welded expansion connection in doorway throat, air jacket on inner oven for cooling, ½” thick silicone rubber atmosphere seal, blower shaft seal, positive latching door hardware, adjustable offset door hinges, outlet with pressure relief, interior seams welded gas-tight and all wall penetrations fitted with compression fittings. A 325 CFM blower pulls air through the air jacket on the inner oven for cooling.

Controls on No. 855 include a special heating/cooling temperature controller to control heating elements for heating and modulating damper on cooling blower for cooling. The oven also has an SCR power controller and circular chart recorder onboard.

For more information, please contact: THE GRIEVE CORPORATION, 500 Hart Road, Round Lake, Illinois 60073-2835 USA. Phone: (847) 546-8225. Fax: (847)546-9210. Web: http://www.grievecorp.com. Email: sales@grievecorp.com Attention: Frank Calabrese.

Continue readingThe ideal solution for industrial-grade applications

With the new Sinamics G120C, Siemens is extending its product portfolio of inverters. This compact device is suitable for industrial-grade applications including pumps, compressors, fans, mixers and extruders, as well as conveyor belts and materials handling machines.

Siemens Industry, Inc. released today the new Sinamics G120C, a compact inverter designed for various industrial applications such as pumps, compressors and fans, as well as mixers, extruders, conveyor belts and materials handling machines. With a rated power range of 0.75 to 25 hp (0.55 to 18.5 kW), the Sinamics G120C sets new standards in the industry with its compact dimensions, fast commissioning times, simple operation, ease-of-servicing and highly-integrated functionality.

This compact inverter offers one of the highest power densities in its class. Compared to conventional systems on the market, the Sinamics G120C requires up to 30 percent less space, with up to 40 percent higher power output. Quick-connecting plug-in terminals allow faster installation.

An optional operator panel may be mounted to the inverter for commissioning. A port for inserting a memory card is also available for faster inverter commissioning. It can be configured using a PC, via USB interface, as well. Standard protective coatings on the PC boards make the unit extremely robust in hostile or corrosive environments. The new Sinamics G120C is designed for ambient temperatures of up to 140ºF (60ºC).

Each Sinamics G120C inverter features Safety Integrated as standard. The unit is equipped with dual safe inputs to control the STO (Safe Torque Off) function without the need for external devices. The G120C offers users the performance of the Siemens Sinamics platform, enabling precise, cost-effective control and more energy-efficient operation of induction motors.

For network communications, this new Sinamics G120C supports Profibus. It can also be directly integrated into other widely-used communications structures via USS protocol, ModBus RTU and CAN Open. The default setting on each G120C enables field bus operation without time-consuming configuration.

See the SINAMICS Drives video on YouTube here.

For more information about the Sinamics G120C, visit www.usa.siemens.com/drives.

For specific product information and inquiries, call (800) 879-8079 ext. Marketing Communications or send an e-mail to: SiemensMTBUMarCom.industry@siemens.com.

Continue readingCost-efficiency and flexibility in one complete panel

This pre-wired solution is offered complete and fully tested with all necessary components mounted onto a back panel. Sinamics DC Master Base Drives are an extremely flexible and cost-effective solution for new installations and retrofits where space is limited. They are ideal for end-users and third-parties such as system integrators and Siemens solution partners.

Sinamics DC Master Base Drives offer more power per panel in the same footprint as compared to the previous two generations of base drives. These base drives are rated from 15A–850A continuous current.

Standard features of the new SINAMICS DCM Base Drive include — input fuses, output DC fuses (regen only), control transformer, AC line contactors, PROFIBUS, BOP20, UL508A Certification and 65KA SCCR rating. They are ready-to-order with deliveries available after February 2012.

For more information about the Sinamics DC Master Base Drive, visit our web page www.usa.siemens.com/motioncontrol.

For specific product information and inquiries, call (800) 879-8079 ext. Marketing Communications or send an e-mail to: SiemensMTBUMarCom.industry@siemens.com.

Continue reading

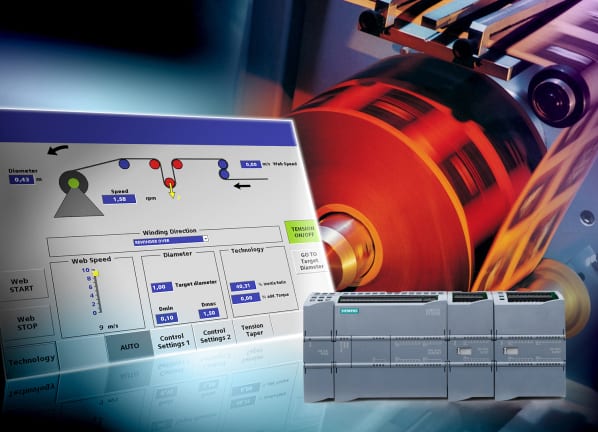

Value-added converting solutions for both the machine and the plant

The Simatic module completes the application set that includes the Simotion® module, a group of high-performance motion control converting solutions, and the Sinamics® DCC (drive control chart) module with drive-based converting solutions. It offers the capability to integrate full converting lines and machines centralized on the Simatic S7 PLC platform. Functions include center winder, sectional drive control and a host of converting process and large functions. Systems can be implemented in Ladder, structured text or in a graphical functional block language.

Machine builders are now able to achieve considerably faster time to market by reducing the time required for engineering, programming, commissioning and documentation, as much as 80 percent in some cases. It offers modular open functions, for items such as winding, laminating,

cross-cutting, calendaring, perforating, embossing, coating, flying saw, die cutting, traversing and more.

Components of the Converting Toolbox take the form of pre-programmed functions. Sample applications demonstrate how each function can be effectively and efficiently implemented into a machine design. Some of the applications are ready-to-use after only minor modifications and even include basic HMI functionality.

For more information about the Converting Toolbox, visit www.usa.siemens.com/converting.

For specific product information and inquiries, call (800) 879-8079 ext. Marketing Communications or send an e-mail to: SiemensMTBUMarCom.industry@siemens.com.

Continue readingThrough the use of Siemens SINUMERIK CNC technology, plus PLC and HMI, on a combination servo-controlled cold saw cut-to-length and brush deburring system, Rattunde customer achieves triple the output on small engine exhaust components

Rattunde ACS + BDM tube and bar production system at Cosmos.

Rattunde Corporation of Grand Rapids, Michigan is the five-year-old subsidiary of Germany’s Rattunde & Co. GmbH, a machine tool builder of tube, pipe and bar processing equipment. The company is already making its mark in the American manufacturing industry, as demonstrated by a recent success it had at Cosmos Manufacturing of South Chicago Heights, Illinois, a major supplier of small engine exhaust tubes to the leading outdoor power equipment manufacturers in the country.

The Rattunde system, incorporating a servo-controlled cutoff saw and brush deburring mechanism, is consistently producing up to 11,000 parts per hour at Cosmos, according to Mike Jemilo, the end user’s general manager. “This number represents triple the output production for Cosmos.” He continues, “Better still, it’s been in operation more than a year and we have not reported a single reject, with only routine maintenance and zero downtime due to machine problems. This is truly a win-win scenario for the machine tool builder and us alike.”

At the heart of the Rattunde system, according to Richard Stadler, company president, is the computer numerical control (CNC) system used by this builder. It consists of a Sinumerik 840D CNC, Simatic S7 PLC with various analog and Profibus modules, plus numerous Simotics servomotors, motor protection devices, circuit breakers and other components supplied by Siemens.

Machine performs all servo-controlled saw cut-to-length, washdown, brush deburring and packing operations on a single line, controlled by Siemens CNC and HMI.

At Cosmos, this Rattunde system is used to process mill-length tubes to customer-specified dimensions, using a fully NC-controlled cold saw. Cut-to-length parts are then automatically measured for dimensional accuracy and brush deburred. Production of these parts runs up to 11,000 units per hour, according to Cosmos’ Mike Jemilo. Because of the overall improvements in automation, speed and parts handling, plus the precision of the Sinumerik CNC system, Cosmos is further experiencing significant reductions in parts handling, secondary operations and final assembly.

The primary products being produced on this equipment at Cosmos include mountings, connectors and sections for muffler tubes in dozens of lengths, typically in 3/8-inch, 7/16-inch, 12 millimeter and 1/2-inch sizes. Products are routinely run in mild steel, aluminized steel and stainless steel on the same Rattunde system, with offline pre-programming done by the Cosmos engineering team. The final products are sold by Cosmos to leading manufacturers of chain saws, leaf blowers, lawn mowers and other small engine-powered equipment.

All machine functions and 13 axes of movement are affected by the Siemens CNC, which also provides remote monitoring capability for the builder Rattunde.

Jemilo concluded by citing the Rattunde service advantages. “From the initial contacts with their application engineering, through the build process, commissioning and on-site training, we’ve been extremely impressed with their work — very professional and responsive. Our previous system had nowhere near the production of the Rattunde solution and we are already working with this supplier on our next system.”

From the machine tool builder’s perspective, the same relationship is echoed about Siemens. Alec Banish, vice-president at Rattunde, commented, “We were asking Siemens to do some fairly complex operations in motion control, including 13 total axes with an articulating gearbox, plus the conveyor and part articulations, spindles and servomotors.” He further noted the scalloped motion of the ID/OD brushing with disc transfers all presented unique motion challenges for the control hardware and software alike. “The Siemens servo technology automated our entire process in a totally controlled, high-precision manner, allowing customers such as Cosmos to process a wide variety of materials, dimensions, shapes and lengths with easy-to-manage presets.” Banish concluded by saying, “The Siemens support is greatly enhanced by the remote monitoring capability of the Sinumerik CNC. About 70 percent of our issues are resolved remotely, working between us and Siemens or directly with the customer’s plant personnel.”

Prior to the implementation of the Rattunde system, all the piece part work done at Cosmos required two or three saws, with the attendant fixturing, parts handling, logistics and labor costs. These bottlenecks in production were eliminated by the fully automated and single operation processing of the tubes provided by the Rattunde system. Four tubes are processed per cycle, with servo control of the entire bundle, as it moves through the saw, brush and loading zones on this fully integrated machine line.

Rattunde builds various production systems for tube and bar product manufacturers.

From a factory utilization perspective, the prior system at Cosmos ran in three shifts for six days, each week. Today, with the Rattunde system on the floor, occupying a far smaller footprint, one shift per day working just five days produces the same output with far superior quality and virtually no rework, according to company sources.

Rattunde President Richard Stadler further comments on the power of the Siemens CNC and related motion control products. “We’re using all ten channels and pushing the axis capability to some extreme limits, but have seen absolutely no problems in signal degradation or processing speeds.” Stadler also observed the Sinumerik CNC program storage capabilities were quite impressive. “All the operator needs to do is provide a size range indication onscreen and all the relevant programs appear for easy selection. Repeatability is obviously critical for our customer, who often process dozens of shapes and sizes per shift.”

He recalled meeting the Cosmos team at FABTECH in 2009. “They approached us with their scenario and it was right in our wheelhouse. We did some test cuts and time/motion studies for them and the results were quite impressive, both to them and to us,” Stadler muses.

Rattunde operates facilities in Grand Rapids, Michigan as well as a service center in Burlington, Ontario to better serve their North American customer base.

Rattunde markets its tube and bar production systems to makers of precision parts. Currently selling 60 percent automotive, the company’s systems produce airbag canisters, cam shaft cylinders, steering components, rack mounts, driveshafts, frame components, seating parts, headrests, shock absorber parts, door impact devices, luggage racks and a variety of axles. In addition to the cut-off and brush deburring system detailed here, the company also supplies production systems to perform various types of secondary machining operations, including threading, facing, chamfering and ID turning.

For further information on this story, please contact:

RATTUNDE CORPORATION

4980 Kendrick St. SE

Grand Rapids, MI 49512

Phone: 616-940-3340

Web: www.rattunde-corp.com

Email: r.stadler@rattunde-corp.com

Attention: Richard Stadler, president or Alec Banish, vice-president

OR

SIEMENS INDUSTRY, INC.

DRIVE TECHNOLOGIES

MOTION CONTROL

MACHINE TOOL BUSINESS

390 Kent Avenue

Elk Grove Village, IL 60007

Phone: 847-640-1595

Fax: 847-437-0784

Web: www.usa.siemens.com/cnc

Email: SiemensMTBUMarCom.sea@siemens.com

Attention: John Meyer, Manager, Marketing Communication

Follow us on Facebook: www.facebook.com/SiemensCNC or Twitter: www.twitter.com/siemens_cnc_us.

—

Siemens Industry Sector is the world’s leading supplier of innovative and environmentally friendly products, solutions and services for industrial customers. With end-to-end automation technology and industrial software, solid vertical-market expertise, and technology-based services, the sector enhances its customers’ productivity, efficiency and flexibility. With a global workforce of more than 100,000 employees, the Industry Sector comprises the Industry Automation, Drive Technologies and Customer Services Divisions as well as the Metals Technologies Business Unit. For more information, visit http://www.usa.siemens.com/industry.

The Siemens Drive Technologies Division is the world’s leading supplier of products, systems, applications, solutions and services for the entire drive train, with electrical and mechanical components. Drive Technologies serves all vertical markets in the production and process industries as well as the infrastructure/energy segment. With its products and solutions, the division enables its customers to achieve productivity, energy efficiency and reliability. For more information, visit http://www.usa.siemens.com/drivetechnologies.

Continue readingSiemens Sinumerik 840D is the control of choice on turning, grinding and turn/grind models, resulting in substantial savings for its customer and EMAG

EMAG L.L.C. is the U.S. subsidiary of a major German machine tool builder who specializes in machine tools for the production of automotive, off-highway, agricultural and oil field components. The company’s equipment ranges from basic prismatic part turning centers to large workpiece, five-axis machining centers, gear hobbing machines and alternative cutting equipment such as lasers and electro-chemical machining centers. This wide variety of machine tools requires an assortment of control technologies to power and manage the motion. For one recent customer requirement, where a major agricultural equipment builder in Iowa needed grinding, turning and turn-grind machines, EMAG looked to its longtime partner Siemens for a standardized CNC solution.

CEO Peter Loetzner put it simply, “We needed to devise a control solution that would satisfy all the needs of the various machines we were supplying to this demanding customer, based on a common platform, to enable easier design, integration, start-up, commissioning on-site and training for our customer’s operations and maintenance personnel.” After reviewing the entire line of CNC offerings from various suppliers, the decision was made to use the Siemens Sinumerik 840D CNC for all of the grinding, turning and turn-grind machines to be supplied. Collaboration was a key element in the decision-making process, as Loetzner explains.

“The control we selected offered great flexibility in application, which was very important to us and our customer. They were seeking a scenario that would allow considerable cross-training of their operators, who might run a turning center one day, then a grinding or turn-grind center the next.” Loetzner further noted the control chosen offered his machine designers and the customer’s production management team an enhanced remote monitoring feature, so changes could be made on the fly with very little downtime. As a result, over 20 machines of various sizes and styles can be monitored over a wireless network, enabling process engineers to see what the operator sees on each machine.

Furthermore, owing to the global capabilities of Siemens, Loetzner commented on the control’s ability to function

in U.S., German and even Asian factories with seamless data integration. Regardless of the machine tool’s location, EMAG and its customer are able to monitor the performance of any particular machine and even report comparative production data from one continent to another. Because it sells into every industrialized nation, EMAG “…works with its customers on every aspect of a job, from the order process to tooling usage, materials handling strategies to predictive maintenance. The cultural differences are substantial sometimes and the control must be programmed to adapt to such variations. We have been most satisfied with the help Siemens has provided to us, worldwide, in this area.”

Those differences, he continued, must nonetheless be based on a common technology to streamline the integration of the CNC on the machines under construction.

Loetzner cited specifics from the project referenced in this story. “We were looking at a fairly diverse group of machines being supplied to the customer. Frankly, many of their operators were more comfortable with a CNC that is very popular in the American job shop community. However, we were able to demonstrate the immediate advantages of the Siemens control to them and they accepted our recommendations.” This value proposition, he said, hinged on the greater capability of the Sinumerik 840D to run different machine types, which translated into considerable savings on the training and commissioning side of the equation. Coupled with the remote monitoring and programming aspects of the Siemens control solution, the customer was convinced.

Production VSC from EMAG is a vertical pick-up turning center capable of milling, turning, grinding, drilling, even gear profiling and honing.

More than 75 percent of the EMAG machines at this particular customer are equipped with robotic devices, enabling a lights-out manufacturing scenario, another instance where the Siemens remote monitoring via Ethernet feature benefits both the machine tool builder and its customer alike. Loetzner explains, “Remote monitoring of the machine tools can be done directly through the Sinumerik CNC in a one-to-one exchange between our customer and us. Alternatively, we can communicate with Siemens and our customer in a three-way exchange of machine data and cycle information, all protected through a firewall for security and customer peace-of-mind. That’s important with all our major OEMs, of course.” Loetzner cited one customer in the agricultural machine building market, who’s used the remote monitoring capability of the Sinumerik CNC on a wide variety of EMAG machines for over three years currently, with all data communicated through a single information network, accessible by both EMAG and the control supplier. Significant reductions in downtime, service calls and troubleshooting identification time have been achieved, translating into documented savings for everyone.

Shaft machining is done on a VTC, with full 4-axis machining plus loading and unloading, all controlled by a Siemens CNC.

As a further advantage to the machine tool builder, the space reduction of more than 20 percent in the control, compared to competitive brands, meant a smaller footprint for the machine, further improving the workspace productivity of the EMAG machines for their customer. Especially in brownfield applications, where a limited space is being utilized to maximize production for an OEM, this physical space-savings combines with other advantages of the Siemens control, according to Peter Loetzner. These include reduced wiring and lower power consumption with the attendant lower operating temperatures, due to reduced ambient heat.

At this particular customer, the EMAG machines are used to produce gears, gear blanks, shafts and splines for

powertrain applications. Gear hobbing and synchronous support grinding are among the advanced machining technologies performed here. Heavy, hardened steels are the most often worked substrates.

The specific control used on these machines is the Siemens Sinumerik 840D solution line, a distributed, scalable and open control for up to 31 axes of motion, incorporating the CNC, HMI, PLC, closed loop control and communications functions into a single NC unit. Sinumerik Safety Integrated further provides a comprehensive, yet efficiently packaged suite of personnel and machine protection functions, fully compliant with internationally-accepted standards.

Commenting on the competing brands of CNC often found in job shops worldwide, Loetzner noted that the Siemens communication architecture easily accepts input from such devices, owing to its ability to capture, standardize and transmit all data in a seamless manner through its legacy tracking. “This service is another example of a forward-thinking supplier, such as Siemens, responding to brownfield conditions in the marketplace,” he noted.

EMAG machines are used by the majority of American companies for the production of such products in the Agriculture, Earthmoving, Motorcycle and Automotive and subsequent leading TIER1 suppliers. The machine builder has had a presence in the American market for over 20 years and, according to Peter Loetzner, “…we’ve received great support from Siemens, both in Germany and in the United States, for on-site service, application engineering, parts distribution, remote monitoring implementation and communications between our customers and us.”

For more information on this story, please contact:

EMAG L.L.C.

Peter Loetzner

CEO

38800 Grand River Avenue

Farmington Hills, MI 48335

Phone: 248-477-7440

Fax: 248-477-7784

Web: www.emag.com

Email: info@emag.com

OR

SIEMENS INDUSTRY, INC.

DRIVE TECHNOLOGIES

MOTION CONTROL

MACHINE TOOL BUSINESS

390 Kent Avenue

Elk Grove Village, IL 60007

Phone: 847-640-1595

Fax: 847-437-0784

Web: www.usa.siemens.com/cnc

Email: SiemensMTBUMarCom.sea@siemens.com

Attention: John Meyer, Manager, Marketing Communication

Follow us on Facebook: www.facebook.com/SiemensCNC or Twitter: www.twitter.com/siemens_cnc_us.

—

Siemens Industry Sector is the world’s leading supplier of innovative and environmentally friendly products, solutions and services for industrial customers. With end-to-end automation technology and industrial software, solid vertical-market expertise, and technology-based services, the sector enhances its customers’ productivity, efficiency and flexibility. With a global workforce of more than 100,000 employees, the Industry Sector comprises the Industry Automation, Drive Technologies and Customer Services Divisions as well as the Metals Technologies Business Unit. For more information, visit http://www.usa.siemens.com/industry.

The Siemens Drive Technologies Division is the world’s leading supplier of products, systems, applications, solutions and services for the entire drive train, with electrical and mechanical components. Drive Technologies serves all vertical markets in the production and process industries as well as the infrastructure/energy segment. With its products and solutions, the division enables its customers to achieve productivity, energy efficiency and reliability. For more information, visit http://www.usa.siemens.com/drivetechnologies.

Continue reading