Contact us today:

(847) 934-4500

tdaro@bernardandcompany.com

Contact us today:

(847) 934-4500

tdaro@bernardandcompany.com

Available from German Machine Tools of America, the Präwema SynchroFine 205 HS gear honing machine features direct-driven, digitally controlled spindles for the tool and the workpiece, enabling precise, rigid synchronization

Ann Arbor, Michigan – Now available from German Machine Tools of America (GMTA), the Präwema SynchroFine 205 HS gear honing machine features direct-driven, digitally controlled spindles for the tool and the workpiece, enabling precise, rigid synchronization. The Präwema Honing gear finishing process produces quality comparable to grinding results for spur and helical gears, as well as shafts. The machine’s software checks the stock allowance and workpiece runout and then optimizes the X-axis approach distance. Measuring the workpiece does not affect the cycle time and the process can reduce cycle times by 3 to 5 sec.

The machine features a pick-up design to enable automation. The workpieces and dressing tools are loaded and unloaded by the workpiece spindle. The large X-axis travel enables placement of additional stations adjacent to the loading/unloading station inside the machine, such as a two-flank roll-checking device. External robots and conveyor systems can also be integrated by GMTA engineering.

The honing machine is constructed on a natural granite bed to promote stability and control thermal fluctuations. The X and Z axes are equipped with linear motor drives. The cutting tool is clamped with a hydraulically operated system and the tool spindle can be swiveled into a vertical position, enabling easy access. Additional options are available for machining over-sized drive shafts as long as 850 mm and the Präwema SynchroFine 205 HS-D model, equipped with two spindles, is offered for further reduction of cycle times.

For more information on this announcement, please contact:

GMTA (German Machine Tools of America)

4630 Freedom Drive

Ann Arbor, MI 48108

Phone: 734-973-7800

Fax: 734-973-3053

Web: www.gmtamerica.com

Email: scott@gmtamerica.com

Attention: Scott Knoy, VP

Connect with GMTA online:

5-axis cnc grinder with extended x-y axis paths plus two aux slides for workpiece clamping

Equipped with unique SIGSpro software system to allow full 3D simulation on the HMI or offline for more accurate quotes, complete cycle validation

New Schütte 325linear cylindrical grinding system features extended x-y paths plus two auxiliary slides

Schütte (Jackson, Michigan) today announces the introduction of its new 325linear machine, a 5-axis CNC grinder with extended x- and y-axis movement plus two auxiliary slides for workpiece clamping and improved grinding wheel guidance over the entire machining envelope. Micro tools, gun drills, hob cutters and complex geometries can be accommodated on this new machine, which operates in the range of 2500-4000 rpm, typically. The additional second auxiliary slide enables the 325linear to utilize tool guidance, part support, tailstock or workpiece pallets in operation. This new Schütte machine further expands the user’s automation possibilities, as it also offers significant advancements in wheel change and robotic workpiece handling.

Specifically, on the a-axis, a user can install collet chucks, hydraulic expansion chucks or multi-range chucks. With the automated collet changer on the machine, workpieces with different diameters can be clamped with high concentricity in the unmanned loader station. The Schütte a-axis configuration on this machine also permits position-oriented clamping of non-rotationally symmetrical workpieces. In this way, sequential workpieces with various roughing and finishing requirements can be preset on the machine for continuous processing.

SIGSpro (Schütte Integrated Grinding Software) enables full 3D simulation of the entire cycle, either on the HMI or offline, for improved estimating and safety concerns

Likewise, this new Schütte grinding system offers scalable automation, with a 140-position tool changer, 5-24 grinding wheel magazine and a flexible robotic tool gripper for changing the smallest micro tools as available options. The same base machine can be utilized for continuous production of a single part in a work cell setup or used for sequential one-off work, as needed.

The 325linear features a universal rotation a-axis with a high level of concentricity (<0.0001º resolution) and pitch accuracy, while the xyz-axis resolution is maintained at

The machine is offered with the proprietary SIGSpro (Schütte Integrated Grinding Software) as the programming interface, allowing users to assign clamping options for each grinding operation being performed. When the support and tool guidance system are used, preset distances from the grinding wheel to the workpiece can be defined and held constant. In the 3D mode, all cycle steps can be simulated, controlled and optimized for exact estimating, collision avoidance and even external workstation integration with the other workpieces.

Optional robotic handling, wheel changing and tool magazines allow the same machine scalable automation in use

All motion control on this new grinder is maintained on a Siemens 840D sl CNC with compatible drive technology.

This new Schütte 325linear grinding machine is available for viewing at the company’s North American headquarters in Jackson, Michigan, as well as a number of the upcoming trade shows in 2015.

For further information, please contact:

SCHUTTE MSA, LLC

4055 Morrill Road

Jackson, MI 49201

Phone: 517-782-3600

www.schutteusa.com

rfq@schutteusa.com

AIT uses Siemens highly integrated solutions platform, with SIMATIC Safety PLC, Sinamics drives and Simotion motion control over the PROFINET network, to go above & beyond to improve performance & productivity for Boeing’s Dreamliner fuselage assembly process

Advanced Integration Technology (AIT) is a 20-year-old supplier of turnkey industrial automation systems for the aerospace industry. The company’s strength centers on the design and build of complex, fully integrated manufacturing, tooling and assembly systems for commercial and military aircraft, produced by the world’s leading suppliers, including Boeing, Bombardier, EADS, British Aerospace, Lockheed Martin, Spirit AeroSystems, Vought and others. Its reputation as an established partner to these companies is well known, despite its relative corporate youth. AIT operates six locations in the U.S., Canada, Sweden and Spain to serve its growing customer base.

All actions in each section are controlled and monitored by Siemens SIMOTION motion controllers, SINAMICS drives, failsafe CPU, safety devices and distributed I/O, working either independently or in concert, as the production requires

On a recent project involving production of the Boeing 787 Dreamliner, AIT designed and built all final body assembly systems needed to join the major fuselage components, plus a moving production line. Key elements in this design included the motion control system, servo drive platforms, failsafe CPUs and all distributed I/O, with the entire system communicating over a Profinet network. In addition, the integration of comprehensive safety technology was incorporated into the standard automation on these systems.

As a prime contractor on the 787, AIT had responsibility for the final assembly and body join functions, charged with delivering a fully automated positioning and joining system. In the end, two complete assembly systems and one positioning system were provided. The three main sections of the fuselage are joined, with 14 positioners mounted to transport structures that move either independently or interlocked and indexed to the factory floor for stability. Real-time positioning measurement data are logged with an integrated indoor GPS. AIT designed the alignment and positioning systems to allow rolling them under the aircraft dollies after the sections were brought into the Boeing factory, radically reducing auxiliary equipment needs, materials handling requirements and additional positioning steps in the overall process.

Onsite at Boeing, the 14 positioning system components were moved into their respective locations near the cradle dollies and engaged to lift and move the aircraft sections. Once the system was rigidly joined, a measurement system onboard located the airplane sections. This information was fed to the AIT system’s software application. From those data points, the system could then calculate how much each section (nose, tail, left and right wings) needed to move to ensure an exact fit to the adjoining section. This precise alignment ensured a smooth and more rapid build of each aircraft’s fuselage.

In commenting on the particulars of this system’s requirements for his company, Ed Chalupa, president of AIT, explains, “We looked for a supplier with an off-the-shelf selection of automation and motion control solutions, who could offer us global support. Our goal here was to align ourselves with a leading automation technology supplier and to utilize all current software, integrated safety and control technology advancements. Both Boeing and AIT were keenly sensitive to lifecycle security issues in this critical area of the project.” He further noted that it was vital the chosen supplier be able to provide comprehensive application engineering support, training on both the products and software, plus prototype and demo equipment for AIT’s use with its customer and internally, with ongoing technical support agreements, covering both the products and software updates.

After an extensive review of several global contenders, the selection was made for Siemens control system components.

Click to view -> schematic shows the independent but interconnected nature of the control platforms for each section. The Siemens SCALANCE wireless technology is used for system switching.

The basic scheme of the motion control system implemented here comprises a Simotion D motion controller, Siemens HMI on a Windows-based PC, a SIMATIC S7 Safety PLC and fail-safe/standard I/O modules, all running on a Profinet network. This basic architecture was then multiplied by the number of control nodes for each specific operational system in the overall production line being designed by AIT. Each unit is capable of working independently of the others in the line. Or, with the addition of relatively few Profinet cables and mode selctions on each unit, the final body join assembly tool is able to run as a single entity. When running together in this latter configuration, the safety devices are likewise working coherently, providing proper response levels to all E-stop events on the line. Each unit motion controller receives commands to perform uniform group movements with the tool as a whole via network communications from the HMI.

Specifically, the Siemens Simotion D motion controller used here controls all axis movements to accurately position and align parts. Because AIT delivers a turnkey and dedicated system, customers have no need for further internal customization of the controller hardware or HMI panels.

AIT designed the overall layout of the control architecture, programmed the Simotion system with the Simatic S7 PLC, distributed I/O and integrated safety, plus provided support on the Boeing internal structure and lifecycle support requirements.

The integrated safety concept on this overall system was based upon three core principles: increasingly layered safety architectures, greater degrees of integration between the control and safety systems, plus more use of networking, especially Industrial Ethernet and currently available motion technologies.

In operational sequence, these safety principles manifest themselves in the form of physical barriers and mechanical means such as walls, gates, door interlocks and light curtains, all designed to separate personnel from danger. Meanwhile, the control systems, including programmable safety relays and safety PLCs, monitor operating conditions within established parameters. Finally, safety shutdown systems such as automatic shutdown via safety PLC or manual shutdown via E-stops, offer the final protections.

Siemens engineered a safety protocol that simplified the complexity often encountered in the integration of control and safety systems. This was achieved by reducing the issues related to different programming languages and procedures, installation and configuration requirements, maintenance procedures and human error factors. The result for AIT and its customer Boeing was lower total cost of ownership (TCO), owing to the substantial reduction in engineering, hardware, training and spare parts needed.

With integrated safety and control, the project has a single system for standard and safe automation, with one bus and one engineering system for both standard and safety technology, which further reduces cost. As a collateral benefit, the software solutions allow easier replication of series machines. Likewise, faster troubleshooting and extensive diagnostics onboard reduce downtimes on the floor, with faster restart after issue resolution. Functionally, too, this safety integration in the control system allows uniform user interfaces and data libraries, plus a reduction in the variety of control cabinets needed for the various applications.

PROFIsafe®, the first communication safety-profile meeting the IEC 61508 safety requirements, is the backbone of all fail-safe communication. PROFIsafe® facilitates the transmission of both standard and safety-related data on a single bus cable, using either Ethernet or fieldbus protocol. With advanced PLC and Industrial Ethernet networking technologies combined, the system safety for AIT and its customer became a production asset that protects the workers from harm and also ensures maximum availability and uptime. Reductions in initial capital expense and field operating expense were also realized.

According to AIT engineering, SIMATIC Safety PLC brought the highest possible integration of safety and ease of designing a complex system into the automation scenario for this project.

In the field, the final assembly and body join automated assembly systems, plus positioning system provided to Boeing, are utilized to join Section 41 (forward fuselage), Sections 47/48 (aft fuselage) and Section 12 (left and right side wings) to the mid-fuselage of the 787 Dreamliner aircraft. Two major sub-assemblies, namely the forward/aft body positioners and left/right wing positioners, are further split for transport into left- and right-hand minor sub-assemblies.

Motion Control, advanced PLC systems and industrial Ethernet networking technologies have enabled machine safety to become a production asset that not only protects workers from harm but also ensures maximum availability and uptime.

Machine Safety gives a competitive edge that goes to producers with highly integrated operations that are faster, more flexible and more responsive to changing market demands and opportunities, as AIT has shown in Boeing’s Dreamliner fuselage assembly process.

AIT designs and manufactures custom tooling and assembly equipment used to fabricate and assemble major commercial and military aircraft. As part of its total value proposition, AIT houses over 600,000 square feet for engineering, precision metal fabrication, machining and assembly of its production systems. The company’s equipment is typically used for assembly as well as machining of all the current aircraft structure materials, including aluminum, aluminum alloys, titanium, carbon fiber, Invar and many specialty alloys and composite substrates.

For further information on this story, please contact:

ADVANCED INTEGRATION TECHNOLOGY (AIT)

2805 E. Plano Pkwy.

Suite 100

Plano, TX 75074

Phone: 972-423-8354

Fax: 972-423-8469

Web: www.aint.com

Email: ait@aint.com

Attention: Ed Chalupa, President or Susan Hardaway, Marketing Mgr.

OR

SIEMENS INDUSTRY, INC.

MOTION CONTROL

PRODUCTION MACHINE BUSINESS

390 Kent Avenue

Elk Grove Village, IL 60007

Phone: 847-640-1595

Fax: 847-437-0784

Web: www.usa.siemens.com/simotion

Email: SiemensMTBUMarCom.sea@siemens.com

Attention: John Meyer, Manager, Marketing Communications

Follow us on Facebook: www.facebook.com/siemens.dt.us or Twitter: www.twitter.com/siemens_dt_us

—

Siemens Industry Sector is the world’s leading supplier of innovative and environmentally friendly products, solutions and services for industrial customers. With end-to-end automation technology and industrial software, solid vertical-market expertise, and technology-based services, the sector enhances its customers’ productivity, efficiency and flexibility. With a global workforce of more than 100,000 employees, the Industry Sector comprises the Industry Automation, Drive Technologies and Customer Services Divisions as well as the Metals Technologies Business Unit. For more information, visit http://www.usa.siemens.com/industry.

The Siemens Drive Technologies Division is the world’s leading supplier of products, systems, applications, solutions and services for the entire drive train, with electrical and mechanical components. Drive Technologies serves all vertical markets in the production and process industries as well as the infrastructure/energy segment. With its products and solutions, the division enables its customers to achieve productivity, energy efficiency and reliability. For more information, visit http://www.usa.siemens.com/drivetechnologies.

No. 975 is a 1250ºF (676ºC), electrically-heated cabinet oven from Grieve, currently used for heating metal parts to remove deposits at the customer’s facility. Workspace dimensions of this oven measure 50” W x 50” D x 50” H. 160 kW are installed in Incoloy-sheathed tubular elements to heat the oven chamber, while a 6000 CFM, 5 HP recirculating blower provides horizontal airflow to the workload.

This Grieve cabinet oven features 10” insulated walls comprising 2” of 1900ºF block insulation and 8” of 10 lb/cf density rockwool insulation, top-mounted heating chamber, aluminized steel exterior, Type 304, 2B stainless steel interior and all safety equipment required for handling flammable solvents, including explosion-venting door hardware. The insulated floor of the oven is reinforced for 1000 lb. loading with a 1/4” thick, Type 304 stainless steel plate.

No. 975 controls include a digital indicating temperature controller and manual reset excess temperature controller with separate contactors.

For more information, please contact:

THE GRIEVE CORPORATION

500 Hart Road

Round Lake, IL 60073-2898

Phone: (847) 546-8225

Fax: (847) 546-9210

Web: www.grievecorp.com

Email: sales@grievecorp.com

Attention: Frank Calabrese, VP

The objective of this new development was the integration of the latest servo drive and control technology from Bosch Rexroth. Software developed additionally allows the user to program six different basic cycles without prior knowledge of CNC.

By visualizing these six cycles – drilling – combined drilling (drilling and thread cutting with the one tool) – thread cutting – drilling with chip removal – drilling with jump function – undercutting, the unit has become extremely easy to program.

Plus, should the required machining cycle not be found among the standard selections or prove more complex, the unit can be switched to sentence programming.

The BEA 16 machining unit itself is a precision device from the SUHNER spindle machining unit series that has been designed for gruelling continuous use in multiple shift operations. The BEA 16 has a drilling capacity of 16 mm Æ in 450 N/mm2 steel. The max feed path is 140 mm, and the max speed is 500 rpm.

Today, rising production piece numbers and greater workpiece complexity with all-round machining are leading to a renaissance of the so-called special machine. However, today’s special machines are being used no longer as purely single-purpose solutions, but rather for whole part families.

These require different machining cycles, feed speeds, feed paths and rotating speeds, and, of course, must allow fast retooling. And it is these requirements exactly that the BEA 16 will meet to the full.

SUHNER INDUSTRIAL PRODUCTS, CORP.

Hwy 411 S./Suhner Drive

P.O. Box 1234

Rome, GA 30162

Phone: 706-235-8046

Fax: 706-235-8045

Attention: Lee Coleman, Automation Division

www.suhner.com

automation.usa@suhner.com

Text and pictures files can be found and down loaded at:

www.suhner-press.com

This Grieve jumbo walk-in batch oven features 6” insulated walls, a 36” wide x 1” x 1” flatwire conveyor belt with ½ HP motor drive, variable from 0.7 to 14.3 ipm, two 12” tubeaxial fans, each driven by a ½ HP motor, to push/pull air through the cooling zone, an aluminized steel interior and exterior, plus all safety equipment required by IRI, FM and NFPA Standard 86 for gas-heated equipment, including a 650 CFM powered forced exhauster.

For more information, please contact:

THE GRIEVE CORPORATION

500 Hart Road

Round Lake, IL 60073-2898

Phone: (847) 546-8225

Fax: (847) 546-9210

Web: www.grievecorp.com

Email: sales@grievecorp.com

Attention: Frank Calabrese, VP

Smiths Machine answered the recession with a formula for major change

So what’s the secret to their success?

To begin with, the omission of the apostrophe from the company’s name was deliberate. Being different is in the DNA of Smiths Machine. This is a second-generation, family-owned business that found a way to grow its workforce by 70 people during the last five years That’s a 300% employment surge that mostly happened during the recession, a time when many machine shops (and for that matter, many businesses), were struggling just to hang on.

Ahead of the recession, Smiths Machine did what many machine shops were doing at the time. They were riding the wave of automotive parts production and doing seemingly fine, until the massive downturn came. The bankruptcies of the tier one automotive companies suddenly left many machine shops vulnerable to volume-based supply from overseas competition; and a once well-oiled machine tool business model now seemed unstable and uncertain. Equally uncertain was the idea of moving the business in an entirely different direction.

Manufacturing complex parts for the aerospace and defense industry, demands consistency, high-quality and precision — achieved only with Siemens CNC.

To be or not to be — different

Defense and aerospace part manufacturing require a different business approach altogether, says Tim Smith, vice president of Smiths Machine.

“It is specialized work that requires special approvals, log-down processes and complicated procedures,” Smith says. “The complexity is challenging. And it all starts with a different way of thinking, more of an engineering approach than a production approach.”

Smith says his company needed to build a new business model and the operations to support it. The defense and aerospace machining market is characterized by small lot counts, generally lower margins, and a very low tolerance for errors. Scrap rates thought to be nominal in the past would now be out of the question.

“You can’t make a $6,000 part and have a 30% scrap rate or even a 10% scrap rate,” explains Smith. “The emphasis is not on throughput, but on the high quality, highly precise manufacturing of very complex parts.”

Based on these three inseparable machining requirements — quality, precision and complexity — Smiths Machine set out to reach its greater potential in the machine tool market, not as a production machine shop, but as company focused on complex part manufacturing. Having achieved some early success in this new direction, the way forward for the company soon could be summed up more simply:

“The more complex the part, the more competitive we are,” says Smith.

To protect and grow this competitive advantage, the company’s leadership knew that their internal processes and technology needed to match up with the unique requirements of the defense and aerospace industries. Major investments in large, complex, five-axis machines would need to be enhanced by equally complex control capabilities. Smith recounts how a decision made previously by the company would now come into play in a profound way.

A backbone for change

Traditionally a milling and turning company, Smiths Machine first teamed up with DMG and Siemens in the year 2000 to establish their singular machine tool platform. This brought about a synergistic approach to complex milling and turning; an advantage that took on greater significance when the company decided to focus on the defense and aerospace markets later in the decade.

“Siemens controls were available on DMG milling and turning machines, and that was a natural fit for us,” Smith recalls. The DMG / Siemens platform has enabled Smiths Machine to establish and maintain a high level of operational proficiency. The central advantage here, Smith says, has been the ability to invest, train and keep his people moving forward based on a stable technology platform.

“The technology and the people using it are the backbone of our organization,” Smith asserts. “Even with 25 machines, we can share knowledge between the milling and the turning machines. The common control is a Siemens Sinumerik 840D sl. Our technology purchases are based on where we want to be in ten years, not on a workforce that is fractionally trained and a platform that can rapidly deteriorate due to a change in market condition or a change in employment condition.”

Smith says an example of this singular platform advantage is the control’s similarity across milling and turning operations. “All controls are customized to a certain extent,” Smith acknowledges. “But unlike Siemens, many other control series are individually customized so that the keyboard layout will be different from machine to machine. The Sinumerik 840D sl CNC is consistent. So when you train your operators, you can say, here’s the jog button, here’s the axes button, here’s your alarm button and your offset button. And this level of consistency extends to a graphical interface that really complements how we teach and learn.”

Teaching and learning are closely held values within an organization that uses a breadth of visual techniques to foster education, efficient information sharing, and quality control.

“We are a very visual company,” Smith says. “We use a lot of colors and we buy a lot of printer toner. Our parts inventory uses color-coded tags and the same is true across our production. We use yellows and blues and reds for consistent instruction. And the Siemens 840D sl control uses the same approach. You are guided visually for such things as axis direction, approach point, final depth and other variables inside a cycle. And this is true from control to control, for milling and turning.”

Smith says visually guided information flow is characteristic of today’s complex range of next-generation electronic communications, because this speeds understanding and information sharing. Whether for a smart phone or a CNC, graphically guided interfaces enable rapid learning and proficiency, a fact that has been well leveraged by the 840D control interface design.

Smiths Machine’s plan for stable growth started with its investment in a stable CNC platform: The steady progression of a stable machine / control platform has enabled the company’s similarly growing workforce to build on existing knowledge, rather than learn new and different versions every few years.

New angles on programming

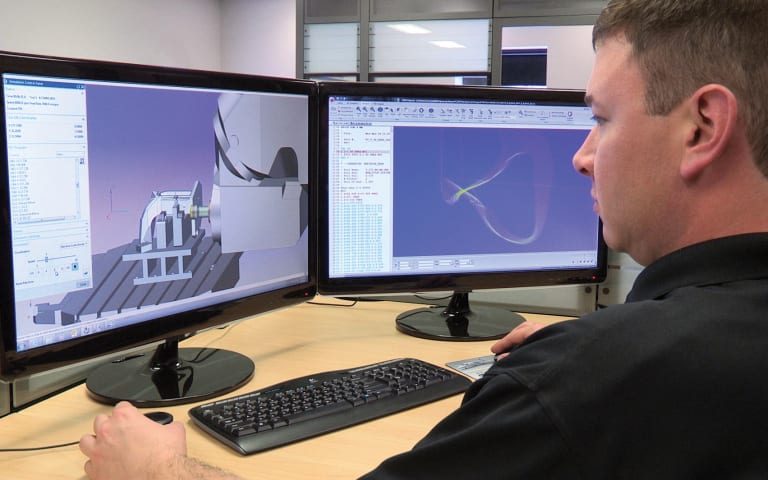

Gerhard Hetzler, engineering manager at Smiths Machine, has experienced firsthand how the company’s singular platform approach has brought continuity to such manufacturing functions as post, machine simulation, NC code, and control functionality.

While the Siemens 840D sl control has evolved in significant ways over the years, Hetzler says these changes have served only to accelerate the performance of the programmers and operators, rather than impede them with new and different procedures. The control platform has also given Smiths Machine the freedom to create custom cycles that can be copied and shared from control-to-control, and so machine-to-machine.

“I’ll give you an example,” says Hetzler. “To catch occasional entry errors on the tool management side, we created a cycle that checks the length of the tool and within a specific tolerance. So within in a matter of milliseconds, the control compares that value to what was entered in the tool management side, and if the tolerance is exceeded by 2mm, the control immediately stops the machine.”

Hetzler says another advantage resulting out of the DMG and Siemens relationship is the continued simplification of complex cutting operations, especially in the area of angular milling heads.

“Siemens has come a very long way to improve the cycles and support related to milling heads,” Hetzler says. “Aerospace requires a lot more use of angular milling. Even a five-axis approach can’t do it. You need an angular milling head. I would put this on the top of my list of the advantages DMG and Siemens have developed. And this relates to another important development, Siemens NX.”

NX as in next

Siemens NX software integrates CAD, CAE and CAM for faster part manufacturing, encompassing all areas of tooling, machining and quality inspection. NX has become integral to Smiths Machine’s CNC platform, because it supports part planning through manufacturing, with the prevention of errors and related costs.

“Our ability to develop all of our own post-processors in house is supported by Siemens NX,” Hetzler explains. “We setup our angular milling heads in NX, so we can post the G-code before we even send it out to the machine.”

An early introduction to the power of NX came when the company found that it needed to write code to produce an especially challenging aerospace landing gear. The code took six-weeks to manually program. This was before the company learned that it could do the same task in nine days using NX.

“Siemens knows five-axis machining and NX is a Siemens product that leverages five-axis,” Hetzler says. “As an example, we can do three-plus-two axes work in NX. There is a cycle for that called Cycle 800. So when NX outputs the NC code, the machine then also understands it. Other control brands will have a cycle that can be made to work, but they are a lot more problematic. We are talking about managing the change of plane, a concept that has been around for a long time and was always problematic to do. Now Cycle 800 in NX does it all for you.”

Hetzler says Cycle 800 makes programming the change of plane easier, faster, and with higher accuracy than traditionally calculated methods. “We would normally round off after the third or fourth decimal,” he recalls. “Now the control calculates to nine decimals. When you start talking microns, especially in the aerospace industry, it makes a huge difference. And this difference has been fully implemented by DMG. They have invested a lot of time and money to make sure from their side that Siemens NX and Cycle 800 work 100% of the time.”

The Cycle 800 function within Siemens NX supports the programming of 2-1/2 axis and 3D milling throughout the rotation of all X-Y-Z planes, while maintaining a zero offset. Functions include automatic shifting of zero offset, tool length and radius compensation in rotated planes, compensation of machine geometry, and all machining cycles can be used.

Please forward all inquiries to:

SIEMENS INDUSTRY, INC.

DRIVE TECHNOLOGIES

MOTION CONTROL

MACHINE TOOL BUSINESS

390 Kent Avenue

Elk Grove Village, IL 60007

Phone: 847-640-1595

Fax: 847-437-0784

Web: www.usa.siemens.com/cnc4you

Email: SiemensMTBUMarCom.sea@siemens.com

Attention: John Meyer, Manager, Marketing Communication

Follow us on Facebook: www.facebook.com/SiemensCNC or Twitter: www.twitter.com/siemens_cnc_us.

—

Siemens Industry Sector is the world’s leading supplier of innovative and environmentally friendly products, solutions and services for industrial customers. With end-to-end automation technology and industrial software, solid vertical-market expertise, and technology-based services, the sector enhances its customers’ productivity, efficiency and flexibility. With a global workforce of more than 100,000 employees, the Industry Sector comprises the Industry Automation, Drive Technologies and Customer Services Divisions as well as the Metals Technologies Business Unit. For more information, visit http://www.usa.siemens.com/industry.

The Siemens Drive Technologies Division is the world’s leading supplier of products, systems, applications, solutions and services for the entire drive train, with electrical and mechanical components. Drive Technologies serves all vertical markets in the production and process industries as well as the infrastructure/energy segment. With its products and solutions, the division enables its customers to achieve productivity, energy efficiency and reliability. For more information, visit http://www.usa.siemens.com/drivetechnologies.

Continue readingMajor Tool & Machine, Inc. retrofitted two of their machining centers in 2010 changing to a CNC technology platform that was completely new to the company. Ten more such large-scale retrofits have followed, bringing increased enthusiasm, momentum and productivity.

Major Tool & Machine has been on track to retrofit over a dozen of its giant milling and turning machines within just two years, all supported by a new Siemens CNC platform. MTM’s management says the process has been an empowering experience for the company.

CNC upgrade enhances performance and precision

Major Tool & Machine (MTM) is a large job shop, producing precision milled and turned hardware throughout the company’s 500,000 square foot Indiana facility. Performance is essential, because MTM contracts with aerospace, energy, nuclear and defense companies on many mission-critical, one-off projects. Owner and CEO Steve Weyreter will tell you openly, MTM is more competitive by way of a significant CNC technology change, starting with an aggressive retrofit strategy.

Günther Zimmermann, CNC Controls Engineer at MTM, says the company’s retrofit program and the decision to change to the Siemens SINUMERIK CNC platform have brought a new enthusiasm and momentum to the company. Over the last two years the change has also brought significant time and cost reductions, especially in the areas of programming, maintenance engineering, and machine operations.

“The initial goal in early 2010 was to retrofit two Cincinnati U5 Gantry machines,” Zimmermann recounts. “We evaluated two CNC technology platforms and after considerable analysis our CEO Steve Weyreter announced that Siemens would best support the company’s future.”

The decision to reduce costs by moving to a single CNC platform was the least difficult decision for the company to make, Zimmermann explains. The larger challenge for MTM was the integration of a new CNC technology platform that was new to the company.

Bill Henderson, MTM’s manager of large machining and maintenance, agrees that the decision to change to a Siemens CNC platform integrated with advanced part and tool probing was critical, because the shop manages constant changeovers from one complex job to the next, making setup times a critical time/cost constraint for the company. Another big advantage is the increased flexibility by only having to train machinists and maintenance personnel on one type of control.

Henderson went on to say “the decision to change to a new control has signaled higher expectations for the company, along with new challenges for those who program, operate and maintain the company’s big machines.

Naturally, there’s a resistance to change,” Henderson says. “People are comfortable with what they normally run, but after our discussions with the people on the plant floor, they understood the overall objective. Our retrofit program is not finished, yet it’s already showing tremendous benefits.”

An advantage MTM gained by its retrofit strategy has been the ability to interchange heads and rotary tables from machine to machine. Easy-to- use head storage and tool management programming provided by the Siemens CNC platform support the new interchange capability.

Retrofitter Doug Huber says having Siemens as a new CNC technology partner has made a difference for Major Tool & Machine, but it’s also been an evolutionary uplift for his own retrofitting company, Indiana Automation.

“Indiana Automation has increasingly retrofit using Siemens controls in recent years, Huber explains. “On a retrofit, we always try to exceed what the original machine could do, and that’s just kind of inherent when you put on a Siemens 840D. Major Tool’s first retrofits were the Cincinnati U5 machines, a bridge model and two gantry models. These are five-axis machines and five-axis is the 840D’s forte. The processing power of the control is so much better, that it just whips through the blocks faster. So right off, cycle time is a major performance enhancement.”

Huber says something else happened this time. As his firm finished retrofitting the first three giant machines with Siemens five-axis controls, drives and motors, the reaction within the company was not just that the machines were now predictably more efficient, but that they performed as very different machines. A new advantage is the ability to interchange machining heads from machine-to-machine, and all driven by the Siemens CNC platform.

Central to MTM’s retrofit program has been the Siemens SINUMERIK 840D sl control, which features the SINUMERIK Operate interface. The highly intuitive interface enables both programmers and operators to easily capitalize on the broad capabilities of the control.

“On many of the U5 machines, the axes come off with the heads,” Huber explains, “and we rebuilt these machines to accept any one of three different heads. That’s one of Major Tool’s key strategies. They insist on having flexible machine capabilities, so that they can run all kinds of different parts. They have straight heads for serious metal cutting, contour heads for five-axis work and finesse work. They have 90-degree heads for more flexibility than a straight head, but it’s also not as fragile as the contour head. And they wanted to interchange all of these heads to automatically go pick up a head out of the shuttle and, on the fly, reconfigure the axes and the zero positions. To do this, the compensation tables all had to be updated. Everything needed to be done with the macro program so that each head came on ready to run.”

The interchangeable head strategy was a challenge, Huber says, because the machines were not originally capable of sharing heads. But with support from Siemens, the strategy has worked, including the ability to interchange rotary tables as well as heads. “Each head or rotary table has a configuration file that has all the settings and compensations and travels with it from machine to machine. So now when you mount that head the control just runs the configuration file that goes with it and its all set up for you. We also incorporated Siemens Tool Management for each machine’s 60-pocket tool chain. We used the feature on these machines to manage all the different tooling MTM uses, both in the automatic tool changer as well as the ones manually loaded.”

Huber says, “MTM’s ability to smoothly transition to more advanced CNC is largely due to the HMI’s ease of use. The Operate interface is a huge help to us and to Major Tool. The HMI helps make better parts. And it didn’t take very long for the operators to fall in love with it.”

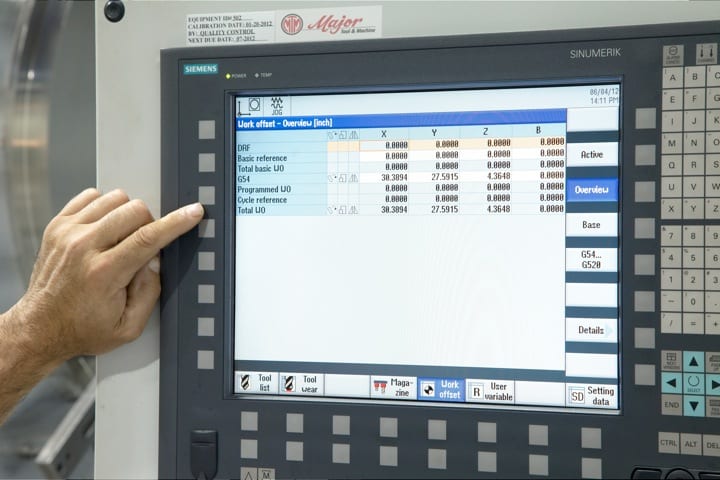

Programming as easy as 1-2-3: Using the SINUMERIK Operate interface, a machinist can turn on coolant flow by 1) pressing Cycle Stop to stop the machine, 2) Coolant On, and 3) Restart.

“I had never used a Siemens control before,” admits MTM machinist Mike Burthay. “I have extensive knowledge of G-code and CNC controls and I would say the Siemens 840D sl with the Operate interface is the easiest one I’ve ever run. It’s user friendly, that’s exactly the words for it.”

Burthay reports several ways in which the Siemens SINUMERIK Operate interface has made his life easier. “There’s not as much G-code,” he says. “The control does it all for you as long as you put in the parameters as to size, length, width. Then once you’re in Job Mode, there’s a screen where you can tool change or jog the machine around to certain positions, or turn the spindle on, turn the coolant on, anything that traditionally required G-code. So now you can push a cycle stop button to pause the machine, enter a change such as turning coolant on, then restart the program.

“Another function I love is Block Search, which allows me to start or restart right in the middle of a program. Say you’re finishing a pocket and you have to run the tool two or three times to get a tight tolerance, I can enter in a line number and hit Block Search, the control picks up every line before that, restarts the spindle and everything for you.”

Burthay says the Siemens control also enables him to program parts right on the machine whenever necessary, using a simple yet robust program called ShopMill. “I can go into ShopMill, type in some parameters and it will kick out that G-code program for me automatically. Say I want to drill a hole two inches deep. I open ShopMill, pick my tool, tell it the depth and these steps are all interactive on the screen. It even shows me 3D motion images of the tool path, confirms the drill going down as expected into the part. So I hit go and it puts a drill cycle into the program for me.”

Programmed for collaborative growth

Lead Programmer, Tim Hayden, has from the beginning conducted all processor setups for the newly retrofitted machines. Hayden says integrating the Siemens CNC platform has been an empowering experience he had not expected, given the fact that he had never before set up a post processor to run a Siemens control, nor had he ever before operated a Siemens control.

“Now, when I look at the Siemens control, I think man, it would have been so much better to have had it all along,” Hayden says, “because the other control I’ve been using is just a lot more cryptic. The Siemens control with the SINUMERIK Operate interface is more powerful for writing macros and the language seems modern, whereas the other control seems like it is still based on an old FORTRAN type language.”

Work offsets for compound angles can be scaled and rotated using the Frames function of the Siemens SINUMERIK Operate interface. Many advanced machining operations can be managed simply, without the use of time-intensive manual G-code programming.

Hayden points to the Frames coordinate and offset programming function of the Siemens interface as an example of improved programming convenience.

“We do a lot of work on compound angles,” Hayden explains, “and with the Siemens Frames function, you can scale and rotate your coordinate system on the control, just plug it in with your work offsets. Whereas, on the other control you will see a G54 request, you’ve got to enter G-code. You can’t just plug it into your work offsets like you can with the Siemens control.”

Hayden says the SINUMERIK Operate interface brings greater programming flexibility. The HMI enables him to enter G-code using a comparatively more advanced manual data entry (MDI) function; however the HMI has all but eliminated the need for G-code entry by way of its intuitive design and evolved capabilities.

Another example of such HMI evolution is in the area of data management.

“When we post a program, we no longer have to use a G-code based MDI,” Hayden explains. “We no longer need to type in T= and enter a nine digit number and then enter M6 to make a tool change. With the Operate HMI, you pick your tool off a screen and hit cycle start. It’s just as easy to program going to a position. Instead of doing things the old way by typing G0X0Y0Z0 into the MDI, you open the Operate interface, click position, then click how you want to wrap it and then you just type the numbers into those fields. So it’s a lot more user friendly.”

Hayden says the Siemens CNC platform has supported greater collaboration at MTM between him and the machinists, and this is helping the company find ways to increase performance and efficiency. He agrees with his coworkers’ assessments that shorter setup times and greater operator freedom are making a significant difference.

“One of our production bottlenecks has been programming,” Hayden says. “The machinists that run our machines are professionals, they’re not button pushers, and with the SINUMERIK Operate interface, we can now rely on them to control and program certain parts right on their machines, while we programmers work on the more complex projects.”

“Siemens was the best fit for all of us,” Hayden concludes. “Siemens CNC is set up as an open control, and with that kind of flexibility, it seems anything is possible.”

For more information on Siemens SINUMERIK CNC, visit www.usa.siemens.com/cnc.

For specific product information and inquiries, call (800) 879-8079 ext. Marketing Communications or send an e-mail to: SiemensMTBUMarCom.industry@siemens.com.

Follow us on Facebook: www.facebook.com/SiemensCNC or Twitter: www.twitter.com/siemens_cnc_us.

—

Siemens Industry Sector is the world’s leading supplier of innovative and environmentally friendly products, solutions and services for industrial customers. With end-to-end automation technology and industrial software, solid vertical-market expertise, and technology-based services, the sector enhances its customers’ productivity, efficiency and flexibility. With a global workforce of more than 100,000 employees, the Industry Sector comprises the Industry Automation, Drive Technologies and Customer Services Divisions as well as the Metals Technologies Business Unit. For more information, visit http://www.usa.siemens.com/industry.

The Siemens Drive Technologies Division is the world’s leading supplier of products, systems, applications, solutions and services for the entire drive train, with electrical and mechanical components. Drive Technologies serves all vertical markets in the production and process industries as well as the infrastructure/energy segment. With its products and solutions, the division enables its customers to achieve productivity, energy efficiency and reliability. For more information, visit http://www.usa.siemens.com/drivetechnologies.

Ann Arbor, Michigan – GMTA (German Machine Tools of America) represents various top-quality German metalworking machine builders, including Wera Profilator, K + G, Pittler, Praewema and WMZ, as well as Arnold lasers and Rosink parts washers. These machines are sold to the North American market exclusively by GMTA, primarily for gear and spline production, as well as other power transmission and various metalworking applications. The company’s target markets include automotive, off-highway, energy and other heavy equipment manufacturing. Machines are provided for gear honing, gear grinding, the patented Scudding® process for gearmaking, polygon milling, turning, gear tooth pointing and multi-task machining operations, as well as various laser operations or laser line integration and parts washing. This newsletter is provided to our friends in the media to keep you and your readers updated on News of Note at GMTA.

In the news…

-GMTA has formed an alliance with Star SU LLC in Hoffman Estates, Illinois to manufacture Scudding® tools for the North American market. Scudding® is the radical improvement on traditional power skiving technology for gear production, long proven in the market to be faster, more accurate and versatile in use. Often thought to be limited to internals only, Scudding is fast beginning to compete in certain applications with hobbing on external gears and splines, as well. David Goodfellow of Star SU signed the agreement with GMTA president Walter Friedrich and VP Scott Knoy.

-GMTA continues to expand its representation of K + G (Kristen + Gormann), a tooling manufacturer in Germany that supplies the industry with products for inside grooving, turning, profile milling, facemilling, geartooth milling, chamfering and back angling. K + G became the third line added in 2014 to the family of manufacturers currently represented by GMTA, joining Arnold lasers and Rosink parts washers.

-GMTA now offers a full integration service for production lines on gears, splines and other powertrain components. Bringing the various machine tool, laser and parts washer lines together, along with robotics, transfer mechanisms and other high-end automation, GMTA engineering has the ability to provide nearly end-to-end capability to many shops and production departments at major OEM’s and Tier vendors. As VP Scott Knoy explains, “We now offer our customers a comprehensive package of equipment, application engineering, tooling support, commissioning and after-sales service.”

-GMTA will be exhibiting at Gear Expo and EMO, this year, the latter in conjunction with partner companies in Europe.

-GMTA is supplying Magna Powertrain a variety of machine tools and systems for its Audi Flex program, both in Muncie, Indiana and Mexico.

-Both Ford and General Motors plants have purchased additional Praewema honing machines for various transmission programs.

-Jernberg Industries, Inc. in Bolingbrook, Illinois has added its fifth Profilator machine for ring gear production.

-GMTA hosted a field trip for the students in the German Clubs at two local schools to the famous Kristkindlmarkt at Daley Plaza in downtown Chicago. The festival is a recreation of the classic German street markets set up for the Christmas season, featuring artisans and craftsmen selling their wares, plus music, food and drink for the season, including gluhwein! The students and their leaders had a good time. Froeliche Weihnachten…that’s Merry Christmas in German. Leading the event for GMTA was the corporate treasurer, Claudia Hambleton. A good time and much gemütlichkeit were had by all!

For more information on this announcement, please contact:

GMTA (German Machine Tools of America)

4630 Freedom Drive

Ann Arbor, MI 48108

Phone: 734-973-7800

Fax: 734-973-3053

Web: www.gmtamerica.com

Email: scott@gmtamerica.com

Attention: Scott Knoy, VP

Connect with GMTA online:

Now for iOS and Android!

You asked and we listened. Our popular Easy CNC app is now available for Android devices. Easy CNC contains all the current training manuals for Siemens Sinumerik CNCs and will ensure that you always have the latest updates.

With no more heavy manuals to carry, you have access to over 4,000 pages of vital CNC instruction and content. In addition, a handy G-code compatibility tool lets you quickly find compatible codes for Siemens and ISO G-codes. The glossary feature is your reference guide to CNC terminology, and web-links to service, support and CNC social media feeds open the door to our online user community. Don’t wait – download the Easy CNC app for iPhone, iPad and Android devices for free.

To download Easy CNC to your mobile device, visit: http://www.usa.siemens.com/cnc-apps

—

For specific product information and inquiries, call (800) 879-8079 ext. Marketing Communications or send an e-mail to: SiemensMTBUMarCom.industry@siemens.com.

Follow us on Social Media:

Twitter: www.twitter.com/siemens_cnc_us

Facebook: www.facebook.com/SiemensCNC

The Siemens Industry Sector is the world’s leading supplier of innovative and environmentally friendly automation and drive technology, industrial software and technology-based services. The Sector’s comprehensive portfolio covers the entire industrial value chain, from product design, engineering and production to services. Siemens enhances its customers’ productivity, efficiency, and flexibility in a wide variety of different industries. With a global workforce of more than 100,000 employees, the Industry Sector comprises the Divisions Industry Automation, Drive Technologies and Customer Services as well as the Business Unit Metals Technologies.

Continue reading