Contact us today:

(847) 934-4500

tdaro@bernardandcompany.com

Contact us today:

(847) 934-4500

tdaro@bernardandcompany.com

New catalogs for Mori Seiki, TSUGAMI and Miyano machines offer standard tools from live tooling leader

Heimatec, a market leader in live tooling for the North American machine tool industry, has released a series of four new catalogs showcasing the company’s lines of machine brand specific tooling.

Already offering the most complete line of live tools available in the industry, with over 40,000 designs in its database, Heimatec machine brand specific tooling includes products for the following popular brands:

Heimatec sets the standard for the highest precision and most advanced technology in the machine tool accessory market. The company is acknowledged as a world leader in live tools, angle heads and multi-spindle drill heads.

In addition to its standard tooling and machine brand specific line, Heimatec also offers custom designed tooling. Heimatec tooling experts work directly with customers to design solutions to suit specific requirements for all CNC lathes, helping to solve the most challenging applications in multiple markets served by the company, ranging from orthopedic devices to oil & gas drilling equipment.

Heimatec North American distribution headquarters are located in Prospect Heights, Illinois (Chicago) with world headquarters plus all manufacturing based in Germany. A team of manufacturers’ representatives covers the North American market for Heimatec.

Visit Heimatec at IMTS 2016, Booth # W-2054 in Chicago.

For more information or to receive a PDF copy of the new dedicated tool catalogs, please contact:

Preben Hansen, President

Heimatec Inc.

16 East Piper Lane, Suite 129

Prospect Heights, IL 60070

847-749-0633

www.heimatecinc.com

phansen@heimatecinc.com

No. 868 is a 500°F (260°C), high-temperature special top-loading oven from Grieve, currently used for testing oil field downhole equipment at the customer’s facility. Workspace dimensions of this oven measure 185” W x 18” D x 24” H. The oven features 34.8 KW installed in Nichrome wire heating elements, while 4000 CFM total from two 2-HP recirculating blowers provide horizontal front to rear airflow.

This Grieve special top-loading oven features 4” insulated walls, aluminized steel interior and exterior, plus reinforced ¼” steel plate workspace floor designed to hold 3600 lbs. distributed load. The oven is supported on six swivel casters with swivel locks and brakes and has a motor-operated, rear-hinged door.

Controls on No. 868 include a digital indicating temperature controller, a manual reset excess temperature controller with separate contactors and a recirculating blower airflow safety switch.

For more information, please contact: THE GRIEVE CORPORATION, 500 Hart Road, Round Lake, Illinois 60073-2835 USA. Phone: (847) 546-8225. Fax: (847) 546-9210. Web: www.grievecorp.com. Email: sales@grievecorp.com. Attention: Frank Calabrese.

Continue readingMajor German supplier of finished length tube and solid bar processing equipment opens its doors in Monterrey/Apodaca to serve the Mexican market with sales, service, spare parts and engineering

Rattunde Corporation President Rick Stadler (front, left), Rattunde Mexico Director Javier Lopez (center, left), Director of Technical Services Renato Luna (center, right) and the team from Rattunde’s new facility celebrate the ribbon-cutting ceremony to open the company’s Mexican headquarters in Monterrey/Apodaca in the state of Nuevo Leon.Rattunde Corporation, the North American arm of a German-based manufacturer of finished length tube and solid bar production systems, has been operating from a single location in the Grand Rapids, Michigan area for over nine years. The company’s considerable success in the market resulted in the recent grand opening of a new facility in the Monterrey, Mexico area to serve its growing customer base in that country.

Rattunde Corporation President Richard Stadler and VP Alec Banish, joined by Rattunde Mexico Director Javier Lopez and his team, proudly opened the doors to the new facility in Monterrey/Apodaca on February 4, 2016.

This new 8,073 square-foot (750 square-meter) tech center houses the Mexican sales and service operations, application engineering and spare parts inventory. Future plans include a machine onsite in 2017 for demonstration and training. This decision to open a tech center in Mexico was reached, after an analysis of the current and anticipated business needs of the company in-country, according to Rick Stadler. “Our growth in America and in Mexico has been rapid, though not unexpected, due to the unique nature of our equipment and the reliability and performance characteristics of our machines. With a solid install base and growing demand for local service in Mexico, this move simply made a lot of sense to us.” Stadler further noted that solid growth of the company into diverse markets throughout North America made the new facility a logical choice. In addition, he said the new machine sales generated directly from Mexico-based management and procurement personnel also contributed to the decision.

This 8,073 square-foot (750 square-meter) facility will be a full tech center with application engineering, sales, service and spare parts inventory. Plans for a demo machine are in the works for 2017.

Concurrent with this new tech center, Rattunde has expanded its workforce in Mexico with technical service, sales and administrative personnel. As Stadler explains, “Whenever a machinery company grows quickly, there’s an ever-present need for more customer service and technical assistance personnel. Of course, new people must be found and trained.” Stadler went on to explain that rapid growth also means working smarter. Rather than waiting for a customer to reach out to Rattunde in a time of need, the company is proactively sending technicians to its customers and performing comprehensive machine inspections, identifying and correcting small issues before they become large ones.

For Mexico, two Rattunde service technicians are now in-country, one operating from the new tech center in Monterrey/Apodaca and another based in Guadalajara.

In the end, Stadler says, “This new facility solidifies our Mexican presence in the high-volume tube and solid bar production markets such as auto, appliance and aero, thus benefiting our current and future customers in many ways. We’re selling to a large number of companies in various markets, in-country, so it was a logical move for us to be here, in many ways.”

Other attendees at this grand opening included Rattunde personnel, sales representatives from the North American network, honored guests from the parent company in Germany, plus customers, prospective business partners and suppliers to the company.

For more information on this development, please contact:

RATTUNDE CORPORATION

5080 Beltway Drive SE

Caledonia, MI 49316

Phone: 616-940-3340

Fax: 616-940-2771

Web: www.rattunde-corp.com

Email: company@rattunde-corp.com

Attention: Richard Stadler or Alec Banish

OR

RATTUNDE MEXICO

Parque Industrial Kalos Encarnacion

Seccion 9 Edificio 1

#132 Ignacio Sepulveda

Apodaca, Neuvo Leon 66633

Phone: +52 81 10860406

Director: Javier Lopez

j.lopez@rattunde-corp.com

Ann Arbor, Michigan – GMTA (German Machine Tools of America) represents various top-quality German and other metalworking machine builder companies, including Profilator GmbH, Praewema, K + G, Rasoma, FIMAT and BvL, as well as Arnold lasers and other equipment. These machines are sold to the North American market by GMTA, primarily for gear and spline production, as well as other power transmission and various metalworking applications. The company’s target markets include automotive, off-highway, energy and other heavy equipment manufacturing. Machines are provided for gear honing, gear grinding, the patented Scudding® and now the game-changing Hard Scudding® process for gearmaking, polygon milling, turning, gear tooth pointing and multi-task machining operations, as well as various laser operations or fully-engineered machine tool and laser line integration. This newsletter is provided to our friends in the media to keep you and your readers updated on “News of Note” at GMTA.

In the news…

GMTA Mexico exhibited BvL parts cleaning technology and our full line of machine tool and laser offerings at ExpoMaq in Leon.

For more information on any items in this announcement, please contact:

GMTA (GERMAN MACHINE TOOLS OF AMERICA)

4630 Freedom Drive

Ann Arbor, MI 48108

Phone: 734-973-7800

Fax: 734-973-3053

Web: www.gmtamerica.com

Email: scott@gmtamerica.com

Attention: Scott Knoy, VP

Customer needed post-assembly validation of fine wire configuration

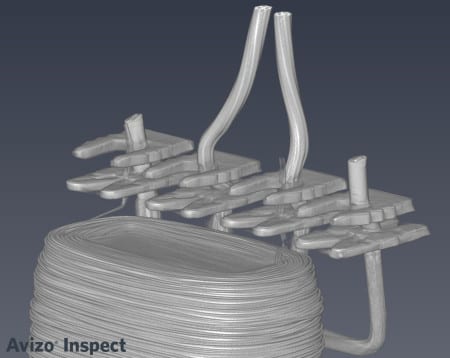

Scans of wire bobbin, showing precise path taken by 0.008” diameter wires inside; scan completed after final assembly of the unit, an inspection process not possible without CT scanning capability

Exact Metrology, working at the company’s Brookfield, Wisconsin location, has successfully used its ProCon industrial CT scanning technology to validate the position of a wire configuration in the bobbin of an electronic lock assembly for one of its customers.

As techician Sean Plastine explains, “A customer came to us to verify the position of a 0.008” diameter wire inside its electronic lock assembly. The position of the wire could not previously be verified while the components of the lock were being assembled. Inspection of the wire bobbin after assembly was also impossible.”

By using its CT scanning technology on the completed lock assembly, Exact technicians were able to determine the wire’s precise position without the need for disassembly or other compromise on the finished article. Any deviation of the wire’s nominal position could be noted, allowing for subsequent changes in the assembly protocol, as needed.

The CT scan clearly shows the path that the wire pair follows inside the lock assembly.

Plastine adds, “We are very excited by the possibilities of this technology, as it’s opening new doors for our contract services at many existing and many more new customers.”

Exact Metrology is an ISO 9001:2008 and AS9100 Certified Company.

For more information on this application or to arrange a demonstration, please contact:

EXACT METROLOGY, INC.

Dean Solberg, President

20515 Industry Avenue

Brookfield, WI 53045

Phone: 262-533-0800

Local: 866-722-2600

www.exactmetrology.com

deans@exactmetrology.com

—

Exact Metrology, with facilities in Cincinnati and Milwaukee and affiliated offices throughout the Midwest, is a comprehensive metrology services provider, offering customers 3D and CT scanning, reverse engineering, quality inspection, product development assistance and 2D drawings. The company also provides turnkey metrology solutions, including equipment sales and lease/rental arrangements.

Continue reading

This Grieve cabinet oven has 6” insulated walls and an aluminized steel exterior. Features include a Type 304 stainless steel, 2B finish interior and one 38” wide x 20” long roller shelf at bottom of workspace rated for 200 lbs. loading.

Controls on the No. 1035 include a digital indicating temperature controller, a manual reset excess temperature controller with separate contactors, plus a recirculating blower airflow safety switch.

For more information, please contact:

THE GRIEVE CORPORATION

500 Hart Road

Round Lake, IL 60073-2898

Phone: (847) 546-8225

Fax: (847) 546-9210

Web: www.grievecorp.com

Email: sales@grievecorp.com

Attention: Frank Calabrese

Machine builder utilizes Siemens hardware, software and communications platform on lines up to 11 layers of co-extrusion; achieving <1ºF of temp variation

Hosokawa Alpine American (Natick, Massachusetts) is a leading supplier of blown film extrusion systems to the North American plastics industry; with standard lines ranging from single-layer to 9-layer co-extrusion. The company recently rolled out its new 11-Layer X-Die line, featuring an advanced zone temperature control system that enables faster changes in recipe and data acquisition to allow on-the-fly adjustments for enhanced production performance. A recent installation of this system at a large multi-national Blown Film Company is already yielding trackable performance improvements at their plant.

Hosokawa Alpine blown film system, the X-Die with 11 lines

As Alpine’s VP of Engineering Jay Ragusa observes, “We had a very successful machine design from the 1990’s and it had performed extremely well, but we saw dramatic improvements in new controls and data transmission technology from our longtime partner Siemens together with their local distributor, Dittman & Greer (Middletown, Connecticut), a specialist in electric temperature systems and machine controls.” Among these advancements, Ragusa notes, are a new zone temperature control system, as well as the Box PC with full automation and visualization software onboard running with WinCC.

Alpine had a “light bulb” moment, as Ragusa explains. “We quickly realized this new system would give us the ability to design a machine with a complete zone temperature control system and remote I/O, plus the necessary hardware and touchscreen HMI to give operators and production management an entirely new approach to in-process control and product quality monitoring”.

The company conducted its due diligence, calling in various competitors for the business. Thorough testing in the Alpine lab pilot plant was conducted, with strong emphasis on component failure analysis, system fault detection and the robust qualities of the competing systems for 24/7 use in the harsh environment of the blown film industry.

“Beyond those benchmarks of evaluation,” Ragusa continues, “we were seeking a system with enhanced flexibility, so we could provide our customers a better way to change recipes in a quicker, more efficient manner, while maintaining a very high degree of product quality.”

Siemens motor and drive assembly, plus PLC and HMI, control the processing and allow fast recipe changes.

After the completed testing and evaluation process in-house at Alpine, the decision was made to move forward with the Siemens system, comprising a new zone temperature control, Profinet communication platform, motors, drives, PLC and touchscreen HMI.

As the new system and other improvements were implemented into the first machine built and test-run at Alpine, a documented higher yield was achieved, with a higher degree of control accuracy. Ragusa notes there is an additional benefit of real-time monitoring and adjustment of all machine conditions.

This new machine included up to 120 separate temperature control zones. According to Ragusa typical systems allow for a 2º-3ºF variation in zone temperatures; with the new system that variation is reduced to less than 1ºF.

Jay Ragusa also details other system improvements made by Alpine on the new machine. “The new industrial flat panel on the PC has a wider screen for easy viewability. Plus, our older system, while modular, had little remote I/O and the new system brings us that benefit, too. The auto-tune function, combined with the better CPU in the PLC, gives us a much stronger package of internal software in combination with hardware. Since we were making the transition within a Siemens protocol, no significant software conversion was required and all data feeds continue on Profinet.”

A temperature accuracy better than 1ºF per zone yields superior, consistent quality in blown films.

Data transmission overall has also improved, he notes, as the communication speeds are significantly faster, plus the open architecture of the system can convey all data to the other departments seamlessly.

Two more advantages of the Siemens system include the plug-and-play remote I/O hardware and the open architecture of the control system. The quick- connect, plug-and-play remote I/O hardware reduces installation, commissioning and replacement time of the system hardware. The open architecture of the control system allows end-user adjustment of control parameters to suit each specific application and stores thousands of recipe data points. Alpine routinely customizes the front end of the controller HMI to facilitate easier customer training and a seamless transition from legacy systems for operators in use. As Ragusa notes, “The field wiring savings alone are incredible, as our machines are fully tested in our facility, then dismantled and assembled onsite at the customer location.”

On the maintenance side, a customer can quickly determine component faults and either take corrective action or literally order a new component from the onboard controller, as the Siemens protocol offers internet connectivity.

For more information on this story, please contact:

HOSOKAWA ALPINE AMERICAN

5 Michigan Drive

Natick, MA 01760

Phone: 508-655-1123

www.halpine.com

Attention: Jay Ragusa, VP of Engineering or Alana Carr, Marketing Coordinator

or

SIEMENS

Digital Factory

Factory Automation

5300 Triangle Parkway

Norcross, GA 30092

Phone: 770-871-3848

www.usa.siemens.com/drives

Attention: Hollie Davis or Alisa Coffey

About Siemens USA

Siemens Corporation is a U.S. subsidiary of Siemens AG, a global powerhouse focusing on the areas of electrification, automation and digitalization. One of the world’s largest producers of energy-efficient, resource-saving technologies, Siemens is a leading supplier of systems for power generation and transmission as well as medical diagnosis. With approximately 348,000 employees in more than 190 countries, Siemens reported worldwide revenue of $86.2 billion in fiscal 2015. Siemens in the USA reported revenue of $22.4 billion, including $5.5 billion in exports, and employs approximately 50,000 people throughout all 50 states and Puerto Rico.

Hahn Automation provides “glocal” solution to ThyssenKrupp damper business for stacking and assembly of assorted product types; enables quick recipe changes

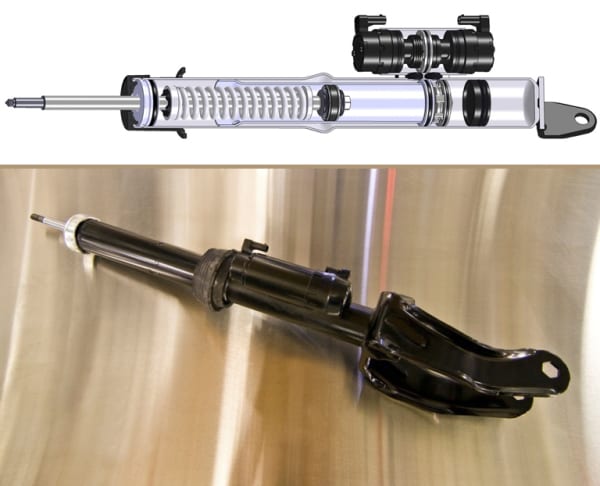

Stackers and 4-axis FlexPickers integrated by Hahn Automation for ThyssenKrupp; used in the flexible production of various shock absorber products for customers like Mercedes, Porsche and other high-performance automobile manufacturers.

ThyssenKrupp Bilstein of America is a leading supplier of premium shock absorbers, struts and suspensions to the auto, truck, racing and other markets. With its recent development of the DampTronic® Sky, which provides continuously variable damping force adjustment of the shock absorber to accommodate road and driving conditions, the company, with U.S. operations based in Hamilton, Ohio, recognized the need for greater flexibility in its production on a global scale. With a substantial assortment of products for OEM and aftermarket alike, ThyssenKrupp required a scenario for fast recipe changes, with flexible and high-accuracy production of frequent short runs to suit its product demands in the market.

Further, with global operations in its manufacturing, the company sought to partner with an automation supplier who would mesh well with the culture of ThyssenKrupp and the engineering requirements this challenge presented. The solution came their way in Hahn Automation, based in Germany, with its U.S. operations headquartered nearby to ThyssenKrupp’s damper business, in Hebron, Kentucky.

The DampTronic® Sky technology from ThyssenKrupp provides constant variable pressure, adjusted in milliseconds to accommodate road and driving conditions, utilizing two continuously variable valves to adjust the damping force in both extension and compression modes.

This combination provided what Dave Vibbard, Senior Process Engineer at ThyssenKrupp terms a “glocal” relationship, a portmanteau word made from global and local. Correspondingly, John Baines, president of Hahn Automation, says, “We also work under the philosophy that we should build it where it gets used, so we needed a partner for the controls and application engineering assistance who could work seamlessly with both our German and U.S. operations. We found that supplier in Siemens and their local solution partner, C&E Sales.” For the project, the control supplier furnished all drives, PLCs, master HMI and remote control pendants to give freedom of movement to the operators, as they work around the cell stations. Siemens and C&E Sales also provided Hahn their application engineering assistance and the TIA Portal, an engineering network from Siemens which allows all programming of motion controllers, distributed I/O, HMI and other devices through a single point of command. In addition, TIA Portal maintains a library with the operating protocols, hardware designations and performance characteristics of task-specific projects, enabling subsequent recall, system reconfiguration on-the-fly and substantial engineering time savings for the integrator and end user alike. Hahn was able to utilize the TIA Portal at every step in the configuration and commissioning of the work cells devised for ThyssenKrupp on this project. As Baines notes, “The diversity of products being produced were all nonetheless similar in nature and mechanical composition, so many of the motion control commands and assembly sequencings could be done using the library of programmed information in the TIA Portal. Siemens provided us considerable assistance on this project, though we had previous experience with this engineering network.” Baines further notes the TIA Portal resulted in significant cost and time savings for Hahn and ultimately the end user.

Siemens drives, HMI, remote operator pendants and PLC technology operate the system. Hahn utilizes the Siemens global support of its products, while sourcing many components locally, thus the term “glocal” was coined.

On this project, Hahn provided ThyssenKrupp the first of several cells, comprising six “valve stacker” modules for the pre-assembly, kitting and riveting of the shock absorber washers and piston rod assemblies, plus the gas and oil fill, welding and functional testing procedures. For each model produced, an assortment of washers with various profiles and dimensions is stacked on the piston, assembled and then the shock absorber body is filled with gas and oil, all to pre-programmed levels. The “recipe” for each model made is stored in the HMI onboard, which drives the individual module PLCs. At each station in the cell, an operator can instantly visualize the recipe in progress and enjoys the free movement around the cell, using the remote control pendant. As the model changeover is required, the master recipe exports the particular data requirements to each module, and then the ramp-up of the overall cell begins anew. Washers of various sizes and profile configurations are used for the buildup of each model produced, so the required components are brought to the assembly stations by a series of 4-axis ABB iRB 360 FlexPickers and ceiling mounted Epson G10’s, utilizing Selective Compliance Articulated (Assembly) Robot Arm (SCARA) technology. Functionally, the various commands are executed via the PLC, an S7-1500 from Siemens, which features seamless integration with the TIA Portal, as well as fully integrated onboard safety and security modules.

As Baines explains, “The setting adjustments are quite substantial for each damper product produced, so the load on the control system required strict monitoring and validation. There’s the master cell with six modules, including four valve stackers and two final assembly stations. Interestingly, half our design and assembly work was done in Germany and half was done here in Hebron, Ky., where we also did the final configuration of the control platform, runout and performance evaluations prior to delivery to ThyssenKrupp.” He noted the support provided by Siemens, both in Germany and local to his facility. Baines also cited the upgrade to the higher level Simatic S7-1500 PLC as a significant advantage for Hahn in the overall achievement of this project’s success. He particularly noted the safety and system security features, plus the fast response time and easy commissioning of this PLC platform for his team and TK personnel.

Greg Earle, VP for sales at Hahn, adds, “The Siemens TIA portal was a terrific engineering tool, as we were able to configure all the motor and drive components in a tag-based protocol for the individual slave PLCs and the master HMI. It was a very fluid connection process and, in the field, the operators enjoy the added benefit of movement, using the remote pendants provided with the system.” As each recipe is called up, he added, the changeover time is significantly reduced, compared to the previous systems in use at ThyssenKrupp. The single supplier for the new component feed systems is located in Germany, so the presence of both Hahn and Siemens there was a further advantage to TK on this project.

Vibbard of ThyssenKrupp comments, “Hahn was extremely competent and also price-competitive on this project, a very desirable combination in any business relationship. They were able to complete the build and execute the handshaking between the modules, with full verification on performance, error tracking, safety considerations, fault recovery and alarm alerts.” He noted an extra benefit on the operator screens was a dual language capability, so immediate access and troubleshooting could be accomplished by the engineering teams both in Germany and America.

In use, all the communications in the cell, whether from the robotics PLC, Siemens hardware and software systems or Hahn proprietary logic, are transmitted on a field bus to a single point of control and command, according to Vibbard, who cites this seamless protocol as a significant upside for our process engineers and maintenance personnel alike. “The assembly and testing procedures are all TCP/IP friendly, so the cell controls are easily accessible both by our team and remotely by Hahn for troubleshooting and faster resolution of any issues.”

Washers of various sizes are stacked on a piston rod for assembly, with differing levels of air and oil fill to suit the specifications of the individual products at ThyssenKrupp; modular, programmable work cells provide great flexibility in production.

According to the official ThyssenKrupp description of the new shock absorber technology that partially drove the development of this project, “The new DampTronic® Sky damper (shock absorber) is a further milestone in resolving the conflict between driving comfort on the one hand – an aspect of particular interest in the premium segment – and the driving safety and agility of the car, on the other hand. In this new generation, two continuously variable valves adjust the damping force in each damper: one valve controls the rebound phase – i.e. the force that ensues when the wheel travels down – and the other controls the compression phase. Using the data it receives from the acceleration and wheel-path sensors, the control module of the suspension system can individually adapt the damping forces for each wheel within just a few milliseconds to eliminate the effects of rough road-ride conditions that may detract from the driving comfort for the passengers, while at the same time controlling the dampers in such a way that the chassis is stabilized to the best possible degree. Thanks to the use of two adjustable valves, the damper is also able to ensure that the damping force can be adjusted according to the skyhook principle even in the high-frequency spectrum of the wheel vibrations. By independently adjusting the extension and compression forces, the new ThyssenKrupp DampTronic® Sky damper constitutes the high-end system in the semi-active damper segment.”

The customer here, ThyssenKrupp, expects significant improvements in the production schedules with the Hahn Automation master cell on the floor at the facility in Hamilton, Ohio.

Baines concludes, “The relationship we established with and the solution we proposed to ThyssenKrupp would not have been possible without the assistance of the Siemens team, both here in our area and in Germany, supplying product, engineering know-how and controls expertise in both locations.”

A “glocal” success, indeed.

For more information on this story, please contact:

SIEMENS

Digital Factory

Factory Automation

5300 Triangle Parkway

Norcross, GA 30092

Phone: 770-871-3848

www.usa.siemens.com/drives

Attention: Hollie Davis, Sandra Tigert or Alisa Coffey

Or

HAHN AUTOMATION

3012 Kustom Drive

Hebron, KY 41048

Phone : 859-283-1820

www.hahnautomation.com

Attention : John Baines

Or

THYSSENKRUPP BILSTEIN OF AMERICA

8685 Bilstein Boulevard

Hamilton, OH 45015

Phone: 513-881-6394

www.bilsteinus.com

Attention: Fabian Schmahl or Dave Vibbard

About Siemens USA

Siemens Corporation is a U.S. subsidiary of Siemens AG, a global powerhouse focusing on the areas of electrification, automation and digitalization. One of the world’s largest producers of energy-efficient, resource-saving technologies, Siemens is a leading supplier of systems for power generation and transmission as well as medical diagnosis. With approximately 348,000 employees in more than 190 countries, Siemens reported worldwide revenue of $86.2 billion in fiscal 2015. Siemens in the USA reported revenue of $22.4 billion, including $5.5 billion in exports, and employs approximately 50,000 people throughout all 50 states and Puerto Rico.

Product demonstrations and technical presentations from principals impress large crowd at dual open house

On March 17, 2016, Exact Metrology held a tech event in Cincinnati, Ohio with partner company, 3DVision Technologies at both of their offices. Held on St. Patrick’s Day, the event was cleverly titled “Lunch, Learn & Luck,” and had a “March Madness” theme with basketball games playing on multiple widescreen televisions. The event was attended by over 100 people from local area industries, including automotive, aerospace and consumer goods.

Co-Hosted by Steve Young, Exact Metrology co-founder and President, and Todd Majeski, President of 3DVision Technologies, the day included presentations and product demonstrations of the newest products transforming the manufacturing industry in 3D printing and 3D scanning. The informative event provided insight and hands-on experience, while displaying the newest technology that is reshaping the traditional manufacturing process.

The day began at 3D Vision Technologies office, (a provider of engineering solutions & 3D printing for manufacturing companies), with a presentation by Todd Majeski. Majeski discussed the company’s long-term partnership with Exact Metrology, and how both companies work together to improve processes, increase quality, and get their customer’s products to market faster through 3D scanning and reverse engineering. After several presentations and a question-and-answer session, attendees were welcomed into a showcase of 3D printer demonstrations and product displays of printed samples from miniature to lifesize versions, including a skateboard, helmet, and an automotive front grill.

The second part of the tech event was held at Exact Metrology’s office, conveniently located just a short walk away. Participants walked together and, after a St. Patrick’s Day themed lunch, began the afternoon session with a presentation by Steve Young. Young discussed the newest technology in CT (Computed Tomography) scanning systems, which allows users to not only scan the outside of a part, but to actually see inside of it without taking it apart, or damaging the item. Until recently, this technology was used primarily in the medical field but is creating much excitement within a variety of industrial markets now, as it enables manufacturers to check for defects, internal contact points after assembly, porosity and dimensional accuracy, comparing actual scans to point cloud data, CAD files etc. According to Young, this type of 3D scanning has been a “huge success” for his company, which he co-founded with Dean Solberg, who runs the company’s facility in the Milwaukee area.

Products displayed at the event included the P40 Leica Scanner, a long-range scanner, which, according to presenter Jacob Wallace, Processing Engineer at Exact, can be set up and ready to scan in 30 seconds. The scanner has a 150-meter range and will show everything in the surrounding area. Wallace recently scanned an entire office to make an accurate 3D model, complete with windows, doors, ceiling and wall thickness. Other uses of these long-range scanners include collecting topography of roadways (without stopping traffic) and large buildings of 500,000 square ft. or more, to collect information inside and outside of the building, all within a reasonable timeframe.

Other products displayed and discussed at the expo were the Romer Absolute 77, an Articulated Arm with a Laser Line Scanner, the Atos Triple Scan, the Artec EVA Handheld Portable Scanner and the NDI ScanTrak Large Volume Laser Scanner.

Exact Metrology ended the afternoon with a St. Patrick’s Day raffle, with two lucky attendees winning a 48” high-def television and a MakerBot 3D printer.

Exact Metrology offers a complete line of portable scanning and measurement technologies as well as contract measurement for 3D laser scanning services, reverse engineering services, non-contact inspection, metrology services, 3D digitizing and training.

For more information on this new equipment, please contact:

EXACT METROLOGY, INC.

11575 Goldcoast Drive

Cincinnati, Ohio 45249

Phone: 513-831-6620

Toll Free: 866-722-2600

www.exactmetrology.com

stevey@exactmetrology.com

Steve Young, President

Exact Metrology is an ISO 9001:2008 Certified Company.

—

Exact Metrology, with facilities in Cincinnati and Milwaukee and affiliated offices throughout the Midwest, is a comprehensive metrology services provider, offering customers 3D scanning, reverse engineering, quality inspection, product development and 2D drawings. The company also provides turnkey metrology solutions, including equipment sales and lease/rental arrangements.

This Grieve inert atmosphere furnace has a roof-mounted, heat-resisting alloy circulating fan powered by a 1-HP motor with V-belt drive, water cooled bearings and inert atmosphere shaft seal. Furnace features include 9” thick insulated walls comprised of 5” of 2300°F ceramic fiber and 4” of 1900°F block insulation; 8 ½” floor insulation comprised of 4 ½” of 2300°F firebrick and 4” of 1900°F block insulation. Other features include ¼” plate exterior reinforced with structural steel, ½” steel face plate at doorway with air-operated vertical lift door. Inert atmosphere construction includes continuously welded outer shell, high-temperature door gasket, sealed heater terminal boxes, inert atmosphere inlet, inert atmosphere outlet, inert atmosphere flow meter and manual gas valve.

Controls on No. 1039 include a digital programming temperature controller, a manual reset excess temperature controller with separate contactors, paperless event recorder and SCR power controller.

For more information, please contact:

THE GRIEVE CORPORATION

500 Hart Road

Round Lake, IL 60073-2898

Phone: (847) 546-8225

Fax: (847) 546-9210

Web: www.grievecorp.com

Email: sales@grievecorp.com

Attention: Frank Calabrese, VP