Contact us today:

(847) 934-4500

tdaro@bernardandcompany.com

Contact us today:

(847) 934-4500

tdaro@bernardandcompany.com

Guill Tool, the global leader in extrusion tooling, now offers a wide variety of extrusion equipment specifically for food processing. Extrusion is increasingly becoming one of the primary methods of producing a variety of traditional and innovative food products, and the company’s extrusion tooling is designed to accommodate producing all of them. From pastas, hot dogs, and snack foods to chewing gum, licorice, and pet food, Guill’s balanced flow designs control dimensional tolerances in order to increase product quality while reducing waste.

Custom-made extrusion tooling and dies make it easy to efficiently and consistently manufacture a variety of food products. More precise tooling allows for considerably reduced wasted extrudate. Furthermore, Guill’s extrusion tooling enables precise temperature control, allowing food to be manufactured under both high and low temperatures.

Intended to increase tube wall strength, the 300 Series heads achieve concentric heads at all speeds. Additional features include low inventory/quick color change and elimination of secondary stage processing. The company’s 600 Series crosshead offers flexibility in design and extruder orientation with split balanced flow, while the 700 Series is fully adjustable and accepts existing tooling.

Guill’s 800 Series simple crosshead can be configured to be fixed center or adjustable, featuring built-in cartridge heaters and a low volume split feed balanced flow. The 900 Series Spiderless in-line head offers simplicity and fewer parts with a low volume split balanced flow. Lastly, the Bullet™ is suitable for high and low-volume applications and is accommodated with the simple, easy changing of just one component.

For more information, please contact:

Tom Baldock

Sales Manager, Extrusion

Guill Tool & Engineering

10 Pike Street

West Warwick, RI 02893

USA

Phone: 401-465-5526

Email: tbaldock@guill.com

The Siemens Machine Tool Business sadly announces the death of Randy Pearson, 70, on May 21, 2024 in Reno, Nevada, following a long battle with lung cancer. Randy had recently retired after more than 20 years with Siemens, where he served as dealer support manager … and much more.

As Motion Control group VP Rajas Sukthankar notes, “When I think of Randy, I think of my good fortune in life to work with an individual that cared as passionately and deeply about his work as I do. I first met Randy when he was hired as an application engineer at Hyundai Machine Tools in 1995. Our association went back over two decades. I had the chance to work with him as both a customer and a valued Siemens employee. As a skilled machinist himself, Randy trained and educated a generation of new machinists in his career. I treasure the time I spent working with Randy and will miss his infectious laugh and energy.”

Randy’s associate in machine tool training at Siemens, Chris Pollack, recalls, “I was always amazed how he remembered everyone’s name. Walking around a trade show with Randy was like being with the mayor of the town. Everyone knew him and, more importantly, he knew everyone. He was always there to help others and he surely helped me a lot in my career.”

Marion Kica, executive assistant at the Siemens Machine Tool headquarters in Elk Grove Village, IL adds, “He always brightened my day with his humor and good cheer, plus he was there to handle all the engineering questions callers would have. He was a kind, supportive friend who took his responsibilities very seriously but could still find humor in life’s ups and downs.”

John Meyer, head of marketing communications for the motion control group, was a close associate of Randy’s throughout all his years at Siemens. He notes, “As a marketer, when I came to Siemens, I had a challenge to learn about machine tools and manufacturing technologies such as CNC. I wasn’t an engineer, so Randy took me under his wing to teach me what I needed to know to be successful in my career. It became a technical education over 20+ years and I’m very thankful for the knowledge Randy instilled in me.”

During his long career in the machine tool industry, Randy served as an applications engineer or sales manager at such leading companies as Bridgeport, Toyoda, ROMI, Kitamura and Hyundai, as well as machine tool dealer Iverson & Company.

Always willing to share the talents he possessed, Randy authored regular CNC expert advice columns that appeared in several machine tool magazines, over the years. He brought a wealth of technical expertise in CNC technology along with his hands-on practical experience as a machinist, when giving his help to the industry.

A native of Chicago, Randy and his wife Susan, whom he met when they both worked at Bridgeport, were married 34 years and had two children.

Following in his dad’s footsteps, Randy’s son Jeremy has now been with DMG machine tools for 10 years.

After his retirement from Siemens, Randy and Susan decided to “go west” and landed in Reno.

A memorial service for Randy Pearson will be held at 11 AM Central on July 13 at United Methodist Church in Roselle, IL. Donations can be made to the American Cancer Society at www.cancer.org or the American Lung Association at www.lung.org.

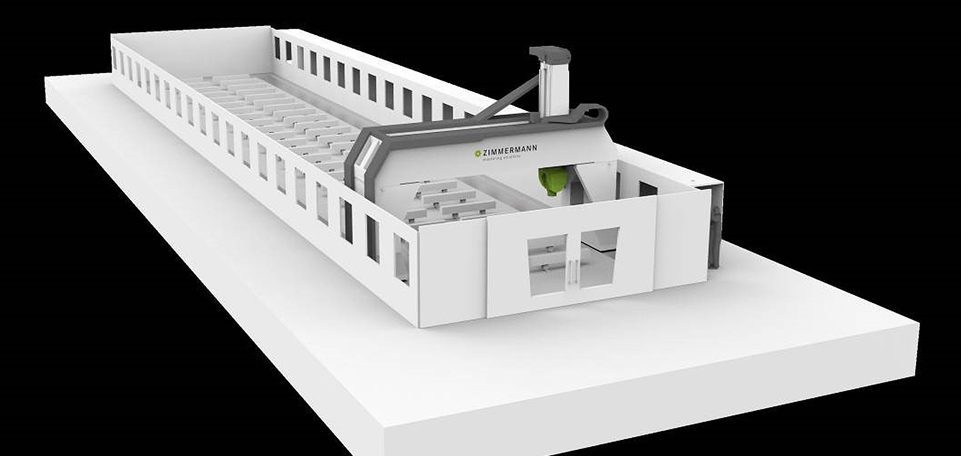

With the FZG, Zimmermann introduces a portal milling machine with a low rail gantry

With the new machine line FZG, Zimmermann has added a 5-axis portal milling machine with a low rail gantry to their portfolio, which is well-suited to process particularly long components. Accessible from the side, the FZG allows easier loading and unloading processes. The developers were utilizing the well-proven thermo-symmetrical portal concept and modified its basic design, resulting in a distinct benefit. With the FZG, the user will receive a stable system which provides the highest precision, even when processing large and long components.

“Especially in future-oriented industries such as the aerospace, energy or rail sector, producers must be able to efficiently process large and, above all, particularly long components. We have recently received many more requests with these exact requirements,” reports Daniel Demlang, technical leader at Zimmermann. To meet the needs of the market, the machine manufacturer developed this new machine series, the FZG, in line with customer specifications. For this line of machines, the engineers relied on the innovative concept of the thermo-symmetrical design, which has already proven its worth with the Zimmermann machine lines FZP and FZU. However, the engineers redesigned its base structure. “We lowered the machine onto ground level, enabling the portal to be moved horizontally in almost any desired length,” explains Mr. Demlang. Zimmerman can adjust this design for any custom application. Therefore, the line is suited for processing complete components, such as wing structures for the aviation industry, entire railway wagon side sections for the rail sector, tanks in the energy sector, exterior components for the aerospace industry as well as components for the defense industry.

With the new FZG machine line by Zimmermann, large and long components can be manufactured with highest precision.

The proven modular system from Zimmermann acts as the base structure of the new FZG line. It offers many different length and height variants as well as extensive equipment options, such as process cooling with minimum quantity, lubrication or an onboard movable vacuum dust extraction system for abrasive materials and plastics. An onboard movable tool changer is standard. The energy supply and covers are recessed into the floor.

“The thermo-symmetrical design makes the machine less vulnerable in adverse environmental conditions,” continues Cornelius Kiesel, president of Zimmermann in America. The idea behind this is that incurring thermal influences can be substantially absorbed by the machine structure itself. “To achieve this, we appropriately designed and intelligently arranged all structural and drive unit components, guides and other components responsible for accuracy, for all the machines in our extended portfolio. This way, the structure can expand in non-critical directions,” says Kiesel. The centrally guided Z-slide of the portal in double-bridge construction makes the machine particularly stable. By using this design, Zimmermann achieves very high rigidity. Since there isn’t any possibility of one-sided temperature rise, accuracy is greatly increased, thus making the machine line suitable for very high-precision applications.

“For us, this combination of thermo-symmetrical machine design and the modified base structure was a logical next step,” says Mr. Demlang. Because the core machine relies on proven technology, this development was possible in a relatively short timeframe. Additionally, the synergetic benefits of the FZG, due to the existing portfolio, also have a positive impact on the profitability of the machine.

About the company

Zimmermann is based in Germany and is a leading global high-tech supplier of portal milling machines. These are characterized by huge workspaces, substantial machining dynamics and cutting performance. The company, founded in 1933 by Friedrich Zimmermann, now has over 200 employees worldwide. With its product range, our innovative company has one goal above all: to offer the right solution for our customers and thus be able to guarantee high economic efficiency. “Quality made in Germany and supported locally” is our motto. The company’s special machines are used worldwide in the automotive, aerospace, moldmaking, transportation, off-highway and mechanical engineering sectors. The company has its North American headquarters in Wixom, Michigan, near Detroit, where it operates a full tech center, offering engineering assistance, commissioning, parts and retrofit services, as well as multiple machines for demonstration purposes. Zimmermann Inc. is headed by President Cornelius Kiesel.

For more information, please contact:

ZIMMERMANN INC.

30587 Century Drive

Wixom, MI 48393

Phone: 248-956-8511

www.zimmermann-inc.com

Ms. Lena Kiesel, Marketing Manager

lena@zimmermann-inc.com

Developed in 1998 with guidance from the International Fastener Institute, the CFS advanced technical training program is the most noteworthy measurement of technical aptitude for fastener professionals. With more than 1,400 alumni of the CFS program, the Fastener Training Institute has helped professionals and businesses nationwide advance the fastener and manufacturing industries by improving safety and championing professional development.

Wanting to further his education on the technical side of fastener related products, Lindsly-Roach participated in the CFS program. To receive the designation, participants must complete seven full-day training sessions or a weeklong intensive Fastener Training Week program (offered throughout the year) and pass a final exam. Classes feature topics such as: fastener specifications/terminology, dimensional/material specifications, the bolted joint, quality assurance and testing. Furthermore, the intensive training also includes plant tours.

Between December 4-8th 2023, Lindsly-Roach participated in the Fastener Training Week. Then, he took the CFS test mid-December. Upon passing, Lindsly-Roach received the CFS title/plaque. Commenting on how the certification adds value to his work at the company, he said, “This certification helps me be a more complete technical resource to our team at E-Z LOK on a variety of fastener related topics. It was also a great opportunity to network with like-minded individuals and companies in the fastener industry.”

For more information, please contact:

Kyle Lindsly-Roach, Director of Sales & Marketing

E-Z LOK

240 E. Rosecrans Ave

Gardena, CA 90248

USA

Phone: 310-323-5613 x221

klindsly@ezlok.com

www.ezlok.com

E-Z LOK is a leading manufacturer and master distributor of threaded inserts for metal, plastic and wood. Inserts for metal include solid wall and helical wire-thread inserts, while inserts for plastic feature press-in and ultrasonic/heat stake designs. Those for wood are die cast zinc alloy hex drives for softwood and brass knife threads for hardwood. A variety of kits for the above inserts are available and feature installation tools, drill bits, etc.

E-Z LOK is a third- generation family owned and operated company. Founded in 1956, it primarily sells through local, regional, and national industrial distributors.

Guill Tool, the global leader in extrusion tooling, offers their patent pending extrusion tooling, Series 400. It’s adaptable to a wide variety of corrugated equipment and molds. The Series offers a host of benefits for OEMs, as well as for automotive and medical applications.

The unique tooling includes the multi-port spiral flow design that provides a balanced compound distribution with no weld lines to the corrugator. The elimination of weld lines significantly increases the finished product’s overall strength.

Models offered include 420, 423, 432 and 434. Features of the 400 Series include Spiderless Inline, fixed center or adjustable, built in cartridge heaters, adjustable gum space, low inventory, expandable to multi-layer, heated core pin and one-piece body/flow diverter.

Since there are no spider lines, there’s room for more air and no cold legs. Most products should be run fixed. Users can change only one component and become fully adjustable. The cartridge heaters offer even heat for better flow and ensure there aren’t any cold spots. More control of product size is achieved with adjustable gum space. Low inventory results in no burning or stagnation-quick color change. Due to the fact that it’s expandable to multi-layer, the crossheads run a variety of products. Lastly, benefits of the heated core pin and one-piece body/flow diverter are better temperature control and easy cleaning-quick changer, respectively.

For more information, please contact:

Tom Baldock, Sales Manager, Extrusion

Guill Tool & Engineering

10 Pike Street

West Warwick, RI 02893, USA

Phone: 401-465-5526

tbaldock@guill.com

Bringing together a number of its hardware automation, digitalization software and services, Siemens will present the new path towards digitalization for machine tool users and machine builders

At the upcoming IMTS 2024 in Chicago, September 9–14, Siemens will present its extensive machine tool CNC portfolio and digitalization software technology, highlighted by the digital native SINUMERIK ONE control platform for machining applications. Also, using a sports theme of “Speed, Agility and Endurance,” aimed at the machine shop on its path to digitalization, Siemens will introduce MACHINUM to the North American market. MACHINUM brings together machine tool controls, digitalization software and machine shop services from Siemens to help manufacturers optimize their production processes, to provide agility for quick adaptation to changing customer requirements and calculated uptime needs, plus enable digitally proven endurance to maximize the productivity of the entire machine shop or production department.

Detailing the elements of MACHINUM:

Speed

Siemens adaptive feedrate control reduces cycle times, while maintaining a stable machining process. This results from instantaneous and continuous analysis of the current cutting conditions on a machine tool in real time, automatically optimizing the feedrate.

Agility

Through strategic digitalization and software that seamlessly integrates the machine tool CNC systems and a shop’s internal communications, MACHINUM can significantly boost the agility of a machine shop or production department to accommodate changes in design, quantity output and even machining characteristics, based upon customer input and overall production and workflow landscape characteristics.

Endurance

Continuing the sports theme, over the long “run”, MACHINUM enables a heightened level of maintenance capability with leading “edge” machine monitoring that anticipates potential issues before they escalate. This results in reduced cost and substantially less downtime on machines, due to unplanned maintenance. This feature is especially useful for linked and sequential production lines.

MACHINUM also offers substantial benefits to machine builders, as Siemens integrated digital twin technology allows more streamlined off-machine programming and machining simulation in an office environment. This approach facilitates faster prep time, more accurate design specs on the final machine, faster component acquisition near the build time and a reduction in costly downtime, due to last-minute design changes, as those are anticipated, simulated and resolved, all in a virtual world. MACHINUM also represents the integration of existing Siemens digitalization software such as Create MyVirtual Machine, Run MyVirtual Machine, Adaptive Control and Monitoring (ACM), Analyze MyWorkpiece and Manage MyMachines.

Under the theme “Empowering the Digital Machine Shop”, Siemens will display its digital threads, from blueprint to finished part, digital twin to simulation, part production, as well as the total integration of these processes into the digital factory for job shops and production departments, all brought to life by Siemens hardware automation and digitalization software.

eRod Continues Its Path

Building off the successful rollout of its eRod “electric buggy” at IMTS 2022, Siemens will further demonstrate the end-to-end production of the aluminum wheel rim and gear housing for this electric vehicle on display in the booth. The wheel rim is made by traditional 5-axis and multi-technology machining (mill-turn, turn-mill) and the gear housing is manufactured through additive/subtractive machining processes. At every stage of each part’s development, including machining, displays will take visitors through the digital manufacturing process. From the popular Siemens NX CAM software, which enables the use of 3D models, data and processes to seamlessly connect planning and shopfloor operations, to the powerful SINUMERIK ONE, the digital-native CNC that permits a digital twin of the machine tool and its full operation in production, Siemens has streamlined machine shop operations as well as leading automotive, aerospace, off-highway, medical part and myriad consumer durable production facilities worldwide.

Additional highlights of the Siemens booth will include:

Aimed at developing a complete eco-system for the machine tool builder and end-user, the Siemens Xcelerator portfolio brings together the breadth of engineering and manufacturing to provide the optimum solution for customers of any size in any industry.

Digitalization solutions will shorten the machine tool builder’s time-to-market through Digital Twin technology, where all machine design and operational kinematics are simulated prior to the machine being built. This development enables substantial savings for the builder and end-user alike — not only in the design, building and commissioning, but also during the startup and training phases of machine implementation.

With SINUMERIK ONE, Siemens is accelerating the digital transformation of the machine tool industry. The new CNC control platform works with software to create the machine controller and the associated digital twin from a single engineering system and thus contributes to the total integration of hardware and software. Thanks to its seamless interaction between the virtual and real worlds, including high-performance PLC, drive and motor hardware, SINUMERIK ONE is setting new standards in terms of productivity, performance and digitalization. It is the future-proof machine controller in the increasingly digital world of manufacturing.

With Create MyVirtual Machine and Run MyVirtual Machine, SINUMERIK ONE is provided with software to create the universal concept of the digital twin, powerful hardware and integrated IT security, making it a forward-looking CNC.

Using Mcenter, the open and modular platform for efficient shopfloors, end-users can seamlessly link all their machine tools and network with company’s IT landscape.

Finally, a fun highlight at this year’s show, Siemens will hold a golf putting contest and raffle two putters twice daily during IMTS 2024. The putter heads will be machined utilizing Siemens CNC hardware automation and digitalization software and feature custom engraving.

For more information about Siemens at IMTS 2024, please visit: https://usa.siemens.com/imts

For more information about the new MACHINUM portfolio, please visit: https://usa.siemens.com/machinum

Siemens Digital Industries (DI) is an innovation leader in automation and digitalization. Closely collaborating with partners and customers, DI drives the digital transformation in the process and discrete industries. With its Digital Enterprise portfolio, DI provides companies of all sizes with an end-to-end set of products, solutions and services to integrate and digitalize the entire value chain. Optimized for the specific needs of each industry, DI’s unique portfolio supports customers to achieve greater productivity and flexibility. DI is constantly adding innovations to its portfolio to integrate cutting-edge future technologies. Siemens Digital Industries has its global headquarters in Nuremberg, Germany, and has around 75,000 employees internationally.

Siemens Corporation is a U.S. subsidiary of Siemens AG, a global powerhouse focusing on the areas of power generation and distribution, intelligent infrastructure for buildings and distributed energy systems, and automation and digitalization in the process and manufacturing industries. Through the separately managed company Siemens Mobility, a leading supplier of smart mobility solutions for rail and road transport, Siemens is shaping the world market for passenger and freight services. Due to its majority stakes in the publicly listed companies Siemens Healthineers AG and Siemens Gamesa Renewable Energy, Siemens is also a world-leading supplier of medical technology and digital healthcare services as well as environmentally friendly solutions for onshore and offshore wind power generation. For more than 160 years, the company has innovated and invented technologies to support American industry spanning manufacturing, energy, healthcare and infrastructure. In fiscal 2018, Siemens USA reported revenue of $23.7 billion, including $5.0 billion in exports, and employs approximately 50,000 people throughout all 50 states and Puerto Rico.

Sharing a booth with its sister company TCI Precision Metals

E-Z LOK, a leading manufacturer and master distributor of threaded inserts for metal, plastic and wood will display its products during IMTS 2024, in Chicago, September 9-14 in Booth 432123. The company will be co-located with its sister company TCI Precision Metals, a leading supplier of metal materials and near-net shapes to machine shops and fabricators. Highlight of the show for E-Z LOK will be its new line of ultrasonic/heat-stake metal inserts and staking tools for plastics, which can be used for OEM builds as well as retrofits and even injection molding over core pins for creation of strong components with higher torque and pullout strength in use.

In addition, the full line of E-Z LOK threaded carbon inserts with factory-applied LOCTITE™ 204 adhesive coating will be displayed. Once installed in a metal substrate for repair or added strength in an OEM application, the adhesive seals against liquids and gases to 6000 psi and can perform in temperatures up to 300°F. These proprietary inserts were developed by the current owner Ben Belzer’s grandfather for the aerospace industry as an alternative to helical inserts.

A new feature of the E-Z LOK website, www.ezlok.com is the CAD file, which allows an engineer to incorporate any of the thousands of E-Z LOK insert into a design.

Director of Sales & Marketing, Kyle Lindsly-Roach and a team of E-Z LOK engineers will attend the show, displaying the full line of E-Z LOK products. Emphasis will be placed on the company’s threaded inserts for metal, wood and plastic. Speaking about his hopes for the show, Lindsly-Roach said, “We are excited to be able to present our portfolio of products to a wide range of customers, including engineers, OEMs and distributors. We hope to be able to expand our customer base and the industries where our products are, as well as our existing supply chain partners in the OEM, fastener distributor and machine shops.”

Visit E-Z LOK at IMTS Booth 432123 during the show.

For more information, please contact:

Kyle Lindsly-Roach, Director of Sales & Marketing

E-Z LOK

240 E. Rosecrans Ave

Gardena, CA 90248

USA

Phone: 310-323-5613 x221

klindsly@ezlok.com

www.ezlok.com

E-Z LOK is a leading manufacturer and master distributor of threaded inserts for metal, plastic and wood. Inserts for metal include solid wall and helical wire-thread inserts, while inserts for plastic feature press-in and ultrasonic/heat stake designs. Those for wood are die cast zinc alloy hex drives for softwood and brass knife threads for hardwood. A variety of kits for the above inserts are available and feature installation tools, drill bits, etc.

E-Z LOK is a third-generation family owned and operated company. Founded in 1956, it primarily sells through local, regional and national industrial distributors, as well as direct to major OEM’s in a variety of end user market segments.

Continue reading

QUICK® knurling and marking tools used in various industries including medical, aerospace, automotive and fitness; to be shown at IMTS 2024

Platinum Tooling, the importer and master distributor of live tools, angle heads, marking tools, Swiss tools and multi-spindle tools manufactured by various global suppliers, is now the North American importer of the QUICK® knurling and marking tools from Hommel & Keller. The announcement was made by Platinum Tooling president, Preben Hansen, at headquarters in Prospect Heights, Illinois, near Chicago. The line will be displayed at IMTS 2024 Booth 432245 and will be running in the Marubeni booth 339419 on Miyano/Citizen lathes during the show.

A longtime global leader in high-end knurling and marking tools, Hommel & Keller manufactures the QUICK® line with a combination of function and innovation. Quality, precision and stability are the key principals used to make QUICK® tools successful. Furthermore, the company prides itself on a rich history of providing customized solutions for its customers.

The QUICK® product spectrum offers innovative solutions for diverse knurling technology applications. For both form knurling and cut knurling, QUICK® fulfills the most stringent quality standards and masters difficult tasks. Knurling tools are available for use on a wide range of workpiece diameters, including small tools for Swiss type lathes from Ø 1.5 mm.

QUICK® marking tools make it possible to mark workpieces in seconds on a variety of surfaces and part geometries. Through single marking segments, the marking text can be individually customized. Tools are available in two diameters for interchangeable lettering, as well as custom logos.

These tools are used whenever absolute precision and first-rate surface quality are needed. Examples include medical and dental instruments, watches, fishing gear, windshield wiper shafts, barbells, screwdriver bits, fittings, connectors plus welding and cutting equipment.

To download the full catalog, click: https://platinumtooling.com/catalog/quick-catalog/

For further information, please contact:

Preben Hansen, President

PLATINUM TOOLING TECHNOLOGIES, INC.

16 E. Piper Lane

Suite 128

Prospect Heights, IL 60070

Phone: 847-749-0633

Fax: 847-749-2445

Email: phansen@platinumtooling.com

Platinum Tooling Technologies, Inc. in Prospect Heights, IL, near Chicago, serves its growing North American customer base with an extensive inventory of machine tool accessories. Its experienced staff is dedicated to providing the most innovative tooling and technology. Platinum Tooling Technologies, Inc. serves the auto, aero, medical, woodworking, composites and other industries, as well as an ever-increasing number of machine tool OEMs, through its network of manufacturers’ representatives. Platinum Tooling is the master importer of Heimatec, Henninger, Tecnicrafts, Hommel + Keller QUICK tools and REV broaching tools in North America. In addition, Platinum Tooling represents Rineck Shrink Fit Tooling in the United States and Mexico.

Company to bring its machining, testing and assembly talents to work on non-Fischer spindles

Under the theme of “Technology Leader with Perfect Rotation,” FISCHER USA, Inc. will display its branded spindles plus offer a new service at IMTS 2024, Booth 237470, in Chicago, September 9-14. With 85 years of experience in high-performance machine tool spindle design, in-house manufacturing and best-in-class repair services, the company will formally introduce the expansion of its repair services and exchange programs for non-FISCHER spindle brands to the North American market.

As Vice President Doug Kranz notes, “We have invested substantially in recent years in new machines, processes and, our most important asset, our people, to support our growth. Today, we can now offer our full battery of services to work on non-FISCHER spindles most commonly found on high performance, high precision machines.” Kranz further says that the company has curated a special niche in the machine tool market in North America, focusing on more complicated spindles that other repair shops may tend to avoid. “We pride ourselves in taking on the spindles many others stray away from.”

For the immediate future, Kranz explains FISCHER USA will target Kessler spindles, commonly found on large format SW machines, typically used in the automotive market for high-production work. In addition, the company is focusing on Makino spindles for several lines of that builder’s machines, specifically MAG3. “Currently, MAG3 machines are well known to have spindles that only Makino repairs. We have been asked to repair them for several years now and have decided to make a major commitment to this type of work. As a result, FISCHER has invested in a pool of spindles and we will repair them, stock them and roll out our exchange program for MAG3 users Q1 2025,” says Kranz.

The MAG3 machines are used primarily in the aerospace sector, where FISCHER has a long history and strong presence directly with the aerospace manufacturers and their first and second tier suppliers.

Finally, FISCHER will target a repair and exchange program for Voumard multi-spindle, ID high-speed grinding machines. The company will maintain a pool of those spindles in stock, ready for immediate exchange with fast delivery and a competitive price point.

In regard to pricing, Doug Kranz observes, “Our price points will be lower than the OEM’s in most cases, while we maintain the very high-quality standards FISCHER has long established in the American market.”

At the booth, FISCHER will also display its impressive array of branded spindles and head assemblies for milling, drilling and grinding operations.

Visit FISCHER at IMTS 2024 in the North building, Level 3, Booth 237470.

For more information, please contact:

FISCHER USA, INC.

3715 Blue River Avenue

Racine, WI 53405

www.fischerspindle.com

Phone: 262-632-6173

Attention: Doug Kranz, Vice President, Sales & Marketing

Email: Doug.Kranz@fischerspindle.com

FISCHER USA, Inc. is the North American operation for FISCHER Spindle Group AG, based in Switzerland. The company builds and markets milling head and spindle combinations, performs spindle analysis, repair and testing at its headquarters in Racine, Wisconsin.

Production facilities are increasingly the targets of cyberattacks. Industrial companies are therefore required to identify and close potential vulnerabilities in their systems. To address the need to identify cybersecurity vulnerabilities on the shop floor as quickly as possible, Siemens has launched a new cybersecurity software-as-a-service.

The cloud-based SINEC Security Guard offers automated vulnerability mapping and security management optimized for industrial operators in OT environments. The software can automatically assign known cybersecurity vulnerabilities to the production assets of industrial companies. This allows industrial operators and automation experts who don’t have dedicated cybersecurity expertise to identify cybersecurity risks among their OT assets on the shop floor and receive a risk- based threat analysis. The software then recommends and prioritizes mitigation measures. Defined mitigation measures can also be planned and tracked by the tool’s integrated task management. SINEC Security Guard is offered as cybersecurity software-as-a-service (“SaaS”), is hosted by Siemens and will be available for purchase in July, 2024 on the Siemens Xcelerator Marketplace and on the Siemens Digital Exchange.

Increasing protection by reducing manual effort

“With SINEC Security Guard, customers can focus their resources on the most urgent and relevant vulnerabilities, while having full risk transparency in their factory. It is unique because it takes the specific situation of the customer’s operational environment into consideration while providing a single pane of glass for security- relevant information in the OT area,” says Dirk Didascalou, CTO of Siemens Digital Industries. “When developing the SINEC Security Guard, we drew on our extensive experience with cybersecurity in our own factories.”

Today, industrial operators are tasked with continuously safeguarding their production assets on the shop floor. They need to analyze vendor security advisories, manually match them to the asset inventory of their factory and prioritize mitigation measures. Because this process is time-consuming and error-prone using the existing tools, factories are running the risk of missing critical vulnerabilities in their assets or producing false-positives. This can lead to incorrectly configured plant components and inadequately allocated resources. With the SINEC Security Guard, industrial operators can tackle these challenges without needing in-depth cybersecurity knowledge.

Attack detection at scale with Microsoft Sentinel

For a comprehensive view of IT and OT cybersecurity, SINEC Security Guard will also offer a connection to Microsoft Sentinel, Microsoft’s Security Information and Event Management (SIEM) solution for proactive threat detection, investigation and response. Once connected, SINEC Security Guard can send alerts for security events including attacks to Sentinel, enabling a security analyst to incorporate SINEC Security Guard insights and conclusions in investigations and responses with Microsoft Sentinel powered Security Operations Centers.

“As information technology and operational technology systems continue to converge, a holistic cybersecurity architecture is key to protecting IT and OT

capabilities alike. By combining our domain knowledge, Siemens and Microsoft make it easier for industrial operators to efficiently detect and address cybersecurity threats at scale,” says Ulrich Homann, Corporate Vice President, Cloud + AI at Microsoft.

SINEC Security Guard also supports the manual upload of existing asset information for asset inventory. Siemens recommends, however, that industrial operators use the Industrial Asset Hub, the Siemens cloud-based Asset Management solution, to enable continuous automated asset inventory management.

Functionalities also include signature-based network intrusion and attack detection via the SINEC Security Guard Sensor, an Industrial Edge app, which gives users live information about their industrial network. The SINEC Security Guard Sensor App is available at the Siemens Industrial Edge Marketplace.

The initial release of SINEC Security Guard only supports Siemens OT assets but third-party device support is planned in the future. SINEC Security Guard will expand the existing Siemens software portfolio for OT network security consisting of SINEC Security Inspector and SINEC Security Monitor.

SINEC Security Guard is a cloud-based cybersecurity software that provides full risk transparency and cybersecurity management of OT assets.

Further details on the new SINEC Security Guard can be found at: www.usa.siemens.com/sinec-security-guard

Siemens Digital Industries (DI) is an innovation leader in automation and digitalization. Closely collaborating with partners and customers, DI drives the digital transformation in the process and discrete industries. With its Digital Enterprise portfolio, DI provides companies of all sizes with an end-to-end set of products, solutions and services to integrate and digitalize the entire value chain. Optimized for the specific needs of each industry, DI’s unique portfolio supports customers to achieve greater productivity and flexibility. DI is constantly adding innovations to its portfolio to integrate cutting-edge future technologies. Siemens Digital Industries has its global headquarters in Nuremberg, Germany, and has around 75,000 employees internationally.

Siemens Corporation is a U.S. subsidiary of Siemens AG, a global powerhouse focusing on the areas of power generation and distribution, intelligent infrastructure for buildings and distributed energy systems, and automation and digitalization in the process and manufacturing industries. Through the separately managed company Siemens Mobility, a leading supplier of smart mobility solutions for rail and road transport, Siemens is shaping the world market for passenger and freight services. Due to its majority stakes in the publicly listed companies Siemens Healthineers AG and Siemens Gamesa Renewable Energy, Siemens is also a world-leading supplier of medical technology and digital healthcare services as well as environmentally friendly solutions for onshore and offshore wind power generation. For more than 160 years, the company has innovated and invented technologies to support American industry spanning manufacturing, energy, healthcare and infrastructure. In fiscal 2018, Siemens USA reported revenue of $23.7 billion, including $5.0 billion in exports, and employs approximately 50,000 people throughout all 50 states and Puerto Rico.

Continue reading