Contact us today:

(847) 934-4500

tdaro@bernardandcompany.com

Contact us today:

(847) 934-4500

tdaro@bernardandcompany.com

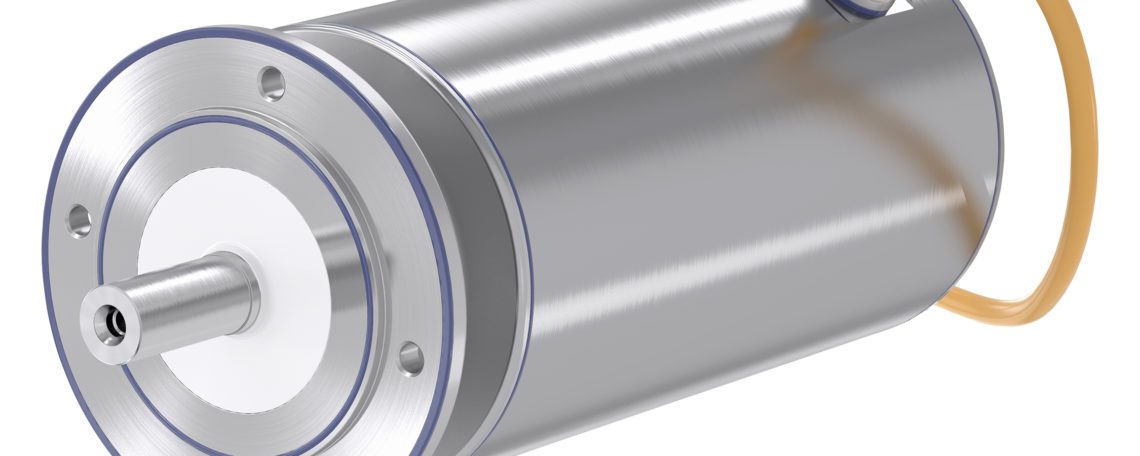

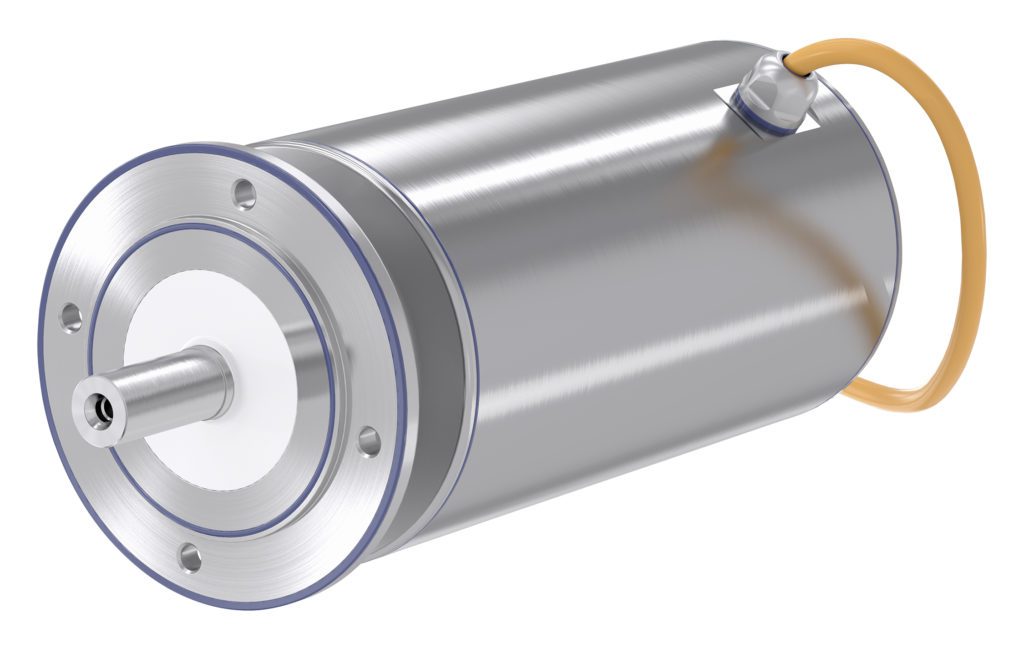

Stainless steel housings suited to high standards of hygiene and cleanliness; three sizes to 2kW (2.68 hp) power range and up to 14 Nm (10.32 ft-lbs.) torque

Siemens is introducing the new SIMOTICS S-1FS2 line of servomotors, designed for the clean condition requirements of the food, beverage, sterile packaging, pharmaceutical and other process industries. These new servomotors are offered in a variety of power ratings, from 0.45–2kW (0.60–2.68 hp) with torque from 3.1–14 Nm (2.28–10.32 ft-lbs.). Crafted with housings of 1.4404 (AISI 316/316L) stainless steel, EPDM seals and bearing grease with NSF H1 approval, these new servomotors are highly resistant to corrosion and acidic chemicals found in the process industries. This extremely high degree of protection is in accordance with IP66/67 standards on the entire motor, with IP69k (30-bar) protection provided on the motor housing.

High dynamics due to low inherent inertia plus high overload capacity for use in pick-and-place applications, plus precise movement of heavy loads, are added features. One cable connection is provided for easy installation and cleaning. The standard absolute encoder is 22-bit multi-turn.

The SIMOTICS S-1FS2 family of motors is suitable for clean-in-place (CIP) processes and for use with all commercially available cleaning agents used with washdown motors.

Quality construction further highlights this new family of motors, providing the machine builder and end-user long service life. These motors are especially designed for the 3-A (U.S.) and EHEDG (Euro) requirements of the food and beverage industries.

Options include a holding brake, stainless steel shaft with or without feather key, cable tail for direct drive connection and a MOTION CONNECT coupling. MOTION CONNECT is the Siemens fully assembled power and signal cable design for use on production machinery of many types.

SIMOTICS S-1FS2 is compatible with the SINAMICS S210 drive system.

Selection/configuration data, dimensional drawings, CAD models, data sheets and full specifications for SIMOTICS S-1FS2 servo motors are available immediately from Siemens.

Siemens introduces the new SIMOTICS S-1FS2 stainless steel servomotor for food, beverage, sterile packaging, pharmaceutical and other process applications

For more information regarding SIMOTICS S-1FS2 servo motors, please visit:

usa.siemens.com/simotics-s1fs2

Siemens Digital Industries (DI) is an innovation leader in automation and digitalization. Closely collaborating with partners and customers, DI drives the digital transformation in the process and discrete industries. With its Digital Enterprise portfolio, DI provides companies of all sizes with an end-to-end set of products, solutions and services to integrate and digitalize the entire value chain. Optimized for the specific needs of each industry, DI’s unique portfolio supports customers to achieve greater productivity and flexibility. DI is constantly adding innovations to its portfolio to integrate cutting-edge future technologies. Siemens Digital Industries has its global headquarters in Nuremberg, Germany, and has around 75,000 employees internationally.

Siemens Corporation is a U.S. subsidiary of Siemens AG, a global powerhouse focusing on the areas of power generation and distribution, intelligent infrastructure for buildings and distributed energy systems, and automation and digitalization in the process and manufacturing industries. Through the separately managed company Siemens Mobility, a leading supplier of smart mobility solutions for rail and road transport, Siemens is shaping the world market for passenger and freight services. Due to its majority stakes in the publicly listed companies Siemens Healthineers AG and Siemens Gamesa Renewable Energy, Siemens is also a world-leading supplier of medical technology and digital healthcare services as well as environmentally friendly solutions for onshore and offshore wind power generation. For more than 160 years, the company has innovated and invented technologies to support American industry spanning manufacturing, energy, healthcare and infrastructure. In fiscal 2018, Siemens USA reported revenue of $23.7 billion, including $5.0 billion in exports, and employs approximately 50,000 people throughout all 50 states and Puerto Rico.

Continue reading

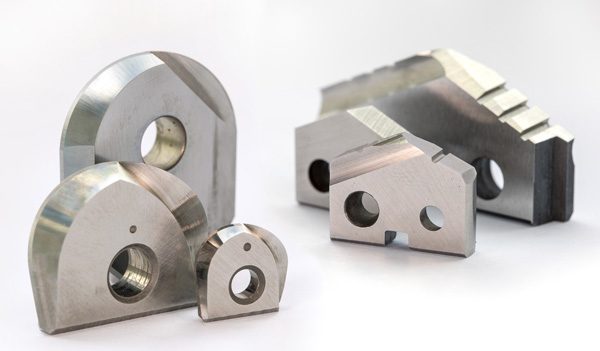

Set up for accurate, consistent and automated insert grinding and diversify production

Solid endmill and drill production is a highly competitive market, making it challenging to differentiate yourself from your competitors. Inserts for milling and drilling applications offer various advantages over solid carbide tools, but present unique challenges in manufacturing. For those that successfully master the production of insert tools, new market opportunities can be yours. ANCA’s insert grinding solutions may just be the answer you need to take this step.

Inserts appeal to users of tools, firstly because one tool body can take a variety of inserts, making them very versatile. Additionally, the cost of replacing just the insert is significantly less than an entire solid carbide tool. For insert manufacturers however, the challenge is automated production of these uniquely shaped parts.

The ANCA Insert Solution, based on the MX tool grinding machine platform, offers work-holding, automation and supporting tool programming software to produce a diverse range of rotary endmill and drill inserts. Inserts that feature common locating datums and clamping features are an ideal fit for the ANCA Insert Solution.

ANCA’s unique Insert Chuck provides the foundation of insert grinding capability. Its versatile design means one chuck can hold a variety of inserts with precise repeatability and necessary rigidity during the grinding operation. Onto the standard chuck, interchangeable jaws are fitted in minutes. These jaws are custom designed based on the insert datum and holding features, as well as considering wheel clearance for necessary grinding operations. ANCA will work with you to design jaw sets that cover your complete insert design and size range.

Economical production requires automation. For insert grinding, the RoboMate robot loading system is kitted up with the dedicated pallets and grippers for unattended manufacturing. As with the chuck jaws, ANCA will collaborate with you to design a range to pallets and grippers that suit your inserts.

Comprehensive and flexible programming software is the final element needed for insert grinding. As always, ANCA has it covered with iGrind – our industry-leading tool programming software, that caters for various special endmill and drill insert geometries. In addition, special digitizing routines will determine the datum location and exact position of the insert before commencing the grinding operation. This ensures the insert production batch remains accurate and consistent, delivering quality results expected in the market.

Finally, with production flexibility in mind, the insert grinding system can be easily switched over to solid carbide tool production, meaning a given grinding machine is not locked into production of just one tool type. By switching the Insert Chuck for PremierPlus collet system, and replacing RoboMate pallets and grippers, the transition to solid tool production can be done quickly and efficiently, ensuring your machines productive grinding time is maximized and adaptable to your market demands.

The insert grinding solution is offered not only on new machines, but can equally be retrofitted on existing MX machines. Setting up for diversifying your cutting tool product portfolio to include inserts has never been easier. Having alternate production capabilities that can quickly be adapted to meet customer demands is a winning long-term strategy for the success of your tool grinding business.

For further information, please contact:

Johanna Boland

Group PR and Communications Manager, ANCA

M: +61 407799779

Johanna.Boland@anca.com

ANCA is a market leading manufacturer of CNC grinding machines. It was founded in 1974 in Melbourne, Australia where the company still has its global headquarters. ANCA has offices in the UK, Germany, China, Thailand, India, Japan, Brazil and the USA as well as a comprehensive network of representatives and agents worldwide.

ANCA CNC grinders are used for manufacturing precision cutting tools and components across a diverse range of competitive industries including cutting tool manufacture, automotive, aerospace, electronics and medical.

Continue reading

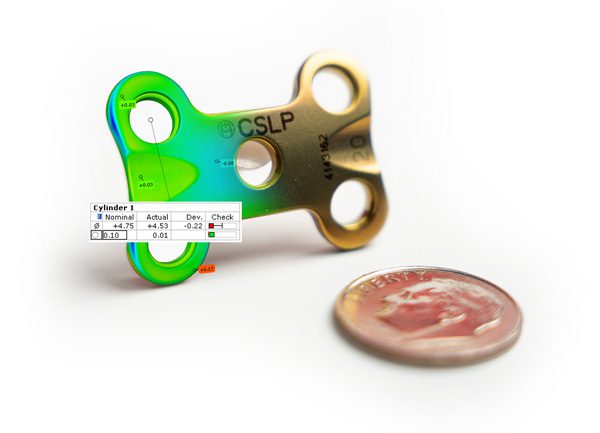

Exact Metrology: A Division of In-Place Machining Company and a comprehensive 3D metrology service provider and hardware sales company, scanned a titanium cervical spine locking plate. The scan was completed by Brendon Belongia, an Applications Engineer at the Brookfield, Wisconsin office using the ZEISS METROTOM 6 scout.

The METROTOM 6 scout digitizes complex parts including the internal geometries at the finest level of detail. Users obtain a complete 3D image for GD&T analysis or nominal-actual comparisons. High- resolution images can be captured for precise measuring tasks or detailed inspections of internal structures. Be it shrinkage holes, pores, cracks, sink marks or warpage, all defects or deviations can be detected nondestructively. Furthermore, the combination of a 3k detector and 225 kV X-ray enables ZEISS METROTOM 6 scout to provide high contrast, high-resolution measurement results and exceptional sharpness of detail. As a result, even the smallest defects in the part become visible and can be analyzed to the last detail. A 5-axis kinematics with integrated centering table helps clients optimally position the part in the measuring volume and the control of the device and the metrological evaluation of the data are combined in a single software package, making additional software or intermediate steps redundant.

With this CT scan, the company demonstrates its ability to scan even the smallest part, such as 4 mm. This vertebrae plate was measured within a 5-micron resolution and used a deviation color map with the GOM Volume Inspect software. The color representation of a point cloud or mesh data set is compared to its intended, nominal CAD model. This spectrum of colors can tell users how far a value deviates compared to the CAD surfaces. Thus, a weak spot can be detected and can be fixed before a part is used.

The ability of the ZEISS METROTOM 6 scout to see the tinniest defect or detail is especially crucial for medical devices, especially those that go into the human body.

Exact Metrology: A Division of In-Place Machining Company, is ISO9001, AS9100 Certified as well as ITAR Registered.

Exact Metrology: A Division of In-Place Machining Company, with facilities in Cincinnati, Ohio, Moline, Illinois and Milwaukee, Wisconsin, plus affiliated offices throughout the country, is a comprehensive metrology services provider, offering customers 3D and CT scanning, reverse engineering, quality inspection, product development and 2D drawings. The company also provides turnkey metrology solutions, including equipment sales and lease/rental arrangements.

For more information, please contact:

Exact Metrology: A Division of In-Place Machining Company

Steve Young, Vice President

11575 Goldcoast Drive

Cincinnati, OH 45249

Local: 513-831-6620

Toll Free: 866-722-2600

www.exactmetrology.com

stevey@exactmetrology.com

For a short video on this collaboration between Zimmermann and Commercial Tool & Die, please see:

Zimmermann Milling Solutions, a leading global high-tech supplier of portal milling machines recently designed three custom milling machines for Commercial Tool & Die (CTD).

CTD is a family-owned and operated business with a long-standing reputation of building exceptional and extremely large plastic injection molds. Markets served include automotive, truck cab bodies, construction equipment and others. They have been successfully using Zimmermann machinery since 2018, so when a need arose for new milling machinery, they went directly to Zimmermann. “We reached out to Zimmermann that we needed a world-class milling machine, because that is what they have,” said Darin Hall, Plant Manager, Commercial Tool & Die.

Machining plastic injection molds has specific requirements and Zimmermann worked with CTD for over three years to design and build machines that met those needs. “We went the extra mile because we knew that this was what Commercial Tool was looking for and we wanted to be the right partner,” said Cornelius Kiesel, President, Zimmermann. The final result was machines with the unique Zimmermann head design with multiple cutting axis to enable CTD to complete projects by speeding up production and improving accuracy without an excessive number of setups.

When J.D. Bouwman, President, Commercial Tool Group, was asked about the collaboration between the two companies and his favorite thing about the new machines, he replied, “We’ve challenged Zimmermann and they’ve really done a great job of responding to those challenges. Our Zimmermann’s have really helped us bring our machining to the next level. We’re able to achieve unattended numbers that we’ve never had before in the shop and that’s really a testament to our relationship with and the quality of the machines and just the overall build quality of the Zimmermann. It’s just a super, super solid machine.” He added, “I know that if we’re looking for a big machine in the future, we’re definitely going to be turning to Zimmermann.”

For more information, please contact:

ZIMMERMANN INC.

30587 Century Drive

Wixom, MI 48393

Phone: 248-956-8511

www.zimmermann-inc.com

Ms. Lena Kiesel, Marketing Manager

lena@zimmermann-inc.com

Four large FZ40c portal millings machines providing significant changes to business strategy at Commercial Tool & Die and Franchino Mold & Engineering in Michigan

Zimmermann FZ40c milling machines enabled both moldmakers to grow their business in their home markets of automotive injection molds and die cast diework, in a unique partnership for each moldmaker

It began in 2017, when Commercial Tool & Die (CTD), a division of Commercial Tool Group in the Grand Rapids, Michigan area, contacted Zimmermann at a mold show and IMTS. This 68-year-old company, founded by the grandfather of the current president, JD Bouwman, was heavily leveraged in automotive and off-highway injection moldmaking, but was seeking to grow into new markets with larger machining capacity. Meanwhile, over in Lansing, Michigan, Franchino Tool & Engineering was prospering in automotive molds and die cast diework but was seeking to increase their 5-axis machining capability, travel and speed. The short version of this story is that CTD ended up with three new Zimmermann machines, while Franchino bought the first CTD stock machine from Zimmermann, as it fit their needs quite well, according to Franchino President Mike Heatherington.

Commercial Tool & Die Looking To Grow

As Plant Manager Darin Hall explains, “We had reached out to Cornelius Kiesel, president of Zimmermann Inc. in Wixom, Michigan, at a mold show and then again at IMTS. We were impressed with their large CNC 5-axis machines. CTD had four goals we were seeking to accomplish with our new machine capability. Namely, we wanted reliability, efficiency to run unattended, rigidity to hold accuracies across a long travel and surface quality to meet our very high standards for automotive products.” He notes the FZ compact line of Zimmermann appeared to have the essentials they sought at CTD, though some modifications would be needed.

Company President JD Bouwman elaborates. “We found in Zimmermann the combination of a great machine with a flexible team who was willing to expand their horizons and ours. Although the basic version of the FZ40c is an excellent machine, in the end, we made 31 changes that were specific to CTG’s needs, including increased ram, with a goal to purchase three machines for our increased production.” Bouwman further comments how this enhanced capability would allow CTD to move into new markets and increase share in their home market of automotive. Today, that process has already yielded positive results, as the company is producing injection molds of much larger size than in the past, thereby opening new segment of automotive, off-highway and commercial building products.

After the initial investigation, the decision was made to lease an FZ40c to trial the machine. This portal mill has a work envelope of 197” W x 118” D x 59” H with a feed rate to 2362 ipm. As the trials proceeded over the one-year lease agreement, according to Darin Hall, “We quickly saw that the machine was very solid and would allow us to strategize differently in our approach to production.” Concurrently, CTD was realizing their market and manufacturing needs would require some significant changes to the machine, especially the ram height, for use on molds in the off-highway, construction equipment and building products market segments CTD was seeking to penetrate.

He continues, “We also realized we had a great partner in Cornelius and the team at Zimmermann, both in Wixom and in Germany, where we visited a number of times, as they did here. These folks were open to our suggestions and worked diligently to affect them.” Hall notes this lease arrangement was the first in the 68-year history of the company. “I guess you could say we knew where we wanted to go but weren’t quite sure of the machine design that would get us there.” The CTD and Zimmermann teams thus began a collaboration that would run nearly three years, culminating in today with three FZ40c gantry mills on the floor at CTD, each with an enhanced rigidity and cast mono-block fork head with unique process cooling for high precision machining, especially on models and molds. The FZ40c has a base x-axis of 236”, giving CTD the additional size they needed. Among the changes made to the machine design was an increased ram.

In the end, JD Bouwman concludes, “We had a big machine concept in mind to get us to our goal and the three modified FZU machines were the answer. Day to day, the machines give us much higher unattended machining numbers, a real testimony to the quality. Zimmermann has allowed CTD to quote new projects, bigger workpieces and enter new markets, exactly where we wanted to go.” He expressed a “big thank-you” to Cornelius Kiesel and the Zimmermann team, citing the dedication on both sides over a three-year period resulted in machines “…that simply allowed us to go to a new level as a company and that’s very exciting.” A future goal between the companies is to build an even bigger machine with increased capacities to reach even higher levels of market participation.

“Our relationship with Zimmermann is based on true collaboration and we’re mutually assisting the other to accomplish our goals. That’s as good as a business partnership can be,” concludes Bouwman.

One additional change to the FZ40c as requested, according to Cornelius Kiesel, and it presented a unique challenge to Zimmermann, he jokes. “The CTD company color is gold and they requested we paint the machine heads that color for them. We are machine tool engineers and builders but we took up the challenge and found the right paint for this challenging application. Looks nice, doesn’t it?”

Franchino — right place at the right time

That’s an old expression but it’s true in this case. About an hour east of CTD sits Franchino Mold & Engineering in Lansing, Michigan. According to company President Mike Hetherington, “Our business is currently about half in automotive injection molds and half in die cast diework for a variety of industries, including construction, stormwater and septic management. During this recent period in business, with all its challenges, we’ve been flexible in seeking new jobs in various industries and it’s paid off, resulting in a sizable increase in our sales volume.”

The connection between Franchino and CTD requires a bit of explanation, as Hetherington notes. “We were on a business trip to Germany, seeking new machine concepts. We had occasion to tour the Zimmermann factory and, while there, we saw the FZ40C portal milling machine being built for Commercial. We were looking for that type of machine and had our checklist. The FZ40C began to check off the boxes and we knew it was the machine for us. As it happened, we learned the machine was being leased to Commercial down the road from us in the Grand Rapids area and we’d known them for years. We don’t often directly compete, so we made some contacts and decided to wait for their lease to expire, then we purchased their machine and it was shipped to our facility in Lansing.” He also mentions several particulars. The machine needed to work both steel and aluminum molds, be a true 5-axis mill, be able to efficiently rough, semi and finish all in one setup, have an HSK spindle, run 1400 ipm and be up for two shifts reliably. The FZ40c was found suitable on all these points, according to Hetherington.

On one job, he notes with a smile, the shop took a roughing cycle from 16 hours to 3 hours, due to the machine’s rigidity, speed and accuracy. As a bonus, the Heidenhain CNC onboard the Zimmermann machine provided a monitoring capability that enabled the Franchino Machining Supervisor, Chris Cook, to learn the status of the machine remotely.

Cook cites another example of the company’s use of the Zimmermann FZ40c. “We run molds for huge septic tanks and the Zimmermann is currently at 3000 hours of run time at 2000 ipm with no issues.”

Hetherington adds the machine purchased from CTD recently ran for two months solid at 90% capacity. “Looking back, I’d say we were definitely in the right place at the right time, discovering this machine on our trip to Germany. It’s been a very valuable investment for Franchino, providing reliable production on big workpieces. It will open up more opportunities for our company in various existing and new markets.” Hetherington has been president at the company since December, 2020, having gone, as he says, “…from mowing the lawn as a school kid to coming to work here with my engineering degree to engineering manager to VP of operations and now president.”

Franchino Mold & Engineering was founded in Lansing in 1955 by Richard Franchino, whose son and recently retired president Bob began as the first employee, sweeping the floor for $0.25 an hour. Mike Hetherington is currently working on the construction of an additional 60,000-square foot facility with an 80-ton overhead crane to handle the massive workpieces produced at this shop, which produces molds & dies plus does considerable repair work for its customers nationwide.

About the company

Zimmermann is based in Swabia (Germany) and is a leading global high-tech supplier of portal milling machines. These are characterized by huge workspaces, substantial machining dynamics and cutting performance. The company, founded in 1933 by Friedrich Zimmermann, now has over 200 employees worldwide. With its product range, our innovative company has one goal above all: to offer the right solution for our customers and thus to be able to guarantee high economic efficiency. “Quality made in Germany and supported locally” is our motto. The company’s special machines are used worldwide in the automotive, aerospace, moldmaking and mechanical engineering sectors. The company has its North American headquarters in Wixom, Michigan, near Detroit, where it operates a full tech center offering engineering assistance, commissioning, parts and retrofit services, as well as multiple machines for demonstration purposes. Zimmermann Inc. is headed by President Cornelius Kiesel.

For more information, please contact:

ZIMMERMANN INC.

30587 Century Drive

Wixom, MI 48393

Phone: 248-956-8511

www.zimmermann-inc.com

Ms. Lena Kiesel, Marketing Manager

lena@zimmermann-inc.com

In addition to the latest press technology, Schuler will demonstrate its “Digital Suite” solutions for networking forming technology

Canton, Michigan. August 25, 2021 – After a year off due to the pandemic, the FABTECH trade show will return to Chicago’s McCormick Place in September from the 13th through the 16th. At booth D46935, Schuler will not only present its latest servo and hydraulic press technology, but also its “Digital Suite” solutions for networking forming technology. They include, among others, “Visual Die Protection” which prevents unwanted production shutdowns and “Schuler Connect” which offers fast assistance in resolving unforeseen problems.

“Without a FABTECH show last year, we are especially looking forward to exhibiting in Chicago this September,” Kevin McAllister, President of Schuler North America, points out. “We will bring lots of exciting developments that we would love to show to our customers, because our solutions can really make their lives easier. As the largest service provider of any press supplier in North America, we’re anxious to highlight our service capabilities and offerings.”

Schuler’s “Cloud Solutions,” e.g., can be used to retrieve data on press forces and stroke rates. Cooling and lubrication circuits, temperatures and system pressures as well as power consumption are also recorded and visualized. Schuler also recently established a new U.S. workshop with a 50-ton crane that significantly expands the service footprint, especially the ability to execute large modernization projects.

For more information, please visit:

https://digitalsuite.schulergroup.com

For further information on Schuler Inc., North America, please contact:

Kevin McAllister, President, North America

Schuler Incorporated

7145 Commerce Blvd.

Canton, MI 48187 USA

734-207-7200

Kevin.McAllister@schulergroup.com

About the Schuler Group – www.schulergroup.com

Schuler offers customized first-rate technology in all areas of forming – from the networked press to press shop planning. In addition to press, our product includes automation and software solutions, dies, process know-how and service for the entire metalworking industry. Our customers include automotive manufacturers and suppliers, as well as companies in the forging, household appliance and electronics industries. Press from the Schuler Group mint coins for more than 180 countries. When it comes to the digital transformation of the forming technology, we support our customers worldwide as a supplier of innovative system solutions. Founded in 1839 with headquarters in Göppingen, Germany, Schuler AG has about 5,000 employees at production sites in Europe, China and America, as well as service companies in more than 40 countries. The company is part of the international technology group ANDRITZ.

Continue reading

Exact Metrology: A Division of In-Place Machining Company and a comprehensive 3D metrology service provider and hardware sales company, just used their new Coordinate Measuring Machine (CMM) at their Moline, IL facility.

Douglas Machine & Engineering, located in Davenport, Iowa, is a manufacturer of fixtures, broaches, reamers, straighteners, vises, pliers, cutters, burnishers, plugs, spindle nut presses and grinders. They also offer custom manufacturing including welding, EDM machining, fabrication, turning and milling. The company serves the aerospace, defense, construction, agricultural, robotics, food grade packaging and pharmaceutical industries.

Recently, they machined an aluminum plate that will become a locating fixture for the military. Per the military contract, Douglas Machine & Engineering had to provide a full dimensional layout report before shipping the plate. Unable to measure in-house, they discovered that Exact Metrology had this CMM capability in Moline and sent the part there.

The higher accuracy specification of this CNC coordinate measuring machine gives it more than double the effective measuring range in terms of accuracy-guarantee capability. Combining high speed and high acceleration, measuring time is greatly reduced. Thus, Douglas Machine & Engineering achieved a quick turnaround on their part.

They were very pleased with the results, having used Exact Metrology services in the past. Nick Roman, the President of Douglas Machine & Engineering said, “The communication is always top notch and the end result it always what we look for when doing business with a company. Exact always goes above and beyond to come on site or get things done when needed.”

Exact Metrology: A Division of In-Place Machining Company, is ISO9001, AS9100 Certified as well as ITAR Registered.

Exact Metrology: A Division of In-Place Machining Company, with facilities in Cincinnati, Ohio, Moline, Illinois and Milwaukee, Wisconsin, plus affiliated offices throughout the country, is a comprehensive metrology services provider, offering customers 3D and CT scanning, reverse engineering, quality inspection, product development and 2D drawings. The company also provides turnkey metrology solutions, including equipment sales and lease/rental arrangements.

For more information, please contact:

Exact Metrology: A Division of In-Place Machining Company

Dean Solberg

20515 Industry Avenue

Brookfield, WI 53045

Local: 262-533-0800

www.exactmetrology.com

deans@exactmetrology.com

Cerin invested in ANCA technology to take on these challenges and succeed – achieving precision, repeatability and stability in their grinding

Ivan Cuscov, Plant Director started at Cerin SpA ten years ago as a mechanical engineer and today is responsible for production. Ivan said, “Cerin was founded in 1971 by Mr. Cerin and my father joined the company a few years later. We were one of the first Italian companies to work with solid carbide and today serve many industries, from aerospace to construction, shipbuilding, energy and automotive.”

“Half our sales are in Italy and the other half abroad, mainly exporting to Germany but also Russia and Japan, China and England. Our customers choose to work with us because we manufacture a good product. If you ask our customers to say something about CERIN, they will only say, ‘A Cerin tool is a good tool.’ And that’s what I think is what makes us successful.”

“From the beginning we never worked with high speed steel as we had a feeling that solid carbide was the technology of the future and so we tried to make the biggest step possible into the future. It was very challenging at the time as there was limited knowledge on how to use solid carbide. Many people in the industry didn’t know of diamond wheels and thought of diamond as a jewel and not a grinding material!”

“We were a pioneer with many challenges working in unknown territories, but on reflection, I would say that taking on this challenge was key to our success.”

Cerin continues to invest in their pioneering culture to stay ahead of technology change

“At Cerin we try our best to understand our customers production requirements. If the customer has a problem, we look at their machining process — how the machine works, how the workpiece is placed on the machine, and what are the critical issues, vibration and so on. We have even built a Development Center to try new materials and new machine technology.”

“Currently we are looking into the exotic nickel alloys or otherwise called high temperature alloys – which are still niche materials, but we think it’s important to understand given the increasing requirement for energy efficient engine performance. For these applications, high performance requires higher thermal mechanical properties and that is driving tool technology.”

“These materials are particularly critical mainly for heat generation and elastic to plastic transition. Cutting those materials requires specific coating and sometimes a specific combination between solid carbide coatings and dedicated geometries.”

Tool makers must consider the entire development life cycle

“A good tool is the combination of elements. The right geometry and the combination between carbide and coating. Developing a new tool might require a few weeks to many months. The first technical work is designing and testing a basic tool of a certain length and diameter, which fulfills the initial targets. After that you need to organize the whole commercial offer, extend the tests to the rest of the product family, and of course create the stock availability.”

“Over the weekend we mainly produce standard tools and in some areas with unmanned shifts which helps us contain costs, increasing our capacity. Our operators create optimal production conditions, looking at correct machine and grinding wheel set ups. Our attention to detail when setting up processes means we can guarantee quality.”

“Our quality control department is responsible for checking tools during and after production. We have the complete traceability of our production batches and at any time can retrieve design information, even look at the raw materials.”

ANCA technology offers precision, repeatability, and stability – all essential for lights out manufacturing

“In our machine center we have a MX7, MX7 Linear, FX7 Linear, GX7, TX7 and even a TG7. At the moment we are mainly using ANCA machines for standard and cylindrical endmills and we keep the FX7 and one MX7 linear for mixed production of endmills and drills.”

“Precision, repeatability and stability are two advantages of using ANCA machines and over the years we have found ANCA machines to be thermally stable with a wide range of technology offered. A stable grinding machine is very important for unmanned shifts to keep tolerances and tool dimensions under control. In fact, repeatability means that we have the grinding process under control and can be confident with the quality of the end product we deliver to our customers.”

“iGrind is a very good software package mainly because of flexibility and because it allows you to do many different things easily. iGrind is great for cylindrical grinding to profile tools and especially with tool segments where you can split the tool operations as much as you want. We also use ANCA’s

ToolDraft in combination with AutoCAD.“

“We have been recently using iView with a camera for profile tools and it looks promising because it is a good way to control the tolerance of a complex tool all along the profile. If a profile is being controlled at a single point it is too difficult if you are trying to keep a whole profile within a certain tolerance to a few microns. For that you need a specific device and iView is very interesting.”

“Our operators are happy with the Wheel Probe which references the grinding wheel directly on the machine. The benefit using the probe is that you don’t need to waste any time with an external preset and can make your measurements directly on the machine. And you don’t need to mount and dismount the wheel before and after measuring because that of course might change the basic reference a little bit. So you’re going to measure the wheel in the same place where the wheel will work.”

For further information, please contact:

Johanna Boland

Group PR and Communications Manager, ANCA

M: +61 407799779

Johanna.Boland@anca.com

ANCA is a market leading manufacturer of CNC grinding machines. It was founded in 1974 in Melbourne, Australia where the company still has its global headquarters. ANCA has offices in the UK, Germany, China, Thailand, India, Japan, Brazil and the USA as well as a comprehensive network of representatives and agents worldwide.

ANCA CNC grinders are used for manufacturing precision cutting tools and components across a diverse range of competitive industries including cutting tool manufacture, automotive, aerospace, electronics and medical.

Continue reading

GMTA (German Machine Tools of America) in Ann Arbor, Michigan represents the Profilator line of gear pointing, rounding, cutting, Scudding®, Hard Scudding®, deburring and polygon machine tools in North America. These highly modular machines are used for polygon and slot facing, shifter stop machining, chamfering and deburring of highly complex automotive and other powertrain gears.

Profilator also developed the S-type machine. This is a compactly and modularly designed, vertical single spindle pick-up gear cutting machine. Machines in the S Series are better than broaching and most applications feature a dry machining process. All machine components are designed for especially high static stiffness and optimal dynamic behavior. Furthermore, the machine’s twin spindle arrangement speeds up the process considerably. S-type machines are available in three sizes, namely Profilator S-150, Profilator S-250 and Profilator S-500. Profilator S-150 has a part diameter up to 150 mm, while Profilator S-250 and S-500 have a part diameter up to 250 mm and 500 mm, respectively.

The Scudding® and Hard Scudding® process offers a marked improvement on skiving technology. To see our series of Profilator videos, click here:

For more information, please contact:

GERMAN MACHINE TOOLS OF AMERICA (GMTA)

4630 Freedom Drive

Ann Arbor, MI 48108

Phone: 734-973-7800

Fax: 734-973-3053

Web: www.gmtamerica.com

Email: sales@gmtamerica.com

Attention: Walter Friedrich, President

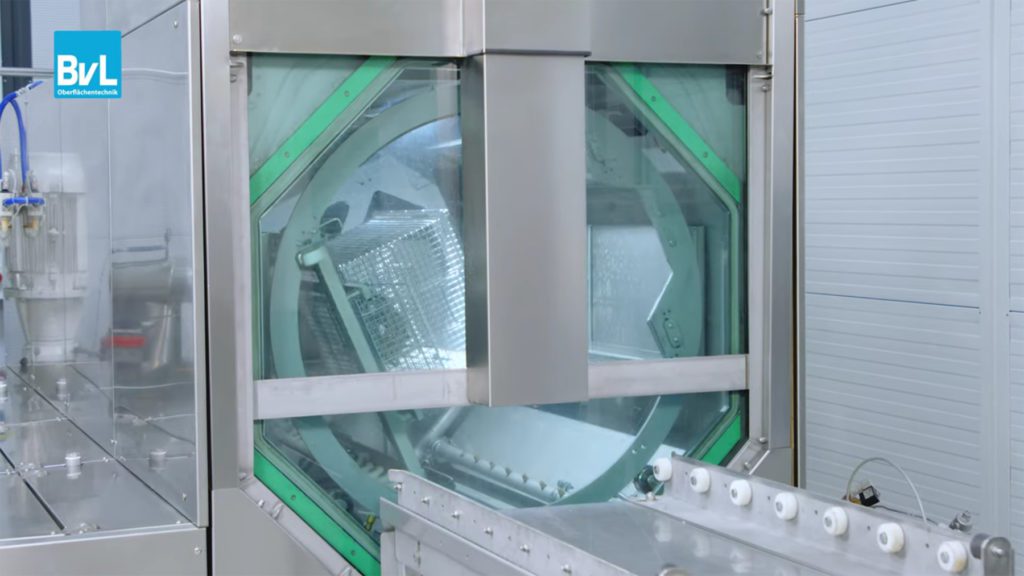

BvL, a designer and builder of quality parts washer systems and partner with German Machine Tools of America (GMTA), recently opened a technical center at their company headquarters in Germany. The new technical center gives customers the chance to go through a real world cleaning process scenario on a demo system.

Various demo systems allow customers to select the cleaning agent, temperature, circle times and method. The hands-on experience shows them exactly how their parts will be cleaned. Technicians are available to answer questions and help customers try out different settings in a safe environment. They can also help them to make minor modifications and fine tune, if necessary.

For a short video on the new BvL Technical Center, please see the link below:

GMTA is the exclusive distributor for a number of top-quality German and other metalworking machine builders companies including Arnold, BvL, K+G, Praewema, Profilator, Rasoma, Samag and WEMA Glauchau. The company’s headquarters is located in Ann Arbor, Michigan with a subsidiary in Queretaro, Mexico.

For more information, please contact:

GERMAN MACHINE TOOLS OF AMERICA (GMTA)

4630 Freedom Drive

Ann Arbor, MI 48108

Phone: 734-973-7800

Fax: 734-973-3053

Web: www.gmtamerica.com

Email: sales@gmtamerica.com

Attention: Walter Friedrich, President