Contact us today:

(847) 934-4500

tdaro@bernardandcompany.com

Contact us today:

(847) 934-4500

tdaro@bernardandcompany.com

Besides showcasing the ATOS Q and Absolute Arm, the company will present the new T-SCAN hawk 2

Exact Metrology: A Division of In-Place Machining Company and a comprehensive 3D metrology service provider and hardware sales company, will be exhibiting at the MetalCasting Congress and present innovative solutions from ZEISS, GOM and Hexagon in booth 815.

Produced by the American Foundry Society, this unique event is taking place between April 25-27 at the Huntington Convention Center in Cleveland, Ohio. The program offers exhibits, interactive demonstrations, and a direct connection with metalcasters, top suppliers and service providers. Present at the Exact Metrology booth will be Dean Solberg, Vice President of Metrology Sales and Services, Darin Sherry, Regional Sales Manager and David Nichols, Applications Engineer. The advanced metrology instruments that will be demonstrated in the Exact Metrology booth are the T-Scan hawk 2 from ZEISS, the GOM ATOS Q, and the Absolute Arm from Hexagon Manufacturing Intelligence.

The ZEISS T-SCAN hawk 2 is the next generation lightweight portable 3D scanner with metrology-grade precision and ease of use. Working distance can be controlled with a new projection mode. Furthermore, the satellite mode can scan up to multiple meters, eliminating the need for classical built-in photogrammetry with coded markers. The T-SCAN hawk 2 features four buttons to start and navigate the workflow directly. Seamless adjustments for resolution and field of view are applied for fine details, large objects, deep pockets, confined spaces, or hard-to-reach areas. This scanner supports scanning on a wide range of materials and surfaces, delivering precise 3D data.

GOM ATOS Q is a flexible 3D scanner for complex measurement and inspection tasks in different industries. The scanner delivers fully traceable measurement results, especially in harsh conditions. It captures quality information quickly and with a high degree of detail, providing a reliable basis to easily interpret the information. ScanCobot, a mobile automated 3D scanning system, easily integrates with ATOS Q.

The Absolute Arm from Hexagon Manufacturing Intelligence has an IP54 protection rating, a market first for portable measuring arms. It features an environment-related improvement that sees the system’s maximum operating temperature increased to 45°C. There are also improvements to the functionality of the Absolute Arm wrist display, now upgraded to a touchscreen, and the RDS software that drives it.

Besides the mentioned products, Exact Metrology also offers dimensional metrology services, including post processing options of reverse engineering and inspection. With First Article Inspection, which is a design verification process, measurements for each manufactured feature of a part are generated. Thus, a manufacturer can ensure all specifications are to design specifications before manufacturing a part.

Visit Exact Metrology in booth 815 during MetalCasting Congress.

In-Place Machining Company: On-Site Machining Solutions In-Place, Any Place in the World.

In-Place Machining Company, with facilities in Wisconsin, Washington, Virginia, Ohio, and Ontario, Canada, is the premier provider of high-precision engineered on-site machining, metrology, and large scale cutting & drilling services for a wide range of renewable energy, aerospace, industrial, and military customers throughout the world.

Exact Metrology: A Division of In-Place Machining Company, is ISO9001, AS9100 Certified as well as ITAR Registered.

Exact Metrology: A Division of In-Place Machining Company, with facilities in Cincinnati, Ohio, Moline, Illinois and Milwaukee, Wisconsin, plus affiliated offices throughout the country, is a comprehensive metrology services provider, offering customers 3D and CT scanning, reverse engineering, quality inspection, product development and 2D drawings. The company also provides turnkey metrology solutions, including equipment sales and lease/rental arrangements.

GOM GmbH

GOM, a company of the ZEISS Group, specializes in industrial 3D coordinate measuring technology, 3D computed tomography and 3D testing. From product development to production and worldwide distribution, GOM offers machines and systems for manual and automated 3D digitizing, evaluation software, training and professional support from a single source. In industries such as automotive, aerospace, energy and consumer goods, more than 17,000 GOM system installations are in use internationally. At more than 60 locations and with more than 1,200 metrology specialists, GOM guarantees profound advice and first-class service. Since mid-2019, GOM has been a part of the ZEISS Group and has formed the Center of Excellence for optical metrology. With more than 31,000 employees in 50 countries and annual revenue totaling more than 6.4 billion euros, ZEISS is an internationally leading technology enterprise operating in the fields of optics and optoelectronics.

Exact Metrology: A Division of In-Place Machining Company and a comprehensive 3D metrology service provider and hardware sales company, exhibited at POWERGEN International together with In-Place Machining Company (IPM), Oasis Alignment Services: A Division of In-Place Machining Company and East Coast Metrology: A Division of In-Place Machining Company in booth 3014. Representatives were on hand to offer solutions for the thermal, hydro, nuclear, wind and diesel industries.

The show was recently held at the Orange County Convention Center in Orlando, Florida. POWERGEN is the largest networking and business hub for generators and solution providers engaged in power generation. Power producers, utilities, EPCs, consultants, OEMs and large-scale energy users gather to discover unparalleled education, peer-to-peer networking and solutions from top providers.

Exact Metrology displayed its Leica RTC360. Manufactured by Leica Geosystems, these portable coordinate measuring machines are designed to measure large-scale objects. The RTC360 3D Reality capture scanner is ideal for professionals managing project complexities with accurate and reliable 3D representations. This scanner effectively combines a high-performance 3D laser scanner with Leica Cyclone Field 360, a mobile device app for edge computing that automatically registers scans in real time and Leica Cyclone REGISTER 360, an office software that integrates the 3D model into the workflow. Additional features include capturing scans, including enriching HDR imagery, in less than two minutes, automatically recording moves from station to station and augmenting data capture with information tags.

Measurement services displayed by OASIS Alignment Services included 26 power plant (hydro, steam and gas) jobs performed in 2020. Most jobs involved metrology support, with two including mechanical work. In 2021, the total number was 37, most of which were metrology supported, with six jobs including mechanical work. Last year, 29 power plant jobs were performed, two including mechanical work. To date in 2023, 10 jobs have been accomplished, three involving mechanical work. Examples of mechanical jobs in the power industry typically include cooling tower fan alignment, pump alignment, replacement of turbine bearings, generator alignment, new coupling installment, gearbox alignment, circular pump alignment, repair of broken shaft and solar generator alignment. Some metrology alignment jobs comprised inspection of turbine components, monitoring of components during a rebuild, structural movement studies, flatness inspections and others.

Present at the event were Dean Solberg, Vice President of Metrology Sales and Services at Exact Metrology, IPM Sales Managers Noel Brekas, Ronnie Onofry and Rob Ellington, Paul Parry, Director of Sales-Field Machining and Ulises Uscanga, Head of Industrial Plant Solutions at Leica Geosystems.

Dean Solberg highlighted the importance of having East Coast Metrology at the show. “The recent acquisition of East Coast Metrology allows IPM Measurement Group to provide nationwide coverage with metrology services to complement its field machining capabilities. We are excited to continue serving our customers’ needs as their one-stop shop.”

IPM discussed its recent acquisition of East Coast Metrology, which now afford the company nationwide coverage with metrology services to complement its field machining capabilities.

In-Place Machining Company: On-Site Machining Solutions In-Place, Any Place in the World.

In-Place Machining Company, with facilities in Wisconsin, Washington, Virginia, Ohio, and Ontario, Canada, is the premier provider of high-precision engineered on-site machining, metrology, and large scale cutting & drilling services for a wide range of renewable energy, aerospace, industrial, and military customers throughout the world.

Exact Metrology: A Division of In-Place Machining Company, is ISO9001, AS9100 Certified as well as ITAR Registered.

Exact Metrology: A Division of In-Place Machining Company, with facilities in Cincinnati, Ohio, Moline, Illinois and Milwaukee, Wisconsin, plus affiliated offices throughout the country, is a comprehensive metrology services provider, offering customers 3D and CT scanning, reverse engineering, quality inspection, product development and 2D drawings. The company also provides turnkey metrology solutions, including equipment sales and lease/rental arrangements.

OASIS Alignment Services: A Division of In-Place Machining Company

OASIS Alignment Services: A Division of In-Place Machining Company, provides 3-Dimensional Metrology Services, Precision Alignment Inspections and Diagnostics and Mechanical Services across a wide range of industries including aerospace, automotive, power generation, shipbuilding, pulp and paper, converting, printing, plastics, textiles and more. OASIS has completed thousands of successful projects since its inception in 1982 and continues to set industry standards in alignment procedures, specialized tooling and reporting techniques. OASIS operates service centers in New Hampshire, North Carolina, Florida, Ohio, Wisconsin, California, Washington, and Ontario and Québec, Canada. For more visit www.oasisalignment.com

East Coast Metrology: A Division of In-Place Machining Company

East Coast Metrology is a globally recognized full-service contract measurement company specializing in 3D scanning and modeling, reverse engineering & design, training and certification, instrument calibrations, equipment rentals, integration & alignment services. Headquartered in Topsfield, Massachusetts, ECM hosts an ISO/IEC 17025 Accredited Laboratory where they perform instrument calibrations, repairs, and CMM part inspection and programming. For more visit www.eastcoastmetrology.com

For information, please contact:

EXACT METROLOGY, INC.

Dean Solberg

20515 Industry Avenue

Brookfield, WI 53045

Local: 262-533-0800

www.exactmetrology.com

deans@exactmetrology.com

EXACT METROLOGY, INC.

Steve Young

11575 Goldcoast Drive

Cincinnati, OH 45249

Local: 513.831.6620

Toll Free: 866.722.2600

www.exactmetrology.com

stevey@exactmetrology.com

The new EFC-02 combines a century of Suhner’s abrasives and material removal expertise with smart automation for the highest surface quality results.

Rome, GA – Recognizing the role robotics plays in adding efficiency and lowering production costs for manufacturers of all types and sizes, Suhner continues to expand its robotics offering. The fully electric EFC-02 delivers precise, constant force throughout robotic grinding, sanding and deburring processes – resulting in superior, consistent surface quality.

Introducing EFC-02 – Suhner’s Electric Force Compliance System

Active compliance for robotic material removal

With today’s supply chain and labor challenges, manufacturers of all types and sizes are looking for solutions to help them do more with fewer resources. That’s what smart manufacturing is all about – and why Suhner is expanding its suite of robotic grinding accessories and tools with the fully electric EFC-02 active compliance system.

Smart Automation for High Surface Quality Results

Exact contact force with the surface is the single most crucial factor in robotic grinding, sanding and deburring processes. It’s also one of the biggest challenges, especially for hard-to-reach areas. Thoughtfully designed based on Suhner’s decades of material removal process know-how – the EFC-02 helps overcome that challenge.

As with any end-of-arm tooling, the EFC-02 connects a grinding machine – angle grinders, orbital sanders, angle polishers, straight grinders and others – to the robot. What makes Suhner’s system unique, however, is its compact design and fully electric operation.

The lightest and smallest in its category, the EFC-02 can be used for material removal or surface finishing even in tight or narrow spaces often found when processing stainless tanks and vessels for the food and pharma industries or fiberglass bathtubs and sinks. The all-electric technology also allows high-frequency measurements to monitor force and acceleration throughout the process. An advanced control algorithm then dynamically adjusts force and automates grinding processes based on pre-programmed parameters.

The result? Constant contact force with each movement from start to finish for a consistent surface quality – regardless of the surface type, shape, size or orientation.

In Line with Industry 4.0 Standards to Support Digital Transformation

Robotic processes are no longer just for mass production. As the technology has evolved, robotics have become easier to use and more flexible – making them ideal for both small- and medium-sized manufacturers looking to add efficiency, lower production costs or both.

Suhner engineered the EFC-02 with this in mind, giving users:

One stop for a custom, end-to-end solution

The end-of-arm EFC-02 active compliance system is fully compatible with Suhner’s end effectors, including angle grinders, orbital sanders, angle polishers and straight grinders. Optional automatic changers for abrasives or belts, which integrate easily with the EFC-02, are also available. By storing and dispensing new abrasives for pickup by a sander – these automatic changers effectively help speed processes and increase productivity.

Suhner also gives its customers access to one of the most comprehensive ranges of abrasives in the market from all the industry’s leading manufacturers. Plus, Suhner’s ABRACare customized, volume-based pay-as-you-go inventory management program ensures you always have the abrasives you need.

Working with Suhner means more than having access to industry-leading tools and abrasives – manufacturers also have access to a global network of seasoned abrasives and material removal experts ready to help you solve virtually any challenge.

Put Suhner to Work for You Today

The EFC-02 combines over a century of Suhner’s abrasives and material removal expertise with smart automation for the highest surface quality results. Its compact size, all-electric technology and simple programming make it possible to replicate and automate most grinding, polishing, sanding and deburring on a variety of surfaces. This gives manufacturers a cost-effective, low-maintenance solution for replacing many time-consuming and tedious manual processes – saving time and money.

Get in touch with your local Suhner representative to take control and let the robots grind.

The company will showcase the EFC-02 at Booth #1850 at the upcoming AUTOMATE 2023, May 22-25, in Detroit, MI.

For more information, contact:

Suhner USA, Inc.

43 Anderson Road S.W.

Rome, GA 30161

706-235-8046

machining.us@suhner.com

https://robotic-grinding.suhner.com/en/

By Jan Irzyk, AIMS Product Manager at ANCA CNC Machines

The tool manufacturing industry embraces automation solutions at an unprecedented pace. This is a worldwide trend driven by several factors – labor shortage, increasing labor costs, the need for maximizing uptime, push for 24/7 machine availability and customers demanding shorter lead times. Manufacturers need to be more flexible and responsive than ever before.

ANCA has been providing a wide range of automation solutions for many years. One of the recent offerings in this space is our ANCA Integrated Manufacturing System, or AIMS for short. AIMS is an ecosystem of individual modules – or building blocks – which could be configured to build a tailored automated tool manufacturing system. Modularity and flexibility mean that it caters to both small and large enterprise type manufacturers. The system could be designed to be very simple, using a trolley for manual pallet and tool transfer with basic ERP connectivity. It could also be a complex, fully autonomous production solution which requires minimal human intervention.

One of the most noticeable components of a fully automated AIMS cell is AutoFetch – the AMR robot responsible for transferring pallets between the setting station called AutoSet, to the tool grinder. It also automatically transfers single tools for spot check measurements outside of the grinder. As you can imagine, there’s a lot of traffic and the AutoFetch can get very busy. An AIMS cell is typically configured within a footprint of the existing factory with adjoining areas where standard, manual operations are taking place. This is a great flexibility feature but also raises many questions about how autonomous operation can function alongside the traditional production plant with frequent foot traffic.

There’s no need to fence off the AIMS area thanks to unique technology used with the AutoFetch robot. There are generally two types of automatic vehicles used on the factory floor – AGV and AMR. AutoFetch is an AMR (Autonomous Mobile Robot) which is different to AGV (Automatic Guided Vehicle). The main difference is the way both units navigate their way around the factory. An AGV always follows a predetermined route which is defined by using various guiding aids like strips embedded in the floor, or reflectors fitted to the walls around the route. The AMR on the other hand, travels from one location to another using its array of sensors and initially scanned map of the area. It doesn’t require any additional infrastructure to transfer material from A to B. You just scan and map the relevant area during AutoFetch setup, mark the load and unload positions and then the robot, using sophisticated algorithms, will find the optimal way from one point to the other.

Autonomous material transfer with AutoFetch – safety implications

One of the most common questions we’re being asked is related to safety of the AutoFetch. This is understandable since AutoFetch operates alongside personnel in the factory. The good news is the AutoFetch AMR is designed to safely operate in a factory environment where people are present. The AMR moves from one station to another using an optimized route, and it constantly scans the immediate area for unexpected objects. When an object is detected, the AutoFetch will stop and navigate around it. An array of sensors – laser scanners, 3D cameras and proximity sensors – are used for this purpose. For extra security, an AMR prohibited area could be defined on the map to exclude autonomous traffic altogether. In addition, the AutoFetch could be programmed to reduce speed in certain areas and warn nearby staff with audio warnings such as beeper, horns, or pre-recorded spoken messages.

72% of manufacturers report accidents related to using traditional means of material transport like pallet jacks, trolleys or forklifts. The use of AMRs contributes to increased safety in the factory and reduced accidents due to the elimination of human factors like fatigue, lack of focus or awareness.

To learn more about how AIMS can help in your factory, contact your local ANCA representative.

Jan Irzyk is currently focused on ANCA Integrated Manufacturing System (AIMS ). He is driving the expansion of the ANCA portfolio with ground-breaking solutions in line with ANCA’s innovative spirit of helping tool manufacturers maximize their outcomes and face current challenges.

Jan has an academic background in Mechanical Engineering that is applied in commercial and B2B professional experience, and extensive international experience across various manufacturing verticals providing automation, integration and traceability solutions. All of these apply to modern tool manufacturing with the concepts of Industry 4.0, Smart Factory and lights-out manufacturing that have been receiving a lot of traction in recent years.

For further information, please contact:

Amanda Bakun

Marketing & Communications Manager – Americas

248-497-1168

amanda.bakun@anca.com

ANCA is a market leading manufacturer of CNC grinding machines. It was founded in 1974 in Melbourne, Australia where the company still has its global headquarters. ANCA has offices in the UK, Germany, China, Thailand, India, Japan, Brazil and the USA as well as a comprehensive network of representatives and agents worldwide.

ANCA CNC grinders are used for manufacturing precision cutting tools and components across a diverse range of competitive industries including cutting tool manufacture, automotive, aerospace, electronics and medical.

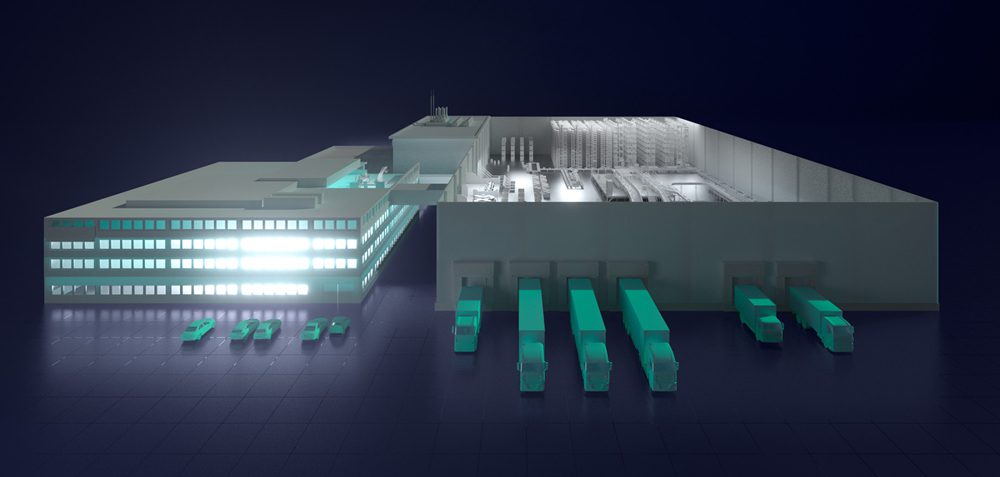

The Intralogistics segment will provide a holistic, systematic approach for materials handling

Siemens recently announced the formation of the new Intralogistics vertical that brings best-in-class material handling thought leadership, hardware automation, software and service solutions to customers in the United States. Siemens is leveraging its broad technology to address the market needs for digital transformation, cybersecurity, safety and sustainability. This new group will operate both as a vertical industry group and a horizontal business operation. It will reside within the Siemens Digital Industries — Motion Control business and functions in tandem with the organization’s existing additive manufacturing, aerospace, automotive, food-and-beverage, and other industry verticals.

Joel Thomas is the head of the Intralogistics vertical. Besides management of the group, Thomas will also work closely with trade associations who serve the intralogistics industry and will foster programs at Siemens to educate the next generation of engineers, programmers, software developers and plant operations personnel who will manage the warehouses of the future.

Products and software, plus the communications protocols needed to gather, prioritize and act upon plant conditions, will be key deliverables for this unit of Siemens.

This new group will serve machine builders and end-customers alike. For example, using the Siemens TIA Portal, a warehouse facility or postal clearing house will be able to integrate all its motion control hardware, software systems and communications protocols, internal and external, as needed. Additionally, Siemens digital twin and simulation technologies allow a warehouse or manufacturing operation to test all the “what ifs” before taking action on a material handling challenge.

Further, notes Joel Thomas, “The goal for all companies should be smart manufacturing and automated material flow, which is adaptable to changing market and technology conditions. This is especially challenging in older brownfield operations, where the legacy equipment might not handle the needs of the company, tomorrow or even today.”

Predictive analytics and predictive maintenance will also be among the key drivers for the Siemens Intralogistics business, as it strives to offer users the needed system components to maximize productivity and to gather the data needed to monitor and maintain the operation. The biggest challenge for this new group, according to Thomas, is to identify and bring the necessary skills and solutions to the resident knowledge base for each customer. He notes this varies considerably based upon each company’s size and onboard skill sets.

Thomas also comments how sustainability, which involves energy consumption and the ability to anticipate what equipment and software will be needed in the future to keep the plant running at maximum efficiency, will be a critical factor in the service package provided to customers.

Lastly, with use of this digital-to-real world technology, the Intralogistics business will help companies achieve a more productive eco-system and, with various Siemens solutions and services, a homogenous environment in the future-proofing of their operations.

Siemens Digital Industries (DI) is an innovation leader in automation and digitalization. Closely collaborating with partners and customers, DI drives the digital transformation in the process and discrete industries. With its Digital Enterprise portfolio, DI provides companies of all sizes with an end-to-end set of products, solutions and services to integrate and digitalize the entire value chain. Optimized for the specific needs of each industry, DI’s unique portfolio supports customers to achieve greater productivity and flexibility. DI is constantly adding innovations to its portfolio to integrate cutting-edge future technologies. Siemens Digital Industries has its global headquarters in Nuremberg, Germany, and has around 75,000 employees internationally.

Siemens Corporation is a U.S. subsidiary of Siemens AG, a technology company focused on industry, infrastructure, transport, and healthcare. From more resource-efficient factories, resilient supply chains, and smarter buildings and grids, to cleaner and more comfortable transportation as well as advanced healthcare, the company creates technology with purpose adding real value for customers. By combining the real and the digital worlds, Siemens empowers its customers to transform their industries and markets, helping them to transform the everyday for billions of people. Siemens also owns a majority stake in the publicly listed company Siemens Healthineers, a globally leading medical technology provider shaping the future of healthcare. In addition, Siemens holds a minority stake in Siemens Energy, a global leader in the transmission and generation of electrical power. In fiscal 2022, which ended on September 30, 2022, Siemens Group USA generated revenue of $18.6 billion and employs approximately 45,000 people serving customers in all 50 states and Puerto Rico.

Continue reading

Strategic Partnership Expands Industrial Machining and Repair Capabilities and Strengthens Commitment to Providing Customer Service Excellence

March 15, 2023 | Milwaukee, WI – In-Place Machine Company, LLC (IPM) is pleased to announce the acquisition of Western Machine Works, LLC (WMW) as part of a long-term growth strategy to expand reach and service offerings to customers and prospects across the U.S. and Canada. Globally recognized as the premier provider of high-precision industrial solutions, IPM has long been the leader in on-site machining, diamond wire cutting and drilling, and alignment and measurement services. Adding the expertise in engineering and precision machine shop services of WMW to the extensive field machining capabilities and solutions of IPM, greatly enhances the benefits to customers across a multitude of industries.

“This is a very exciting time for WMW”, said Greg Allen, SVP and General Manager of Western Machine Works. “It was very important to us that we partner with a company that excels in machining and has experience in the industries we serve. IPM’s onsite machining capabilities and experience are unmatched and complement the services we provide to create a unique benefit to our customer base.” Mr. Allen added, “I am confident that our employees and our customers, will benefit greatly from this new venture.”

In-Place Machining Company continues to grow and strengthen its capabilities by adding the leaders in industrial solutions to its team. With the newest addition of Western Machine Works, LLC to the IPM Machining Services Division as well as its strong Measurement & Alignment Services Division of OASIS Alignment Services, Exact Metrology, and East Coast Metrology, IPM brings a level of experience, knowledge, tooling, and service that is unrivaled in the industry.

In-Place Machining Company: On-Site Machining Solutions In-Place, Any Place in the World.

With seventeen facilities across the United States and Canada, In-Place Machining Company is the premier provider of high-precision engineered on-site machining, large scale cutting & drilling, 3D scanning, and measurement and alignment services for a wide range of industries including renewable energy, aerospace, industrial, and military customers throughout the world. For more visit www.inplace.com.

Western Machine Works: A Division of In-Place Machining Company

Western Machine Works, LLC helps companies improve production efficiency by providing engineering and precision machine shop services including industrial repair, shaft manufacturing, precision roll grinding, thermal spray services, and roll manufacturing. Located in Portland, OR, WMW provides services to heavy industries including pulp and paper, wind and hydro power generation, marine, steel and more. For more visit www.westernmachine.com.

Corporate Contacts

Dean Flint

President & CEO In-Place Machining Company, LLC

3811 N. Holton Street

Milwaukee, WI 53212

414.562.2000

DFlint@inplace.com

Greg Allen

Sr VP & GM, Western Machine Works, LLC

12005 N. Burgard Road

Portland, OR 97203

503.286.7791

GregA@westernmachine.com

Guill Tool, global leader in extrusion tooling, recently announced the hire of three new employees. Peter Leary is the company’s new Technical Sales Engineer, while Lori Vaz and Diane Whittaker will provide customer service to clients. The announcement was made by Chuck Paull, Chief Marketing Officer, at the company’s West Warwick, Rhode Island headquarters.

Peter Leary is a mechanical engineer who brings over 10 years of application engineering experience from manufacturing, R&D and the medical/pharma industry. In his role as Technical Sales Engineer, Leary provides technical sales support and application advice for Guill Engineering products in the extrusion division. He is also available to make facility visits for consulting, troubleshooting or process improvement.

Diane Whittaker joined the company in December, 2022 as a Customer Service Representative. She supports Guill customers with order entry, order follow up and answering emails. She has worked in manufacturing for over 20 years and, before joining the company, she held several positions including customer service representative, production control lead and QC lead for a manufacturing company in Warwick, Rhode Island.

Lori Vaz became a part of the Guill team in January, 2023 as a Customer Service Representative. Her job duties are the same as Diane’s. She has extensive experience in jewelry manufacturing and 25 years of customer service experience.

Commenting on the new team members, Paull said, “They are a great addition to Guill Tool, bringing with them a wealth of experience that will undoubtedly benefit our customers across the industries we serve.”

For more information, please contact:

Tom Baldock, Sales Manager, Extrusion

Guill Tool & Engineering

10 Pike Street

West Warwick, RI 02893

USA

Phone: 401-465-5526

tbaldock@guill.com

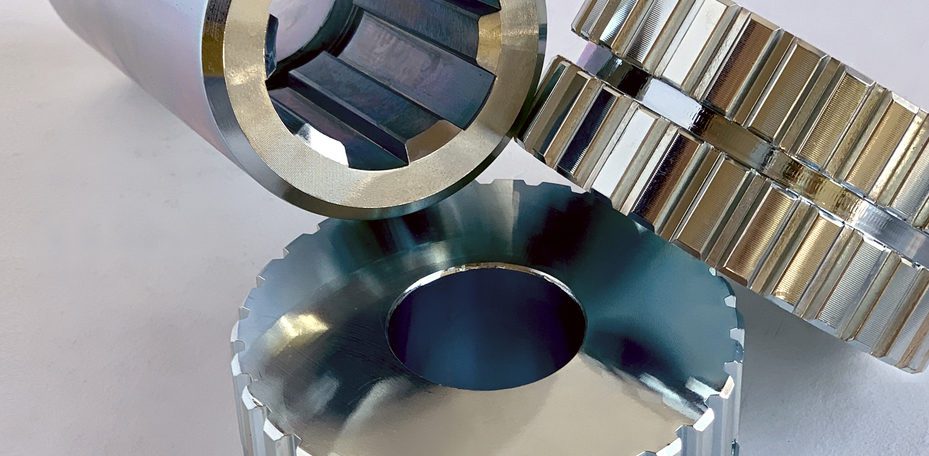

Innovative Broaching Solutions for Both CNC Lathes and Machining Centers

Platinum Tooling, the importer and master distributor of live tools, angle heads, Swiss machine products, knurling and marking tools manufactured by various international suppliers, will now carry REV broaching tools exclusively in North America. This announcement was made by Platinum Tooling president, Preben Hansen, at their headquarters in Prospect Heights, Illinois, near Chicago.

R

The REV motorized broaching tool is designed for use on live tool lathes. Single machine set-up eliminates the need for secondary operation or outsourcing. REV tools are ideal for high production runs, offer easy installation and fast processing time. These tools are designed for maximum rigidity, offer long tool life and an excellent finish.

REV broaching tools are a perfect complement to the Heimatec live tools that are sold by the extensive network of Platinum Tooling manufacturers’ representatives and distributors throughout North America.

For further information, please contact:

Preben Hansen, President

PLATINUM TOOLING TECHNOLOGIES, INC.

16 E. Piper Lane

Suite 128

Prospect Heights, IL 60070

Phone: 847-749-0633

Fax: 847-749-2445

Email: phansen@platinumtooling.com

Platinum Tooling Technologies, Inc. in Prospect Heights, IL, near Chicago, serves its growing North American customer base with an extensive inventory of machine tool accessories. Its experienced staff is dedicated to providing the most innovative tooling and technology. Platinum Tooling Technologies, Inc. serves the auto, aero, medical, woodworking, composites and other industries, as well as an ever-increasing number of machine tool OEMs, through its network of manufacturers’ representatives. Platinum Tooling is the importer of Heimatec, Henninger, Tecnicrafts, AMF, Hommel + Keller QUICK tools and REV broaching tools in North America. In addition, Platinum Tooling represents Rineck Shrink Fit Tooling in the United States and Mexico.

Schuler’s Digitalization & Modernization Workshop provided innovative and practical solutions for creating a fully networked press shop

Canton, MI, March 2, 2023—Schuler North America, subsidiary of Schuler Group GmbH, hosted a Digitalization & Modernization Workshop last week. The workshop was also the grand opening of Schuler’s Michigan Ave Service Facility.

Attendees included senior leaders, directors, and engineers from major OEM and Tier-One suppliers, the Supervisor from the Charter Township of Canton, Anne Marie Graham-Hudak, and senior editors from top trade publications.

Schuler’s Visual Die Protection (VDP) is a camera-based system designed to stop presses before damages or failures occur.

“We want our customers to take tangible information back to their shop and know that Schuler is available to support them in their digitalization journey,” states Kevin McAllister, President of Schuler North America. “I can safely say we achieved this objective based solely on the feedback we received. We will certainly host more workshops to support those that could not attend last week.”

Domenico Iacovelli, CEO of Schuler Group GmbH and Member of the Executive Board Andritz Group, and Kevin McAllister opened the workshop with a live press conference. Session topics included:

The Press Shop of the Future, presented by Tiago Vasconcellos, Sales Director at Schuler North America, identified key technologies used at Schuler’s Smart Press Shop that reshape costs, output, and carbon footprint. The Press Shop of the Future was instrumental in laying the foundation for the entire workshop as it provided attendees with the current market status and future expectations of digitalization.

Optimize Shop Floor Operations, presented by Andreas Gebele, Product Manager of Digital Automotive Solutions at Schuler Pressen GmbH, provided solutions to achieve increasements in availability, performance, and quality with Schuler’s Track & Trace, laser serialization, blank measurements, and downtime detection.

Protect Dies & Prevent Damages with VDP, presented by Samuel Czyzewski, Service & Digitalization Engineer at Schuler North America, included a live demo of Schuler’s Visual Die Protection (VDP) and the immediate ROI from the camera-based system’s capability to detect foreign objects, inspect processes, and monitor die functions.

The Shop Floor Tour, presented by Robert Tyler, Facility & Operations Manager at Schuler North America, gave attendees an inside look at the 32,000 sq. ft. facility’s 50-ton crane, in-house press pit for rebuilds and assembly, specialized equipment, and team of field service and engineering support at work.

Press Shop Planning with Cloud Solutions, presented by Andreas Gebele and Flavio Rudiger, Lead Digitalization Engineer at Schuler North America, included a live demo of Schuler’s machine applications that provide predictive maintenance to avoid efficiency losses and damage risks.

Schuler Connect provides remote service and troubleshooting support via smart glasses, smart phone, or tablet.

Get Proactive with Service Agreements, presented by Andy Osborn, Director of Modernization at Schuler North America, provided value-add predictive maintenance, remote service, and spare parts with Schuler’s Service Agreements. Two supporting topics included Schuler Smart Inspections, presented by Rodrigo DePaula Branco, Engineering Group Lead at Schuler North America, and Schuler Connect, a live demo of the smart glasses and application for safe and cost-effective remote support and troubleshooting, presented by Flavio Rudiger and Samuel Czyzewski.

Future Products, presented by Flavio Rudiger and Andreas Gebele, covered all Schuler Digital Suite products coming soon to the USA. Solutions included DIGISIM simulation software to increase productivity, Smart Assist to increase output, Smart Monitoring System (SMS) to detect machine stress from older equipment, Visual Quality Inspection (VQI) to detect part quality issues efficiently, and Service Portal to access contracts, warranties, technical equipment data, inspection protocols, service history, Schuler’s 24/7 helpline, and spare parts stock availability.

“The Digitalization & Modernization Workshop highlighted our local availability,” explains Telvi Zanin, Vice President of Service at Schuler North America. “Schuler North America has over 300 employees. We are the largest local OEM service support, and the grand opening of our new facility greatly enhances our capabilities for the local market.”

Website

About Schuler Group—www.schulergroup.com

Schuler offers customized cutting-edge technology in all areas of forming—from the networked press to press shop planning. In addition to presses, Schuler’s products include automation, dies, process know-how, and service for the entire metalworking industry. Schuler’s Digital Suite brings together solutions for networking forming technology and is continuously being developed to further improve line productivity and availability. Schuler customers include automotive manufacturers and suppliers, as well as companies in the forging, household appliance, and electrical industries. Schuler presses are minting coins for more than 180 countries. Founded in 1839 at the Göppingen, Germany headquarters, Schuler has approximately 5,000 employees at production sites in Europe, China and the Americas, as well as service companies in more than 40 countries. The company is part of the international technology group ANDRITZ.

Schuler’s global portfolio of world-renowned brands include BCN (Bliss Clearing Niagara) Technical Services, Müller Weingarten, Beutler, Umformtechnik Erfurt, SMG Pressen, Hydrap Pressen, Wilkins & Mitchell, Bêché, Spiertz Presses, Farina Presse, Liebergeld, Peltzer & Ehlers, Schleicher, and Sovema Group.

About Schuler North America—www.schulergroup.com

Schuler North America (Schuler), headquartered in Canton, Michigan, is the North American subsidiary of Schuler Group. Schuler provides new equipment, spare parts, and a portfolio of lifecycle services for all press systems—including preventative maintenance, press shop design and optimization, turnkey installations, retrofits for existing systems, and localized production and service. Schuler’s best-in-class position in the metalworking and materials industry serves automotive manufacturers and tier suppliers, as well as home appliance, electronics, forging, and other industries.

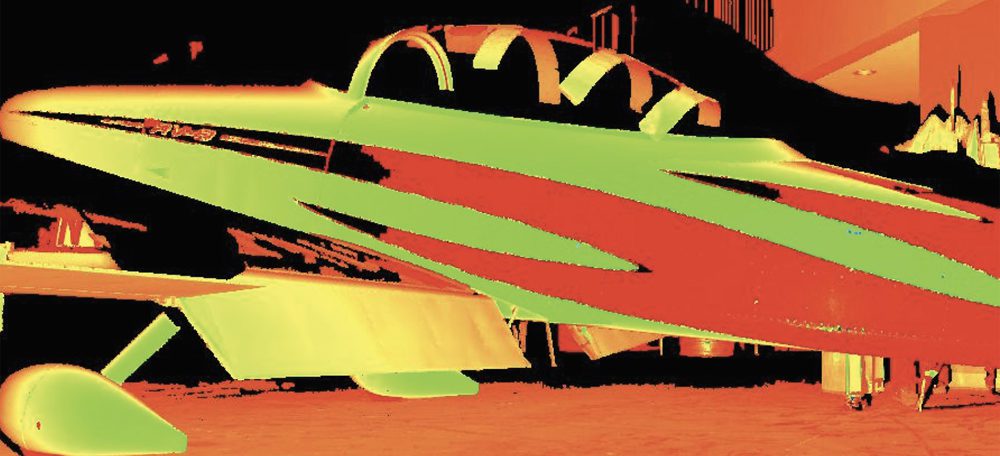

Greg Groth, Exact Metrology Division Manager, provides insight into aerospace industry trends and the benefits of recent metrology developments

Exact Metrology: A Division of In-Place Machining Company, a comprehensive 3D metrology service provider and hardware sales company, has recently seen an uptick in requests for scanning large aerospace components. Greg Groth, Division Manager at Exact Metrology’s Brookfield, Wisconsin location shares his thoughts on this development.

It is widely known that the aerospace industry has long been a driver of 3D scanning and the implementation of this technology into quality systems. When speaking of the surge in interest in scanning from aerospace customers, Groth said, “As the scanning technology’s accuracy has improved and data collection has become much faster, the viability of scanning full vehicles or component level parts has seen a dramatic increase in demand.”

For example, scanning an airplane exterior can now be completed in a matter of days when, in the past, it would take up to a week. Additionally, data processing has also become much quicker with advancements made in software and data handling. Groth added that he has seen the number of full aircraft scans nearly triple in the last year at his company.

For scanning projects of this size, Exact Metrology uses a combination of laser trackers and long-range scanners. The use of these high-precision metrology instruments allows quick scanning of large volumes as well as control of the scan-to-scan for fit and accuracy. Additionally, the alignment challenges that have long been present in the aerospace industry have been greatly reduced with the innovative capabilities of both laser trackers and today’s long-range scanners.

With aluminum continuing to be the most often used material in manufacturing aerospace skins and components, advancements made in metrology instruments now allow for highly accurate scanning both indoors in an environmentally controlled condition and outdoors when conditions are less than ideal. Newer technology can combat both the high reflectivity of chrome finishes and material expansion.

Due to scale, the metrology instruments used by Exact Metrology can vary. Groth commented that the same level of precision may not be required for a full body scan as the required specifications for panels or component level details. For these tight tolerance areas, Exact Metrology will use higher precision scanners such as PCMMS (Portable Coordinate Measurement Machines) or Structured Light scanners.

Fastening of components and structure sections is also critical. Exact Metrology specialists can leverage several different pieces of equipment with the current bandwidth of metrology hardware. For example, if off-vehicle and internal structural information is needed, CT scanning can be used. CT scanners have the ability to assess a clogged fuel line or a small manifold, for example, including evaluation of cracks or manufacturing imperfections such as porosity.

Discussing the importance of having highly precise and accurate inspection data for the aerospace industry, Groth said, “The precision we’re achieving on scans allows for more accurate duplication in reverse engineering applications, while the precise representation increases the confidence in part validation on the inspection. Accurate representations allow for more improved virtual testing such as FEA (Finite Element Analysis) or any flow based testing.”

Exact Metrology: A Division of In-Place Machining Company, is ISO9001, AS9100 Certified as well as ITAR Registered.

Exact Metrology: A Division of In-Place Machining Company, with facilities in Cincinnati, Ohio, Moline, Illinois and Milwaukee, Wisconsin, plus affiliated offices throughout the country, is a comprehensive metrology services provider, offering customers 3D and CT scanning, reverse engineering, quality inspection, product development and 2D drawings. The company also provides turnkey metrology solutions, including equipment sales and lease/rental arrangements.

In-Place Machining Company: On-Site Machining Solutions In-Place, Any Place in the World.

In-Place Machining Company, with facilities in Wisconsin, Washington, Virginia, Ohio, California, and Ontario, Canada, is the premier provider of high-precision engineered on-site machining, metrology, and large scale cutting & drilling services for a wide range of renewable energy, aerospace, industrial, and military customers throughout the world.

For more information, please contact:

Greg Groth

20515 Industry Avenue

Brookfield, WI 53045

Phone: 262-533-0793

www.exactmetrology.com

gregg@exactmetrology.com