Contact us today:

(847) 934-4500

tdaro@bernardandcompany.com

Contact us today:

(847) 934-4500

tdaro@bernardandcompany.com

High component quality with low production costs is required in many applications involving machining chucked parts. At IMTS, September 10 – 15, 2012 in Chicago, EMAG will be showing these solutions which combine these requirements. One of the highlights at the show will be the introduction of the brand new VL 2 P, a vertical pick-up turning machine which operates using pendulum technology.

Whether you want to manufacture small chuck parts or larger components, the machining processes must ensure accurate component geometry while also guaranteeing low component costs. These requirements and more are met with the VL 2 P and VL 5i vertical turning machines as well as the VSC 400 DDS turning and grinding center from EMAG. The advance in productivity is provided by the EMAG design of these machines with the integrated pick-up automation and a machine body made of polymer concrete as well as the vertical design which ensures perfect chip flow conditions.

VL 2 P: Swinging to success

Workpieces up to 100 mm in diameter can be machined in full on the innovative VL 2 P, a two-spindle turning machine. The machine has two spindles because while one workpiece is being machined, the second spindle automatically loads itself using the pick-up method. This means that the next raw part is immediately ready for machining, resulting in extremely short chip-to-chip times. The focus during the design of this machine was efficiency and eliminating idle times. The VL 2 P also has an incredibly small footprint due to its compact design, which helps decrease the chip-to-chip times. See it in action at IMTS 2012 HERE.

VL 5i: Short idle times, perfect automation

The VL 5i turning machine is a universal solution for production companies. It can completely machine workpieces of up to 250 mm in diameter in a single clamping operation. In addition to the powerful pick-up working spindle with a rating of 28 kW and a torque of 300 Nm, the machine also has an automation system with a revolving belt which contains drag frames. The machine could be described as being self-automated, which means that new raw parts can be positioned and finished parts removed at any time. Another strength of the VL 5i is its short idle times because the distance between the loading and the machining positions is just 550 mm.

VSC 400 DDS: Grinding and turning combined

The VSC 400 DDS vertical grinding and turning center combines a range of processes and guarantees extremely cost-effective processes in the production of complex chuck parts with a diameter of up to 400 mm. Within a single clamping operation, the center can complete scroll-free turning and hard turning as well as subsequent grinding processes. Grinding is only used where quality and process reliability demands it. The center can also be fitted with drilling tools or hardening modules to suit the required machining task. Even measuring tasks can be integrated.

For more information:

EMAG LLC

38800 Grand River Avenue

Farmington Hills, MI 48335

Tel: (248) 875-0313

Fax: (248) 477-7784

E-mail: info@usa.emag.com

Web: www.emag.com

Attention: Peter Loetzner

BOOTH E-5010

For machine tool builders and end-users, Siemens will exhibit the newest innovations in CNC (Computer Numerical Control), motor and drive technology, as well as new value-adding services ranging from condition monitoring and manufacturing IT to innovative solutions for CNC training and machine tool retrofits.

Highlighting the booth for attendees will be a raffle to win a Harley-Davidson motorcycle, as well as the opportunity to register for a 60-day free trial license on Sinutrain, the full suite of Siemens CNC training modules.

NEW CNC SOLUTION FOR THE SHOPFLOOR

New at IMTS 2012, Siemens will introduce a shop floor CNC specifically designed and engineered for the 230V, three-phase) economy-priced market, with up to three-axis plus spindle control capability in milling or turning applications. Offered as a package with Siemens Sinamics drives and Simotics motor solutions, this new control will be demonstrated on a knee mill, during the show. This new CNC will be available for both OEM machine builds and in-the-field retrofit.

SOLUTIONS FOR THE JOB SHOP

Introduced at IMTS 2010 and already a world-class force in the mid-range machine tool market, the Sinumerik 828D will be running on various machines and simulators in the booth. New for IMTS 2012, the Sinumerik 828D BASIC T (turning) and BASIC M (milling) will also be on display, expanding this range of Siemens CNC to enhance job shop performance in all segments of this market.

The Sinumerik 828D BASIC T is designed to address the needs of shopfloor turning machines.

It combines CNC, PLC, operator panel and axis control for five axes/spindles, including live tooling. Milling and drilling operations on a turning machine, both for face and peripheral surfacing, are therefore possible. In tandem with the new Sinamics S120 Combi drives package, the 828D BASIC T represents a new level of efficiency and virtually maintenance-free operation, as the fans, hard disks and batteries of past CNC generations are eliminated.

Likewise, the new Sinumerik 828D BASIC M class features the same quality performance as the T class, for use on milling machines. Even in complex moldmaking operations, mirror-smooth surfacing and reduced machining times are enabled. Again, in tandem with Sinamics S120 Combi drives package and Simotics feed and spindle motors, the 828D BASIC T will operate a milling machine at the highest level of performance possible. Superior axis and spindle dynamics within a broad speed bandwith yield quality workpieces, every time.

All the other benefits of the Siemens CNC family, including the Sinumerik Operate graphical user interface platform as well as ShopMill and ShopTurn easy programming are offered in these new 828D CNCs.

The Sinumerik 828D is capable of full graphical, high-level language command and supports ISO programming that is customary in the United States. This control family is ideal for single-part and small-batch production. Programming time can be further reduced for small-batch production with the use of the ShopMill and ShopTurn graphical workstep programming system, while high-level language programming can be used in conjunction with programGuide to significantly reduce programming times for large-scale serial production.

Also included with this expansion of the Sinumerik 828D family of CNC, modern PC and mobile phone technology are also available to the mid-range machine tool. Extensive online help animations and a new type of input prompting system with moving picture sequences provide the basis for exceptional user convenience. USB, Compact Flash (CF) card and Ethernet ports enable high-speed data transfers onto storage media or integration of the control system into corporate networks.

Through the use of its Easy Message functionality, the Sinumerik 828D family offers production status monitoring by text messaging (SMS). Depending on the recipient’s profile settings, the machine tool can transmit information about workpiece machining status, report on the tool condition currently in use and send machine maintenance bulletins to a mobile phone, anytime and anywhere. These combined functions are designed to help keep machine downtime to a minimum.

STILL THE HIGHEST STANDARD IN CNC

Still the highest technology standard in the industry, the Sinumerik 840D sl CNC makes

another series of advancements, all being demonstrated at this year’s show. The system platform

offers a comprehensive range of functions for machine tools. This universal control covers wide-ranging machining technologies used in metalworking operations such as turning, drilling, milling, grinding, laser machining, nibbling and punching, plus it can be used in multi-tasking machines such as turn-mill or mill-turn centers. Whatever the application, Sinumerik 840D sl leads to maximum productivity for the job shop or industrial-scale production department, as well as optimum surface quality for all mold and tool building applications.

Sinumerik Operate is the graphical user interface that provides an integrated milling function for turning machines or integrated turning function for milling machines.

With the benefit of modern touchscreen operation, the new Sinumerik operator panel OP 019, now extended to include the new Power Control Unit (PCU) 50.5, allows high-speed key actuation at the large 19-inch glass front, which conforms to the IP66 protection rating. Another new feature of the OP 019 design is the wide LEDs, which allow the operator to clearly visualize every key actuation, no matter what the angle of vision, and an integrated key lock helps safeguard against operating errors. The new operator panel is able to provide a basic machine display with three or four channels showing up to 13 axes.

Sinumerik CTRL-E is the new green high achievement in CNC operation, designed for the strict requirements of the international energy efficiency standard EN16001. It provides a full assessment of the energy consumed by the machine tool in every cycle, on every part produced and throughout the machine’s life cycle. Specific power loads can be shut down automatically during downtimes, plus generated braking energy can be stored or fed back into the power grid. In this way, Siemens Sinamics drives package are achieving up to 99% energy efficiency, while Simotics motors are likewise running 90%+ levels, unprecedented in the machine tool market previously.

Sinumerik Integrate is an onboard CNC solution that allows machine tool data to be integrated quickly, simply and reliably into other company processes. This IT integration of production processes allows managers, machine operators, part programmers, maintenance engineers and machine tool builders to be inter-connected with each other and integrated into the overall system by means of defined processes. Sinumerik Integrate facilitates this network by concentrating IT-related functions into a single process suite, using six different available modules that cover every aspect of the machine tool integration process.

SOLUTIONS FOR AEROSPACE

For the aerospace market, the Sinumerik 840D sl is the latest in CNC technology that increases performance and user productivity. It is a universal and flexible CNC system featuring the innovative Sinamics S120 drives that can be used with up to 31 axes. It is a distributed, scalable, open and

inter-connecting system, offering a wide range of specialized functions for milling, drilling, turning, grinding and handling technologies, with full kinematic transformations for optimum machining and surface quality.

The Sinumerik 840D offers users innovative features that increase productivity on the manufacturing floor, especially the challenging segments of high-speed and five-axis

aerospace machining.

Connectivity is the watchword in aerospace at this year’s show. From a single solution provider, machine builders and end users alike can enjoy full and seamless connectivity of their CNC and PLC technologies, plantwide and worldwide among facilities, as Siemens provides its international network of support to all facilities, in all operating and conversational languages. Hardware and software solutions from a single source are available, to the scale and scope needed by any aerospace OEM or tier vendor.

SOLUTIONS FOR AUTOMOTIVE

In the automotive industry, Siemens continues to solidify its position with the Transline System Solution, the solution for automotive powertrain. This system integrates diverse metalcutting technologies such as milling, drilling, turning and grinding, and the assembly of powertrain parts, under a common system architecture. With the introduction of the Flexible Assembly Configuration System (FACS), Siemens has now also streamlined the line changeover world in dramatic fashion. What took weeks now takes hours.

Based on the new Sinumerik 840D sl, Simatic PLC and Simotics motor technologies, Transline solution line transforms the company’s concept of “productivity in motion” into a real-world application for total factory automation. By specifying Transline, machine tool users benefit from faster start-up times, better equipment serviceability and increased productivity. Operator cross-training and workcell operation are further enhanced.

SOLUTIONS FOR MANUFACTURING EXCELLENCE

During the show, Siemens will also have displays of its Totally Integrated Automation (TIA) services, as well as Siemens Safety Integrated and other production network offerings. TIA Portal, enables the design and configuration of all process automation from a single computer screen, along the entire process supply chain. Siemens Safety Integrated for Factory Automation comprises advanced drive technologies, automation systems, operator control and machine monitoring, fail-safe communications and safe industrial control advancements.

SOLUTIONS FOR CNC TRAINING, CUSTOMER SUPPORT AND MOBILE APPS

SinuTrain, the Siemens package of CNC training software on CD-ROM, provides milling and turning machine operators with a high degree of practical hands-on experience, prior to using the CNCs on their actual machines. It is designed to run on Windows XP or Windows 7 operating systems and is the optimal solution for machine tool control-identical simulation training. It installs and operates with less memory, so other work can easily be accomplished during simulation of the machining.

With SinuTrain, actual NC programs are developed and simulated, using a direct connection to the company’s CAD systems to further speed the program generation protocol. In this way, machine tool operators not only learn the control language commands, but they also visualize part programs on a PC screen that are identical to the actual machine screen. As a further benefit, programs generated through SinuTrain on the PC software can then be used on the machines.

A FREE 60-DAY TRIAL LICENSE of Sinutrain will be available to all show attendees.

My Documentation Manager allows Siemens CNC users to customize online service and operations manuals to suit their specific machine tools.

New mobile apps for iOS and Android devices that are now available from Siemens will be demonstrated, including Easy CNC with G-code compatibility conversion, Motion World, the Siemens customer magazine for CNC automation and CNC4you.

Other exhibits on display in the Siemens booth include the new Simotics 1FK7 / 1FT7

high-inertia servomotors, the 1PH8 main spindle motor, linear motors and direct-drive torque motors that contribute to the increase in machine performance. The exhibition will also focus on machine tool retrofit, field service, customer service, spare parts and repair, all of which support the machine tool builder and end-user. Special displays will also feature Siemens solutions for medical part manufacturing and power generation.

In the booth’s theater area, educational seminars about CNC technology, Product Lifecycle Management (PLM) developments, factory automation and more will be presented.

Finally, Siemens will have active participation in the Automation Pavilion being held at IMTS 2012, directly adjacent to the Siemens booth in the East Hall.

For more information about Siemens CNC solutions for the machine tool industry, visit our website: www.usa.siemens.com/cnc.

Please forward all inquiries to:

SIEMENS INDUSTRY, INC.

DRIVE TECHNOLOGIES

MOTION CONTROL

MACHINE TOOL BUSINESS

390 Kent Avenue

Elk Grove Village, IL 60007

Phone: 847-640-1595

Fax: 847-437-0784

Web: www.usa.siemens.com/cnc

Email: SiemensMTBUMarCom.sea@siemens.com

Attention: John Meyer, Manager, Marketing Communication

Follow us on Facebook: www.facebook.com/SiemensCNC or Twitter: www.twitter.com/siemens_cnc_us.

—

Siemens Industry Sector is the world’s leading supplier of innovative and environmentally friendly products, solutions and services for industrial customers. With end-to-end automation technology and industrial software, solid vertical-market expertise, and technology-based services, the sector enhances its customers’ productivity, efficiency and flexibility. With a global workforce of more than 100,000 employees, the Industry Sector comprises the Industry Automation, Drive Technologies and Customer Services Divisions as well as the Metals Technologies Business Unit. For more information, visit http://www.usa.siemens.com/industry.

The Siemens Drive Technologies Division is the world’s leading supplier of products, systems, applications, solutions and services for the entire drive train, with electrical and mechanical components. Drive Technologies serves all vertical markets in the production and process industries as well as the infrastructure/energy segment. With its products and solutions, the division enables its customers to achieve productivity, energy efficiency and reliability. For more information, visit http://www.usa.siemens.com/drivetechnologies.

Continue readingLeading supplier of electro-chemical technologies introducing new machines for aero, auto, medical and nano markets

Farmington Hill, Michigan – EMAG L.L.C. here today announces the introduction of its ECM and PECM machines to the North American market. As a longtime European leader in these technologies, the company will sell and support these machines with application engineering, field commissioning and technical service from its Detroit-area location.

Electro-chemical machining takes many forms, but all involve the electrolytic dissolving of metal substrates. This technique is often utilized in applications involving hard-to-machine materials such as Inconel, high-nickel alloys, titanium etc.

Because ECM is a non-contact machining process with no heat input involved, the process is not subject to the variances inherent in conventional machining, such as tool wear, mechanical stress, microcracking caused by heat transfer, plus surface oxidation and recast layer present with EDM (electrical discharge machining), for example. By contrast, the ECM process is characterized by stress-free stock removal, smooth and precise transitions in machining contours with burr-free surfaces. End products from turbine blisks to dental implants and automotive industry products are ideal uses for this technology, according to Tobias Trautmann, product manager for ECM/PECM Products at EMAG ECM.

The many advantages of the EMAG ECM and PECM technologies for the end user include: low tool wear on the cathode, ideal for batch production; surface finishes to Ra 0.05, depending on the material, suitable for high precision pro

duction in nearly all machining areas; reproducible cutting depth to <20mm; extremely high-precision machining; no negative thermal or mechanical effects on the material, so no changes in microstructures; basic material properties are unaffected; hardness, magnetic and other performance properties are unchanged; nano and extremely thin-walled section contours are possible, critical in aero and medical applications, for example; high repeatability, owing to the consistency of the mechanical components and predictability of the machining conditions; minimal secondary operations; roughing, finishing and polishing in one machine. The process allows users to employ multiple fixtures and run the process simultaneously.

Standard features offered on the EMAG ECM Basic Series machines are a Siemens S7 controller with full graphics display, current relay and voltage monitor, pH control and conductance monitor, temperature control module, machining area of 1150mm x 950mm (45.27” x 37.40”) and two-handed operator safety controls. EMAG also provides ancillary equipment interfacing for work cell set-ups, including pre- and post-op cleaning stations and multiple machining units, as well as robotic workpiece handling.

Precise Electrochemical Machining (PECM) machines operate on the same basic principle of electrolytic dissolution, but include a mechanical oscillation mechanism for more intricate 2D and 3D microstructures. All standard machines include EMAG scalable generator technology up to 30,000 Amps, pulse frequencies to 100 kHz and a machine base of MINERALIT® or granite.

The Premium Series further offers precision imaging, surface finishes up to Ra 0.05 (relative to the material) and a high degree of precision in lowering speeds, essential for micromachining.

Complementing this new machine series is the EMAG test laboratory. Users can examine a variety of test cut scenarios to determine the optimum conditions for machining, fixturing, process performance and materials specification, matching the requirements to the most productive machines and systems available.

For more information:

EMAG LLC

38800 Grand River Avenue

Farmington Hills, MI 48335

Tel: (248) 875-0313

Fax: (248) 477-7784

E-mail: info@usa.emag.com

Web: www.emag.com

Attention: Peter Loetzner

Continue readingLeading supplier of machine tools partners with Oakland Community College; $200,000 agreement from Michigan New Jobs Training program to create 21 new jobs

EMAG president Peter Loetzner addresses a gathering during the Oakland County (MI) Economic Outlook Luncheon, April 26, 2012

Farmington Hills, Michigan – EMAG L.L.C. announces its receipt of a five-year, $200,000 agreement with Oakland Community College (OCC), through the Michigan New Jobs Training (MNJT) program, for the training of 21 new employees in manufacturing technology, CNC machine tools, mechanical maintenance, electrical and robotics disciplines.

Peter Loetzner, EMAG CEO, accepted the award from Dr. Timothy Meyer, chancellor of Oakland Community College, and J. Brooks Patterson, Oakland County Executive, during the Oakland County Economic Outlook Luncheon, held at the Troy Marriott on April 26, 2012.

Beginning the speeches at the event, OCC Chancellor, Dr. Timothy Meyer noted the critical importance of education and training in the creation and retention of manufacturing jobs in Southeastern Michigan, an area hard hit by the recent economic downturn in the auto industry and other manufacturing sectors of the economy. He then introduced Oakland County Executive J. Brooks Patterson, who continued this theme, citing the recent creation of 36,000 new jobs in Oakland County as well as other awards made to companies who’ve chosen to locate in the area.

Introducing Peter Loetzner, Meyer then detailed the collaboration between OCC and EMAG, noting how the study of mechatronics would raise the skill level of both engineers and the plant workforce to higher levels of technical competence and multi-functional abilities.

Oakland Community College Chancellor Tim Meyer announces the award of $200,000 in Michigan New Jobs Training to EMAG; 21 new employees will be trained in manufacturing at the EMAG facility in Farmington Hills, near Detroit

During his remarks, Loetzner recounted his own experience as a student in this now rapidly growing field of mechatronics, where mechanical engineering melds with electrical and electronic engineering to help students better understand the inter-relationship of components on a machine. Mechatronic engineers and field technicians are now highly valued individuals in many industries, Loetzner noted. He added that EMAG will have at least 20 openings in engineering throughout the next few years at his company, the result of increased sales and the EMAG commitment to serving the North American market from its expanding headquarters in the Detroit area. He further commented how such programs have the dual advantages of growing the manufacturing base in the area, as well as raising the skill level of the employees, which in turn attracts more businesses to Oakland County.

EMAG has engaged in training for its employees as well as its customers’ programming, operator and maintenance personnel throughout the company’s history, both in Germany and in America. The company sells its machines to job shops and original equipment manufacturers’ metalworking departments worldwide, with a heavy concentration in the automotive and off-highway machinery markets.

Loetzner thanked the OCC and Oakland County personnel who helped develop this program, especially Meyer, Patterson and Sharon Miller, the vice chancellor of external affairs at OCC. He concluded his remarks on a humorous note, “As we say in mechatronics, keep thinking INSIDE the box.”

L. Brooks Patterson, Oakland County (MI) Executive congratulates Peter Loetzner of EMAG on the award

Sharon Miller next spoke at the event, citing the creation of five new jobs programs in the last year, awarded to companies ranging from the start-up mode such as Oxus, a portable oxygen equipment distributor for the medical industry, to the multi-national truck parts supplier Meritor, who added 63 employees in Troy, Michigan as a result of the MNJT program.

Dr. Meyer concluded the speaking with several observations on the nature of education. He cited the need for institutions to be more proactive in redesigning their curriculum to better suit the needs of the local manufacturing base, plus the need to partner with more companies in the area, as well as community organizations. “After all,” he concluded, “community is our middle name!”

EMAG equipment covers the entire spectrum of machining processes in the metalworking industry, offering the latest technological advances in turning, drilling, milling, grinding, gear cutting, electrochemical machining and laser welding for the automotive, oil field, power generation and earth moving equipment industries. EMAG is a trendsetter in the field of vertical turning centers, multi-spindle machining centers and multi-functional production machines, and has become an important partner in the realization of complete process streams in the manufacture of automotive transmission, engine and chassis components.

Oakland Community College is the largest community college in Michigan, and the 21st largest in the nation. With five campuses throughout Oakland County, OCC offers degrees and certificates in more than 160 fields including university transfer degrees in business, science and the liberal arts, as well as workforce training and certificate programs. Approximately 750,000 students have enrolled at the college since it opened in 1965.

OCC also announced an award to Denso, one of the world’s largest suppliers of automotive components, totaling $2.6 million to support the creation of 169 jobs in e-learning, project management, leadership, quality and engineering at the company’s Southfield, Michigan facility.

For more information:

Kristal Kilgore

EMAG LLC

38800 Grand River Avenue

Farmington Hills, MI 48335

Tel: (248) 875-0313

Fax: (248) 477-7784

E-mail: kkilgore@emag.com

Web: www.emag.com

Major German supplier joins with new master distributor for North America; variety of presses to be marketed to iron & steel industry sectors

Ann Arbor, Michigan – During the upcoming AISTech show, May 7-10 in Atlanta, MAE Maschinen-und Apparatebau Götzen GmbH (Erkrath, Germany) will display its various press technologies for the iron and steel industry and related business sectors in Booth 1536. MAE recently announced its formation of a partnership with American Wera here for representation throughout North America.

Built on three pillars: The MAE product portfolio

In the last decades, MAE has developed increasingly from a manufacturer of standard hydraulic presses to specialists for select niche markets. The company has established a leading market position with innovative products in the fields of straightening machines, hydraulic presses and assembly machines, serving metals producers, rail, heavy equipment, energy and marine markets.

Straightening– MAE has the broadest portfolio of manual and automatically controlled straightening machines for handling round, profiled and complexly shaped workpieces available worldwide. Press forces from 15 to 25,000 kN make it possible to straighten workpieces with lengths from 40 mm to 30 m and weights from 5 g to 20 tons. Straightening accuracy to 0.01 mm is possible. In addition to the conventional bending-straightening method, MAE also offers peening-straightening for through-hardened workpieces and torsion-straightening for twisted section bars. The MAE straightening controller for the manual straightening presses in the S-RH and P-H RH Series guarantees precise and repeatable metalworking and does not necessitate specially trained operators. Measurement and straightening in one setting ensures optimal cycle times. The M-AH, ASV and ASRU Series enable automatic straightening of small, large and complex shaped workpieces. The software of the RICOS straightening controller is the result of decades of experience with various applications. Innovative MAE design ideas are further making the straightening process increasingly more powerful and faster. Various interlinking concepts allow continuous operation with low manpower requirements.

Hydraulic presses – The broad range of hydraulic standard presses in the S and DS Series with C- and O-frames as well as the four-column presses in the VS Series are based on a modular system. By recombining and adapting the individual modules, MAE finds an inexpensive, individually optimized solution with press forces up to 25,000 kN for customer needs. Hydraulic presses are exposed to considerable stresses in daily use. With 60 years of experience, MAE has a reputation for sturdy dimensioning on all components. Comprehensive calculation software in design, including the finite-element method, is a further guarantee of exceptionally strong machine construction.

Assembly – Whether you want to assemble gear parts, rotor shafts or wheelsets, MAE offers many suitable solutions. The MAE machine Series S and M-S with hydraulic or mechanical servo drive are robust machines tailored to customer application. The OPUS controller with flexible software that can be modified to fulfill customer-specific requirements guarantees control and documentation of the entire assembly process. Our horizontally acting wheelset presses in the RADS Series with forces up to 8,000 kN are the industry choice for mounting and dismounting wheelsets from railway vehicles. They stand out primarily for their innovative underlying concept, rational interlinking systems and extensive control functions.

Service – An innovative and high-quality machine is only the basis for high customer satisfaction. Equally important for continuous duty with high availability are quick-response service from experienced technicians and spare parts available immediately from stock. North American installation and service is provided by American Wera service technicians in Ann Arbor, Michigan and Queretaro, Mexico. Additionally, with our optimally staffed service centers at our headquarters in Erkrath, Germany and Beijing, China, we are able to respond quickly worldwide. Telephone support and remote diagnostics onboard the machines usually allow MAE to correct minor problems without complication or onsite service. In partnership with American Wera, our North American master distributor, MAE seeks to continue as a powerful force in the industry.

During AISTech, the following individuals will be present to assist visitors:

Robert Singer, MAE Sales Manager for North America

Joseph Kemple, MAE Product Manager for North American distributor American Wera

For more information, please contact:

GMTA (German Machine Tools of America) Formerly AMERICAN WERA, Inc.

4630 Freedom Drive

Ann Arbor, MI 48108

Phone: 734-973-7800

Fax: 734-973-3053

Web: www.gmtamerica.com

Email: joseph@american-wera.com

Attention: Joseph Kemple, MAE Product Manager

Facebook: GMTA

Twitter: @GMTA_US

A Detroit-based manufacturer of workhorse diesel engines for trucks that run millions of miles tests the durability and performance of each engine with dynamometers. This testing burns more than two million gallons of fuel each year and generates tremendous amounts of heat that is released through cooling towers in the roof. In a pilot project using Siemens Sinamics® variable frequency AC drives to control two dynamometers, the company is capturing the wasted heat energy and returning it to the factory grid, saving about $150,000 a year in utility costs. Once deployed across all 30 test stands, this solution could save $2.2 million and reduce CO2 emissions by 15 metric tons each year, making the operation more sustainable, more compliant and more profitable.

Burning more than two million gallons of diesel fuel a year should do more than simply heat the skies above Detroit, Michigan.

For years, though, that was all one leading manufacturer of diesel engines was getting from the heat produced during virtually non-stop operation of a diesel engine testing facility the size of a major league stadium. Then the company had a brilliant idea: Why not capture the energy generated by its testing and put it back into its own grid to lower its utility costs?

As part of one of the largest truck manufacturing companies in the world, the engine maker produces diesel engines for trucks, heavy equipment and other applications requiring lots of horsepower over long time periods. Its truck engines are the 600 horsepower workhorse engines that power big semi-trailer truckson the nation’s highways. They are designed to run millions of miles and non-stop testing helps ensure they can go the distance.

Although there are different types of dynamometers, this diesel engine producer uses one with an eddy-current clutch, which puts an electrical flux around the rotor of a motor providing resistance to the engine. The test beds are cooled via a water-to-air cooling system that circulates cool water through the hot machinery. The rotational force generated by the engine is used to pump the heated water up to the cooling towers on the roof where it the cool Detroit air absorbs the heat. After the cooling towers, the water is ready to be used to cool the system again.

In 2008, and the testing labs’ facilities manager and environmental engineering manager began discussing the possibility of recovering the energy produced by the engines and feeding it back into the facility’s own grid. They thought the electricity generated internally could help offset the 2.1 megawatts of electricity it buys each year from the local utility.

The Solution

With the help of AEM, Inc., a long-time Siemens channel partner, the diesel engine producer developed a pilot solution based on recovering the wasted energy by replacing the eddy-current dynamometer of two test stands with an induction motor and four-quadrant Sinamics® S150 variable frequency drive (VFD). The motor will be holding back against the customer’s test engine and thus generating energy. The S150 VFD has an “active front end” design that provides regeneration capability to recover the energy previously wasted as heat and return it to the company’s own power grid.

Planning and designing the solution using Siemens variable frequency drives began in 2008 and the deployment occurred in mid-2009.

The Results

While the pilot solution is a significant departure from the company’s existing test bed technology, the expected maintenance and environmental savings has the facilities team considering a full migration to the Siemens solution.

Given economies of scale in converting the rest of the test stands, the recovered energy will make this Siemens customer more energy self-sufficient. And the energy cost-savings would add up to potentially an additional $2.1 million a year. The company would also prevent about 15 metric tons in CO2 emissions each year.

For further tech detail on the Siemens S150 drives, please visit:

For further information on this story, please contact:

SIEMENS INDUSTRY, INC.

DRIVE TECHNOLOGIES

MOTION CONTROL

MACHINE TOOL BUSINESS

390 Kent Avenue

Elk Grove Village, IL 60007

Phone: 847-640-1595

Fax: 847-437-0784

Web: www.usa.siemens.com/cnc

Email: SiemensMTBUMarCom.sea@siemens.com

Attention: John Meyer, Manager, Marketing Communication

Follow us on Facebook: www.facebook.com/SiemensCNC or Twitter: www.twitter.com/siemens_cnc_us.

—

Siemens Industry Sector is the world’s leading supplier of innovative and environmentally friendly products, solutions and services for industrial customers. With end-to-end automation technology and industrial software, solid vertical-market expertise, and technology-based services, the sector enhances its customers’ productivity, efficiency and flexibility. With a global workforce of more than 100,000 employees, the Industry Sector comprises the Industry Automation, Drive Technologies and Customer Services Divisions as well as the Metals Technologies Business Unit. For more information, visit http://www.usa.siemens.com/industry.

The Siemens Drive Technologies Division is the world’s leading supplier of products, systems, applications, solutions and services for the entire drive train, with electrical and mechanical components. Drive Technologies serves all vertical markets in the production and process industries as well as the infrastructure/energy segment. With its products and solutions, the division enables its customers to achieve productivity, energy efficiency and reliability. For more information, visit http://www.usa.siemens.com/drivetechnologies.

Continue readingSiemens Sinumerik 840D is the control of choice on turning, grinding and turn/grind models, resulting in substantial savings for its customer and EMAG

EMAG L.L.C. is the U.S. subsidiary of a major German machine tool builder who specializes in machine tools for the production of automotive, off-highway, agricultural and oil field components. The company’s equipment ranges from basic prismatic part turning centers to large workpiece, five-axis machining centers, gear hobbing machines and alternative cutting equipment such as lasers and electro-chemical machining centers. This wide variety of machine tools requires an assortment of control technologies to power and manage the motion. For one recent customer requirement, where a major agricultural equipment builder in Iowa needed grinding, turning and turn-grind machines, EMAG looked to its longtime partner Siemens for a standardized CNC solution.

CEO Peter Loetzner put it simply, “We needed to devise a control solution that would satisfy all the needs of the various machines we were supplying to this demanding customer, based on a common platform, to enable easier design, integration, start-up, commissioning on-site and training for our customer’s operations and maintenance personnel.” After reviewing the entire line of CNC offerings from various suppliers, the decision was made to use the Siemens Sinumerik 840D CNC for all of the grinding, turning and turn-grind machines to be supplied. Collaboration was a key element in the decision-making process, as Loetzner explains.

“The control we selected offered great flexibility in application, which was very important to us and our customer. They were seeking a scenario that would allow considerable cross-training of their operators, who might run a turning center one day, then a grinding or turn-grind center the next.” Loetzner further noted the control chosen offered his machine designers and the customer’s production management team an enhanced remote monitoring feature, so changes could be made on the fly with very little downtime. As a result, over 20 machines of various sizes and styles can be monitored over a wireless network, enabling process engineers to see what the operator sees on each machine.

Furthermore, owing to the global capabilities of Siemens, Loetzner commented on the control’s ability to function

in U.S., German and even Asian factories with seamless data integration. Regardless of the machine tool’s location, EMAG and its customer are able to monitor the performance of any particular machine and even report comparative production data from one continent to another. Because it sells into every industrialized nation, EMAG “…works with its customers on every aspect of a job, from the order process to tooling usage, materials handling strategies to predictive maintenance. The cultural differences are substantial sometimes and the control must be programmed to adapt to such variations. We have been most satisfied with the help Siemens has provided to us, worldwide, in this area.”

Those differences, he continued, must nonetheless be based on a common technology to streamline the integration of the CNC on the machines under construction.

Loetzner cited specifics from the project referenced in this story. “We were looking at a fairly diverse group of machines being supplied to the customer. Frankly, many of their operators were more comfortable with a CNC that is very popular in the American job shop community. However, we were able to demonstrate the immediate advantages of the Siemens control to them and they accepted our recommendations.” This value proposition, he said, hinged on the greater capability of the Sinumerik 840D to run different machine types, which translated into considerable savings on the training and commissioning side of the equation. Coupled with the remote monitoring and programming aspects of the Siemens control solution, the customer was convinced.

Production VSC from EMAG is a vertical pick-up turning center capable of milling, turning, grinding, drilling, even gear profiling and honing.

More than 75 percent of the EMAG machines at this particular customer are equipped with robotic devices, enabling a lights-out manufacturing scenario, another instance where the Siemens remote monitoring via Ethernet feature benefits both the machine tool builder and its customer alike. Loetzner explains, “Remote monitoring of the machine tools can be done directly through the Sinumerik CNC in a one-to-one exchange between our customer and us. Alternatively, we can communicate with Siemens and our customer in a three-way exchange of machine data and cycle information, all protected through a firewall for security and customer peace-of-mind. That’s important with all our major OEMs, of course.” Loetzner cited one customer in the agricultural machine building market, who’s used the remote monitoring capability of the Sinumerik CNC on a wide variety of EMAG machines for over three years currently, with all data communicated through a single information network, accessible by both EMAG and the control supplier. Significant reductions in downtime, service calls and troubleshooting identification time have been achieved, translating into documented savings for everyone.

Shaft machining is done on a VTC, with full 4-axis machining plus loading and unloading, all controlled by a Siemens CNC.

As a further advantage to the machine tool builder, the space reduction of more than 20 percent in the control, compared to competitive brands, meant a smaller footprint for the machine, further improving the workspace productivity of the EMAG machines for their customer. Especially in brownfield applications, where a limited space is being utilized to maximize production for an OEM, this physical space-savings combines with other advantages of the Siemens control, according to Peter Loetzner. These include reduced wiring and lower power consumption with the attendant lower operating temperatures, due to reduced ambient heat.

At this particular customer, the EMAG machines are used to produce gears, gear blanks, shafts and splines for

powertrain applications. Gear hobbing and synchronous support grinding are among the advanced machining technologies performed here. Heavy, hardened steels are the most often worked substrates.

The specific control used on these machines is the Siemens Sinumerik 840D solution line, a distributed, scalable and open control for up to 31 axes of motion, incorporating the CNC, HMI, PLC, closed loop control and communications functions into a single NC unit. Sinumerik Safety Integrated further provides a comprehensive, yet efficiently packaged suite of personnel and machine protection functions, fully compliant with internationally-accepted standards.

Commenting on the competing brands of CNC often found in job shops worldwide, Loetzner noted that the Siemens communication architecture easily accepts input from such devices, owing to its ability to capture, standardize and transmit all data in a seamless manner through its legacy tracking. “This service is another example of a forward-thinking supplier, such as Siemens, responding to brownfield conditions in the marketplace,” he noted.

EMAG machines are used by the majority of American companies for the production of such products in the Agriculture, Earthmoving, Motorcycle and Automotive and subsequent leading TIER1 suppliers. The machine builder has had a presence in the American market for over 20 years and, according to Peter Loetzner, “…we’ve received great support from Siemens, both in Germany and in the United States, for on-site service, application engineering, parts distribution, remote monitoring implementation and communications between our customers and us.”

For more information on this story, please contact:

EMAG L.L.C.

Peter Loetzner

CEO

38800 Grand River Avenue

Farmington Hills, MI 48335

Phone: 248-477-7440

Fax: 248-477-7784

Web: www.emag.com

Email: info@emag.com

OR

SIEMENS INDUSTRY, INC.

DRIVE TECHNOLOGIES

MOTION CONTROL

MACHINE TOOL BUSINESS

390 Kent Avenue

Elk Grove Village, IL 60007

Phone: 847-640-1595

Fax: 847-437-0784

Web: www.usa.siemens.com/cnc

Email: SiemensMTBUMarCom.sea@siemens.com

Attention: John Meyer, Manager, Marketing Communication

Follow us on Facebook: www.facebook.com/SiemensCNC or Twitter: www.twitter.com/siemens_cnc_us.

—

Siemens Industry Sector is the world’s leading supplier of innovative and environmentally friendly products, solutions and services for industrial customers. With end-to-end automation technology and industrial software, solid vertical-market expertise, and technology-based services, the sector enhances its customers’ productivity, efficiency and flexibility. With a global workforce of more than 100,000 employees, the Industry Sector comprises the Industry Automation, Drive Technologies and Customer Services Divisions as well as the Metals Technologies Business Unit. For more information, visit http://www.usa.siemens.com/industry.

The Siemens Drive Technologies Division is the world’s leading supplier of products, systems, applications, solutions and services for the entire drive train, with electrical and mechanical components. Drive Technologies serves all vertical markets in the production and process industries as well as the infrastructure/energy segment. With its products and solutions, the division enables its customers to achieve productivity, energy efficiency and reliability. For more information, visit http://www.usa.siemens.com/drivetechnologies.

Continue reading

Al Hunter passed peacefully on October 29, 2011 in Naples, Florida. A true giant in the world foundry market, Mr. Hunter changed the way sandcasting was done, by his invention of the matchplate molding and mold handling system in 1964, when he built his first machine, helped by his son and current president of the company, Bill, for sale to Moline Corporation of St. Charles, IL, a malleable iron foundry. He will be missed by all who knew him and appreciated his zest for life and especially his love of invention.

Born on the family farm in Wilkie, Saskatchewan on July 13, 1922, Al left home at 17, took a bus to Edmonton, Alberta and worked in a meat packing plant. In the Spring of 1940, he took a training course in airplane mechanics and then joined the Royal Canadian Air Force at 18.

Married to the late Margaret in Montreal in 1943 and released from military service in 1945, Al moved to Toronto to enter the university there, working as a floor molder at John T. Hepburn Foundry to pay for his part-time schooling.

Three children followed, Bill (current president of Hunter Automated) in 1946, Dianne in 1947 and Linda in 1949. In 1951, Al received his BSME from the University of Toronto and moved back to Montreal to accept a position with Dominion Engineering.

A daughter Heather (wife of current Hunter VP Kevin Purdy) was born in 1956. The following year, Al brought the family to America and accepted a position as chief engineer at Beardsley & Piper in Chicago, a leading builder of machinery for metalcasting and inventors of the SandSlinger technique.

At the end of 1963, Al left B&P to develop his concept for an automatic matchplate molding system. In March of 1964, he founded Hunter Automated Machinery Corporation.

Having run the company day-to-day through 1988, Al turned over the operations to his son Bill, wishing to devote more time to his design and invention activities.

During his tenure at the head of the company, Al formed partnerships and reciprocal agreements with companies worldwide, a tradition that continues today, as Hunter Automated continuously seeks to serve its myriad customer needs for sand handling, testing, molding and finishing operations. Hunter Automated is known worldwide in the foundry industry and its machines are found on every continent.

Al developed various concepts used every day in foundry operations, including multi-level mold handling systems and automatic coresetters. His pioneering, can-do spirit will be missed by all who knew him and admired his total commitment to improving the world foundry market.

He was a member of AFS since 1960, was presented with the society’s Management Service Citation in 1990 and received the foundry industry’s prestigious Grede Award in 2001. He held over 80 patents.

Al will be mourned by his children, their spouses, his 13 grandchildren, 19 great-grandchildren and 1 great-great-grandchild, as well as his family of employees at Hunter Automated, who will carry on his legacy.

The Hunter family asks that interested parties please contribute in Al’s memory to the Foundry Educational Foundation, c/o AFS, 1695 N. Penny Lane, Schaumburg, IL 60173 or at www.fefinc.com.

For more information, please contact:

HUNTER AUTOMATED MACHINERY CORPORATION

2222 Hammond Drive Schaumburg, IL 60196

Phone: (847) 397-5110

Fax: (847) 397-8254

Email: info@hunterfoundry.com

Attention: Bill Hunter, CEO

Web: www.hunterfoundry.com

Connect with Hunter Foundry online:

Simotion D motion control systems are the ideal solution for production machines covering all levels of performance — from simple single-axis positioning tasks to complex synchronous applications — with extremely short cycle times on a large numbers of axes. Thanks to its scalability, Simotion D offers users a high degree of flexibility for the ever-changing demands on machine automation. The Simotion D drive-based multi-axis control system not only offers PLC, motion control and advanced technology functions, but also an integrated drive control based upon Siemens Sinamics S120 drives.

Today, with the new Simotion D445-2 DP/PN and D455-2 DP/PN versions, the performance range has been extended even higher. Compared to the previous generation, the maximum quantity has been doubled to 128 axes and the memory capacity significantly expanded. This has increased the PLC and motion control performance by a factor of three. With Simotion D445-2 DP/PN and D455-2 DP/PN, the previously optional Profinet I/O interface has now been integrated on the modules as standard. This frees up the option slot for other expansion cards. The onboard interface is equipped with an integrated three-port switch and facilitates different network topologies such as line, star or tree structures, without the need for additional external switches. The interface not only supports real-time (RT), but also isochronous real-time (IRT) data exchange and can be operated as a controller and / or device of another controller.

In addition to the Profinet interface, Simotion D445-2 DP/PN and D455-2 DP/PN also have two Profibus and two Ethernet interfaces, as well as 28 digital I/Os, of which 16 can be used for technology tasks such as output cams and measuring inputs with micro-second resolution.

For more information about motion control solutions and services from Siemens, point your web browser to www.usa.siemens.com/motioncontrol. Join the community by following us on Facebook: www.facebook.com/siemens.dt.us and talking to us on Twitter: www.twitter.com/siemens_dt_us.

The new Simotion D motion controllers for production machines cover all levels of performance, from simple positioning tasks to demanding applications with extremely short cycle times or large numbers of axes, up to 128.

Please forward all inquiries to: Siemens Industry, Inc. Motion Control Business 390 Kent Avenue Elk Grove Village, IL 60007 Attn: Marketing Communications

For specific product information and inquiries, call (800) 879-8079 ext. Marketing Communications

or send an e-mail to: SiemensMTBUMarCom.industry@siemens.com

Siemens Industry

Siemens Industry, Inc. is the U.S. affiliate of Siemens’ global Industry Sector business—the world’s leading supplier of production, transportation and building technology solutions. The company’s integrated hardware and software technologies enable comprehensive industry-specific solutions for industrial and infrastructure providers to increase their productivity, sustainability and profitability. The Industry Sector includes six divisions: Building Technologies, Industry Automation, Industry Solutions, Mobility, Drive Technologies and Osram Sylvania. With nearly 204,000 Siemens Industry Sector employees worldwide, the Industry Sector posted a worldwide profit of $4.7 billion on revenues of $47.3 billion in fiscal 2010. www.usa.siemens.com/industry

Drive Technologies

A division of Siemens Industry, Inc., the Drive Technologies Division is the world’s leading supplier of electrical and mechanical products, applications and solutions that cover the entire drive train. Drive Technologies is the global leader in energy-efficient motors and drives, as well as products and services for production machinery and machine tools. Technologies include standard products, industry-specific control and drive solutions, as well as mechatronics support and online services for web-based fault management and preventive maintenance. Drive Technologies provides its customers with energy-efficiency, productivity and reliability in industries as diverse as clean and renewable energy, transportation, oil and gas, utilities, metals and mining, machinery manufacturing and machine tools. With nearly 36,000 employees worldwide, the Drive Technologies Division posted worldwide revenues of $9.5 billion in fiscal year 2010. www.usa.siemens.com/drives

Continue reading

Free 1-Hour Webinars:

Tuesday, August 23

Wednesday, September 7

SIGMASOFT®: Analyze the Entire Mold

Wednesday, September 21

SIGMASOFT®: Benefits of Multi-Cycle Analysis

Tuesday, September 27

SIGMASOFT®: Simulation Setup Demo

Wednesday, October 12

Thursday, October 13

SIGMASOFT®: Post-Molding Simulation

Webinar Time: 1pm ET / 10am PT

When it comes to making the right design, tooling, and process decisions, the accuracy of simulation makes all the difference.

Sign up now to learn why SIGMASOFT® is the polymer injection molding simulation software of choice.

“We are pleased to recommend SIGMASOFT® as the most promising simulation package today. We think both the software and the people behind it can be trusted to support your quest for accurate results; results that produce good molds and good processes that the processors can actually run.”

– Matt Groleau, President & CEO, RJG, Inc.

Webinar Descriptions

Introduction to SIGMASOFT®

The reason SIGMASOFT® simulations are so accurate is rooted in its history. The core simulation physics and programming in SIGMASOFT® were developed by the same company that makes MAGMASOFT® – the foundry and die casting industry’s de facto standard for metal casting simulation. Taking those decades of 3D simulation expertise and applying them to the realm of polymer injection molding, SIGMASOFT® delivers an unprecedented set of 3D simulation tools for designers, engineers and analysts, relevant to today’s complex design-for-injection molding process. SIGMASOFT®’s key differentiators will be highlighted through a detailed presentation.

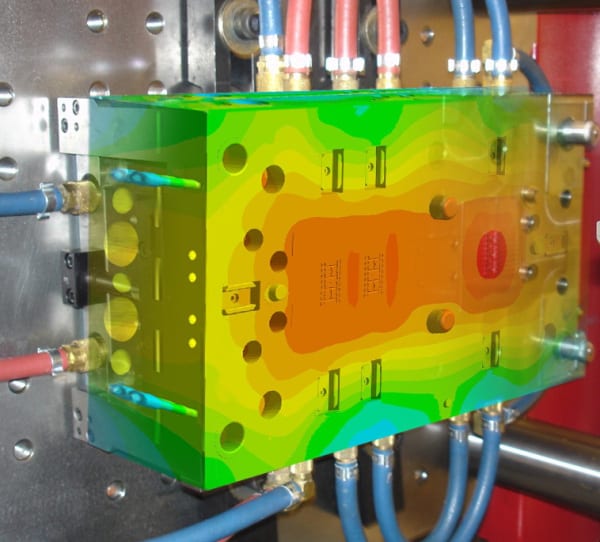

SIGMASOFT®: Analyze the Entire Mold

SIGMASOFT® generates simulations in a fundamentally different way than traditional simulation tools. When process simulation is coupled with all of the mold components, the entire injection mold and process is simulated, rather than assumed. This allows users to make accurate and confident decisions about tooling designs and process parameters. These capabilities will be shown through a powerpoint presentation and software demonstration.

SIGMASOFT®: Benefits of Multi-Cycle Analysis

SIGMASOFT® Multi-Cycle analysis enables you to analyze multiple cycles as the mold reaches the quasi-stationary state and use the actual mold temperature variances for the simulation. This ensures the most realistic process and accurate simulation. These capabilities will be shown through a powerpoint presentation and software demonstration.

In-depth injection molding simulation software has traditionally been used by analysts who have the expertise to setup the complex mesh model required for simulation. With SIGMASOFT®, the meshing is done quickly without requiring “mesh clean-up”. This allows designers, engineers, and managers in charge of mold and process layout to run complex injection molding scenarios easily. Companies no longer need to rely on a “meshing expert” to employ injection molding simulation. A software demonstration will highlight the model import and setup process for running analysis.

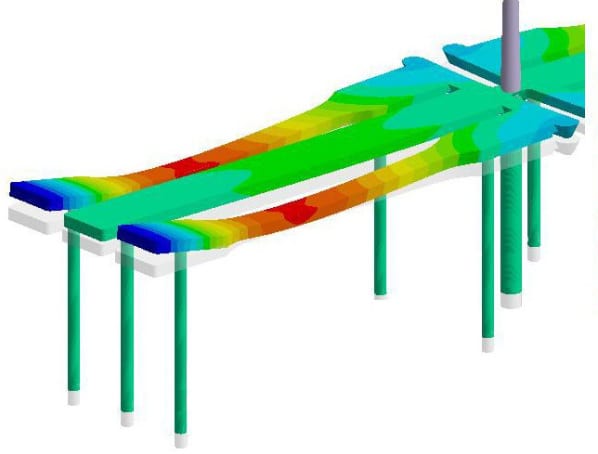

SIGMASOFT®: Importance of Post-Molding Simulation

Calculate more and assume less. SIGMASOFT® continues to calculate what happens to the part(s) after ejection. After ejection, the part continues to cool to ambient temperature which results in additional stress relaxation & crystallization (for semi-crystalline materials). Capturing this portion of manufacturing is important to the final shrinkage, warpage, and stress prediction. These capabilities will be shown through a powerpoint presentation and software demonstration.

NOTE: Attendees will have the opportunity to ask questions at the end of each webinar. It is recommended to attend the “Introduction to SIGMASOFT®” webinar prior to attending the topic-specific webinars (but not required).

Continue reading