Contact us today:

(847) 934-4500

tdaro@bernardandcompany.com

Contact us today:

(847) 934-4500

tdaro@bernardandcompany.com

SCHAUMBURG, IL – Hunter Foundry Machinery Corporation, world leader in matchplate molding and mold handling, has announced the promotion of two key international sales directors. Former Director of Hunter-Europe Paolo Nazari, PhD has been named Managing Director – International, and former Director of Hunter do Brasil Eng Gustavo Debona has been named Director – South America.

According to company President & CEO William G. Hunter, “Paolo and Gustavo have been instrumental in enhancing and expanding our global presence. These promotions recognize their contributions to our company, as well as helping to affirm its future direction.”

The opportunity to deepen customer support and consolidate its European presence prompted Hunter to open a sales and engineering facility in Legnano (Milan) Italy, when Dr. Nazari began with the company in April 2011. As Managing Director – International he is responsible for directing and managing sales, and operations (including Hunter’s sales agent network) in Europe, Russia and the Commonwealth of Independent States (CIS) countries, plus Africa and the Middle East, as well as South America.

Eng Gustavo Debona joined Hunter in 2001, as service manager for its South American customers when the company opened its Santa Catarina, Brazil facility. In 2010 he was named Director of Operations for Hunter do Brasil, and as Director – South America is responsible for coordinating service, sales and management of operations throughout the continent.

For more information on the products in this story, please contact:

HUNTER AUTOMATED MACHINERY CORPORATION

2222 Hammond Drive Schaumburg, IL 60196

Phone: (847) 397-5110

Fax: (847) 397-8254

Email: info@hunterfoundry.com

Web: www.hunterfoundry.com

Connect with Hunter Foundry online:

—

ABOUT HUNTER

Hunter Foundry Machinery Corporation was established in 1964 as Hunter Automated Machinery Corporation with the invention of the world’s first gravity-filled automated matchplate molding machine. This began the company’s history of innovation and launched the foundry industry into a new industrial revolution. Pioneered by William “Al” Hunter in his home garage, the original HMP-10 machine streamlined the laborious metal casting process by offering foundries unimagined new capabilities by producing as many molds in one hour as most had previously been produced in an entire day. As industry demands grew, Hunter responded with advanced solutions such as automated mold handling equipment and coresetters.

Now in its 50th year, Hunter Foundry Machinery Corporation’s inventions have earned nearly 150 U.S. and international patents. Hunter has produced more than 1,800 molding machines and mold handling systems for customers around the world. The company’s global reach extends from offices in the U.S., Brazil, China, India and Italy through North American, South American and Asia-Pacific manufacturing sites. Hunter’s sales and technical support is underscored by its $12 million parts inventory, established to maintain each machine’s original production capability across the worldwide foundry market.

Continue reading

The new interactive e-brochure offered from Chemcoaters includes a virtual tour of their leading “green” coil coating facilities, with links to company literature and videos from the company’s management team.

Click HERE to download the e-brochure!

Based in Gary, Indiana, Chemcoaters is a leading supplier of green coil coatings, as well as traditional prepaint and protective coil coatings such as dry film lubes and RoHS-compliant coatings. Virtually no VOCs or HAPs are present in the process.

The company’s patented InterCoat®ChemGuard is formulated with trivalent vs. hexavalent chrome, making it environmentally friendly in all building, architectural and mechanical appliance applications. Superior corrosion resistance, as well. Chemcoaters offers a presentation that evidences that fact to all interested parties.

For more information, please contact:

Mike Tieri

Director of Sales Marketing

Chemcoaters, Inc.

700 Chase Street

Gary, IN 46404

Phone: 877-411-2905

Email: miket@chemcoaters.com

Website: www.chemcoaters.com

Family of high-performance, corrosion-inhibiting coatings, used as stand-alone coating or hybrid pre-treatment

Effective immediately, InterCoat® ChemGuard is now a registered trademark of Eco-Green Coatings, LLC a division of Chemcoaters, Inc., the Gary, Indiana-based coil coater in service to metals producers, service centers and OEMs nationwide. This announcement was made today by company president Bill Capizzano at Chemcoaters headquarters.

The InterCoat® ChemGuard family of stand-alone coatings and hybrid pretreatments is highlighted by the ChemGuard 300 Series, a RoHS-compliant (hexavalent chrome-free) coating that features the unique chemistry of trivalent chromium vs. the standard hexavalent chromium used for decades in the metals coating industry. With comparable or, in many applications, superior corrosion resistance to hexavalent chrome treatments, this coating bridges the long-standing divide between performance and environmentally-friendly product in the market.

InterCoat® ChemGuard is a highly corrosion-inhibiting and adhesion-enhancing coating technology that creates a permanent covalent reaction with any zinc or zinc-alloy coated substrate. Used as a hybrid pretreatment, the product enhances corrosion resistance in a 20%-50% thinner coating onto the substrate, while exceeding the prevalent corrosion standards in industry, ASTM A1003/A1003M.

Since its development in 2011, the InterCoat® ChemGuard family has grown to include a RoHS compliant trivalent chrome product with many color tinted versions of the product now available.

Used as a pretreatment, InterCoat® ChemGuard is an ideal complement to pre- and post-paint, powder and other surface coating requirements.

Originally developed for the metal stud and other building/construction applications, InterCoat® ChemGuard coatings are now used extensively in end products for the transportation (automotive, bus, truck and RV), consumer products (appliance, power-gen, and HVAC), agricultural and off-highway vehicle markets, among others.

Based in Gary, Indiana, Chemcoaters, Inc. is a leading supplier of green coil coatings, as well as traditional prepaint and protective coil coatings such as dry film lubes and other RoHS-compliant coatings. Virtually no VOCs or HAPs are present in the process.

The company’s patented InterCoat® ChemGuard 300 coating is formulated with trivalent chrome vs. hexavalent chrome, making it environmentally friendly in all building, architectural, transportation and consumer appliance applications. InterCoat® ChemGuard 300 coating has superior corrosion resistance, as well. Chemcoaters offers a presentation that evidences this fact to all interested parties.

See the video to learn more HERE.

For more information, please contact:

Mike Tieri

Director of Sales Marketing

Chemcoaters, Inc.

700 Chase Street

Gary, IN 46404

Phone: 877-411-2905

Email: miket@chemcoaters.com

Website: www.chemcoaters.com

Connect with Chemcoaters online:

Continue reading

BOOTH E-5010: Click here to add Siemens to your IMTS Show Planner!

From the job shop to the retrofit operation, moldmakers to mass production departments at the world’s leading auto, aero and medical manufacturers, Siemens continues to push the envelope on CNC technology. With the introduction of the Sinumerik 808D at IMTS in 2012, we took a bold step into the job shop world, as this basic CNC brings the power, flexibility and reliable performance of Siemens technology to the job shop. Already accepted as an OEM component by numerous mill and lathe builders, the 808D provides job shops the unique opportunity to apply advanced and unmatched CNC power to their existing machines, breathing “new life into old iron,” as the saying goes.

The 808D rounds out the growing family of CNC models from Siemens, which now spans the range from the most basic 3-axis machines to dedicated milling and turning center controls in the Sinumerik 828D to CNC for the most advanced five-axis machining centers, with full robotic integration, secondary ops management and transfer line capability, all on a single control, the Sinumerik 840D sl solution line, still the benchmark by which all other CNC technology in the market is judged. Simply put, nobody matches the muscle of Siemens. Come to booth E-5010 and see the difference. Productivity in Motion!

For more information about Siemens CNC solutions for the machine tool industry, visit the website: www.usa.siemens.com/cnc.

Please forward all inquiries to:

SIEMENS INDUSTRY, INC.

DRIVE TECHNOLOGIES

MOTION CONTROL

MACHINE TOOL BUSINESS

390 Kent Avenue

Elk Grove Village, IL 60007

Phone: 847-640-1595

Fax: 847-437-0784

Web: www.usa.siemens.com/cnc

Email: SiemensMTBUMarCom.sea@siemens.com

Attention: John Meyer, Manager, Marketing Communication

Follow us on Facebook: www.facebook.com/SiemensCNC or Twitter: www.twitter.com/siemens_cnc_us.

—

Siemens Industry Sector is the world’s leading supplier of innovative and environmentally friendly products, solutions and services for industrial customers. With end-to-end automation technology and industrial software, solid vertical-market expertise, and technology-based services, the sector enhances its customers’ productivity, efficiency and flexibility. With a global workforce of more than 100,000 employees, the Industry Sector comprises the Industry Automation, Drive Technologies and Customer Services Divisions as well as the Metals Technologies Business Unit. For more information, visit http://www.usa.siemens.com/industry.

The Siemens Drive Technologies Division is the world’s leading supplier of products, systems, applications, solutions and services for the entire drive train, with electrical and mechanical components. Drive Technologies serves all vertical markets in the production and process industries as well as the infrastructure/energy segment. With its products and solutions, the division enables its customers to achieve productivity, energy efficiency and reliability. For more information, visit http://www.usa.siemens.com/drivetechnologies.

Continue readingLeading supplier of quenchants to commercial and captive heat treaters will also display assortment of Chemtool lubricants and greases for the industry

Photo courtesy of Scot Forge

Pioneers in the development of polymer quenchants back in the 1960’s, Tenaxol, part of the Chemtool family of companies in Rockton, Illinois, will demonstrate its comprehensive line of UCON® brand polymer quenchants at this year’s Furnaces North America show, being held October 6-8 in Nashville, Tennessee. Tenaxol will be located in Booths 300-302 at the show.

Photo courtesy of Scot Forge

Polymer quenchants were developed by Ross Blackwood, the founder of Tenaxol, in the early 1960’s and the first UCON® products were patented in 1965 as a safe alternative to oil quenching, owing to their unique polyalkylene glycol chemistry plus corrosion inhibitors. The products also yield superior surface integrity on all ferrous and non-ferrous metals, when compared to water quenching, especially in the areas of thermal cracking and distortion. UCON® brand polymer quenchants have become the industry standard over the years and the full range of products today includes UCON® ULTRAQUENCH PLUS, featuring advanced anti-microbial protection and enhanced foam control, plus a non-nitrite corrosion inhibitor for improved surface protection. Additionally, UCON® ULTRAQUENCH RL PLUS is an ideal solution for quenching medium high-carbon steels and most alloyed grades, including 300 and 400 Series stainless.

Chemtool is a global leader in the formulation and supply of various lubricants, cleaning agents, cutting fluids for metalworking machinery and other solutions for a wide variety of industrial applications.nThe company is also a major private label supplier to the distribution channels at many of the giants in the off-highway and other machinery markets.

Tenaxol has factory sales based in the Rockton, Illinois headquarters, near Chicago, plus manufacturers’ representative offices in strategically located cities throughout North America.

For more information, please contact:

TENAXOL TECHNOLOGIES

A Chemtool Company

801 West Rockton Road

Rockton, IL 61072

Phone: 815-957-4140

Web: www.chemtool.com

Email: sales@chemtool.com

Attention: Jim Harrison

Advanced Machine & Engineering Co.

AME is taking it to the next level with Inbound Marketing + Social Media + CRM + Tradeshows.

Advanced Machine & Engineering Co. (AME) has achieved manufacturing excellence over the last few decades by providing some of the highest quality machine tool component products and services the market has to offer. Now, we are taking the next steps to improve our business and increase our market share even more. It hasn’t always been easy getting from where we were nearly 50 years ago to where we are now. But we can honestly say the hardest parts are behind us. You can only improve products and processes so much before there is little to no room left for improvements. Although we will continue to innovate further, we have successfully neared that point in our manufacturing processes for a few reasons.

First, we have implemented lean thinking principles which allow us to operate with less unnecessary expenses, for example, excess inventory and waste. Second, we have become a continuous improvement…

Continue readingby Gerhard Flores, Andreas Wiens, Oliver Stammen

Download the PDF HERE.

Summary

The possibility of position correction with high precision and material removal of up to 0.350 mm in 18 s puts the single-machine honing of transmission gears and other components firmly in the forefront of current automotive manufacturing technology. Despite very high cutting performance, the low machining forces and temperatures enable the lowest marginal zone variances and high residual compressive strength. The surface roughness with a high material content in low cutting depth and the hone angle structure have a positive tribological effect on the sliding function of the gear.

An additional innovative manufacturing strategy is the use of machines for combination machining. This fact is especially advantageous in the machining of planetary gears. Here, the process of flat finishing, ID grinding and honing are systematically combined in a single machine, as detailed in this presentation.

Introduction

The honing of gears, by definition, facilitates ease of operation, low noise and smoother performance in a transmission. Honing also contributes to reduced friction in the powertrain. Both the intense cutting (roughing process) as well as the functionally fine finishing of transmission gears can be performed in one setup, on one machine. Honing in mass production is a well-established process, owing to the intelligent machine layout and other combinations with defined cutting geometries. It should be technologically and economically considered as a serious production method. Furthermore, the combined process of flat surfacing and honing on one machine is a further recent innovation for the finish machining of planetary gears in mass production.

The design of components for modern vehicle transmissions such as manual, automatic or dual clutch styles seeks to reduce friction, thereby increasing gear efficiency in addition to function. Therefore, for the gear bores of various active transmission components and planetary gears, there is the requirement for low-friction and wear-resistant contact topographies. Also, there is the desire for economical finish machining of the bore in one process, whenever possible.

The finish machining of transmission components in mass production is currently being done using rough honing and finish honing. In one process, consisting of two steps on one machine, the functionally accurate shape and position tolerances, as well as the desired surface structure, can be achieved. Therefore, secondary hard turning and grinding processes are seldom required as finish processes in mass production, neither individually nor as combined processes in a work cell.

The diverse quality characteristics require an adjustment to individual process components of honing. The manufacturing quality of the conventional hone process is defined by the terms “dimensional tolerance” and “surface finish.” Furthermore, for the function of gear wheels, the quality terms “axial run-out” and respectively, “perpendicularity” and “radial run-out” (out of round) are relevant. If one also wants to use honing for the finishing of gear wheels, the process of these broadened quality terms is modified accordingly.

Function and Quality

The bore in a transmission component functions as a rotary and translational slideway. The tolerances are selected accordingly. The honed topography with high material mass benefits the frictional behavior and homogenizes the application of force. The honed surface profile with a large topographical contact surface enables a stabilization of the lubricating film, when mixed friction occurs. The loaded contact surfaces have a high adhesion for the gear oil, which prevents a breakdown of the lubricating film on the contact surfaces. This acts to reduce friction and minimize wear in the switched condition with high system pressure on the contact surfaces as well as the unloaded rotating idler. Also, the hone angles contribute to the even distribution of the lubricating oil in the lengthwise and circumferential direction of the bore.

In order to avoid local high surface pressures, there are also tight shape and position tolerances of the required macro-geometrical conditions for equal lubrication gap widths. The tight geometrical tolerances (axial run-out) and radial run-out have a positive effect on the smooth operation of the gear wheel sets. This is the purpose of the statistical tolerance limits. At a machine capacity of cmk 1.33, for example, the straightness is reduced from 3 µm to about 2.1 µm, despite very different wall thicknesses.

Honing involves the boring of gear wheels (such as planetary gears, transmission gears, switching sleeves, layshaft gears, bevel gears) of various shape, dimension, material and hardness. Honing of transmission gears goes beyond the previous quality terms. The following tolerances can be defined (Tab. 1):

In addition to the geometric tolerances, highly stressed components are increasingly evaluated according to the marginal zone of the functional surface. The mechanical and thermal stress of the material due to the machining forces during the final machining steps contributes to the microstructure in the area near the surface. Here, there are significant differences between the process used and the finishing operation. The honing process is one operation with comparatively low machining forces and temperatures. The conditions for developing a lasting, highly durable marginal zone are therefore especially advantageous with honing. Therefore, hardened parts are also the subject of material testing in terms of compressive stresses that positively influence the fatigue strength of highly stressed bore surfaces [1].

Honing Control Wheels – Machining Principle

An important feature of honing is the alignment of the tool axis and bore axis. In the conventional layout of tool and part, the expansion of the tool results in an equiaxial alignment. The tool-part system has designated degrees of motion freedom which enables the centering and tipping up to identical axis position. An improvement in dimension, shape and surface quality is achievable with this mechanical system.

If the position of the bore needs to be corrected, that is, the perpendicularity of the bore axis to the front face or the axial runout of the front face to the bore axis, the angular degree of freedom (tilting) must be replaced by a rigid perpendicular positioning of the tool axis and clamping surface [2]. The reference surface for honing is the machined front face, which is supported on the clamping level (Dia. 1). Centering on an inaccurate gear tip circle diameter is not necessary.

As a result, the center of the gear wheel bore can align itself to the tool via the floating part holder. Due to this condition, the radial run-out (bore to gear teeth) remains unchanged. The deviation of the angle position of the bore axis to the tool axis is corrected in the subsequent material removal. Next, the tool machines the raised areas of the lateral surface. With the additional clamping, the entire bore is machined and a new bore axis is established.

Honing Transmission Components – Machining Concept

The common principle among the various possibilities for gear wheel machining is the moveable part holder and the rigid tool holder. Also, the conventional honing process with adjustable honing stones has been carried through. For honing such components, vertical rotary indexing machines with the single part holder in floating fixtures are used (Tab. 2).

The preparation consists, as a rule, of boring and hardening, so that they must be machined in two honing operations. The tools are exclusively loaded with CBN-abrasives. Furthermore, fully automated production honing machines are equipped with various standard components such as gage stations, handling systems, force-controlled electromechanical feed devices (EMZ-F) and electromechanical ballscrew stroke drives.

Honing Transmission Components – Requirements and Process Considerations

Because honing of hardened gear wheels has undergone major development in the past few years, this illustration is presented simply as an example. The hardened gear wheels are mainly machined on fully automatic, multiple spindle, rotary indexing honing machines. The machining concept for individual machining consists of conventional multiple stone tools. The attachments are designed to be interchangeable for various gear wheels. Honing a gear wheel bore is defined by the following quality terms and tolerances (Tab. 3):

The high stock removal during rough honing with a honing allowance of up to 0.350 mm is the prerequisite for the successful implementation of the honing process in the mass production of gear wheels. This is how honing maintains its competitiveness compared to hard turning. The smoothing of the surface end quality takes place in the 2nd machining station only by changing the cutting material and adjusting the process parameter. The radial run-out achieved in pre-machining should remain unchanged.

The layout of a machine for machining gear wheels shows the stations named in Table 2. After the load and unload station, the mechanical pre-gaging is performed. Here, the minimum dimension of the bore is checked, in order to prevent a collision with the tool. Rough honing works with robust parameters, especially with high cutting speed of about 150 m/min and large removal rates of about 20-30 µm/s in diameter. The subsequent finish honing operation completely removes the rough profile of the rough honing operation and leaves behind the functional component quality (Dia. 2). Pneumatic post-gaging is the final quality assurance; spinning the gear minimizes the spreading of the honing oil.

The machining parameters are summarized in the following table (Tab. 4).

The high removal rate is primarily determined by the high delivery rate and high cutting speed. With increasing rpm, a rise in material removal is clearly noticeable (Dia. 3). The mathematical removal characteristic is determined by the feedrate, i.e., by the diametric preset diametrical honing stone feed per unit of time. The difference between calculated and measured stock removal results from feed losses caused by deflecting the components in the complete feeding system. The increasing deviation from about 1500 rpm is explained by an increase in coolant flow at increased rpm. The influence of the stroke speed in the area examined in not significant. Because of the material properties and the high cutting capacity, the rough honing operation produces less fine-grained hone sludge. Instead, fine, long continuous chips in the form of a steel wool ball result.

Dia. 3: Correlation of rpm and stock removal (control wheel diameter 35 x 26 mm, forged steel, 680 HV30, hone time 18 s, L600 honing machine)

The function of CBN-abrasives of a middle concentration (stock removal 0.300 mm in 18 s) is decisive for the entire process. The use of low viscosity honing oil ( = 4.6 mm²/s) has a positive effect on the cutting behavior and, thereby, on the consistent manufacturing quality and tool life. In addition to the constructive design of the hone tools, the condition of the abrasives is of vital importance. They are composed of a metallic binder, fused with the proper concentration of CBN-abrasive crystals (Dia. 4). Apart from the selection of binder and grain material, the sinter parameters in the manufacturing process of honing abrasives determine the quality. The hone tools are rigidly connected to the spindle. Below the part, the tool body is formed as a carbide reinforced guide shaft. The tools, depending on design feasibility, have as many abrasives as possible. This improves the machining accuracy with regard to dimensional stability and increases cutting performance and tool life.

The individual processing with conventional abrasive tools is the most economical variation of gear honing. The stationary fixtures are arranged under the two hone spindles. With the rotary index movement, the gears are loaded into the fixture. The fixture consists of the floating part holder and the zero-clearance hold-down device (Dia. 5). The part is situated on one of the flat sides of a moveable pallet. The hydrostatic friction bearing of these pallets enables effortless but not undamped movement on the flat. A torque recorder in the gear teeth has been proven effective. This occurs by means of the insertion of the gear into an integrated switch sliding sleeve or by applying a safety catch. The zero-clearance hold-down to accept the upper facing axial force helps with the deformation-free fixation of the gear. The lower guide stabilizes the tool axis to the clamping level at a right angle.

The described process design can reliably achieve the required tolerances. The roughness and the axial run-out are not statistically evaluated here. With the finish hone stones (B46), the Rz-value amounts to about 1.5 – 2.5 µm and the axial run-out precision of 15 to 25 µm only meets about 40% to 50% of the tolerance. The cycle time achieved is 20 s with an allowance of 0.300 mm in the 1st operation (determined by cycle time). The quality parameters of diameter, roundness and parallelism are also calculated to meet tolerances and satisfy the statistical tolerance limits.

Measuring the compressive stress with the help of x-ray diffraction shows the condition of the material structure in the area of the marginal zone of the honed bore surface. The compressive and tensile stresses in the sub-surface are depicted. The stress in the area of the functional surface is substantially influenced by the hardening process and the stress of the finishing operation. The penetrating x-rays are reflected in the relaxed marginal zone according to the particular grid pattern of a material at a constant angle. Tensile or compressive stresses, however, imply deviations in the grid pattern from the normal value for the relaxed state, caused by the machining forces of the finish operation. They are verified by changing the reflection angle. In terms of fatigue strength, the highest possible compressive stress (-) is always advantageous [3].

The available measurements (Dia. 6) were taken with a Stresstech XSTRESS 3000 instrument. The values were measured axially and tangentially. The hone angle of about 20° causes an uneven distribution of the compressive stresses in both directions on the honed surface. With increasing material depths, that is, with diminishing influence of the machining forces, a broad homogenization of the clamping is measurable. The achieved results indicate the advantage of the honing process. They clearly exceed the values of competitive processes such as hard turning [2] or grinding.

Honing planetary gears in combination machining

The combination machine with the processes of flat finishing, grinding and honing offer a new possibility for machining planetary gears, as shown here. This rotary indexing machine completes the processes on the part, one after another in one clamping. This allows various machining geometries, such as one bore and one face surface to be machined, each with tight tolerances relative to the other. The compact machine workspace essentially consists of a circular rotary table, on which the rotary driven units are constructed and the central column, where the machining units are assembled to the upright surfaces. The result is a self-sufficient machine with a small footprint and short transport route in the indexing of the part. The circular rotary tables make the machining units easily accessible for maintenance work and tool changes.

Dia. 7 depicts the process steps for such combination machining. The part is only pre-machined on the front and in the bore. The gear wheel is located in the fixture with an unfinished side up and is clamped radially on the gear teeth. The tip diameter or the involute teeth are the geometric identifying elements for the position of the part. The upper front is machined by flat finishing 1. Then, the part is turned, so that the previously finish-machined end surface fits in the fixture as the locating surface. In the subsequent grinding operation, the bore is ID ground centric to the gear teeth. With this, the desired radial run-out tolerance is achieved.

This enables the subsequent station to work with a tightly clamped hone tool because the alignment is made to the unchanged clamping fixture and guarantees the centric ground bore. Therefore, a new bore axis will not be partially processed. The hone process consists of a rough hone and finish hone operation. Between the two hone operations is a gage station, in which a plug gage records the rough hone diameter using the principle of pneumatic length measurement. After finish honing, the flat finishing 2 takes place. Here, the second end face is machined parallel to the first end face.

Diagram 8 shows the individual machining stations, with the flat finish machining directly after the load and unload station in the left-hand photo. In the right-hand photo, the grinding spindle directly before plunging in the part is depicted. The middle photo shows the honing stations arranged after grinding, as well as the gage station for measuring the diameter after honing. All stations together work the rotary driven part. This is especially unusual in a hone process, but allows a significantly simplified spindle set-up. The hone tool only performs a feeding movement and a stroke movement.

The machine concept is designed such that other process sequences are configurable. There is also the opportunity to integrate modified modular units such as deburring, wheel dressers, belt finishing or reaming. The concept of combined machining is especially useful in the manufacturing of planetary gears. Previously, the manufacturing processes for flat finishing, ID grinding and honing required different machines.

The consolidation of the processes into one machine allows high capital investment savings, increased productivity and reduced operational footprint. (Dia. 9). For planetary gears, cycle times of 7 s with material removal in the bore of ≤ 0.15 mm are achieved.

—

Download the PDF HERE.

For more information on this article, please contact:

Gehring L.P.

24800 Drake Road

Farmington Hills, MI 48335

Phone: 248-427-3901

www.gehring.de

rconroy@gehringlp.com

Rita Conroy-Martin, Inside Sales & Marketing Support

Info on Authors

Dipl.-Ing. (FH) Gerhard Flores is Manager of Process Development at Gehring Technologies GmbH in Ostfildern, Germany and a lecturer at the technical university in Esslingen, Germany. His associate, Dr.-Ing. Andreas Wiens, is Team Leader of Process Development for Gehring Technologies GmbH in Ostfildern, Germany.

Gehring Technologies GmbH

Gehringstr.28

73760 Ostfildern

Germany

gerhard.flores@Gehring.de

www.gehring.de

Dipl.-Ing. Oliver Stammen is Sales Manager for Thielenhaus Technologies GmbH in Wuppertal, Germany.

Thielenhaus Technologies GmbH

Schwesterstraße 50

42218 Wuppertal

Germany

stammen@thielenhaus.com

www.thielenhaus.com

Technical References

[1] U. Klink, G. Flores: “Honkonzept mit cBN verbessert die Laufruhe und Qualität von Zahnrädern.” IDR Industrie Diamanten Rundschau 34 (2000) Nr. 1 S. 12 – 19

[2] U. Klink: “Wirtschaftliches Honen von Getrieberadbohrungen.” Werkstatt und Betrieb, 116. Jahrgang 1983, Heft 5, S. 283-286

[3] B.A. Shaw, J.T. Evans, A.S. Wojtas and L. Suominen: “Grinding Process Control Using the Magnetic Barkhausen Noise Method.” Third International Workshop on Electromagnetic Non-Destructive Evaluation. Reggio Calabria, Italy, 14. – 16. September 1997. IOS Press in the Series ‘Studies in Applied Electromagnetics and Mechanics’.

Continue reading

Bernard & Company is proud to announce recent client acquisitions including Suhner Automation, Gehring Technologies GmbH, Chemcoaters, Gray Machinery and S & G Press & Machinery Sales, for which they will be providing full advertising, PR, social media, trade-show and online promotional activity.

Since 1926, Gehring L.P has been a globally operating machine tool company specializing in high performance honing technology.

Website | ThomasNet Profile | |

|

| 24800 Drake Rd. Farmington Hills, MI 48335 | (248) 427-3901

Founded in 2001, Chemcoaters‘ continuous, coil processing line is designed specifically for the most economical application of environmentally friendly waterborne coating sys-tems.

Website | |

|

|

|

| 700 Chase St. Gary, Indiana 46404 | (219) 977-1929

Established in 1966, Gray Machinery Company has over 40 years of experience buying and selling pre-owned machinery.

Website | | 77 E Palatine Rd. Prospect Heights, IL 60070-1811 | (800) 292-1493

Founded in 2000, S & G Press & Machinery Sales operates worldwide, buying and selling used stamping and manufacturing equipment; specializing in metal stamping presses, feed lines and various types of automation, fabricating and tool room equipment.

Website | |

| 16660 East 13 Mile Rd. Roseville, MI 48066 | (586) 563-5000

Since 1914, SUHNER Automation has been providing economical, low-cost manufacturing solutions and machining units for drilling, milling and tapping operations.

Website | ThomasNet Profile | | 43 Anderson Rd. Rome, GA 30161 | (706) 235-8046

Remember this? Star Wars is a great example of maximum creativity in the imagining and depicting of innovative, futuristic gadgets and concepts (meanwhile, creativity for costume design = minimal, pretty sure they all just wore potato sacks and bedsheets)

What’s even more impressive is that THIS IS HAPPENING.

Recently, Watry Industries, LLC exhibited at the AFS 118th Metalcasting Congress and handed out these cards at their booth:

Download the actable™ app for Android, iPhone or iPad and hold the scanner up to the card. Yes – you can even hold it up to a computer screen or the screen of another phone or tablet and scan! Or, if you’re stuck in the dark ages, you can print the card out and scan to play 🙂

See a quick video of the whole thing going down >>HERE<<.

Augmented reality is emerging full force and making big splashes (ex. Pepsi in London and Lego). Computer-generated sensory input (sight, sound, feel) can change and enhance the way we interact with just about anything!

Well done, Watry. We applaud this shiny new toy.

—

Watry is a permanent mold aluminum foundry in Sheboygan, Wisconsin. They take part design and do all of the following, all in-house.

That’s their single-source promise.

Dale Christel

Sales Manager

Watry Industries LLC

3312 Lakeshore Drive

Sheboygan, WI 53081

Office: 1-920-457-4886

www.watry.com

dchristel@watry.com

Connect with Watry Industries online:

During this year’s [MC]2 2014 MTConnect: Connecting Manufacturing Conference, Siemens announced today the appointment of TechSolve (Cincinnati) as a Solution Partner to offer solutions to customers with Sinumerik CNCs who are interested in or have already implemented MTConnect into their factories. Through this development, Siemens proactively responds to the growing demand in the market for MTConnect solutions among the end-user and machine builder sectors. TechSolve was a Founding Sponsor of the Institute and is a major supplier of MTConnect Adapters, translation products as well as support software and services that enable shops and production departments alike to more efficiently gather and analyze machine tool performance data, using the open-source communication standard of MTConnect.

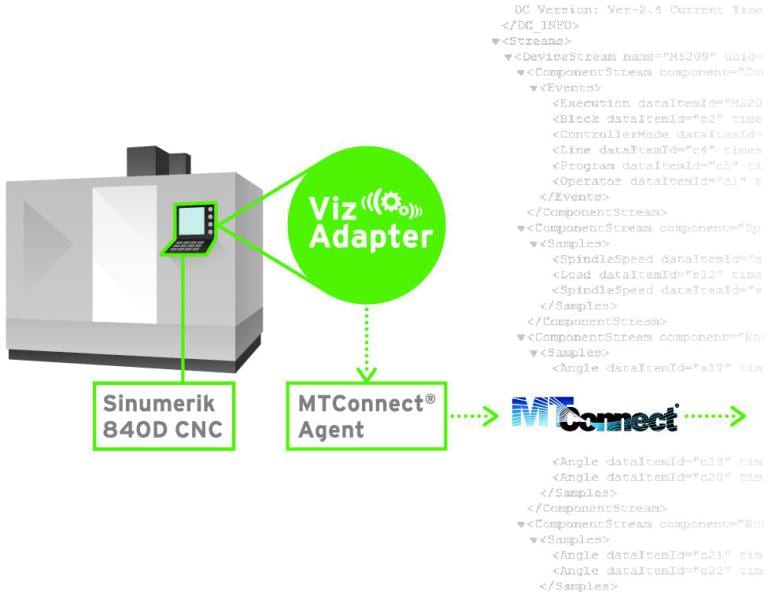

This schematic illustrates the typical scenario for a machine tool control modification at an end-user, where the Siemens CNC is modified with TechSolve Adapter software, allowing machine data to be sent through an agent in MTConnect compatible language. This facilitates a significantly greater degree of information gathering and analysis by the customer, across the open-source standard of MTConnect for greater interoperability between devices and software applications. Machine builders can also make such modifications to their controls, to suit customer needs or respond to market conditions.

In a typical machine tool end-user scenario, TechSolve applies its Adapter software to an existing machine’s CNC, such as the Siemens Sinumerik 840D, which enables data transfer through an MTConnect Agent. For older controls and legacy devices that do not have native communication output, TechSolve can also supply additional hardware and communication software to facilitate this process. The data can then be stored locally or cloud-based for further access and evaluation in an overall equipment effectiveness (OEE) strategy.

Likewise, TechSolve provides Adapter software to machine tool builders for integration into their control schemes to suit particular applications or customer-mandated specifications for MTConnect compatibility.

Ryan Legg, product manager, Sinumerik CNC, Siemens Industry, Inc., explains, “In the U.S. market especially, we are seeing growing demand for MTConnect. This appointment of TechSolve as a Solution Partner to support requests for MTConnect represents our company’s commitment to bring practical solutions to our customers through an experienced and reliable source of both products and services. When MTConnect is written into the specification on any job, we now have an ideal resource to complement our capabilities.”

Noting the open architecture of the Siemens CNC allows easy integration of the TechSolve solutions; Legg further explained the cross-platform advantages of this new relationship. “TechSolve has written their MTConnect Adapter for the Sinumerik CNC

in a way which allows complete flexibility regardless if the system architecture of the Sinumerik employs a PCU or if it is running in an embedded architecture without a PCU. Ultimately, this allows for more customers to take advantage of this offering.”

Ron Pieper, manager, VizProducts™ Group at TechSolve, observes, “To be affiliated with Siemens is a compliment to both of our products and services as well as our engineering talents. We believe this relationship will be mutually beneficial, as it will further promote the acceptance of MTConnect in the machine tool market, plus being a Solution Partner to Siemens will open new doors for our company.”

Pieper further comments on the market need for these solutions. “When all the data from the shop or factory floor is available as it occurs, the customer learns the reality of their situation, then can make confident steps to improve their game, so to speak.

They see where the inefficiencies are, where and why the downtime is occurring and how they might improve or streamline production. All of these factors are crucial in today’s competitive machining market.”

More information on the above-mentioned solutions will be available at the upcoming MTConnect Conference in Orlando, April 8-10, 2014, organized by the MTConnect Institute.

For more information about this announcement, please visit: www.usa.siemens.com/techsolve-pr.

For specific product information and inquiries, call (800) 879-8079 ext. Marketing Communications or send an e-mail to: SiemensMTBUMarCom.industry@siemens.com.

Follow us on Facebook: www.facebook.com/SiemensCNC or Twitter: www.twitter.com/siemens_cnc_us.

—

Siemens Industry Sector is the world’s leading supplier of innovative and environmentally friendly products, solutions and services for industrial customers. With end-to-end automation technology and industrial software, solid vertical-market expertise, and technology-based services, the sector enhances its customers’ productivity, efficiency and flexibility. With a global workforce of more than 100,000 employees, the Industry Sector comprises the Industry Automation, Drive Technologies and Customer Services Divisions as well as the Metals Technologies Business Unit. For more information, visit http://www.usa.siemens.com/industry.

The Siemens Drive Technologies Division is the world’s leading supplier of products, systems, applications, solutions and services for the entire drive train, with electrical and mechanical components. Drive Technologies serves all vertical markets in the production and process industries as well as the infrastructure/energy segment. With its products and solutions, the division enables its customers to achieve productivity, energy efficiency and reliability. For more information, visit http://www.usa.siemens.com/drivetechnologies.

TechSolve is a consulting firm that has helped organizations of all sizes leverage process improvement, machining expertise and innovation to enhance their competitive edge across ever-changing markets. We understand engineering and manufacturing, so we developed an array of machine monitoring software under the umbrella of VizProductsTM.

Our custom-tailored machine-monitoring and data-gathering solutions enable shops and production departments alike to more efficiently gather and analyze machine tool performance data, TechSolve can help manufacturers eliminate extraneous costs, increase productivity, and maximize profits. For more information please visit www.techsolve.org.